Electric spindle motor repair is crucial for the continued success of industrial manufacturing operations. When these components go down, precision and reliability are at stake, leading to costly downtime. Swift and accurate repairs aren’t just a necessity—they are a critical business operation for any manufacturer that relies on CNC machines and other advanced technology.

Here’s a quick snapshot of what you need to know if you’re dealing with spindle motor issues:

- Importance: Essential for maintaining the efficiency and precision of CNC machinery.

- Common Issues: Include lubrication problems, contamination, and balance defects.

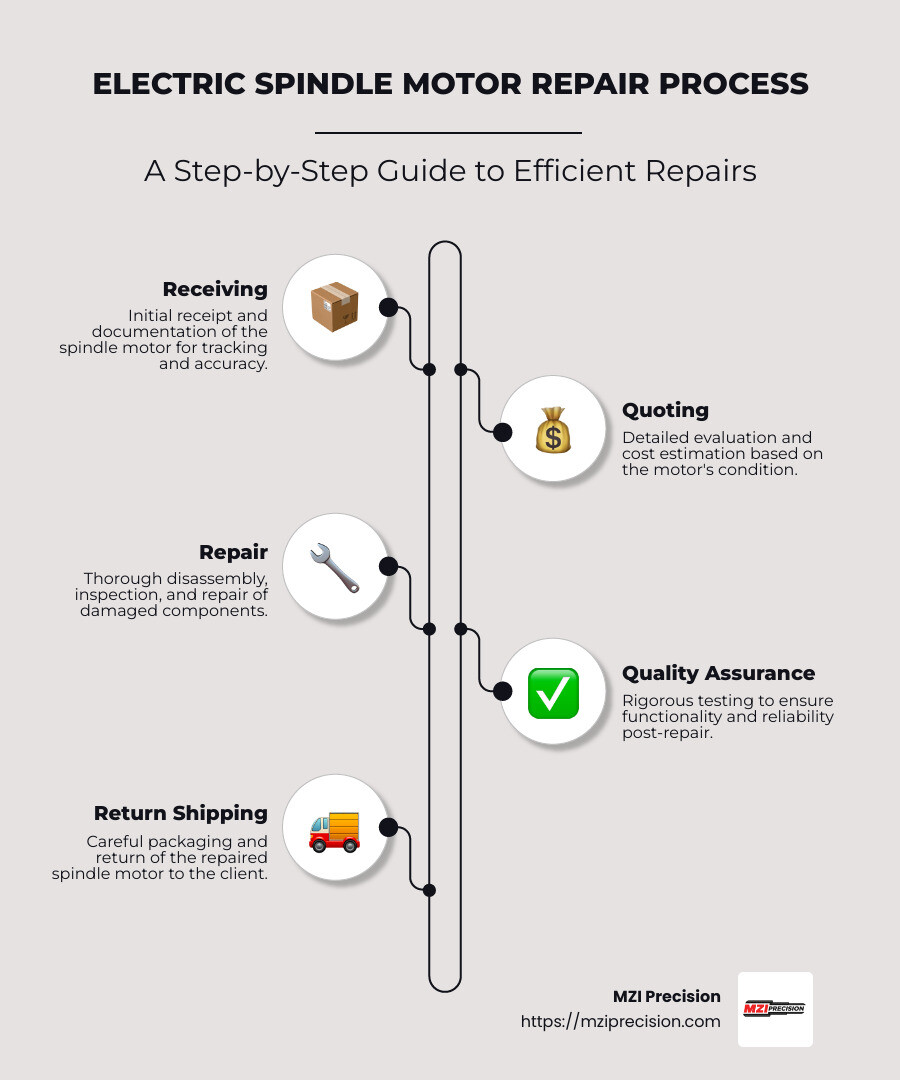

- Repair Process: Involves thorough disassembly, inspection, and testing to restore functionality.

- Benefits: Professional repair can extend equipment lifespan and significantly reduce downtime costs.

Understanding how to manage your spindle motor repair needs is an investment that pays off in the long run. MZI Precision excels in providing these services with expertise, ensuring that your manufacturing processes run smoothly and efficiently.

Relevant articles related to Electric spindle motor repair:

– AC spindle motor repair

– spindle motor disassembly

Understanding Electric Spindle Motors

Electric spindle motors are the heart of many industrial machines. They are essential for tasks that require high precision and speed, such as milling, drilling, and grinding. These motors convert electrical energy into rotational motion, powering various manufacturing processes.

Industrial Applications

Spindle motors are widely used in CNC machines across different industries. From aerospace to medical device manufacturing, these motors are vital for producing intricate and precise components. For example, in the aerospace industry, spindle motors help create engine parts with tight tolerances, ensuring safety and performance.

In the industrial manufacturing sector, spindle motors are crucial for the fast and accurate production of complex components. They enable manufacturers to meet high market demands efficiently. Similarly, in the medical field, these motors are used to craft surgical instruments and dental implants, where precision is non-negotiable.

Precision Engineering

The design of spindle motors is all about precision and efficiency. They must operate at high speeds with minimal vibration to ensure accurate machining. This is why they are engineered with specialized components like high-quality bearings and balanced rotors.

