When your spindle motor fails, quick and reliable repair is critical to minimize downtime. In California and Michigan, MZI Precision stands out for spindle motor repair services, offering a blend of expert troubleshooting, state-of-the-art refurbishing, and a keen focus on customer needs. Whether you’re in the aerospace industry or another sector reliant on CNC machinery, knowing where to turn can save you time, money, and stress.

Services offered include:

– Comprehensive diagnostics and failure analysis

– Precision spindle repair and refurbishment

– Emergency repair services with rapid turnaround

– A detailed warranty on all repair work

Understanding the urgency and complexity of spindle motor repair is our specialty. We simplify the process, making it transparent and customer-focused, ensuring your machinery is back to optimal performance with minimal disruption.

In the bustling sectors of California and Michigan’s manufacturing landscapes, MZI Precision emerges as a pivotal partner for spindle motor repair services, blending unparalleled expertise with a commitment to excellence. Let’s delve into what makes our spindle repair process uniquely reliable and efficient.

Understanding Spindle Motor Repair

When your spindle motor stops spinning or doesn’t turn as it should, it’s a signal that something is amiss. But not to worry, understanding the spindle motor repair process can demystify what happens next and ensure your machinery is back to its best performance. Here’s a simple breakdown of the steps involved:

Evaluation

First things first, any reputable spindle motor repair service begins with a thorough evaluation. This isn’t just a quick look-over. Technicians dive deep to discover exactly what’s wrong. They check for wear and tear, contamination, electrical faults, and more. It’s like a doctor’s check-up for your spindle motor.

Part Breakdown

Once the issue is identified, the next step involves breaking down the motor to its core components. This is a critical step because it helps pinpoint the exact parts that need repair or replacement. Think of it as taking apart a puzzle to find the missing piece.

Repair Quote

After the evaluation and part breakdown, you’ll receive a repair quote. This isn’t just a number. It’s a detailed plan outlining the cause of failure, the parts needed for repair, and how long the job will take. It’s your roadmap to getting your spindle motor back in action.

Part Replacement

With your go-ahead, the repair process kicks off. This could involve cleaning parts, sandblasting, rewinding stators, machining out-of-spec parts back to their original glory, and balancing the rotor. High-speed bearings are installed anew, ensuring everything runs smoothly.

Part Tests

But it’s not enough to just replace parts and call it a day. Every repaired spindle motor undergoes rigorous testing. This includes vibration analysis, run-in tests, and more. It’s like a final exam to ensure your spindle motor graduates top of its class.

Part Returns

The final step? Returning the spindle motor to you, along with detailed documentation of the repairs done, tests conducted, and guidelines for future maintenance. Plus, a warranty for peace of mind. It’s the full package, ensuring you’re not just satisfied but confident in the repair work done.

In California and Michigan, where manufacturing and precision are key, understanding the spindle motor repair process is crucial. From the initial evaluation to the final tests and return, every step is designed to ensure your spindle motor is not just repaired but revitalized. MZI Precision stands at the forefront of this process, offering expertise and commitment to excellence that’s hard to match. Let’s move forward and explore the common reasons for spindle motor failures, ensuring you’re equipped with the knowledge to prevent future issues.

Common Reasons for Spindle Motor Failures

When your spindle motor stops working as it should, it’s not just a bump in the road. It’s a full stop in your production line. Understanding why these failures happen can be your first step in preventing them. Let’s dive into the common culprits behind spindle motor failures.

Spindle Cooling Jacket

Imagine running a marathon in the desert without water. That’s what happens to your spindle motor without a properly functioning cooling jacket. It overheats. Keeping this jacket clean and clear allows coolant to flow and keeps temperatures down. A dirty or blocked cooling jacket is a fast track to motor failure.

Failed Spindle Fan

Your spindle motor’s fan is like a personal cooling system. It’s there to blow away the heat and keep things at a manageable temperature. When the fan fails, heat builds up quickly, and just like any of us after too much sun, your motor can’t function properly. It’s a common reason for motor stops and needs immediate attention.

Failed Spindle Sensor

A spindle motor relies on its sensor to know how fast and in what direction to spin. It’s the brain of the operation. If this sensor fails, the motor is essentially running blind. This can lead to all sorts of problems, from incorrect speeds to total system failure.

Bad Shaft Runout

Imagine your motor’s shaft is a spinning plate. Now, imagine that plate isn’t quite balanced. This is shaft runout. It causes vibration, wear, and tear on bearings, and ultimately, failure. It’s a sneaky problem that can cause big issues if not caught early.

