The Importance of Spindle Motor CNC in Manufacturing

The Importance of Spindle Motor CNC in Manufacturing

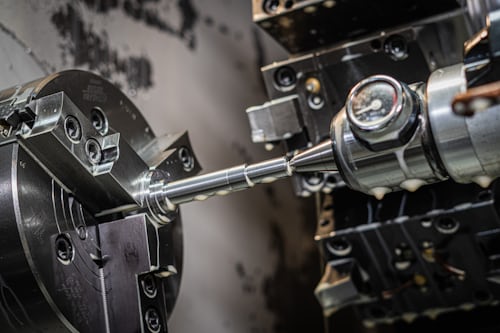

As someone with over two decades of experience in the spindle motor industry, the evolution of spindle motors has been nothing short of transformative. In California, these motors are central to the manufacturing process. They drive CNC machines that cut, grind, and shape materials, making them indispensable for industries such as aerospace, automotive, and electronics. The power and precision provided by these motors enable rapid production with minimal errors, maintaining California’s reputation as a hub of innovation.

At MZI Precision, we’ve seen how technological advancements have pushed spindle motors to new heights. Energy-efficient designs and robust materials have extended motor lifespans, while advanced cooling systems prevent overheating. This progress ensures that spindle motors remain reliable, which is crucial in a state driven by productivity and technological prowess.

Spindle motors also play a vital role in meeting California’s stringent environmental standards. As industries seek to reduce their carbon footprint, the shift towards eco-friendly spindle motor solutions is not just a trend but a necessity. These motors are designed to minimize energy consumption without sacrificing performance, thus contributing to sustainable industrial practices.

Choosing the Right Spindle Motor for Your Needs

In my years of working with a diverse clientele, selecting the right spindle motor CNC California can be a daunting task. Different types serve different industrial applications, and understanding the nuances is vital. Here are some common types:

- Belt-driven spindles: Ideal for operations prioritizing simplicity and cost-effectiveness.

- Direct-drive spindles: Suitable for high-speed, precise tasks requiring superior accuracy.

- Integrated spindles: Perfect for space-constrained environments due to their compactness.

- Electric spindles: Known for efficiency and high-speed capabilities, essential for fast-paced production.

At MZI Precision, we assist businesses by assessing operational requirements such as precision, torque, and spatial constraints. By understanding these factors, we guide our clients towards the most suitable spindle motor, ensuring both performance enhancements and cost savings.

What Are Common Issues with Spindle Motors in California?

Despite their robustness, spindle motors may face issues like overheating, vibration, and bearing failure. Overheating often occurs due to prolonged high-speed operation, which can be effectively managed with proper cooling systems. Regular maintenance checks are crucial to identifying and rectifying cooling inefficiencies before they escalate.

Vibration, another common problem, usually arises from imbalanced motors or worn-out bearings. Ensuring balanced loading and conducting regular inspections can mitigate this issue. Bearing failures, on the other hand, are best prevented through routine lubrication and timely replacements.

At MZI Precision, our comprehensive maintenance programs are designed to address these issues proactively, reducing unexpected downtime and extending the life of the spindle motor CNC California. Proper care ensures that these motors continue to deliver exceptional performance under demanding conditions.

Our approach is not only about fixing problems but preventing them. By leveraging our extensive experience and industry knowledge, we provide actionable advice and solutions that keep spindle motors operating seamlessly.

What Qualifies as a Spindle Motor CNC California Emergency?

A spindle motor emergency in California typically involves sudden, unexpected failures that halt production, leading to potential financial loss. Immediate response is essential to resume operations quickly.

- Diagnose the issue: Quickly assess to identify the cause of failure.

- Contact experts: Reach out to a trusted repair service like MZI Precision for rapid assistance.

- Ensure safety: Follow all safety protocols while awaiting technical support.

- Document history: Prepare repair history to assist technicians upon arrival.

Being prepared with a trusted repair partner is crucial. Quick response and strategic planning are key to minimizing downtime and maintaining operational flow. By partnering with MZI Precision, businesses can benefit from our rapid response services designed to address emergencies efficiently.

Innovations Shaping the Future of Spindle Motors in California

Looking ahead, the future of spindle motor CNC California is exciting as we witness continued advancements in technology. AI and IoT developments are paving the way for smarter motors capable of self-diagnosing and even repairing minor issues autonomously. The move towards automation and precision engineering solidifies the spindle motor’s role in transforming industrial applications across California.

As industries embrace these technological shifts, we at MZI Precision are investing in research and development to remain at the forefront. Our focus on sustainable and efficient spindle motor solutions ensures that our clients are well-equipped to handle future challenges. The integration of eco-friendly designs that reduce energy consumption aligns perfectly with California’s environmental goals, offering both economic and ecological benefits.

What Makes Spindle Motors Essential in California’s CNC Manufacturing Sector?

What Makes Spindle Motors Essential in California’s CNC Manufacturing Sector?