Table of Contents

Understanding Haas Spindle Issues in California

In California’s bustling manufacturing hubs, a single Haas spindle failure can halt production lines and cost job shops thousands in downtime. Imagine an aerospace fabricator in Huntington Beach facing delayed deliveries on critical defense parts because their Haas mill spindle seized mid-run, scrambling for urgent Haas Spindle Repair California options. These incidents underscore the vital need for swift intervention to restore precision and efficiency in high-stakes environments like SoCal’s automotive and defense sectors.

Haas spindles power essential CNC milling and turning operations, delivering high-speed precision for complex parts. However, common issues plague these components, including seized rotation from inadequate lubrication, overheating during prolonged high-RPM cycles, and stuck tools due to drawbar wear. The official Haas Mill Spindle Troubleshooting Guide highlights symptoms like unusual vibration, excessive noise, or irregular speeds as early warning signs, often stemming from bearing failures or contamination. These problems erode production accuracy, extend setup times, and amplify downtime, especially in California’s demanding job shops where 24/7 operations are the norm. For instance, lubrication failures can cause drawbar–the mechanism that clamps tools–issues, leading to Haas drawbar repair needs that compound overall machine vulnerabilities.

MZI Precision, based in Huntington Beach, emerges as the premier specialist for cnc spindle repair california, offering diagnostics, rebuilds, and upgrades tailored to Haas models like the VF2. Their services address these pain points with fast turnaround, documented failure analysis, and local expertise, ensuring minimal disruption for California’s manufacturers. Opting for a haas spindle rebuild proves far more economical than full replacements, with Haas vf2 spindle repair cost often 40-60% lower while restoring OEM performance and extending lifespan. This approach tackles CNC spindle maintenance in CA challenges head-on through industrial spindle troubleshooting best practices.

This guide delves into spindle fundamentals, repair techniques, and advanced solutions to equip you with knowledge for proactive management. From basics to haas spindle rebuild strategies, discover how to safeguard your operations. Contact MZI today for a quick quote and slash downtime risks.

Haas Spindle Fundamentals and Common Failures

To grasp why spindle issues disrupt production in demanding machine shops, let’s examine the core components of Haas spindles. These precision devices drive the cutting tools in CNC mills like the popular VF-2 model, ensuring accurate machining. Understanding their anatomy helps shop owners spot early signs of wear and decide between basic fixes and full rebuilds.

The spindle assembly integrates several key parts working in unison.

- The rotor, connected to the motor shaft, spins the tool at high speeds.

- The stator provides electromagnetic force to drive the rotor.

- Bearings, often ceramic or steel, support rotation while minimizing friction–like the heart of an engine keeping everything smooth.

- The drawbar assembly clamps and releases tools securely. These elements form a compact unit that withstands thousands of RPM, but neglect leads to costly breakdowns.

