Spindle Parts: Essential Precision 2026

UNDERSTANDING THE CRITICAL ROLE OF SPINDLE PARTS IN PRECISION MANUFACTURING

Spindle Parts are the essential components that make up the rotating assembly at the heart of every precision machine tool. These parts work together to deliver the speed, torque, and accuracy required for demanding manufacturing applications.

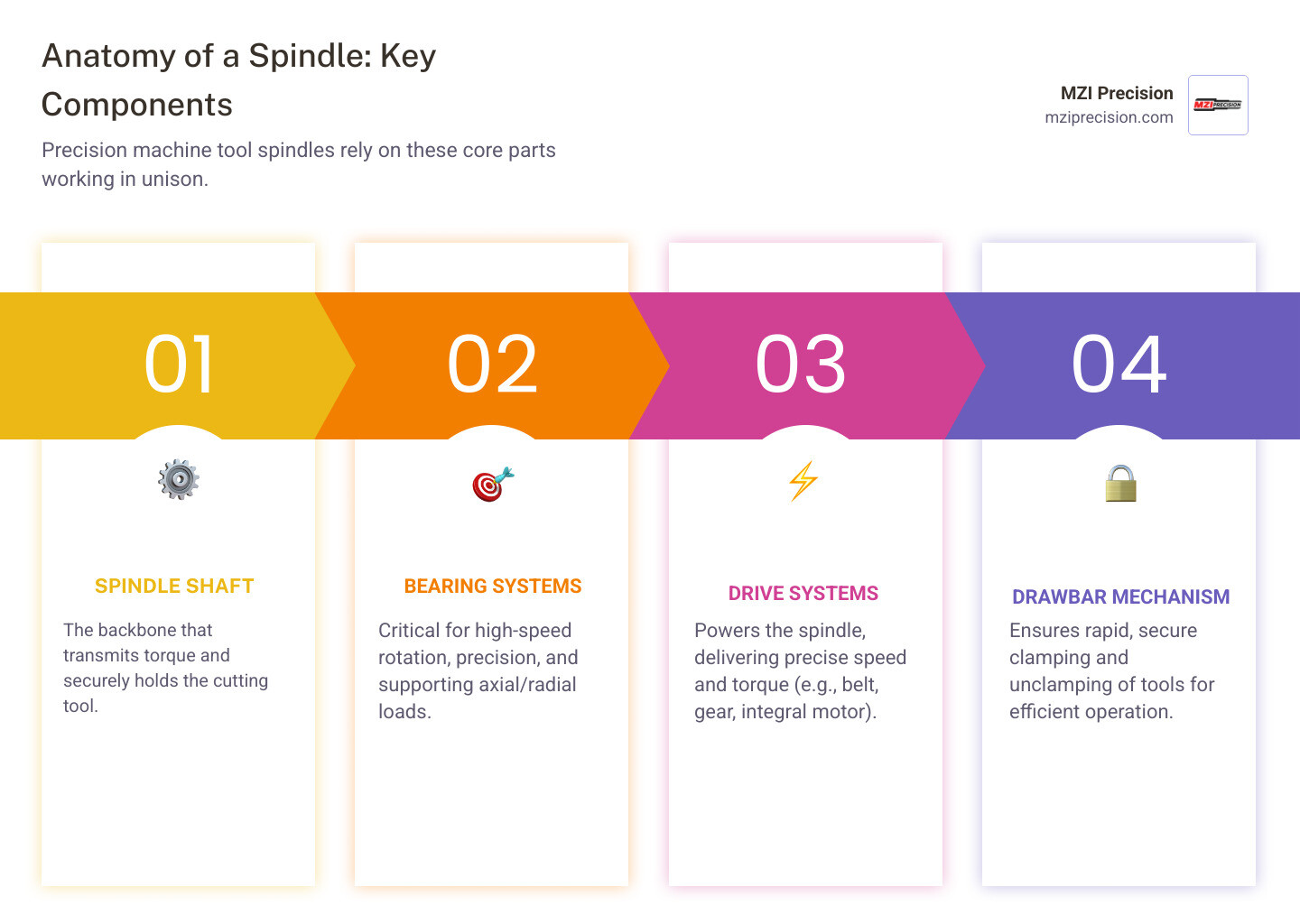

Key Spindle Parts Include:

- Spindle Shaft – Transmits torque and holds the cutting tool

- Bearing System – Supports rotation and ensures precision

- Drive System – Powers the spindle (belt, gear, or integral motor)

- Drawbar Mechanism – Clamps and releases tools securely

- Housing – Provides structural support and protection

- Seals – Prevents contamination from entering critical components

At the heart of any precision machine tool sits the spindle assembly. This complex system defines the accuracy and capability of the entire machine. According to industry data, the global spindle market is projected to reach USD 2.7 billion by 2030, reflecting the critical role these components play in modern manufacturing.

