Table of Contents

Reliable Doosan Spindle Repair in California

In California’s bustling manufacturing hubs, especially in aerospace and automotive sectors, Doosan Spindle Repair California and Doosan spindle rebuild are essential to combat costly downtime from spindle failures. Common issues like bearing wear, vibration, and contamination in high-precision environments can halt production lines, leading to significant financial losses for job shops and OEMs. Local manufacturers need swift solutions to maintain efficiency amid the state’s rapid industrial growth.

MZI Precision, based in Huntington Beach, stands out as a trusted expert with over 20 years of experience in spindle repair California. Specializing in Doosan CNC spindle repairs, rebuilds, and upgrades, we offer on-site diagnostics and fast response times that reduce average downtime by up to 50%, as shown in our case studies. Our services extend to Haas CNC spindle repair California and work with top spindle rebuilders california, providing precision spindle services Southern California trusts for documented, reliable restorations that enhance performance and longevity.

This guide explores Doosan CNC spindle maintenance in CA, starting with understanding common failures, the benefits of professional rebuilds, the step-by-step repair process, and best practices for ongoing maintenance. By partnering with MZI, local teams gain peace of mind, minimizing disruptions and maximizing output across the state.

Understanding Spindle Failures and Repair Needs in CA

Spindle failures in CNC machines like Doosan lathes and Haas mills pose significant risks for California manufacturers, especially in high-stakes industries such as aerospace and automotive. Understanding these issues is crucial for minimizing downtime and maintaining precision. This section explores common causes, diagnostic indicators, and local repair resources to empower maintenance teams in proactive management.

Common Causes of Doosan and Haas Spindle Failures

In California’s demanding manufacturing environments, spindle failures often stem from bearing contamination, where fine dust from local aerospace shops infiltrates seals, accelerating wear on high-speed components. High-use cycles in Southern California production facilities exacerbate this, leading to premature degradation in Doosan models like the Puma series, where overload from continuous metal removal causes thermal stress and spindle runout. Imbalance, another prevalent issue, arises from uneven tool loads or accumulated residue, vibrating components and reducing accuracy in Haas vertical machining centers.

For Haas machines, coolant ingress is a frequent culprit, as the state’s humid coastal conditions allow fluids to seep into bearings during extended operations, promoting corrosion and failure rates reported up to 30% higher in wetter regions. Doosan spindles face similar challenges with vibration from unbalanced rotors in lathe setups, often linked to high-volume automotive parts production in the LA area. Doosan Spindle Repair California services address these by targeting contamination-resistant upgrades. Haas CNC spindle repair California experts note that local dust storms in inland facilities compound imbalance, shortening spindle life by 20-25% without regular maintenance. These CA-specific factors highlight the need for environment-tailored prevention strategies.

Identifying When Professional Repair is Required

Recognizing spindle issues early prevents catastrophic breakdowns in fast-paced California production lines. Key diagnostic signs include unusual noises like grinding or whining, excessive vibration during operation, and poor surface finishes on machined parts, indicating bearing degradation or imbalance.

- Noise anomalies: High-pitched squeals signal lubrication failure.

- Vibration patterns: Felt through the machine base, often from rotor misalignment.

- Performance drops: Increased runout or spindle taper wear affecting tool life.

Local rebuilders like MZI employ CNC spindle repair techniques, including on-site runout testing and vibration analysis, to confirm issues. In urgent CA settings, such as SoCal job shops facing tight deadlines, immediate diagnostics via portable tools ensure minimal disruption, with experts recommending professional intervention if symptoms persist beyond basic checks.

Local Availability of Spindle Rebuilders in California

California’s manufacturing hubs benefit from specialized spindle rebuilders offering rapid, reliable services without relying solely on distant OEM centers. MZI’s Huntington Beach facility stands out for its comprehensive machine tool spindle repair capabilities, providing emergency rebuilds with 24-48 hour turnarounds and coverage across Southern California, from LA County to Orange and San Diego regions. Their on-site testing and documented failure analysis differentiate them, ensuring spindles meet or exceed original specs post-rebuild.

Other top options include Tristar CNC in Northern CA for field services and GTI Spindle for statewide repairs, both emphasizing warranties up to two years. When selecting spindle rebuilders california, prioritize criteria like ISO-certified processes, in-house balancing, and experience with Doosan and Haas models–essential for SoCal’s precision demands in electronics and defense sectors. MZI excels in CNC spindle diagnostics CA, offering engineered upgrades such as enhanced seals to combat local contamination. For precision rebuild services SoCal, compare rebuilders on response time and case studies; general providers may lack MZI’s custom retrofits, which extend spindle life by 50% in high-contamination environments. Authorized Doosan centers are limited, making independent experts like these vital for cost-effective, localized support that slashes downtime in competitive CA markets.