Precision engineering in spindle motors involves maintaining tight tolerances and ensuring that every component is carefully crafted and assembled. This precision ensures that the motors can withstand the demands of industrial applications, providing consistent and reliable performance.

In summary, understanding electric spindle motors involves recognizing their critical role in industrial applications and the precision engineering required to maintain their performance. These motors are not just components; they are pivotal to the success of modern manufacturing.

Key Steps in Electric Spindle Motor Repair

Repairing an electric spindle motor is a meticulous process that requires attention to detail and precision at every step. Let’s break down the key stages involved in electric spindle motor repair to ensure these motors return to peak performance.

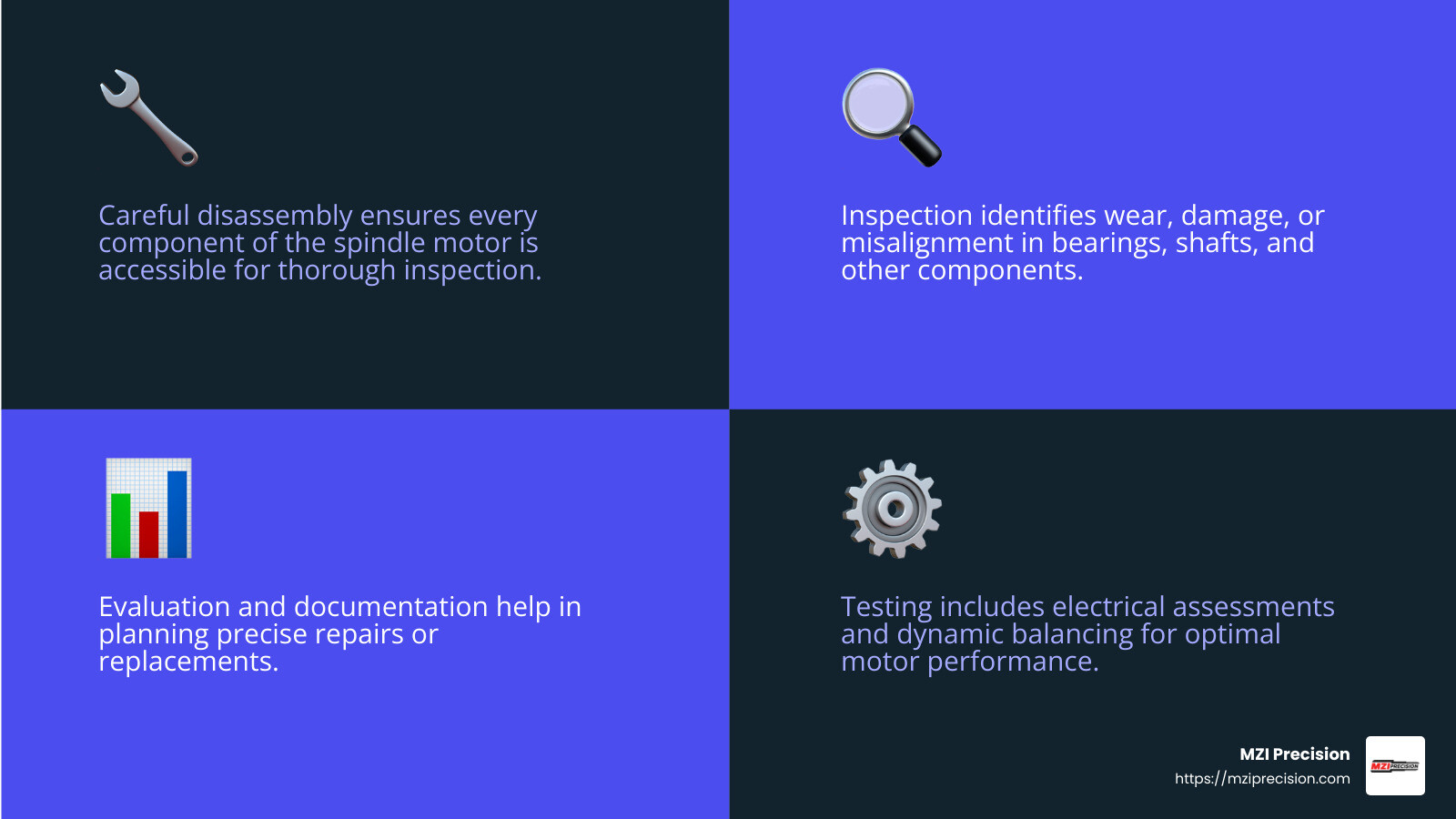

Disassembly

The repair process begins with careful disassembly. Technicians dismantle the spindle motor to access all its components. This step is crucial for identifying any hidden issues that might affect the motor’s performance.

Inspection

Once disassembled, each part of the spindle motor undergoes a thorough inspection. Technicians look for signs of wear, damage, or misalignment. Bearings, shafts, and other critical components are closely examined to determine their condition.

For instance, a worn output shaft can lead to vibration and misalignment, which can compromise the motor’s efficiency.

