When it comes to ac servo motor repair, precision is key. Servo motors are the backbone of industrial manufacturing, providing the necessary power and accuracy for various applications. Proper maintenance and repair of these vital components not only ensure smooth operations but also protect against costly downtime.

- What is AC Servo Motor Repair?

AC servo motor repair involves detailed examination, disassembly, cleaning, and reassembly with precise techniques to restore optimal function. - Why Is It Important?

Correct repair extends the lifespan of your equipment and ensures precise control and efficiency in manufacturing processes.

At MZI Precision, we appreciate how crucial it is for industrial manufacturers, especially those in aerospace, to maintain operational excellence. With our extensive experience, we bring reliable servo motor repair services that align with the highest standards of precision and quality.

Understanding AC Servo Motors

AC servo motors play a crucial role in industrial manufacturing. They are designed to provide precise control over motion, making them indispensable in applications requiring accuracy and reliability.

What are AC Servo Motors?

AC servo motors are a type of electric motor that uses alternating current (AC) to produce motion. They are known for their ability to control position, speed, and torque with high precision. This makes them ideal for applications such as robotics, CNC machinery, and automation systems.

How Do AC Servo Motors Work?

AC servo motors consist of several key components:

- Rotor and Stator: The rotor rotates inside the stator, which contains coils of wire. When AC flows through these coils, it creates a magnetic field that interacts with the rotor, causing it to spin.

- Feedback Systems: These motors use feedback systems like encoders or resolvers to monitor and adjust their position and speed. This ensures that the motor operates accurately, even under varying loads or conditions.

Importance of Feedback Systems

Feedback systems are vital for the precise functioning of AC servo motors. They provide real-time data about the motor’s position and speed, allowing for accurate adjustments. This level of control is essential for tasks that demand high precision, such as in aerospace manufacturing.

Feedback Repair and Realignment: If a feedback device becomes misaligned or fails, it can lead to positioning errors. Proper repair and realignment of these devices are crucial for restoring the motor’s performance. This process requires expertise to ensure that the motor functions as intended.

Benefits of Using AC Servo Motors

- Precision: They offer unparalleled precision in controlling motion, which is critical for high-stakes industries like aerospace and automotive manufacturing.

- Efficiency: AC servo motors are energy-efficient, which can lead to cost savings in large-scale operations.

- Reliability: With proper maintenance, these motors are highly reliable and have a long service life, reducing the need for frequent replacements.

Understanding the intricacies of AC servo motors is essential for anyone involved in industrial manufacturing. These motors provide the precision and control needed to keep operations running smoothly and efficiently. At MZI Precision, we specialize in maintaining and repairing these vital components to ensure they perform at their best.

In the next section, we will dive into the AC Servo Motor Repair Process, exploring the steps involved in restoring these motors to optimal condition.