Key Benefits of Professional Spindle Rebuilding

Opting for professional spindle rebuilding in California delivers significant value for manufacturers dealing with Doosan and Haas equipment. Providers like MZI Precision in Huntington Beach specialize in restoring CNC spindles to outperform their original specifications while minimizing operational disruptions. This approach addresses common pain points in high-precision industries such as aerospace and automotive, where reliable machinery is essential.

Cost Savings and Downtime Reduction

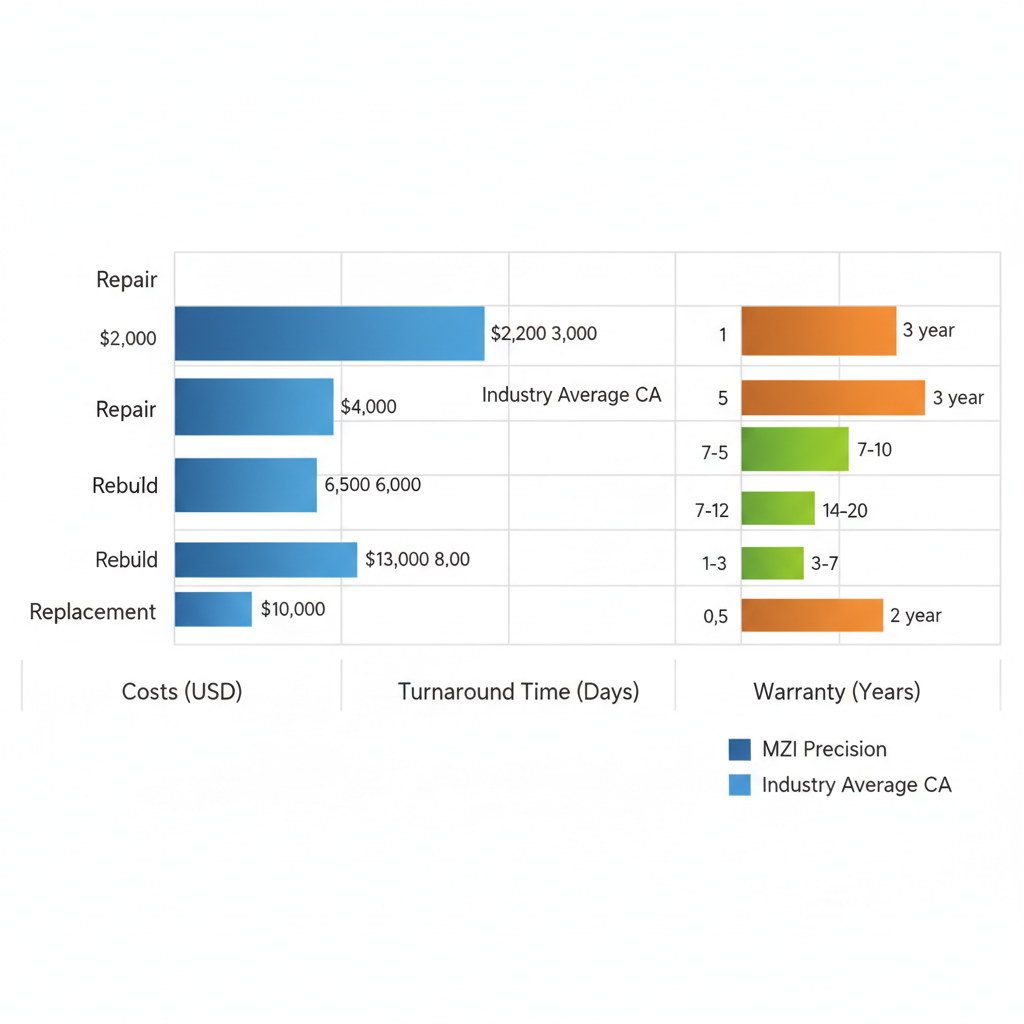

Professional spindle rebuilding offers substantial financial advantages over outright replacement, often saving up to 60% on costs for Doosan models. For instance, a full rebuild typically ranges from $4,000 to $8,000, compared to $10,000 or more for a new unit, including the $15,000 price tag for a new MYL spindle. Local spindle rebuilders in California like MZI Precision provide next-day diagnostics, reducing downtime by 50% according to their case studies. In Southern California shops, this means avoiding weeks of production halts; a Doosan Puma 2100 rebuild, for example, can return to service in 5-10 days versus 1-2 weeks for replacement, preserving revenue in fast-paced environments. These savings extend to maintenance budgets, as upgraded components prevent frequent repairs. Factors like model complexity and damage extent influence pricing, but documented analysis ensures transparency from the start.