Spindle Motor Vibration Testing

Regular vibration testing is like a health check-up for your spindle motor. It can catch imbalances, wear, and potential failures before they happen. Skipping these tests is like skipping regular doctor visits; you might be fine for a while, but eventually, something will go wrong.

In a nutshell, keeping your spindle motor running smoothly boils down to regular maintenance and being vigilant about these common failure points. MZI Precision understands these challenges and is equipped to address them, ensuring your spindle motor repair service not only fixes the problem but prevents future issues.

Next, we’ll explore how to choose the right spindle motor repair service to ensure your machinery is in the best hands.

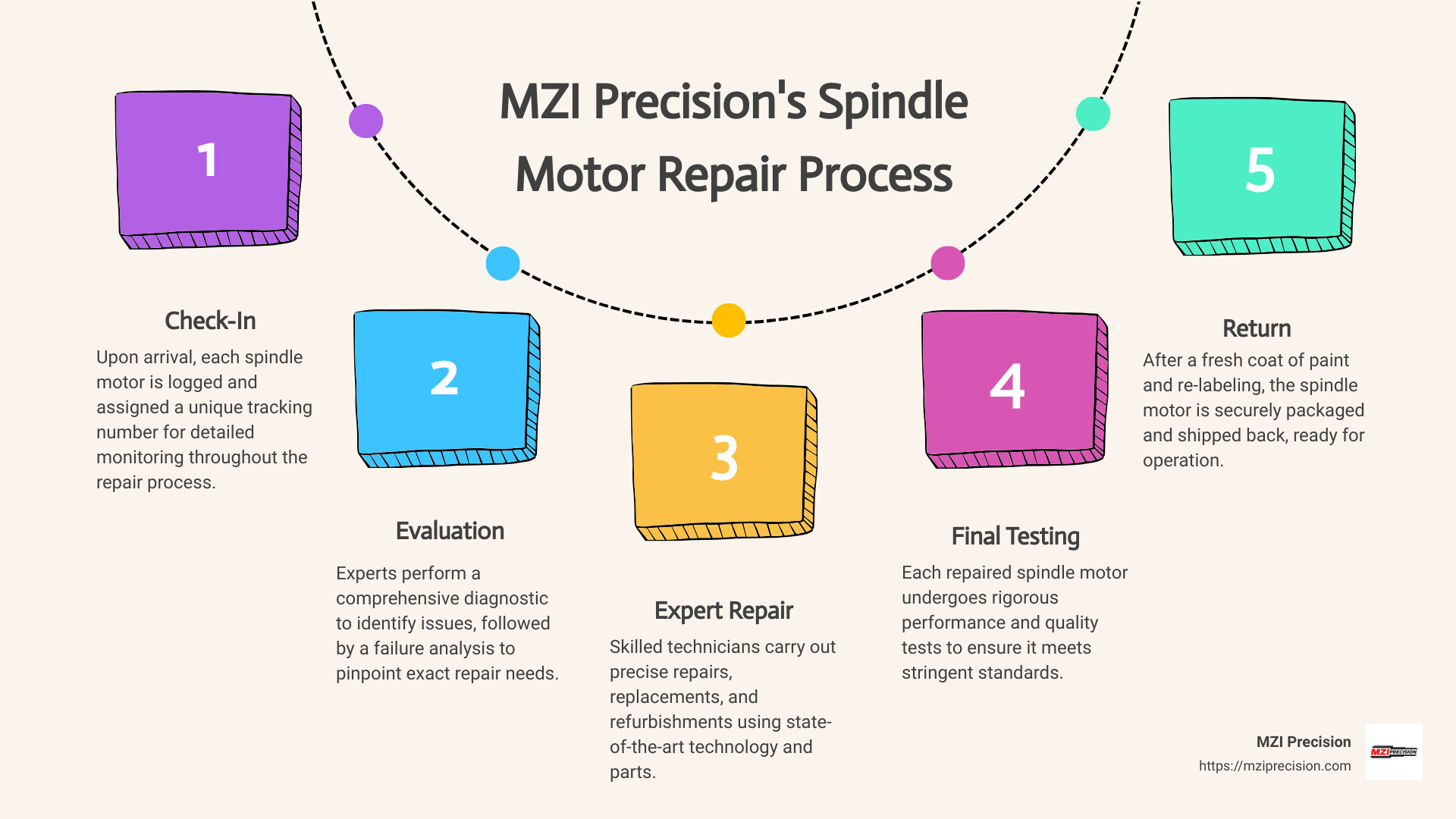

The Process of Spindle Motor Repair

When it comes to spindle motor repair service, the process can seem complex, but it’s all about detail and precision. Let’s break down each step, so you know exactly what happens from the moment your spindle motor arrives for repair until it’s returned to you, ready for action.