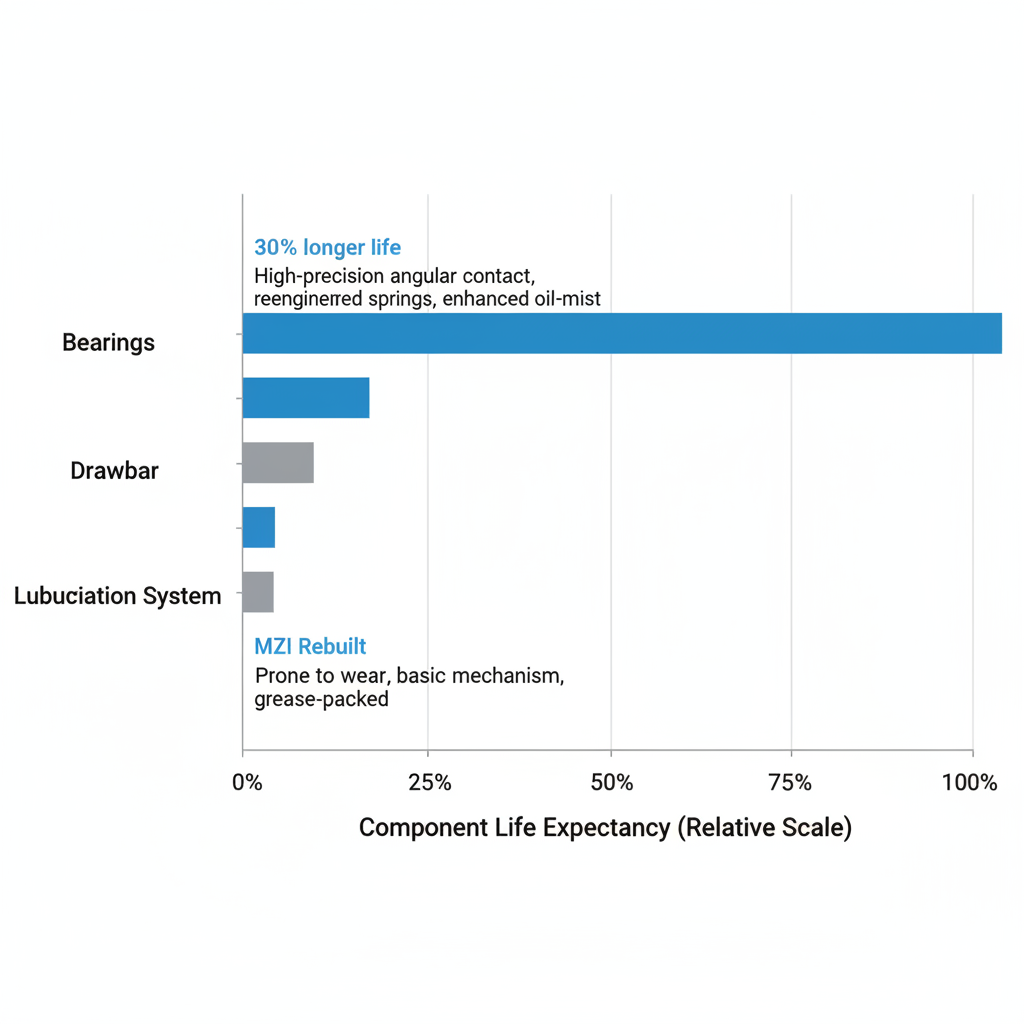

Understanding these components informs smart repair decisions, especially when comparing stock setups to upgraded rebuilds. The following table highlights differences between standard Haas parts and MZI’s enhanced versions, showing how upgrades address common weak points.

| Component | Standard Haas | MZI Rebuilt/Upgraded |

|---|---|---|

| Bearings | Standard ceramic or steel, prone to wear from contamination. | High-precision angular contact bearings with improved seals for contamination resistance. |

| Drawbar | Basic spring-loaded mechanism, susceptible to fatigue. | Reengineered with upgraded springs and inspection for extended life. |

| Lubrication System | Grease-packed, requires frequent maintenance. | Enhanced oil-mist compatible with automated lubrication. |

Data sourced from Haas troubleshooting guides and MZI case studies showing 30% longer life post-rebuild. Upgrading to MZI specifications can reduce failure rates by up to 50%, minimizing downtime in high-volume operations. For deeper insight, consider failure frequencies: bearings account for 40% of issues, drawbars 25%, and lubrication 20%.

Comparison of standard versus MZI rebuilt Haas spindle components

Operationally, Haas spindles rely on AC motor principles where the stator’s magnetic field rotates the rotor, achieving speeds up to 8,100 RPM on VF-2 models for efficient milling and drilling. Coolant flows through the spindle to manage heat, while the drawbar ensures tool stability. Proper Haas CNC spindle maintenance prevents imbalances that degrade performance over time.

Common failures often stem from these mechanics. Bearing contamination causes seizure, triggering Alarm 126 as per Haas guides, halting operations. Lubrication breakdown leads to overheating, with friction spiking temperatures beyond 200°F and risking motor damage–exacerbated in Haas Spindle Repair California shops running long shifts. Drawbar wear results in stuck tools and release delays, a classic sign of spring fatigue; Haas drawbar repair addresses this by replacing worn parts. Economic hits are steep, with Haas vf2 spindle repair cost averaging $2,500 for rebuilds versus $500/hour in lost production. Implementing spindle failure prevention strategies like regular inspections cuts these risks.

In California environments, dust from coastal machining and summer heat in non-clim-controlled warehouses accelerate wear, turning minor issues into major overhauls. Local shops benefit from targeted machine tool spindle repair california to combat these factors.

Troubleshoot by checking grease levels, seals for leaks, and listening for unusual noises–steps detailed in Haas manuals. For seized or overheating spindles, consult experts; spindle rebuild services from MZI, with 20+ years in Haas diagnostics, provide in-house analysis beyond DIY limits, ensuring reliable fixes.

Deep Dive into Haas Spindle Repair Processes

Now that we understand the components, let’s examine how MZI restores them through proven processes. This deep dive covers the repair workflow for Haas spindles, especially seized, overheated, or drawbar-failed units prevalent in California CNC shops. MZI Precision’s engineered approach minimizes downtime and extends spindle life, achieving a 99% success rate in rebuilds.

