Spindle motor repair is critical for businesses relying on CNC machines for precision manufacturing, especially in industries like aerospace where high-speed rotations demand the utmost accuracy. If you’re navigating the complexities of spindle motor maintenance, here’s what you need to know to ensure optimal performance:

- Precision and Speed: Spindle motors are designed for high-speed rotations essential for CNC machines, enabling detailed and accurate machining.

- Maintenance Necessities: Regular checks for wear and tear, along with early detection of issues such as imbalances or overheating, can prevent costly downtimes.

- Repair Expertise: Addressing problems like faulty bearings, vibration, and imbalances requires specialized skills and tools, underlining the importance of expert repair services.

Spindle motors function as the heart of CNC machines, powering the high-speed rotations that allow for precise machining. Due to their complex nature and critical role, maintaining them involves addressing specific challenges like rotor imbalances and exacting tolerances.

Without regular maintenance and expert intervention, issues from excessive vibrations to overheating can impair effectiveness, leading to potential machine breakdowns. This is why partnering with a knowledgeable repair service is essential for ensuring reliability and performance.

Spindle motor repair glossary:

– how does a spindle motor work

– electric spindle motor

– pneumatic spindle motor

Understanding Spindle Motor Repair

When it comes to spindle motor repair, understanding the critical components and common issues is key to maintaining performance and longevity. Let’s break down the essential elements involved in keeping these motors running smoothly.

Spindle Cooling Jacket

The spindle cooling jacket is like the motor’s personal air conditioner. It ensures that the motor stays cool during high-speed operations. If the cooling jacket is clogged or dirty, it can lead to overheating, causing significant damage. Regular cleaning is essential to keep the coolant flowing freely and prevent heat buildup.

Spindle Fan

The spindle fan acts as a cooling system, blowing air over the motor to prevent overheating. If the fan’s bearings or windings fail, the motor can overheat quickly, leading to operational issues. Regular checks and maintenance of the fan can help detect problems early and avoid costly repairs.

Spindle Sensor

The spindle sensor is the brain of the motor, providing critical feedback on speed and direction. A failed sensor means the motor is flying blind, leading to incorrect speeds and potential system failure. Ensuring that the sensor is functioning correctly is crucial for maintaining the motor’s precision and reliability.

Shaft Runout

Shaft runout is a sneaky problem that can cause big headaches. Imagine a spinning plate that’s slightly off-balance; that’s what shaft runout does to a spindle motor. It causes vibrations and can lead to premature bearing failure. Regular checks and adjustments can help keep the shaft aligned and running smoothly.

Vibration Testing

Regular vibration testing is like a health check-up for your spindle motor. It helps catch imbalances and wear before they lead to failure. Skipping these tests is risky, as undetected issues can escalate quickly. Consistent vibration testing ensures the motor runs smoothly and extends its lifespan.

By understanding these components and their roles, you can better maintain your spindle motor and avoid unexpected downtimes. Regular maintenance and expert repair services are crucial for ensuring your spindle motor continues to perform at its best.

Common Issues and Solutions in Spindle Motor Repair

When dealing with spindle motor repair, several common issues can arise, each requiring specific solutions to ensure optimal performance and longevity. Let’s explore the main problems you might encounter and how to address them.

Excessive Noise

Excessive noise is often the first sign that something is amiss with your spindle motor. This noise can stem from various sources, such as bearing failure or misalignment. Bearings made for high-speed motors are costly and must be installed with precision to avoid overheating and noise. Regular monitoring and maintenance can help identify and replace faulty bearings before they cause significant damage.

Overheating

Overheating is a critical issue that can lead to severe damage if not addressed promptly. It often results from inadequate cooling, failed fans, or lubrication failures. To prevent overheating, ensure that the spindle cooling jacket and fans are clean and functional. Regular checks on the lubrication system are also vital to reduce friction and heat buildup.

Spindle Imbalance

Spindle imbalance is like driving a car with an unbalanced tire; it causes vibrations that can damage the motor and affect machining quality. Proper rotor balancing is crucial, especially because spindle motors operate at high speeds. After any repair, the rotor should be balanced to tight specifications to avoid vibration and subsequent damage.

Precision Machining

Precision machining is essential in spindle motor repair, as even minor errors can lead to significant issues. For example, correcting a worn bearing journal or repairing tool holder damage requires meticulous attention to detail. All machining work must be performed with precise measurements and motor balance in mind to ensure the spindle motor operates smoothly and efficiently.