For aerospace and defense manufacturers, understanding spindle components isn’t just technical knowledgeit’s key to maximizing performance and lifespan. External contamination is the leading cause of premature spindle failure, making proper selection and maintenance of Spindle Parts essential for minimizing downtime and maintaining production schedules.

Each component within a spindle assembly serves a specific purpose. From the shaft that transmits torque to the bearing system that ensures precision, these parts must work in perfect harmony to deliver the reliability demanded by high-precision applications. For a general technical overview of machine tool spindles and how they fit within broader machine tool systems, you can also review the background information on machine tools.

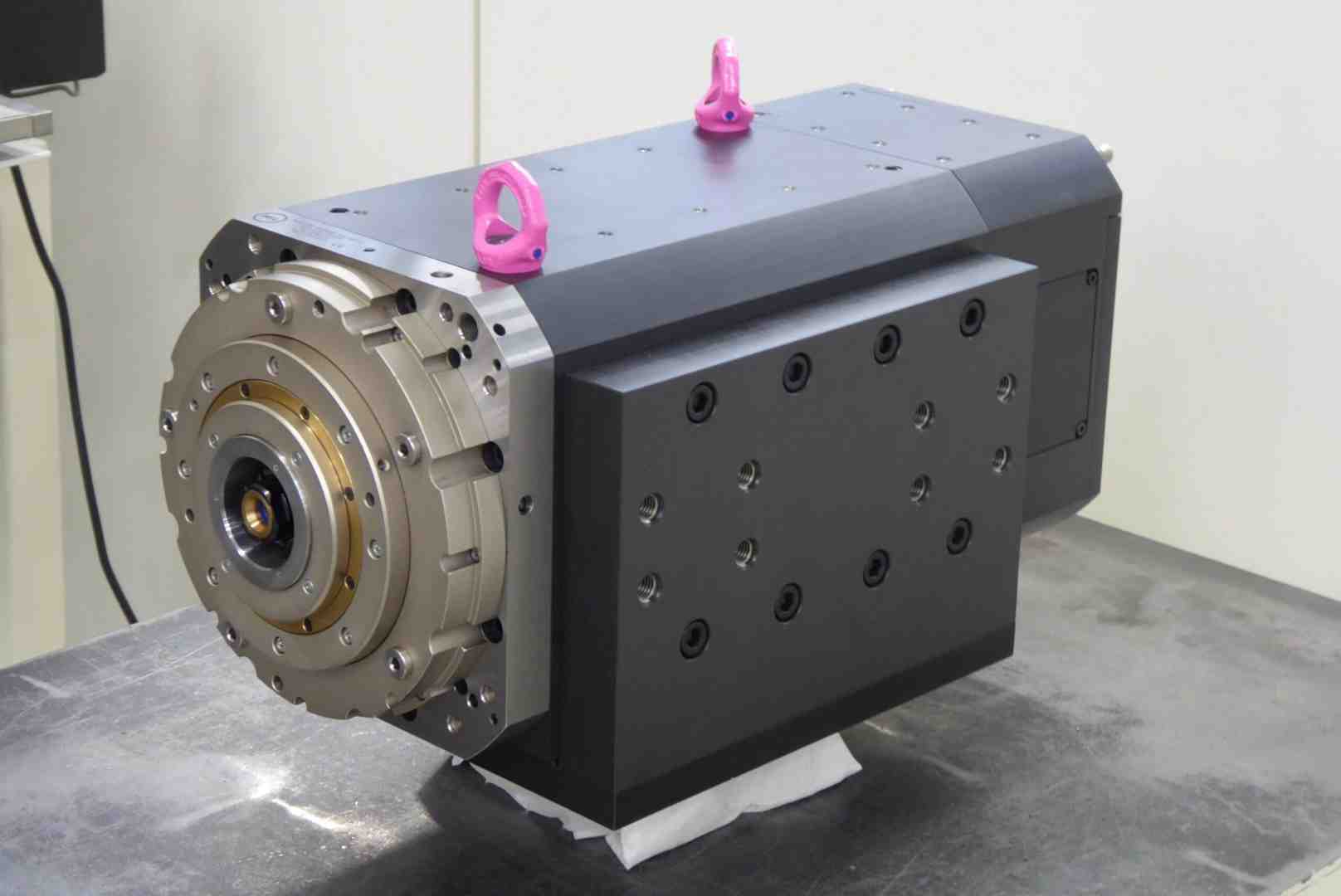

ANATOMY OF A MACHINE TOOL SPINDLE: CORE COMPONENTS EXPLAINED

A spindle is a complex assembly of precisely engineered parts, much like a finely tuned orchestra where each instrument plays a vital role. Each component plays a critical role in delivering the speed, torque, and accuracy that industrial manufacturing demands. Understanding these individual Spindle Parts is the first step toward appreciating the sophistication of modern machining.

The Spindle Shaft: The Backbone of Rotation

The spindle shaft is arguably the most fundamental of all Spindle Parts, acting as the backbone of the entire rotating assembly. Its primary function is to transmit torque from the drive system to the cutting tool. This is where the magic happens, as raw power is converted into precise rotational motion. The shaft typically features a tapered end designed to securely hold various cutting tools, ensuring they remain perfectly centered and stable during operation.

Often, the spindle shaft has a hollow design. This isn’t just for weight reduction; it’s a crucial feature that allows the drawbar mechanism to pass through its core. This internal pathway enables the automated clamping and unclamping of tools, a cornerstone of efficient CNC machining. The material and manufacturing process of the spindle shaft are paramount. Typically made from high-grade alloy steel, these shafts undergo rigorous heat treatment and precision grinding to achieve exceptional hardness, stiffness, and dimensional accuracy. Any imperfection here can lead to runout, vibration, and ultimately, compromised part quality. For more detailed insights into these crucial components, you can find more info about Spindle Parts on our site.

Bearing Systems: Ensuring Precision and Longevity

Think of bearings as the unsung heroes of the spindle. They support the rotating shaft, allowing it to spin with minimal friction while maintaining extreme rigidity and accuracy. The type of bearing system used has a profound impact on the spindle’s overall performance, dictating its speed capabilities, load capacity, and ultimately, its lifespan.

