Impact of Spindle Rebuilding in Arizona

Impact of Spindle Rebuilding in Arizona

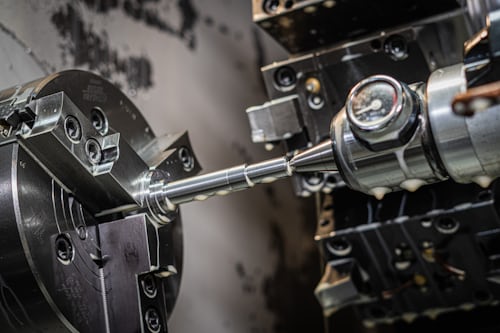

In the world of manufacturing, the spindle is akin to the heart of machinery, responsible for driving rotation and ensuring precision. In Arizona’s dynamic industrial landscape, spindle rebuilding plays a crucial role in maintaining operational efficiency. As a spindle service provider with over twenty years in the field, I’ve seen firsthand how effective spindle rebuilding can significantly extend the lifespan of machinery, reducing costs and avoiding unnecessary downtime.

Arizona’s diverse industries, from aerospace to woodworking, rely heavily on spindle functionality. With a tailored approach, spindle rebuilding can address the unique demands of each sector, providing solutions that align with both technical requirements and budget constraints. Partnering with specialized service providers can lead to customized strategies that enhance productivity and reliability.

Challenges Faced During Spindle Rebuilding

Spindle rebuilding in Arizona presents various challenges that require skill and expertise. One of the primary challenges is accurately diagnosing the root cause of spindle failure. In my experience, symptoms like unusual noise or vibration often mask underlying issues such as bearing wear or contamination. Addressing these issues demands a meticulous approach, employing advanced diagnostic tools to ensure precision in repairs.

Another challenge is the availability of high-quality replacement parts. Original Equipment Manufacturer (OEM) parts provide optimal compatibility, but they can be scarce or costly. Engaging with reputable suppliers is essential to secure genuine parts that promise longevity and performance. A common misstep is opting for cheaply made components which may compromise the integrity of the rebuild.

Time constraints add another layer of complexity. Businesses depend on minimal downtime, and balancing speed with thoroughness is key. An expedited spindle rebuilding service in Arizona can be vital, but it must not sacrifice the durability and quality of the rebuild process.

Key Qualities of Exceptional Spindle Rebuilding Services

Precision and Expertise: Professional spindle rebuilding requires a deep understanding of mechanical intricacies. From diagnosing to execution, precision is non-negotiable. Services that offer certified technicians with extensive training in spindle technology are often more reliable.

Comprehensive Solutions: An effective service provider will offer a spectrum of solutions, such as on-site repairs, preventative maintenance plans, and emergency response capabilities. This versatility is invaluable for addressing the varying needs of Arizona’s industries.

Customer-Centric Approach: A commitment to responsiveness and open communication sets exceptional services apart. Offering transparent pricing and timelines creates a trusting relationship with clients, something that is essential for long-term collaboration.

While the core aim is to minimize downtime, these qualitative aspects ensure that spindle rebuilding in Arizona is not just a quick fix, but a sustainable improvement to production processes.

What Qualifies as a Spindle Rebuilding Arizona Emergency?

In Arizona, a spindle rebuilding emergency arises when a spindle failure leads to immediate production halts or poses safety threats. Swift intervention is required to assess the situation and initiate the repair process. Typically, these emergencies involve catastrophic bearing failure or severe misalignment.

During such scenarios, knowing the steps to take can make a difference:

- Cease all machine operation to prevent further damage.

- Contact a qualified spindle repair service with emergency capabilities.

- Provide detailed descriptions of the failure symptoms to expedite diagnostic procedures.

- Allow trained technicians to conduct a thorough inspection and provide a repair timeline.

Being prepared for these emergencies safeguards Arizona businesses from potential long-term production setbacks, emphasizing the critical nature of rapid response services.

The Process of Spindle Rebuilding: A Step-by-Step Guide

The spindle rebuilding process is detailed and requires precision. Here’s a concise breakdown of the typical steps involved:

- Initial Assessment: This involves a thorough inspection to evaluate the degree of wear or damage.

- Disassembly: The spindle is carefully disassembled, and components are cataloged for analysis.

- Cleaning and Inspection: Parts are cleaned and inspected to identify defects or necessary replacements.

- Reassembly: Using OEM or equivalent high-quality parts, the spindle is reassembled with precision alignment checks.

- Testing: The rebuilt spindle undergoes rigorous testing to verify performance standards are met.

- Delivery and Installation: Finally, the spindle is returned and installed, ensuring seamless integration back into production lines.

Each phase requires attention to detail, underscoring the importance of choosing experienced spindle rebuilding professionals in Arizona.

Cost Benefits of Spindle Rebuilding

One might wonder why spindle rebuilding in Arizona is a preferred solution over outright replacement. From the perspective of cost-efficiency, spindle rebuilding stands out. New spindle units can be prohibitively expensive, particularly for large-scale operations. When managed properly, rebuilding offers a compelling savings potential.

There are additional hidden benefits, such as the reduced environmental impact of refurbishing versus manufacturing new parts. Moreover, rebuilt spindles, when maintained correctly, can operate almost as effectively as new ones, making them a smart investment for budget-conscious businesses.

- Shorter lead times for rebuilding compared to ordering new units

- Environmental sustainability through resource conservation

- Enhanced machine uptime with regular maintenance plans

For Arizona businesses looking to maximize their operational budget, spindle rebuilding presents an economical path without compromising on quality or performance.

What impact does spindle rebuilding have on machinery performance in Arizona’s industrial sectors?

What impact does spindle rebuilding have on machinery performance in Arizona’s industrial sectors?