The Importance of Spindle Grinding in California’s Industry

The Importance of Spindle Grinding in California’s Industry

California’s manufacturing sector heavily relies on the precision and efficiency of machine tools, and at the heart of these machines lie the spindles. Grinding spindles play a crucial role in ensuring the smooth operation of various industries, from aerospace to woodworking. With my two decades of experience in spindle repair, I’ve seen firsthand how critical it is for businesses to maintain their equipment. The ability to offer Grinding Spindles California services means we support the backbone of California’s diverse manufacturing ecosystem.

In industries where precision is non-negotiable, such as medical equipment manufacturing or aerospace, the condition of spindles can make or break the success of a project. Faulty or worn spindles lead to costly downtimes and diminished product quality. The economic impact of poorly maintained spindles can ripple through the supply chain, affecting everything from production schedules to end-user satisfaction.

What Qualifies as a Grinding Spindles California Emergency?

An emergency in Grinding Spindles California occurs when a spindle failure halts production, risking financial losses or safety hazards. As a professional, I prioritize rapid response to mitigate these risks. Spindle grinding emergencies require swift assessment and action to prevent extended downtime and further damage.

Typically, emergencies arise from unexpected spindle damage due to operational mishaps or gradual wear and tear that suddenly reaches a critical point. It’s vital to have a reliable service provider who can respond quickly with the necessary expertise and equipment. In my experience, fostering a strong relationship with a skilled team can save businesses time and reduce stress during these critical moments.

For instance, a client in the defense sector once faced a significant operational setback due to a spindle malfunction. Our team, specializing in Grinding Spindles California, was able to diagnose and address the problem rapidly, ensuring the continuation of their high-stakes project. This not only saved them substantial financial losses but also reinforced the importance of regular spindle maintenance.

Steps to Effective Spindle Regrinding

In my career at MZI Precision, I’ve realized that a structured approach to spindle regrinding can make all the difference. Here are the critical steps we follow for effective grinding spindles in California:

- Initial Assessment: We begin with a comprehensive evaluation of the spindle’s current condition, identifying areas needing attention.

- Disassembling the Spindle: Careful dismantling is crucial to avoid any additional damage.

- Cleaning and Inspecting: Thorough cleaning allows us to inspect every component closely.

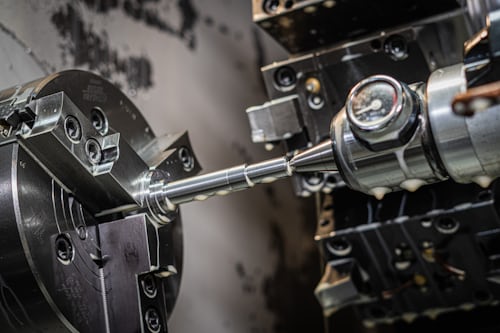

- Precision Grinding: Using state-of-the-art equipment, we grind the spindle to the original specifications.

- Reassembly and Testing: Finally, we reassemble the spindle and conduct rigorous tests to ensure it meets operational standards.

These steps are not just protocol–they represent the standards our clients have come to expect from us. Precision, attention to detail, and commitment to quality define our approach to spindle regrinding.

Exploring the Range of Services for Grinding Spindles California

Given the diverse applications of spindles, the range of Grinding Spindles California services is extensive. At MZI Precision, we cater to an array of industries with a comprehensive suite of services. These include:

- Spindle Rebuilds: Extending spindle life with complete rebuild services.

- Custom Spindle Solutions: Designing and fabricating spindles to meet specific industry demands.

- Drawbar Rebuilds: Ensuring drawbars function optimally to support spindle performance.

- Gearbox and Servo Motor Rebuilds: Addressing all components that work in tandem with spindles.

These services ensure that businesses across California remain at the forefront of their respective industries, with machinery that operates reliably and efficiently.

Addressing Common Concerns and Building Trust

In my years of experience, I’ve learned that trust is key in the spindle repair industry. Clients often worry about downtime, cost, and the longevity of repairs. By addressing these concerns head-on, we build lasting relationships. Transparency about the time frame and cost, backed by a track record of successful repairs, reassures clients.

For example, a client from the automotive industry expressed concern over the frequency of necessary repairs. By providing a detailed analysis and preventive maintenance tips, we helped extend the life of their spindles, reducing overall costs. This proactive approach not only built trust but also positioned us as a partner invested in their success.

Offering warranties on our services is another way we cement this trust, ensuring clients feel secure in their investment. The goal is to keep their operations smooth and troubleshoot issues before they escalate, highlighting the value of skilled Grinding Spindles California services.

In the ever-evolving landscape of California’s industries, the ability to adapt and innovate keeps us relevant. Our commitment to excellence drives our approach, making us a reliable choice for those seeking spindle grinding solutions. Our work is not just about machines–it’s about empowering businesses to achieve greatness.

Why is spindle grinding critical in California’s manufacturing industries?

Why is spindle grinding critical in California’s manufacturing industries?