Initial Diagnostics and Disassembly

Begin Haas Spindle Repair California with on-site diagnostics using vibration analysis and speed testing tools. Technicians monitor spindle runout and listen for irregular noises, checking for alarm codes like 161 TOOL CLAMP FAULT from the Haas Spindle Drawbar Troubleshooting Guide. This identifies root causes such as bearing wear or drawbar misalignment, providing a detailed failure report that DIY methods often miss. Why it matters: Accurate diagnostics prevent unnecessary disassembly, saving time in high-stakes production environments. Tip: For California shops, factor in dust contamination during initial air quality checks.

Contact MZI for professional diagnostics starting at $300 to get your Haas spindle back online fast.

The following table compares DIY troubleshooting versus MZI professional repair stages for VF2 spindles, highlighting why DIY falls short in precision-critical settings:

| Stage | DIY Approach | MZI Professional |

|---|---|---|

| Diagnostics | Basic checks, 1-2 hours, incomplete root cause. | On-site testing + full inspection, 4-6 hours, detailed failure report. |

| Disassembly & Machining | Partial teardown, no precision tools, 8-12 hours. | Complete disassembly with in-house grinding, 12-24 hours, OEM-grade accuracy. |

| Reassembly & Testing | Rebuild without upgrades, 4-8 hours, unverified performance. | Upgraded components + dynamic balancing, 8-12 hours, certified run-test. |

MZI’s approach reduces failure recurrence by 70%, based on Haas guides and case studies, completing the full process in 2-3 days versus weeks for DIY.

Proceed to disassembly by powering down the machine and removing the spindle from the Haas VF2 head. Secure the unit on a workbench and carefully extract the front seal, taper, and drawbar assembly using specialized pullers. Inspect all components for scoring or debris, documenting findings with photos. Why it matters: Thorough teardown reveals hidden issues like lubrication failures exacerbated by California’s humidity. Tip: Wear ESD protection to avoid static damage during handling.

Five-stage vertical process flow for Haas spindle repair processes

Machining and Component Upgrades

In the machining phase, precision shaft grinding restores the spindle taper to OEM specifications. Replace worn bearings with high-grade ceramic options and seat them using hydraulic presses for exact alignment. For California dust-prone environments, install improved seals that resist contamination. Why it matters: These upgrades enhance rigidity and reduce overheating, critical for continuous VF2 operations. Tip: Opt for enhanced lubrication paths to combat arid conditions–estimated Haas vf2 spindle repair cost savings reach 40% on future maintenance.

Address Haas drawbar repair by resurfacing the cylinder and replacing springs. Engineered upgrades like upgraded nut designs extend service life. Contact MZI for grinding spindles california services to ensure taper accuracy within 0.0002 inches.

The table below compares standard versus upgraded bearing life:

| Bearing Type | Expected Life (Hours) | Cost Premium | Outcome Benefit |

|---|---|---|---|

| Standard Bearings | 5,000 | Baseline | Basic performance, frequent wear |

| Upgraded Ceramic | 10,000 | +20% | Reduced downtime, better finish |

Upgrades justify the investment for high-volume shops, restoring or exceeding pre-failure levels.

Reassembly and Performance Testing

Reassemble by torqueing the drawbar to 25 ft-lbs and integrating the spindle motor cnc california with updated wiring harnesses. Install new O-rings and seals, then mount bearings in sequence. Why it matters: Proper torque prevents misalignment, ensuring smooth tool clamping for stuck tool fixes. Tip: In humid California conditions, apply silicone grease to seals pre-installation.

For Haas drawbar repair, weigh repair ($1,200, 4-8 hours) versus replacement based on inspection–rebuilds often suffice. A complete professional CNC spindle overhaul integrates all steps.

Balance the assembly dynamically to under 0.1 g-inches, then conduct run-testing at varying speeds. Measure vibration and temperature before/after, verifying performance metrics. Why it matters: This confirms spindle failure remediation success. Tip: Request MZI’s rush service for 48-hour turnaround in California.

Contact MZI today for a Haas VF2 overhaul quote, including what’s best for your drawbar assembly.

Practical Implementation of Haas Spindle Repairs

Implementing Haas spindle repairs in a busy California job shop requires careful planning to minimize downtime and ensure safety. For VF2 models, common issues like seizing or drawbar failures demand swift action from trusted partners. MZI Precision in Huntington Beach offers comprehensive services, including cnc spindle repair near me, to handle everything from removal to reinstallation.