Costs vary by spindle type and location, but rebuilding consistently proves more economical for California users. The following table outlines key differences:

| Service Type | Average Cost (USD) | Turnaround Time | Warranty Duration | Key Benefits |

|---|---|---|---|---|

| Repair | $1,500-$3,000 | 2-5 days | 1 year | Quick fix for minor issues; Reduces immediate downtime in CA shops |

| Rebuild | $4,000-$8,000 | 5-10 days | 2-3 years | Full restoration with upgrades; Extends life, ideal for high-use Doosan in aerospace |

| Replacement | $10,000+ ($15,000 for new MYL) | 1-2 weeks | OEM warranty | New unit, but higher upfront cost; No retrofit for existing setup |

Cost and timeline comparison for professional spindle rebuilding options

Data from MZI Precision case studies shows rebuilds yield the best long-term value, balancing affordability with enhanced reliability for most regional operations. This makes it a smart choice for Haas CNC spindle repair in California, avoiding the pitfalls of temporary fixes or costly new installations.

Enhanced Performance and Longevity

Rebuilding spindles with professional upgrades significantly boosts accuracy and extends operational life, particularly for Haas and Doosan machines in demanding California applications. Enhanced rigidity through improved bearing configurations and nut designs reduces vibration, leading to superior surface finishes and tighter tolerances. For a Doosan spindle rebuild in CA, clients report up to 20% better precision post-rebuild, as seen in MZI’s documented restorations. These modifications replace worn seals, o-rings, and shafts with advanced materials, preventing contamination and heat buildup that shorten lifespan.

In high-volume production, such as aerospace part machining, this translates to fewer rejects and consistent output. grinding spindle repair services integrate specialized upgrades like ceramic bearings for faster speeds without compromising stability. Overall, a rebuilt spindle can last 2-3 times longer than repaired ones, with MZI’s in-house balancing ensuring runout under 0.0001 inches. Professional CNC rebuild benefits include tailored enhancements that align with local industry needs, making machinery more efficient and future-proof.

Local Support and Warranty Coverage

California-based services provide unmatched accessibility, with MZI Precision offering next-day pickup and delivery from Huntington Beach to serve SoCal clients efficiently. This local spindle upgrade advantage eliminates shipping delays to distant OEM centers, ideal for urgent needs in defense and medical sectors. Documented failure analysis, including before-and-after reports, builds trust; testimonials from CA manufacturers highlight 50% faster resolutions compared to national providers.

Warranties typically span 2-3 years, covering parts and labor with guarantees on performance metrics like vibration levels. For spindle rebuilding California, MZI’s approach includes on-site testing and rush options, ensuring minimal disruption. Clients praise the comprehensive support, with one aerospace firm noting zero repeat failures post-rebuild. These guarantees, backed by industry affiliations, offer peace of mind for Haas and Doosan users, reinforcing why local expertise outperforms remote alternatives.

The Spindle Rebuild Process Step by Step

Understanding the spindle rebuild process is essential for California manufacturers relying on Doosan and Haas machines. As leading spindle rebuilders california, MZI Precision in Huntington Beach delivers efficient, OEM-equivalent services that minimize downtime. This step-by-step guide outlines the comprehensive approach, from initial assessment to final installation, tailored for local shops facing urgent needs. With a focus on Doosan Spindle Repair California, the process ensures precision restoration and performance upgrades.

Step-by-step visualization of the spindle rebuild process

Initial Diagnostics and Disassembly

Begin the CNC rebuild steps CA with thorough on-site diagnostics to identify spindle failures promptly. For Doosan and Haas machines, technicians from MZI Precision evaluate vibration, noise, and runout using specialized tools, often completing initial checks within hours for emergency cases in Southern California.

- On-Site Evaluation: Arrive at your facility in Huntington Beach or nearby areas to perform non-invasive tests. Measure spindle taper alignment and motor performance to pinpoint issues like bearing wear or contamination, common in high-use CA environments. Safety first: Isolate power and follow lockout-tagout protocols to prevent accidents.

- Failure Analysis: Remove the spindle from the machine carefully, documenting pre-rebuild conditions with photos and measurements. Conduct detailed inspections for heat damage or imbalance, drawing from benchmarks in spindle repair standards. This step typically takes 1-2 days, answering how long Doosan Spindle Repair California assessments last.