For high-speed applications, such as those found in aerospace component manufacturing, angular contact ball bearings are the standard. These bearings are designed to handle both radial and axial loads, and when properly preloaded, they offer exceptional stiffness and precision at very high RPMs. We take pride in our expertise with High Precision Spindle Bearings to ensure your machines operate at their peak.

Conversely, for applications requiring greater stiffness and high load capacity, such as heavy-duty milling, roller bearings are often employed. Their larger contact area allows them to distribute heavier loads more effectively. Regardless of the type, proper lubrication is absolutely critical for bearing health. Without it, friction and heat can quickly lead to premature failure. This is why understanding Spindle Bearing Lubrication is so important for extending the life of your spindle.

Drive Systems: Powering the Spindle

The drive system is what gives the spindle its “oomph,” transmitting power from the motor to the spindle shaft. The choice of drive system significantly influences the spindle’s performance characteristics, including its maximum speed, available torque, and overall efficiency.

- Belt-driven systems are commonly used when processes require high torque at relatively lower speeds. An external motor drives a pulley system connected to the spindle shaft via one or more belts. This setup offers flexibility in speed ratios and can help absorb some vibration from the motor. When we work with Belt Driven Spindles in our California facilities, we ensure every component is optimized for performance.

- Gear-driven systems are built for heavy-duty cutting operations where robust power transmission and very high torque are needed. A series of gears connects the motor to the spindle, providing a rigid and powerful link, albeit often with more noise and heat generation than belt drives.

- Integral motor spindles, also known as direct-drive spindles, represent the pinnacle of high-speed machining. In these designs, the motor’s stator and rotor are integrated directly into the spindle housing, eliminating belts or gears. This direct connection minimizes mechanical losses, reduces vibration, and enables much higher rotational speeds, making them ideal for applications requiring extreme precision and rapid material removal. Our team frequently services various types of Spindle Motor systems.

The Drawbar Mechanism: Secure Tool Clamping

The drawbar mechanism is a clever piece of engineering that ensures the cutting tool is securely held in the spindle’s taper and can be quickly released when a tool change is needed. This system is critical for both machining accuracy and operational safety.