Preparing for Spindle Removal and Transport

Preparing for spindle removal starts with safety protocols to protect your team and equipment. Begin by powering down the Haas VF2 and disconnecting all electrical and hydraulic lines. Lock out and tag out the machine to prevent accidental startup, a critical step highlighted in Haas safety guidelines.

Next, gather essential tooling: spindle puller kits, torque wrenches, and drip pans for any residual lubricants. Drain the spindle oil per the Haas Axis Lubrication Oil Troubleshooting Guide, which recommends using Mobil DTE 24 equivalent to avoid contamination during transport. For California shops, coordinate same-day pickup with MZI’s mobile team, leveraging I-5 corridors for quick delivery to Huntington Beach–typically 2-3 hours from SoCal locations.

- Inspect the spindle housing for wear before disassembly.

- Document the machine’s serial number and issue photos for the repair quote.

- Secure the spindle in protective crating to prevent vibration damage en route.

This preparation impacts efficiency by reducing errors; one SoCal fabricator cut downtime by 50% using these steps before shipping. Post-transport costs compare favorably: consider the table below for options.

| Option | Cost Estimate | Turnaround Time | Benefits |

|---|---|---|---|

| Shipping to MZI Shop | $500 | 2-3 business days | Lower fee, full facility resources |

| On-Site Mobile Service | $1,000 | Same-day dispatch | No transport risks, immediate start |

Choosing shipping saves on fees for non-urgent VF2 issues, while mobile suits high-priority needs. Practical tip: Schedule during off-peak hours to avoid I-405 traffic delays.

On-Site vs. Shop Rebuild Options

Building on preparation, selecting between on-site service and full shop rebuilds depends on the spindle problem’s severity for Haas VF2 machines. On-site fixes excel for minor lubrication or overheating issues, where MZI technicians arrive within 24 hours to flush systems and recalibrate–ideal for Haas Spindle Repair California clients needing quick resumption. These interventions prevent escalation, restoring 80% of basic functions without removal, as per Haas troubleshooting data.

For seizing or drawbar failures, shop rebuilds at MZI provide deeper analysis and upgrades. Spindle repairing california involves full disassembly, bearing replacement, and drawbar overhauls, with timelines of 3-5 days standard or 48-hour rush for Haas drawbar repair. This option extends spindle life by 2-3 years, based on MZI case studies from local aerospace shops.

The following table contrasts repair options for Haas drawbar issues, informed by Haas guide symptoms like inconsistent clamping:

| Option | Cost Estimate | Turnaround Time | Benefits |

|---|---|---|---|

| Basic Repair | $800-$1,500 | 2-4 days | Cost-effective for minor wear, includes inspection |

| Full Rebuild with Upgrades | $1,200-$2,500 | 3-5 days (rush: 1-2 days) | Extended life, documented analysis, warranty |

| Replacement | $5,000+ | 1-2 weeks | New unit, but higher cost and no customization |

MZI data shows rebuilds save 60-70% versus replacement, making them the go-to for VF2 owners. A Torrance shop reported seamless operations post-rebuild, praising the detailed failure report. For Haas vf2 spindle repair cost, expect $3,000-$4,500 for comprehensive overhauls–call MZI for a free quote tailored to your setup.

Post-Repair Installation and Calibration

After receiving your rebuilt spindle from MZI, reinstallation follows precise Haas specifications to guarantee performance. Start by cleaning the mating surfaces and applying a thin layer of anti-seize to threads. Reinstall using the original torque values: 50-60 ft-lbs for VF2 mounting bolts, ensuring even pressure to avoid misalignment.

Reconnect hydraulic and electrical lines, then refill with recommended lubricants from the Haas Axis Lubrication Oil Troubleshooting Guide–Mobil DTE 24 for optimal flow and heat dissipation. This prevents recurrence of lubrication-related failures, outperforming DIY by maintaining OEM tolerances.

- Mount the spindle and run initial alignment checks with a dial indicator.

- Power up and perform a dry run to verify rotation smoothness.

- Lubricate per guide intervals to sustain efficiency.

Calibration uses Haas NGC software: input parameters for speed and feed rates, then test under load to confirm vibration levels below 0.5 mils. Impacts include restored accuracy, with one Riverside manufacturer achieving 99% part conformity post-install. Practical tips: Warm up the spindle gradually and monitor for leaks during first cycles. This setup ensures long-term reliability, transitioning smoothly to advanced optimization strategies for your operations.