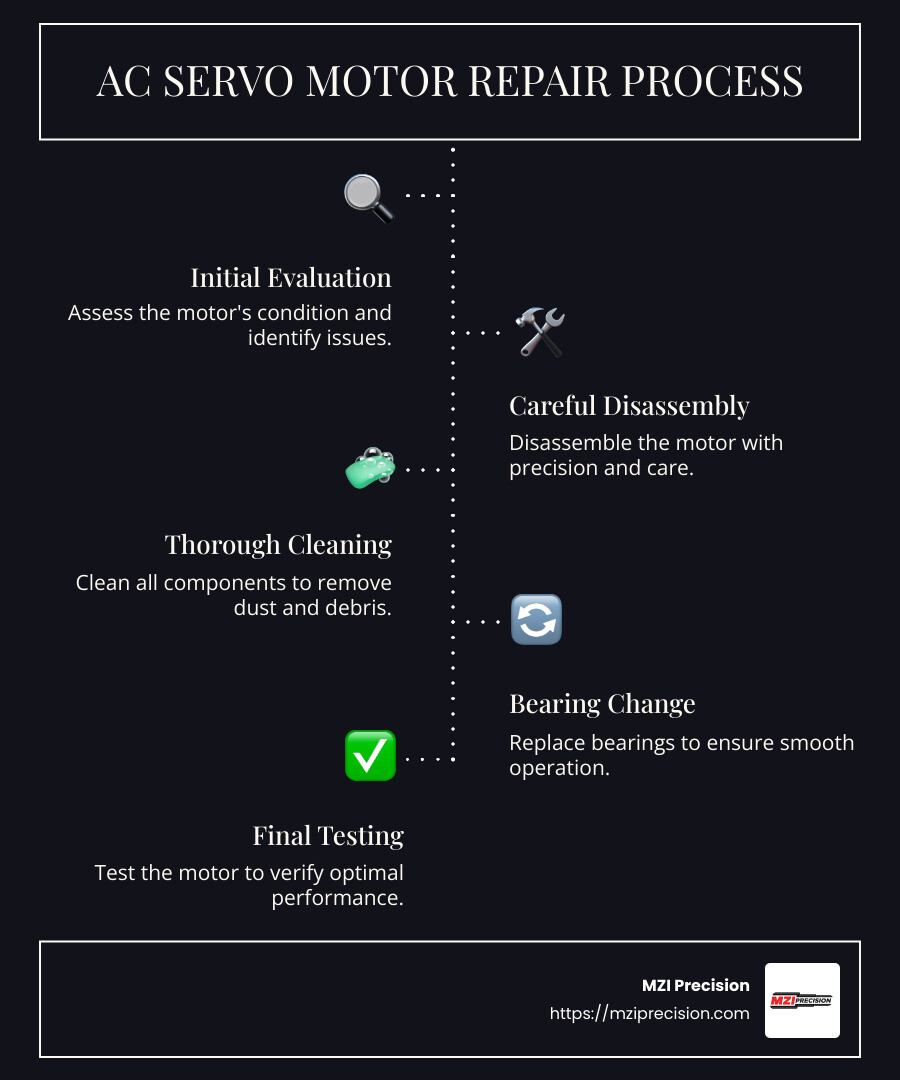

AC Servo Motor Repair Process

When it comes to AC servo motor repair, precision is key. The process involves several critical steps to ensure that the motor is restored to its optimal performance. Let’s break down these steps to understand what goes into a successful repair.

Evaluation

The repair process begins with a thorough evaluation. This involves a visual inspection to check for any obvious damage to parts like the shaft, keyway, endbells, and connectors. Technicians perform tests such as the surge comparison test and insulation resistance test to assess the health of the stator and insulation. A phase balance test ensures windings are balanced, and the KE test evaluates the condition of the magnets. Finally, feedback device functionality is tested using advanced systems like the Mitchell Electronics TI-5000.

Disassembly

After evaluation, the motor is carefully disassembled. This involves removing the backplate, encoder, and encoder housing while disconnecting the wiring. The endbells are taken off, and the rotor is separated from the stator. Bearings, bearing housing, and brakes are also removed. Each component is visually inspected to identify any wear or damage.

Cleaning

Proper cleaning is essential for effective repair. An alkaline washer is used to clean all motor parts. This method is preferred over hand cleaning or pressure washing as it is gentler on the components, ensuring they remain in good condition for reassembly.

Bearing Change

Bearings are often the culprits behind motor failures. Thus, changing every bearing during repair is crucial. High-quality bearings that meet or exceed manufacturer specifications are used to ensure reliability and longevity. Once the new bearings are installed, the motor is reassembled.

Final Testing

The repaired motor undergoes rigorous final testing to verify its functionality. This includes a retest using systems like the Mitchell Electronics TI-5000 and a memory test to confirm the feedback device’s realignment. These tests ensure that the motor operates as efficiently as possible before being returned to service.

By following these precise steps, MZI Precision ensures that every AC servo motor is repaired to the highest standards. Each phase of the process is designed to restore the motor’s performance, providing clients with peace of mind and reliable operation in their industrial applications.

In the next section, we will explore the Key Techniques for Successful Repair, focusing on feedback realignment and the use of high-quality components.

Key Techniques for Successful Repair

When it comes to AC servo motor repair, mastering key techniques is crucial for ensuring a successful outcome. Here, we’ll dig into the importance of feedback realignment, the role of alignment systems, and the use of high-quality bearings.

Feedback Realignment

Feedback realignment is a critical step in the repair of AC servo motors. This process ensures that the motor’s feedback device, such as an encoder or resolver, is perfectly aligned with the motor’s mechanical components. Without precise alignment, even the most expertly repaired motor can fail to perform optimally. Accurate feedback is essential for the motor to provide the precise control needed in industrial applications.

