The Crucial Role of Spindle Repair in California’s Industries

The Crucial Role of Spindle Repair in California’s Industries

In the thriving industrial landscape of California, the role of spindle repair cannot be overstated. CNC machines are integral to sectors such as aerospace, automotive, and agriculture. The spindles within these machines are akin to a heart in human anatomy, and their malfunction can lead to significant downtime and financial loss. With two decades of experience at MZI Precision, I’ve witnessed how efficient machine tool spindle repair in California keeps these industries moving seamlessly.

Companies like MZI Precision in Huntington Beach are renowned for their expertise in addressing spindle issues efficiently. Leveraging their expertise, they diagnose and repair issues swiftly, minimizing the impact of machine downtime. Spindle repair is not just a technical process; it is a business-critical service pivotal in maintaining operational efficiency.

What Commonly Leads to Spindle Failures?

Spindle failures are a frequent concern, often stemming from a few primary sources. Bearing damage due to excessive vibration or misalignment is a leading cause. Just like a car’s suspension system, the spindle relies on precise balance and condition for optimal performance.

Another culprit is inadequate lubrication. Imagine running a marathon without water–spindles too require proper lubrication to prevent friction and wear. Overloading the machine beyond its designed capacity is a third common issue. Given these common causes, proactive identification and maintenance are key in machine tool spindle repair California efforts.

How Does the Spindle Repair Process Work?

An effective spindle repair process involves several critical steps. At MZI Precision, we follow a structured approach to ensure the highest quality outcomes:

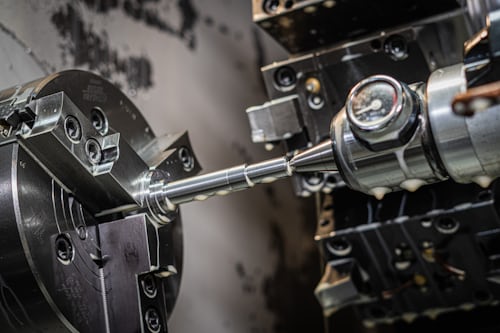

- Inspection: Initial inspections diagnose issues such as run-out or bearing failures.

- Disassembly: The spindle is carefully dismantled, akin to disassembling a jigsaw puzzle, to identify faulty parts.

- Component Replacement: Damaged components are replaced with high-quality parts to ensure optimal performance.

- Reassembly and Testing: Finally, the spindle is reassembled and rigorously tested to meet factory specifications.

Each step is vital, contributing to the operational longevity of the spindle and ultimately, the machinery it powers.

Exploring Innovations in Spindle Repair

The field of spindle repair is evolving with technological advancements. Techniques such as vibration analysis and thermal imaging are game-changers, identifying potential issues before they escalate. By employing these technologies, companies involved in machine tool spindle repair California can offer more proactive and comprehensive services.

- Vibration Analysis: Detects imbalances or misalignments early.

- Thermal Imaging: Spots abnormal heat patterns indicating underlying issues.

- Predictive Maintenance Software: Utilizes data analytics to foresee potential spindle failures.

These tools not only fix current problems but help prevent future breakdowns, significantly extending spindle lifecycles.

What Qualifies as a Machine Tool Spindle Repair California Emergency?

A spindle repair emergency typically involves scenarios where immediate attention is needed to avert extensive operational downtime. Indicators include unusual noise, overheating, or complete motor failure. Addressing such issues promptly is crucial to sustain productivity in high-stakes industries like aerospace and automotive.

At MZI Precision, we understand the urgency of these situations, offering rapid response and rush services. Our team stands ready to restore your equipment to full operational status with minimal delay.

Choosing MZI Precision for Your Spindle Needs

When selecting a partner for machine tool spindle repair California, the choice should be based on trust and proven expertise. MZI Precision specializes in delivering tailored services with an unwavering commitment to quality and customer satisfaction. Our team’s extensive experience across various OEMs positions us uniquely to tackle any challenge.

Client testimonials consistently praise our rapid turnaround and customer-centric approach. Over the years, we’ve built lasting relationships by offering solutions that go beyond mere repair, focusing on enhancing overall machine performance. In an industry where precision and reliability are non-negotiable, MZI Precision stands as a beacon of excellence.

What Makes Spindle Repair Critical for California’s Industries?

What Makes Spindle Repair Critical for California’s Industries?