The mechanism typically consists of a long rod, the drawbar itself, which rides within the hollow spindle shaft. At one end, it connects to a gripper, which engages with the retention knob on the tool holder. At the other end, a spring stack provides the clamping force, constantly pulling the tool holder firmly into the spindle taper. This spring stack is then compressed or released by an actuating cylinder (either hydraulic or pneumatic) to unclamp or clamp the tool, respectively. The consistency and magnitude of the drawbar force are vital; insufficient force can lead to tool pull-out or chatter, compromising machining quality. When your drawbar mechanism needs attention, our experts are ready for a Drawbar Rebuild.

Housing and Seals: Protection and Support

The spindle housing provides the structural integrity for the entire assembly. It accurately supports the bearing arrangement, often incorporating features for lubrication and air passages, and sometimes even cooling jackets to manage thermal expansion. The housing also plays a crucial role in dampening vibrations, ensuring a stable platform for precision machining. Spindle housing designs can vary, from those integral to the machine’s casting to block-style or flanged cartridge designs that allow for easier removal and replacement.

Equally important are the seals, which protect the delicate internal Spindle Parts from the harsh machining environment. External contamination—such as coolant, chips, and dust—is the leading cause of premature spindle failure. Seals act as the first line of defense, preventing these foreign elements from entering the bearings and lubrication system.

- Contact seals, such as lip seals, create a physical barrier by directly touching the rotating shaft. While effective initially, they are subject to wear over time, which can generate heat and eventually lead to leakage.

- Non-contact seals, most notably labyrinth seals, offer a more sophisticated solution. These seals consist of fixed and rotational parts with intricate passageways that create a tortuous path for contaminants. They minimize direct contact, reducing heat generation and wear. Often, labyrinth seals are augmented with positive internal air pressure, which creates an outward flow of air, actively pushing contaminants away from the spindle’s interior. This combination provides robust protection against contamination, significantly extending the life of the Spindle Parts.

SELECTING THE RIGHT SPINDLE PARTS FOR YOUR APPLICATION

Choosing the correct Spindle Parts is not a one-size-fits-all endeavor. It’s a critical decision that directly impacts the efficiency, precision, and longevity of your industrial manufacturing processes. Matching components to specific machining requirements is crucial for optimal performance, considering factors like material to be cut, desired surface finish, and production volume.

Key Performance Considerations

When selecting Spindle Parts, several key performance metrics come into play:

- Speed (RPM) requirements: Different machining operations demand vastly different rotational speeds. High-speed machining, common in aerospace for light alloys, requires spindles capable of tens of thousands of RPM, necessitating specialized bearings and integral motor designs. Our High Speed Spindle Motor solutions are designed to meet these demanding specifications.

- Torque output for different materials: Heavy-duty cutting of tough materials like tool steel or titanium requires substantial torque. This will influence the choice of drive system (gear-driven or robust belt-driven) and the strength of the spindle shaft and bearings.

- Required accuracy and rigidity: The precision of the finished part is directly linked to the accuracy and rigidity of the spindle. Applications demanding micron-level tolerances require extremely stiff spindles with minimal runout, often achieved through precision bearings and robust housing designs. Understanding Spindle Precision Complete Guide is essential for achieving these levels of accuracy.

Matching Components to Industries

The demands of various industrial sectors heavily influence the design and selection of Spindle Parts:

- The aerospace industry is a prime example of an industry that relies heavily on high-speed and precision spindles. The need to machine complex geometries from advanced, often lightweight, materials like aluminum alloys and composites requires spindles that can achieve very high RPMs with exceptional accuracy and minimal vibration. These spindles must also be incredibly reliable to meet stringent quality and safety standards. Our expertise in Aerospace Spindle Repair ensures that these critical components perform flawlessly.

- Defense manufacturing similarly requires robust and durable Spindle Parts. Components for defense systems often involve machining tough, specialized alloys to very tight tolerances, demanding spindles that can handle heavy cutting loads and maintain precision under challenging conditions. The emphasis here is on reliability and the ability to produce mission-critical parts with consistent quality.

Understanding Spindle Specifications

Beyond general performance, specific technical specifications are crucial for compatibility and optimal function:

- Tooling interface standards: Spindles come with various tool holder interfaces, such as CAT, HSK, and BT. Each standard has its own advantages in terms of rigidity, speed capability, and tool change efficiency. Selecting the correct interface is vital for compatibility with your existing tool holders and for achieving the desired machining performance. Many of our customers in California use these standards, and we are adept at servicing them.

- Spindle diameter and length: These dimensions are critical for fitting the spindle into the machine tool and for determining its inherent stiffness and ability to reach specific machining areas.