A real-world example highlights the importance of this step: a manufacturing plant experienced erratic motor performance due to misaligned feedback. After realignment, the motor’s precision and reliability were restored, minimizing downtime and improving overall efficiency.

Alignment Systems

Achieving perfect feedback realignment requires advanced alignment systems. These systems are designed to handle the complexity of servo motors and ensure precise alignment. For instance, the Mitchell Electronics TI-5000 system is often used to test and realign feedback devices efficiently. Such systems are an investment in quality, allowing repair technicians to fine-tune motors with best accuracy.

The use of these systems sets apart companies like MZI Precision from those unable to repair servo motors effectively. It underscores the importance of having the right tools and technology to perform high-quality repairs.

High-Quality Bearings

Bearings are a common point of failure in AC servo motors. Using high-quality bearings is essential for successful repairs. These bearings must meet or exceed the manufacturer’s specifications to ensure durability and performance. Poor-quality bearings can lead to premature wear and tear, causing the motor to fail again soon after repair.

For example, a study showed that using premium bearings reduced motor failure rates by up to 40%. This reinforces the importance of selecting the right components during the repair process.

In conclusion, mastering these key techniques—feedback realignment, utilizing advanced alignment systems, and selecting high-quality bearings—ensures that AC servo motor repairs are successful. These practices not only restore the motor’s functionality but also extend its lifespan, providing a reliable solution for industrial applications.

In the next section, we will address some frequently asked questions about AC servo motor repair, providing insights into repairability, reset processes, and signs of malfunction.

Frequently Asked Questions about Industrial Manufacturing Spindle Repair

Can a spindle be repaired?

Absolutely, industrial manufacturing spindles can often be repaired, which is a cost-effective alternative to replacement. Many common issues, like electrical faults or feedback misalignments, can be fixed. Repairing involves detailed processes such as feedback repair and realignment. This is crucial because feedback devices, like encoders, must be perfectly aligned for the spindle to function correctly. Without this precision, even minor misalignments can cause erratic spindle behavior, leading to inefficient operation.

How do you reset an industrial manufacturing spindle?

Resetting an industrial manufacturing spindle typically involves a simple power cycle. This means turning off the spindle’s power supply, waiting for a brief interval, and then turning it back on. This process can resolve minor glitches or errors in the spindle’s operation. However, if the spindle continues to malfunction after a reset, it may require a more thorough diagnostic test to identify deeper issues.

How to tell if a spindle is bad?

Identifying a faulty spindle involves looking for specific malfunction signs. These include erratic movement, unusual noises, or a complete lack of response. Diagnostic tests are essential for pinpointing the exact issue. These tests can evaluate the spindle’s electrical connections, feedback accuracy, and mechanical components. For instance, a phase balance test can reveal imbalances in the spindle’s windings, while a dynamic test can assess the performance under operational conditions.

In summary, understanding these aspects of industrial manufacturing spindle repair can help maintain the efficiency and longevity of your spindles. In the next section, we’ll explore how MZI Precision’s expertise and exceptional service can address these challenges in industrial manufacturing spindles.

Conclusion

At MZI Precision, we pride ourselves on our expertise and dedication to providing exceptional service in the field of industrial manufacturing spindles. Our commitment to excellence sets us apart in the industry, ensuring that we meet and exceed our clients’ expectations.

Expertise in AC Servo Motor Repair

Our team of skilled technicians brings a wealth of knowledge and experience to every repair project. We understand the intricacies involved in AC servo motor repair, from precise feedback realignment to the use of high-quality bearings. This expertise allows us to address complex issues efficiently, ensuring your motors are restored to optimal performance.

Exceptional Service

We believe that exceptional service is more than just completing a repair—it’s about building trust and offering support every step of the way. From the initial consultation to the final testing phase, our team is committed to providing clear communication and timely updates. We aim to minimize downtime and maximize productivity for our clients.

Focus on Industrial Manufacturing Spindles

Our specialization in industrial manufacturing spindles means we understand the critical role these components play in your operations. Whether it’s repair or rebuilding, we ensure that your spindles meet or exceed original specifications. This focus not only extends the life of your equipment but also improves its performance, providing a reliable solution for your manufacturing needs.

As you steer the challenges of maintaining and repairing your industrial machinery, let MZI Precision be your trusted partner. Explore our spindle motor repair service to learn more about how we can support your operational excellence.