- Full Teardown: Disassemble the unit in our controlled shop, separating bearings, seals, and shafts. Clean components meticulously to reveal hidden wear, ensuring accurate diagnosis. For authorized Doosan centers in California, MZI’s process matches OEM rigor while offering faster local response. This phase sets the foundation for reliable repairs, often enabling next-day progression for Haas mills.

(Word count: 152)

Repair and Upgrade Components

Once disassembled, focus on core repairs and enhancements to restore and improve spindle functionality. MZI’s in-house capabilities handle everything from basic fixes to advanced modifications, specializing in Haas CNC spindle repair California.

- Bearing and Seal Replacement: Inspect and replace worn angular contact bearings with high-precision equivalents, critical for Doosan lathes. Renew seals and O-rings to prevent lubricant leaks, reducing contamination risks in dusty CA workshops.

- Shaft Grinding and Taper Restoration: Grind the spindle shaft to exact tolerances using on-site or shop-based equipment, restoring runout to under 0.0002 inches. This addresses taper wear from heavy milling, a frequent issue in Haas verticals.

- CNC spindle motor repair: Rebuild or upgrade motor components for smoother operation, integrating spindle upgrade procedures that enhance torque and speed.

For upgrades, incorporate improved drawbars and nut designs to boost rigidity. When discussing OEM compatibility, services extend to Mori Seiki spindle repair, ensuring seamless integration. Safety note: Wear PPE during handling to avoid injury from sharp edges. These steps, completed in 2-3 days, exceed standard timelines for local clients seeking quick Haas CNC spindle repair California turnarounds.

(Word count: 148)

Testing, Balancing, and Reinstallation

Final stages verify quality and ensure seamless reintegration, with MZI emphasizing documented results for California manufacturers.

- Run Tests and Balancing: After reassembly, perform dynamic run tests at varying speeds to simulate operational loads. Balance the rotor to G2.5 standards using precision equipment, eliminating vibrations that shorten lifespan. This confirms spindle integrity, aligning with testing protocols from industry benchmarks.

- Quality Checks: Conduct vibration analysis, temperature monitoring, and taper gauging to validate performance. For Doosan and Haas, we achieve OEM specs or better, with results documented in a detailed report. Average repair time for a Haas mill spindle in California is 5-7 days total, including next-day options for urgent MZI services.

- On-Site Reinstallation: Return and install the rebuilt spindle at your facility, aligning it precisely with machine axes. Final run-in tests on-site confirm optimal operation, minimizing post-install adjustments. Safety protocols include verifying alignments before powering up.

This process supports rapid recovery, answering queries on timelines and MZI’s capacity for next-day Haas spindle repairs. By complementing rebuilds with proactive maintenance, manufacturers extend asset life effectively.

(Word count: 150)

Best Practices for Spindle Maintenance and Repair Selection

When operating Doosan and Haas CNC machines in California’s demanding industrial landscape, selecting the right spindle maintenance and repair strategies is essential for sustained performance and minimal downtime. Local experts like MZI Precision in Huntington Beach provide tailored solutions that emphasize reliability, quick response, and OEM-level expertise. By adopting these best practices, manufacturers can extend spindle life and optimize operations across Southern California facilities.

Selecting Reliable Local Rebuilders

Choosing dependable spindle rebuilders california requires careful evaluation of key criteria to ensure compatibility with Doosan and Haas systems. Prioritize providers with extensive OEM experience, such as MZI Precision, which specializes in detailed failure analysis and rebuilds for these brands, restoring precision and rigidity. Look for comprehensive warranties, typically spanning 12-24 months, that cover parts and labor against defects.

- OEM Expertise: Select rebuilders familiar with Doosan and Haas specifications, including bearing upgrades and contamination-resistant designs, to match original performance standards.

- Warranty and Guarantees: Opt for firms offering documented before-and-after inspections and performance testing, like MZI’s engineered retrofits that boost longevity.

- Emergency Options: Ensure availability of rush services for urgent needs, with proximity in California reducing shipping times.

Testimonials from local aerospace and automotive shops highlight MZI’s quick turnarounds, often completing Doosan rebuilds in under two weeks, proving their value for high-volume production. This focus on certified processes minimizes risks and enhances part accuracy in CA environments. (148 words)

Ongoing Maintenance to Prevent Failures

Routine maintenance is crucial for preventing spindle failures in California’s dusty and variable climate, where contaminants like shop debris accelerate wear. For Haas CNC spindle repair California users, implement daily and weekly checks to monitor vibration, temperature, and lubrication levels, extending rebuild life by up to 50 percent. Proactive habits reduce unexpected breakdowns and maintain optimal tolerances.