- Pulley and drive compatibility: For belt-driven systems, ensuring the correct pulley sizes and belt types is essential for achieving the desired speed ratios and efficient power transmission without slippage or excessive wear.

COMMON SPINDLE FAILURES AND PROACTIVE MAINTENANCE

Even the most robust Spindle Parts are subject to wear and tear. External contamination is the leading cause of premature spindle failure, a fact that underscores the importance of diligent maintenance. Proactive maintenance is not just a best practice; it’s the best defense against costly downtime and compromised production schedules in industrial manufacturing.

Identifying Common Failure Modes

Recognizing the signs of impending spindle failure can save you significant time and money:

- Bearing failure symptoms: This is perhaps the most common and critical failure mode. Signs often include unusual noise (whining, grinding, or screeching), excessive heat generation (which can be detected manually or with thermal cameras), or increased vibration. If you suspect bearing issues, our article on Are My Spindle Bearings Bad? can help you diagnose the problem.

- Excessive vibration: Beyond bearing issues, vibration can stem from imbalance, misalignment, or worn components within the spindle assembly. This leads to poor surface finish, reduced tool life, and can accelerate wear on other machine components.

- Loss of accuracy and poor surface finish: If your machine suddenly struggles to hold tolerances or produces parts with noticeable surface imperfections, it’s a strong indicator that the spindle’s precision has been compromised, possibly due to bearing wear, runout, or issues with the drawbar.

- Drawbar clamping issues: A weak or inconsistent drawbar force can lead to tools pulling out during machining, chatter, or difficulty in tool changes. This can result from worn grippers, a fatigued spring stack, or issues with the actuating cylinder.

Understanding these failure modes is crucial for performing effective Spindle Failure Analysis and addressing problems before they escalate.

Essential Maintenance Practices for Spindle Parts

A rigorous maintenance regimen is key to extending the life of your Spindle Parts and ensuring continuous, high-precision operation:

- Scheduled lubrication and grease analysis: Adhering to manufacturer-recommended lubrication schedules and types is paramount. For grease-lubricated spindles, periodic grease analysis can reveal contamination or degradation before it causes damage. For oil-air lubricated systems, ensuring clean, dry air and proper oil mist is vital.

- Contamination prevention strategies: Given that contamination is the number one enemy, maintaining effective seals and, where applicable, ensuring positive air pressure in labyrinth seals is critical. Keeping the machining environment clean and managing coolant effectively are also key.

- Regular vibration analysis: This predictive maintenance technique involves monitoring the spindle’s vibration signature over time. Changes in this signature can indicate developing issues with bearings, balance, or other rotating components long before they become critical failures.

- Spindle runout checks: Periodically checking the spindle’s runout (both static and dynamic) ensures that the tool is rotating concentrically. Excessive runout leads to poor surface finish, premature tool wear, and reduced accuracy. Our guide on How to Check Spindle Runout provides valuable insights.

Implementing these practices, as detailed in our CNC Spindle Maintenance guide, helps maintain spindle health and prevent unexpected breakdowns.

When to Repair or Replace Your Spindle Parts

The decision to repair or replace Spindle Parts (or the entire spindle) is often a complex one, involving a careful cost-benefit analysis.

- Cost-benefit analysis of repair vs. replacement: A comprehensive evaluation considers the cost of repair (parts, labor, shipping) versus the cost of a new spindle. Often, repairing a high-precision industrial spindle is significantly more cost-effective, especially when dealing with specialized or older models. Our guide on CNC Spindle Rebuild Costs Explained can help you make an informed decision.

- Impact of downtime on production: Beyond direct costs, the financial impact of machine downtime can be substantial. A fast, high-quality repair or rebuild service can get your machine back online much quicker than sourcing a new, custom spindle.

- Signs of irreversible performance degradation: Sometimes, a spindle has suffered such extensive damage (e.g., severe housing damage, multiple component failures) that a repair might not restore it to its original precision or reliability. In such cases, replacement might be the more prudent long-term solution.

The choice depends on the extent of the damage, the criticality of the machine, and your budget. Our experts can help you assess your options, ensuring you make the best decision for your operations. For more information, read our guide on Spindle Rebuild or Replace.

THE FUTURE OF SPINDLE TECHNOLOGY

The industrial manufacturing landscape is constantly evolving, and Spindle Parts technology is no exception. With the CNC spindle market expected to grow from USD 1.2 billion in 2023 to USD 1.8 billion by 2028, we’re seeing a clear trend towards increasing efficiency and integrating spindles into the broader smart manufacturing ecosystem. The future promises even more sophisticated and intelligent spindle solutions.