By addressing these common issues with the right solutions, you can maintain the performance and extend the life of your spindle motors. Regular maintenance and attention to detail in repairs are key to preventing unexpected downtimes and costly repairs.

The Spindle Motor Repair Process

When it comes to spindle motor repair, the process is a blend of expertise and precision. Each step is crucial to bringing your spindle motor back to optimal performance. Let’s walk through the stages of this meticulous process.

Evaluation

The journey begins with a thorough evaluation. Technicians check for issues like bearing fits, rotor runout, and cooling jacket condition. They also inspect flange fits, worn shafts, and sensor outputs. This step helps pinpoint the exact cause of failure and lays the groundwork for a successful repair.

Cleaning

Once the evaluation is complete, the cleaning phase kicks in. Every component of the spindle motor is cleaned carefully. Dirt and debris can cause significant issues, so technicians ensure each part is spotless before moving on to the next step. This attention to detail helps prevent future problems.

Inspection

After cleaning, a detailed inspection is conducted. Technicians examine each component for wear, damage, or improper fit. This step is about catching every little issue that might affect the motor’s performance. A comprehensive inspection ensures nothing is overlooked.

Repair

With a clear understanding of what needs fixing, the repair phase begins. Technicians replace faulty components, rewind stators if necessary, and balance the rotor. High-speed bearings are installed to ensure smooth operation. Each repair is done with precision to meet original equipment manufacturer (OEM) specifications.

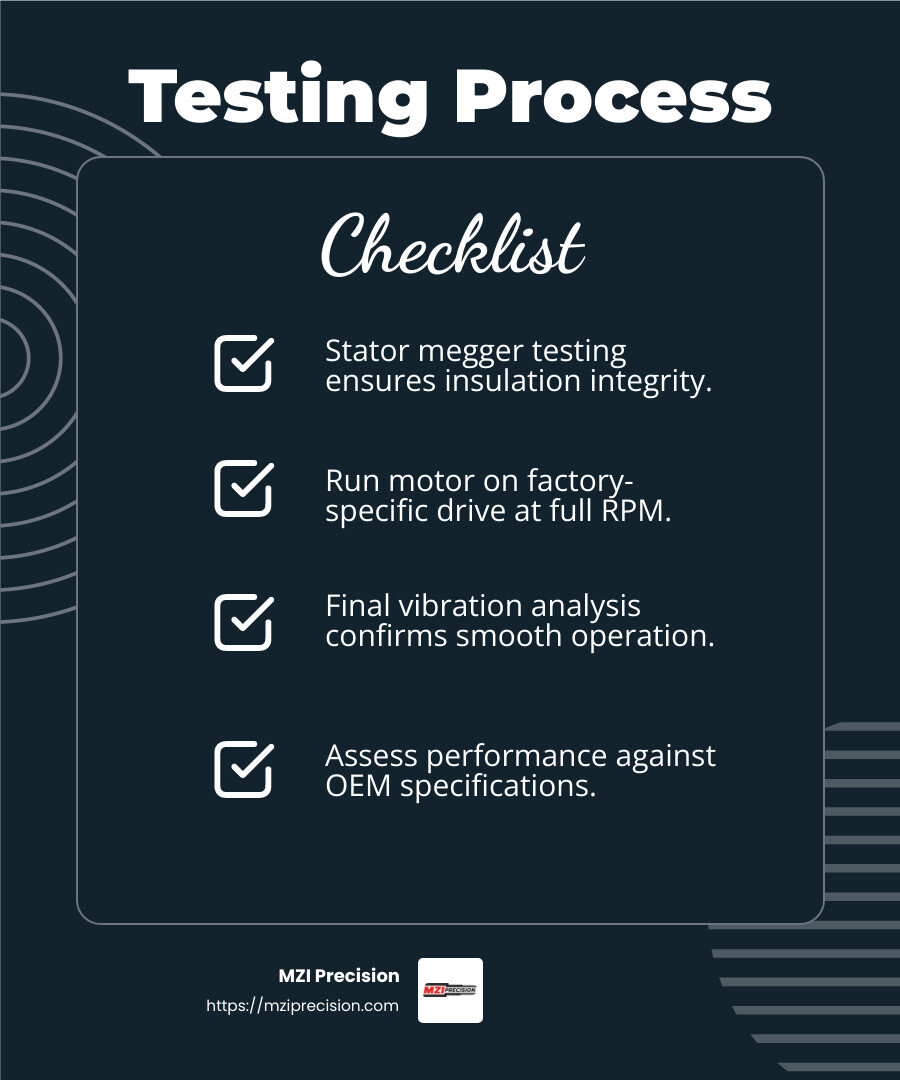

Testing

Testing is where the spindle motor’s readiness is confirmed. The motor undergoes rigorous testing, including stator megger testing and running on a factory-specific drive at full RPM. A final vibration analysis ensures that the motor will run smoothly and efficiently.