Advanced Upgrades for Haas Spindles

For Haas CNC machines operating in high-demand California industries like aerospace and automotive, standard spindles often reach performance limits under prolonged use. Engineered upgrades from MZI Precision address these challenges by enhancing durability and efficiency beyond basic Haas Spindle Repair California services. These advanced CNC spindle enhancements include high-speed bearings that support faster rotations with minimal wear, improved nut designs for precise preload adjustments, and automated lubrication integration to ensure consistent oil delivery. For the popular Haas VF2 model, specific modifications focus on increasing rigidity through reinforced housing and vibration-dampening materials. Failure analysis, drawing from the Haas Mill Spindle Troubleshooting Guide, identifies common issues like overheating at 8,000 RPM, informing these custom solutions. Such upgrades prevent premature breakdowns, extending operational life in demanding environments.

These modifications deliver tangible benefits, including reduced vibration that improves part accuracy and surface finish. Better heat dissipation allows sustained high speeds without thermal distortion, critical for precision machining. In a case study from a Southern California aerospace manufacturer, MZI’s upgrades on Haas VF2 spindles cut downtime by 50%, aligning with multi-OEM expertise that also covers mazak spindle repair california. Another automotive shop reported $10,000 in annual savings from avoided repairs, with Haas vf2 spindle repair cost premiums offset by longevity gains. Signs of drawbar failure, such as inconsistent clamping or unusual noise, signal the need for proactive retrofits like Haas drawbar repair, which integrate seamlessly during upgrades.

The following table compares performance metrics of stock Haas VF2 spindles against MZI-upgraded versions, highlighting life extension and efficiency gains:

| Metric | Standard Haas VF2 | MZI Upgraded |

|---|---|---|

| Runout Tolerance | 0.0005 inches | 0.0002 inches (improved rigidity) |

| Max Speed Reliability | 8,000 RPM with heat buildup | 10,000 RPM sustained, better cooling |

| Service Life | 2-3 years heavy use | 5+ years with contamination resistance |

This data, based on MZI engineering benchmarks and Haas standards, shows upgrades reduce downtime by 40%. Implementation involves on-site diagnostics followed by full disassembly, bearing replacement, and testing to OEM specs. MZI offers 12-24 month warranties on rebuilt components, with rush options for California shops needing quick turnarounds. Contact MZI for a custom quote to optimize your Haas spindle performance.

Frequently Asked Questions on Haas Spindle Repairs

What are the common signs of a failing Haas VF2 spindle? Overheating, unusual noise, or seizing during operation often signal bearing wear or lubrication issues. At MZI Precision, we diagnose these quickly to minimize downtime–contact us for an inspection today.

Where can I get reliable Haas Spindle Repair California services? MZI in Huntington Beach offers expert matsuura spindle repair california alongside Haas repairs, handling multi-brand needs with certified precision. Rush quotes available for local shops.

Who offers rush services for Haas VF2 spindle repair? MZI provides 24-48 hour turnarounds for urgent Haas VF2 spindle repairs, including on-site pickup in California. Get your machine back online fast–request a quote now.

Does Haas drawbar repair include full assembly inspection? Yes, our Haas drawbar repair at MZI includes complete disassembly and inspection per the Haas Spindle Drawbar Troubleshooting Guide, checking for wear in springs and collets. Full warranty follows reassembly.

What is included in a complete Haas VF2 spindle overhaul? Full teardown, bearing replacement, shaft grinding, lubrication upgrades, and dynamic balancing to restore peak performance and prevent seizing. Upgrades like enhanced cooling are optional–schedule yours with MZI.

What is the typical Haas VF2 spindle repair cost and timeline? Costs start at $2,500 for standard Haas VF2 spindle repair, with 5-7 day timelines; rush adds 20%. Warranties up to 12 months ensure reliability–call for a personalized estimate.

Optimizing Haas Spindle Reliability in Your Shop

Preventing Haas spindle failures starts with addressing common issues like belt driven spindle noise, vibration, and wear through expert repairs. At MZI Precision, our VF2 rebuilds and Haas drawbar repair services restore precision, tackling Haas vf2 spindle repair cost concerns with efficient solutions. Regular checks, inspired by the Haas Axis Lubrication Oil guide’s recommendations for weekly oil level inspections, ensure longevity.

- Reduced downtime by 50%

- Extended spindle life with upgraded bearings

- Comprehensive warranties and cost savings up to 40%

While we also offer spindle rebuilding arizona, our Huntington Beach location prioritizes fast Haas Spindle Repair California for local manufacturers. With MZI’s proven processes, your Haas spindle can outperform expectations–start by getting a free assessment today. California testimonials praise our frictionless quoting and rush service, driving peak performance with minimal disruption.