The Importance of Matsuura Spindle Repair

The Importance of Matsuura Spindle Repair

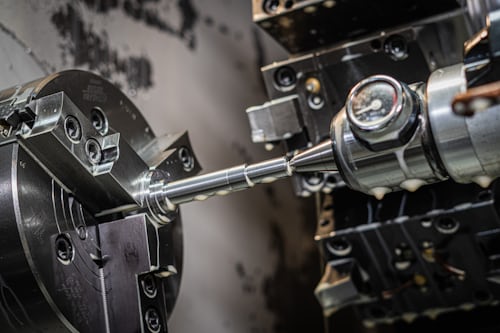

Spindles are the heart of CNC machines, responsible for precision and efficiency in operations. In California, businesses rely heavily on Matsuura spindle repair to maintain optimal performance. Matsuura spindles, known for their accuracy and durability, demand specialized attention when issues arise. Keeping these spindles in peak condition is crucial for avoiding downtime and maintaining production quality.

At MZI Precision, we understand the intricacies of spindle repair, drawing on over 20 years of experience in the industry. Whether it’s a worn-out bearing or a complete rebuild, our team ensures that each spindle functions like new. Our location in Huntington Beach makes us an accessible choice for companies seeking Matsuura spindle repair in California.

Common Issues and Solutions with Matsuura Spindles

Matsuura spindles are engineered to withstand rigorous operations, but they aren’t immune to issues. Common problems include vibration, noise, and thermal expansion. Each of these can lead to reduced accuracy and potential damage if not addressed promptly. Our team at MZI Precision can diagnose and fix such problems, prolonging the life of the spindle.

Regular maintenance and timely repairs are crucial. We offer comprehensive inspections and use advanced diagnostic tools to pinpoint underlying issues. By replacing worn components and optimizing spindle performance, we help businesses in California avoid costly disruptions.

Another frequent challenge is spindle imbalance. Using precision balancing techniques, we ensure your spindle runs smoothly, enhancing overall machine performance. This proactive approach not only saves time and money but also extends the spindle’s lifespan.

Additionally, drawbar issues can affect spindle efficiency. We provide drawbar rebuilds and replacements as part of our Matsuura spindle repair services in California, ensuring seamless operation.

Our Matsuura Spindle Repair Process

When a spindle arrives at MZI Precision, it undergoes a thorough inspection. This initial step identifies visible wear and potential defects. Following the inspection, we provide a detailed report and a recommended course of action. This transparency is essential for building trust with our clients.

- Inspection: Our technicians meticulously examine each spindle component.

- Disassembly: The spindle is carefully disassembled for in-depth analysis.

- Diagnosis: Using cutting-edge tools, we identify the root causes of the issues.

- Repair and Replacement: We fix or replace faulty parts with high-quality components.

- Reassembly and Testing: After repairs, the spindle is reassembled and rigorously tested.

- Final Quality Check: Each spindle undergoes a final inspection to ensure top performance before returning to the client.

Our Matsuura spindle repair California service is designed to minimize downtime and maximize efficiency. By maintaining high standards, we ensure that each spindle we handle meets the demanding requirements of modern manufacturing.

What Qualifies as a Matsuura Spindle Repair California Emergency?

A spindle repair emergency involves scenarios where machine downtime could lead to significant production losses. Immediate action is required to prevent extended disruption and potential financial impact. Signs include severe noise, smoke, or complete machine shutdown.

In such cases, quick communication with experts like MZI Precision is essential. We offer rush services for Matsuura spindle repair in California, ensuring that critical equipment is back in operation swiftly. Our rapid response team is prepared to handle emergencies with efficiency and expertise.

Tips for Maintaining Spindle Health

- Ensure regular lubrication to minimize friction and wear.

- Monitor and control temperatures to prevent overheating.

- Schedule routine inspections and maintenance.

- Utilize vibration analysis to detect early signs of imbalance.

- Keep the spindle and surrounding components clean and free from debris.

By integrating these practices, businesses can prolong the life of their Matsuura spindles and enhance operational efficiency. At MZI Precision, we emphasize preventative measures as part of our Matsuura spindle repair California services, helping clients maintain a competitive edge.

Insights from a Spindle Repair Specialist

Having worked in the spindle repair industry for over two decades, I’ve seen firsthand the impact of timely and effective repairs. One particular case involved a manufacturing client who faced significant losses due to a spindle failure. Our team at MZI Precision quickly identified a faulty bearing and resolved the issue within a day. This swift action restored their production line, preventing further financial strain.

Our commitment to quality and precision is reflected in each repair job we undertake. It’s not just about fixing what’s broken; it’s about enhancing reliability and performance. Every spindle we repair is a testament to our dedication to excellence and customer satisfaction.

What are some common concerns that businesses have about Matsuura spindle repair in California?

What are some common concerns that businesses have about Matsuura spindle repair in California?