Evaluation

After inspection, an evaluation is conducted to assess the extent of repairs needed. Technicians document their findings and develop a detailed plan for restoring the motor to its original specifications. This evaluation helps in identifying whether components need repair, replacement, or adjustment.

Testing

Before moving to reassembly, the motor undergoes several tests to ensure each component functions correctly. These tests include electrical assessments and balance checks to verify that the motor will operate smoothly.

Dreisilker’s approach, as mentioned in the research, involves running electrical tests and dynamic balancing to ensure the motor meets industry standards.

Reassembly

Once testing confirms that all components are in optimal condition, the spindle motor is reassembled with precision. New bearings and seals are installed if necessary. The motor is then put back together, ensuring all parts are aligned correctly.

Reassembly in a certified clean room, as highlighted in the research, ensures that the motor is free from contaminants, which can affect its performance.

By following these key steps, professionals ensure that electric spindle motors are repaired to deliver reliable and efficient performance, minimizing downtime and extending their lifespan.

Benefits of Professional Electric Spindle Motor Repair

When it comes to electric spindle motor repair, going the professional route offers several key advantages. Let’s explore how these benefits can impact your operations positively.

Cost-Effectiveness

Repairing an electric spindle motor is often more affordable than replacing it. By addressing specific issues, you save money on buying a new motor and avoid the hidden costs of downtime.

According to industry insights, a professional repair can return a spindle motor to like-new condition, which is cost-effective compared to the expense of a full replacement.

Extended Lifespan

Professional repairs extend the life of your spindle motor. By replacing worn parts and ensuring everything is in optimal condition, you get more use out of your existing equipment.

Regular maintenance and precise repairs can significantly prolong the operational life of your spindle motor, reducing the frequency of replacements.

Reduced Downtime

Downtime is costly in any industrial setting. Opting for professional repairs minimizes the time your equipment is offline. Skilled technicians work efficiently to get your spindle motor back in action quickly.

Research highlights the importance of a fast turnaround. Professional services often offer quick repairs without sacrificing quality, ensuring your operations continue smoothly.

Investing in professional electric spindle motor repair means you’re choosing a solution that saves money, extends equipment life, and keeps your operations running efficiently. By focusing on these benefits, you can maintain productivity and reduce unnecessary expenses.

Next, let’s address some frequently asked questions about electric spindle motor repair to help you make informed decisions.

Frequently Asked Questions about Electric Spindle Motor Repair

Can a burned out electric motor be repaired?

Yes, a burned out electric motor can often be repaired, depending on the extent of the damage. Skilled technicians can assess the motor’s condition and determine the best course of action. It’s crucial to choose a repair service with EASA-accredited vendors who adhere to high standards of quality and expertise. These professionals use advanced techniques to restore motors to optimal working conditions, potentially saving you from the higher costs of replacement.

Is it worth rebuilding an electric motor?

Rebuilding an electric motor can be a cost-effective solution, especially when the motor shows signs of wear but isn’t entirely beyond repair. Rebuilding involves replacing worn parts and reconditioning the motor, which can bring it back to like-new condition. This option is often more economical than purchasing a new motor, particularly when considering the costs associated with downtime and installation of new equipment. By choosing to rebuild, you extend the motor’s lifespan and maintain the efficiency of your industrial operations.

Are electric motors repairable?

In many cases, electric motors are repairable, and choosing to repair rather than replace can be economically beneficial. The decision between repair and replacement depends on factors like the motor’s condition, repair costs, and the potential for restoring full functionality. Economic considerations should guide your decision, as a repair might be a more feasible option if it restores the motor’s efficiency and reliability at a lower cost. Consulting with experienced professionals can help evaluate whether repair is the best choice for your specific situation.

By understanding these aspects of electric spindle motor repair, you can make informed decisions that balance cost, efficiency, and longevity. Up next, we’ll conclude our discussion with insights into MZI Precision’s expertise in delivering exceptional service.

Conclusion

At MZI Precision, we pride ourselves on our expertise and commitment to delivering exceptional service in the field of electric spindle motor repair. Our team understands the critical role that spindle motors play in industrial manufacturing, and we’re dedicated to ensuring your equipment operates at peak performance.

Why Choose MZI Precision?

-

Expertise: Our team consists of skilled technicians with years of experience in spindle motor repair and rebuilding. We have the knowledge and tools necessary to handle even the most complex repairs, ensuring your motors are restored to optimal condition.

-

Exceptional Service: We go beyond just repairs. Our service includes thorough evaluations, detailed service reports, and clear communication with our clients. We believe in transparency and keeping you informed every step of the way.

-

Commitment to Quality: At MZI Precision, we adhere to the highest standards of quality. Our processes are designed to extend the lifespan of your spindle motors, reduce downtime, and improve your operational efficiency.

Partnering with MZI Precision means investing in the reliability and longevity of your industrial equipment. We invite you to learn more about our services and how we can support your business by visiting our spindle motor repair page.

Together, let’s ensure your operations run smoothly and efficiently, minimizing interruptions and maximizing productivity.