Innovations in Spindle Design

The drive for higher productivity and precision is fueling continuous innovation in spindle design:

- Higher rotational speeds: Manufacturers are pushing the boundaries of RPM, developing spindles capable of ultra-high speeds for micro-machining and finishing operations. This requires advancements in bearing technology (e.g., ceramic hybrid bearings, active magnetic bearings) and dynamic balancing techniques.

- Increased power density and thermal stability: Modern spindles are designed to deliver more power in smaller packages while effectively managing the heat generated at high speeds and loads. This involves improved cooling systems (liquid cooling, air-oil mist) and advanced materials for various Spindle Parts.

- Advanced materials for components: The use of new alloys, ceramics, and composite materials for spindle shafts, housings, and other components is leading to lighter, stiffer, and more thermally stable spindles. Our team is always up-to-date with these advancements, which are crucial for Machine Tool Spindle Design.

The Rise of Smart Spindles

One of the most exciting trends is the emergence of “smart spindles,” which are changing how we monitor and maintain these critical components:

- Integrated sensors for real-time data: Smart spindles incorporate a variety of sensors (temperature, vibration, displacement, acoustic emission) directly into their structure. These sensors collect real-time data on the spindle’s operating conditions.

- Condition monitoring capabilities: This data is then used for continuous condition monitoring, allowing operators to track the health of the spindle and detect anomalies as they occur. This moves away from reactive maintenance towards a more proactive approach.

- Predictive maintenance alerts: Advanced algorithms analyze the sensor data to predict potential failures before they happen. This enables maintenance to be scheduled precisely when needed, minimizing unexpected downtime and maximizing spindle lifespan.

- Integration with Industry 4.0 systems: Smart spindles are designed to seamlessly integrate with broader Industry 4.0 and Industrial Internet of Things (IIoT) platforms. This allows for centralized monitoring, data analysis, and optimization of entire manufacturing processes, paving the way for truly autonomous and highly efficient factories. The development of smart spindles with integrated sensors for condition monitoring and predictive maintenance is indeed a growing trend in the market, promising a future where spindle health is continuously optimized.

FREQUENTLY ASKED QUESTIONS ABOUT SPINDLE PARTS

What are the most critical spindle parts to monitor?

While all Spindle Parts are important, the bearings are undoubtedly the most critical to monitor. Their failure often cascades into catastrophic damage to the entire spindle assembly. Beyond bearings, the drawbar mechanism and seals are also vital. The drawbar ensures secure tool clamping, impacting machining quality and safety, while effective seals are essential for preventing contamination, which is the leading cause of premature bearing failure.

How often should spindle bearings be replaced?

Spindle bearing replacement is typically based on condition, not a fixed schedule. Modern industrial practices favor predictive maintenance, utilizing tools like vibration analysis and temperature monitoring. These techniques can detect the early signs of bearing wear or damage, indicating when a spindle bearing replacement is necessary. Replacing bearings proactively based on condition prevents unexpected breakdowns and more extensive damage.

Can I upgrade my existing spindle with better parts?

Absolutely! Upgrading certain Spindle Parts can significantly improve performance and extend the life of your existing spindle. For instance, replacing standard bearings with higher-precision ceramic hybrid versions can increase speed capabilities and thermal stability. Improving the sealing system can offer better protection against contamination. Additionally, a CNC spindle motor upgrade can boost power, torque, or speed, allowing your machine to handle more demanding applications or improve cycle times.

CONCLUSION: YOUR PARTNER FOR PRECISION SPINDLE SOLUTIONS

High-quality Spindle Parts are not just components; they are an investment in your machine’s precision, reliability, and productivity. Understanding each part’s function, how it contributes to the overall assembly, and the best practices for its maintenance is the first step toward optimizing your industrial manufacturing operations.

At MZI Precision, we understand the critical role these components play. We offer expert spindle repair and rebuilding services from our California locations, including Huntington Beach and Los Angeles, utilizing top-tier components to restore your equipment to OEM standards or better. Our commitment extends to ensuring your machines deliver the accuracy and efficiency you depend on.

We proudly serve a range of demanding industries, including:

- Aerospace

- Defense

- Advanced Manufacturing

For expert guidance on all your spindle needs, from selecting the right Spindle Parts to comprehensive repair and rebuilding, we invite you to explore our comprehensive spindle services.