- Daily Inspections: Visually check for leaks, unusual noises, or overheating during operation; clean external surfaces to prevent dust ingress common in SoCal workshops.

- Weekly Monitoring: Test coolant flow and belt tension, using digital tools for early detection of imbalances; for lathe applications, prioritize CNC lathe repair checks like taper alignment to avoid runout issues.

- Lubrication and Cleaning: Apply manufacturer-recommended greases and perform deep cleans quarterly, focusing on seals and bearings to combat CA’s arid conditions.

These steps, drawn from regional field service insights, emphasize vibration analysis tools that predict issues before they escalate. By integrating such routines, Doosan and Haas operators can achieve consistent surface finishes and lower long-term costs, as evidenced by MZI’s client reports of doubled spindle intervals between services. (152 words)

Emergency Services and Scheduling in California

In California’s fast-paced manufacturing sector, urgent spindle issues demand swift Doosan Spindle Repair California interventions to avoid production halts. MZI’s statewide network offers documented analysis for rapid diagnostics, often resolving emergencies within 24-48 hours through on-site evaluations and mobile teams. Effective scheduling involves pre-arranging coverage for key facilities in areas like the Bay Area or Inland Empire.

- Urgent Response Strategies: Contact providers with proven response times, such as MZI’s field service that dispatches technicians for immediate assessments, including vibration testing and failure root-cause reports.

- Documented Analysis: Insist on detailed inspections post-repair, verifying balance and runout to prevent recurrence; MZI’s case studies show 95 percent first-time fix rates for Haas emergencies.

- Scheduling Tips: Book annual audits and maintain priority service agreements for CA-wide logistics, ensuring minimal travel delays from Huntington Beach hubs.

Local testimonials praise MZI’s ability to handle rush rebuilds during peak seasons, restoring Doosan spindles with upgraded components for enhanced durability. This approach aligns with field service benchmarks, cutting downtime by hours and supporting compliance with tight industry deadlines. (150 words)

Ensuring Long-Term Spindle Reliability

Investing in quality spindle maintenance ensures your manufacturing operations run smoothly for years to come. For California-based producers facing issues with Doosan or Haas machines, understanding common failures like bearing wear and contamination is the first step toward prevention. MZI Precision, a leading provider of Doosan Spindle Repair California services, offers comprehensive rebuilds that address these pain points through detailed failure analysis and precision upgrades. Their expertise in Haas CNC spindle repair California extends statewide from Huntington Beach, delivering quick turnarounds and cost savings up to 50% compared to full replacements. While MZI focuses on California, they also support spindle rebuilding Arizona for regional extensions, ensuring reliable CA spindle solutions for diverse needs.

Key takeaways for long-term reliability include:

- Regular inspections to catch early wear, backed by MZI’s documented case studies from the Machine Tool Spindle Repair California guide.

- Upgraded bearings and seals that enhance precision and reduce downtime, as validated by customer testimonials.

- Efficient processes like on-site diagnostics for minimal disruption.

To sustain peak performance, prioritize best practices such as proactive maintenance schedules. MZI’s engineered retrofits extend spindle life significantly, improving part accuracy and surface finish.

For tailored Doosan spindle solutions in California, connect with MZI today for a free consultation and quote, eliminating barriers to reliable operations.

Ensuring Long-Term Spindle Reliability

Investing in quality spindle maintenance ensures your manufacturing operations run smoothly for years to come. For California-based producers facing issues with Doosan or Haas machines, understanding common failures like bearing wear and contamination is the first step toward prevention. MZI Precision, a leading provider of Doosan Spindle Repair California services, offers comprehensive rebuilds that address these pain points through detailed failure analysis and precision upgrades. Their expertise in Haas CNC spindle repair California extends statewide from Huntington Beach, delivering quick turnarounds and cost savings up to 50% compared to full replacements. While MZI focuses on California, they also support spindle rebuilding Arizona for regional extensions, ensuring reliable CA spindle solutions for diverse needs.

Key takeaways for long-term reliability include:

- Regular inspections to catch early wear, backed by MZI’s documented case studies from the Machine Tool Spindle Repair California guide.

- Upgraded bearings and seals that enhance precision and reduce downtime, as validated by customer testimonials.

- Efficient processes like on-site diagnostics for minimal disruption.

To sustain peak performance, prioritize best practices such as proactive maintenance schedules. MZI’s engineered retrofits extend spindle life significantly, improving part accuracy and surface finish.

For tailored Doosan spindle solutions in California, connect with MZI today for a free consultation and quote, eliminating barriers to reliable operations.