Checking In

- First Steps: As soon as your spindle motor reaches the repair facility, it’s photographed and documented for records. This ensures transparency and accountability right from the start.

- Unique Identification: Each motor is assigned a unique job number. This helps in tracking the repair progress and maintains an organized workflow.

- Acknowledgment: You’ll receive an email acknowledgment, so you’re informed that your motor has safely arrived and is in the queue for evaluation.

Efficient Evaluation

- Thorough Inspection: Technicians check for common issues like bearing fits, rotor runout, and cooling jacket condition. They also assess flange fits, worn shafts, winding condition, and sensor output.

- Diagnosis: This step is crucial to understanding exactly what’s wrong and what needs to be done to fix it.

Quote

- Transparent Pricing: After evaluation, you’ll receive a detailed quote. This includes the cause of failure, parts needed for repair, and the estimated job completion time.

- No Surprises: This step ensures you know the costs upfront, helping you make an informed decision.

Expert Repair

- Precision Work: Technicians clean, sandblast, rewind stators (if needed), machine out-of-spec parts, balance the rotor, and install new high-speed bearings.

- Sensor Setup: They also ensure that sensor outputs meet factory specifications for optimal performance.

Final Testing

- Rigorous Testing: The motor undergoes final testing, including stator megger testing, running on a factory-specific drive at full RPM, and a final vibration analysis.

- Quality Assurance: This ensures the spindle motor will run smoothly and efficiently, just like new.

Painting and Re-Labeling

- Aesthetic Touch: The motor is painted not just for looks but also for protection against contaminants. A new label with the job number is added for easy traceability.

- Like New: This step ensures your refurbished motor not only works like new but looks the part too.

Return Shipping

- Secure Packaging: Motors are securely packaged with spray foam or placed in custom crates for larger models to ensure they arrive back to you safely.

- Peace of Mind: This careful attention to packaging minimizes the risk of damage during transit, ensuring your repaired motor reaches you in perfect condition.

The spindle motor repair process is a blend of technical expertise, meticulous attention to detail, and customer service excellence. MZI Precision stands out by ensuring each step is performed with the utmost precision and care, guaranteeing your machinery operates at its best. With a clear understanding of this process, you can trust your spindle motor repair needs to professionals who are committed to quality and reliability.

In the next section, we’ll delve into how to select the right spindle motor repair service, focusing on key aspects like certification, experience, warranty, and customer service among others.

How to Choose the Right Spindle Motor Repair Service

When your spindle motor stops spinning, the urgency to get it fixed can lead you to make hasty decisions. However, it’s crucial to select a spindle motor repair service that not only fixes the problem quickly but ensures long-lasting performance. Here’s how to choose wisely:

Certification

Look for certified professionals. Certifications are a sign that the repair service adheres to high standards of quality and expertise. It ensures that they are up-to-date with the latest technologies and repair methodologies. Certified technicians know their stuff.

Experience

Experience matters. A service with years of experience in spindle motor repair has likely seen it all and can handle complex repairs with ease. They are more likely to diagnose issues accurately and fix them efficiently. Experience brings reliability.

Warranty

Check for a strong warranty. A confident repair service offers a solid warranty on their work. This not only gives you peace of mind but also speaks volumes about their trust in their own workmanship. Look for warranties that cover a significant period post-repair.

Specialization

Specialization is key. Choose a repair service that specializes in spindle motor repairs. This ensures they have the specific knowledge and tools required to fix your motor. Specialized services are often quicker and more effective at diagnosing and repairing spindle motors.

Customer Service

Evaluate their customer service. Good communication and support are essential. The right repair service is responsive, answers your questions clearly, and keeps you updated throughout the repair process. They should make you feel valued and reassured.

Turnaround Time

Consider the turnaround time. Time is money, especially in industries relying on spindle motors. Look for a repair service that offers a quick turnaround without compromising on quality. However, be wary of services that promise unrealistically quick fixes, as thorough repairs take time.

When selecting a spindle motor repair service, weigh these factors carefully. A service that ticks all these boxes will likely provide a repair that is not just quick but also enduring, ensuring your operations run smoothly without frequent downtime. The right choice now can save you time and money in the long run.