Painting

After testing, the motor gets a fresh coat of paint. This isn’t just about aesthetics; the paint provides protection against contaminants. A new label with the job number is added for easy traceability.

Shipping

Finally, the motor is prepared for return shipping. It’s securely packaged with spray foam or placed in custom crates for larger models. This careful packaging ensures the motor arrives back to you in perfect condition, ready to get back to work.

By following this structured repair process, you can be confident that your spindle motor is in top shape, minimizing downtime and maximizing productivity. Next, let’s dive into some frequently asked questions about spindle motor repair.

Frequently Asked Questions about Spindle Motor Repair

How much does it cost to fix a spindle?

Repairing a spindle can vary greatly in cost, depending on several factors. The complexity and size of the spindle are primary considerations. Larger, more complex spindles often require more labor and parts, which can increase costs.

Use of Original Equipment Manufacturer (OEM) parts also impacts the price. While OEM parts are typically more expensive, they offer a better fit and durability, which can extend the life of your spindle.

Another factor is the extent of damage. Minor repairs might only cost a few hundred dollars, but extensive rebuilds can run into the thousands. Investing in quality repairs and parts can save money in the long run by preventing future breakdowns.

Can a spindle be repaired?

Yes, a spindle can often be repaired rather than replaced. This can be a more cost-effective solution, especially when dealing with high-end or custom spindles.

Signs that your spindle needs repair include unusual noises, excessive vibration, and overheating. These symptoms can indicate issues like bearing failure or rotor imbalance. Addressing these problems early can prevent more severe damage and reduce downtime.

In some cases, welding may be required to fix cracks or damage in the spindle body. Replacement of worn components, like bearings or shafts, is also common. With proper repairs, a spindle can be restored to like-new condition, or even better.

How do you know if a spindle motor is defective?

Detecting a defective spindle motor early can save time and money. Common signs of a defective spindle motor include:

- Noise: Grinding, screeching, or rattling sounds often point to bearing issues or internal damage.

- Vibration: Excessive vibration can be a result of worn components or imbalances, affecting machining quality.

- Overheating: A rise in operating temperature might suggest overload or cooling system failure.

Regular monitoring and maintenance can help catch these issues before they lead to more significant problems. If you notice any of these signs, it’s crucial to consult a professional for an evaluation.

By understanding these aspects, you can make informed decisions about maintaining and repairing your spindle motor, ensuring your machinery runs smoothly and efficiently.

Conclusion

At MZI Precision, we pride ourselves on being experts in spindle motor repair. Our commitment goes beyond just fixing what’s broken; we aim to improve the overall performance and longevity of your machinery. With years of experience and a team of skilled professionals, we ensure that your equipment is in the best hands.

Exceptional Service

Our service is not just about repairs; it’s about building trust and delivering excellence. We understand that downtime can be costly, so we work efficiently to get your machines back up and running. Our team is dedicated to providing swift, reliable solutions custom to your specific needs.

We offer comprehensive support, from initial evaluation to the final test run. Our process includes thorough inspections, precise repairs, and rigorous testing to ensure optimal performance. We also provide a detailed report of the work done, so you’re fully informed every step of the way.

Spindle Repair Expertise

MZI Precision stands out for its expertise in OEM spindle rebuilds. We use high-quality parts and state-of-the-art technology to restore your spindles to their peak condition. Our technicians are trained to handle a wide range of spindle issues, ensuring that each repair meets our high standards of quality and precision.

Our commitment to excellence is backed by our industry-leading warranty, providing you with peace of mind. We believe in the quality of our work and are confident that our repairs will stand the test of time.

For more information on how we can assist with your spindle motor needs, visit our Spindle Motors Service Page. Let us help keep your operations running smoothly and efficiently.

Partnering with MZI Precision means investing in reliable, high-quality service that keeps your machines performing at their best. Trust us to be your partner in maintaining the heart of your industrial operations.