Frequently Asked Questions about Spindle Motor Repair

When it comes to maintaining the efficiency and reliability of your CNC machines, understanding the nuances of spindle motor repair is crucial. Here are some of the most commonly asked questions that shed light on the intricacies of this vital service.

How much does it cost to replace a spindle?

The cost of replacing a spindle can vary widely, typically ranging between $14,000 and $24,000. This variation is due to factors such as the complexity of the spindle, the type of machinery it’s used in, and the urgency of the replacement. It’s worth noting that lead times for replacements can extend up to 32 weeks, depending on availability. Given these considerations, exploring repair options with a trusted provider like MZI Precision can be a more cost-effective and timely solution.

What is the process of spindle repair?

At MZI Precision, the spindle repair process is thorough, ensuring your spindle is returned to optimal condition. Here’s a simplified overview:

- Inspection: Every spindle repair starts with a detailed inspection to identify specific issues.

- Analysis: The root causes of the problem are analyzed, whether they stem from bearing failure, misuse, or wear and tear.

- Repair: Necessary repairs are performed, which may include parts replacement, imbalance correction, or machining of damaged components.

- Balancing: The spindle is carefully balanced to minimize vibration and prevent future wear.

- Assembly: Reassembly is conducted with precision, ensuring all components are correctly aligned and functional.

- Testing: Rigorous testing under operational conditions confirms the repair’s success and the spindle’s performance.

- Quality Control: Continuous quality control checks guarantee the highest standards are met throughout the repair process.

This comprehensive approach ensures your spindle is restored to its best possible condition, ready to perform efficiently.

What does a spindle technician do?

A spindle technician is a specialist who plays a crucial role in the repair and maintenance of spindle motors. Their responsibilities include:

- Conducting detailed inspections to diagnose issues.

- Analyzing problems to determine their root causes.

- Performing precise repairs, from parts replacement to balancing and machining.

- Reassembling spindles with meticulous attention to detail.

- Testing repaired spindles under operational conditions to ensure they meet or exceed original specifications.

- Applying their deep knowledge of spindle technology to prevent future breakdowns.

Spindle technicians at MZI Precision are highly trained and experienced, ensuring that every repair is conducted with the utmost professionalism and expertise.

Choosing the right spindle motor repair service is a critical decision for maintaining the efficiency and longevity of your CNC machines. By understanding the costs involved, the repair process, and the role of a spindle technician, you can make informed choices that ensure your machinery continues to operate at its best. A reliable repair service not only fixes your spindle but also enhances its performance and reliability over time.

Conclusion

At MZI Precision, we understand the critical role that spindle motors play in your machinery’s performance. Our extensive experience and dedication to quality ensure that when you choose us for your spindle motor repair service, you’re getting the best in the business. Here’s why we stand out:

-

Expert Technicians: Our team of specialists brings over 157 years of combined experience in spindle motor repair. This depth of knowledge means we can handle any repair challenge, ensuring your machinery is in expert hands.

-

State-of-the-Art Technology: We utilize the latest technology for testing and repairing spindle motors. This approach guarantees precision and efficiency in every repair we undertake.

-

Quick Turnaround: We know that time is money. That’s why we offer the industry’s most aggressive lead time, with standard repairs completed in 1-3 weeks and emergency repairs often done in 24-48 hours.

-

Comprehensive Service: From evaluation to final testing, we handle every step of the repair process. Our services include dynamic balancing, vibration analysis, and meticulous testing to ensure your spindle motor returns to you in peak condition.

-

Custom Solutions: We don’t just repair; we improve. Our spindle motor upgrades, such as air purge and ceramic bearings, enhance performance and extend the life of your machinery.

-

Guaranteed Satisfaction: Every repair comes with a one-year warranty, giving you peace of mind that our work stands the test of time.

Choosing the right spindle motor repair service is crucial for maintaining the efficiency and longevity of your machinery. At MZI Precision, we’re not just service providers; we’re partners in your success. Our commitment to excellence, combined with our technical expertise, makes us the go-to choice for spindle motor repair.

For more information on how we can help get your machinery back to its optimal performance, visit our CNC Spindle Motor Repair page. Let us help you minimize downtime and maximize productivity. Contact us today and experience the MZI Precision difference.

A reliable repair service not only fixes your spindle but also enhances its performance and reliability over time. Trust us at MZI Precision to deliver the quality and service your machinery deserves.