Understanding a machine spindle is crucial for anyone involved in industrial manufacturing, especially within the aerospace industry. Essentially, this rotating axis is the heart of precision machining, influencing everything from speed and accuracy to the finish quality of a manufactured part.

Key Points About Machine Spindles:

- Definition: A machine spindle is the rotating component of a machine tool that holds and spins the cutting tool or workpiece.

- Function: It enables precise cutting, drilling, or milling by changing digital instructions into physical operations.

- Importance: Critical to achieving high precision and efficiency in manufacturing processes.

The spindle’s design and operation are pivotal to a machine’s performance and, by extension, to the success of products that demand exacting standards, like aircraft components. Whether you’re leveraging CNC mills or lathes, understanding how spindles tick can deeply impact your production capabilities.

At MZI Precision, we know the significance of a dependable spindle in your manufacturing process. Our commitment is to provide expert repair and rebuilding services, ensuring your operations remain smooth and efficient.

Explore more about machine spindle:

– air spindle

– cnc machine spindle repair

– grinding spindle

Understanding the Basics of a Machine Spindle

When diving into machine spindles, grasp their fundamental components and types. These elements define how spindles function within CNC machines, impacting the precision and efficiency of industrial manufacturing.

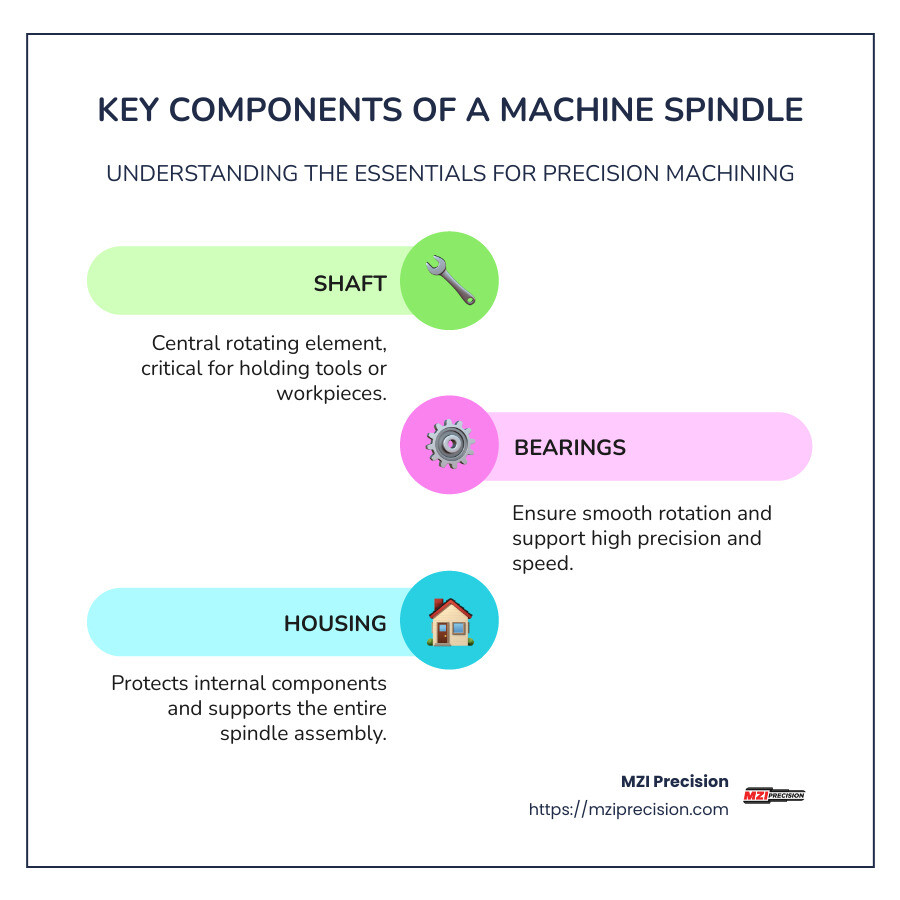

Components of a Machine Spindle

A typical machine spindle consists of several key components:

- Rotating Shaft: The core of the spindle, the shaft, is responsible for holding and turning the tool or workpiece. It plays a crucial role in transmitting torque and ensuring the tool’s precision.

- Internal/External Motor: The motor provides the necessary power for the shaft’s rotation. An internal motor is built into the spindle, making it compact and ideal for high-speed operations. An external motor, however, is located outside the spindle, driving it via belts or gears, which is beneficial when higher torque is needed.

- Bearings: These support the rotating shaft, allowing it to spin smoothly with minimal friction. Properly selected bearings are vital for the spindle’s precision and longevity. Angular contact bearings are common in high-speed applications, while roller bearings are used for greater load capacity.

- Housing: Acting as the protective shell, the housing holds all components together. It also provides additional features like lubrication channels and cooling jackets, crucial for maintaining optimal performance and reducing vibrations.

Types of Machine Spindles

Understanding the different types of spindles is vital for selecting the right one for your application:

- Belt-Driven Spindles: These spindles use an external motor connected by belts. They offer more torque and are often more cost-effective. However, they typically operate at lower speeds compared to integral motor spindles.

- Integral Motor Spindles: With a motor built into the spindle, these can reach high speeds, up to 60,000 RPMs. They’re ideal for applications requiring quick, precise operations but might have limited torque due to their compact design.

- High-Speed Spindles: These spindles are designed for rapid operations, offering excellent accuracy and durability. They are versatile, functioning well under varying temperatures and requiring low maintenance.

Choosing the right type of spindle depends on your specific needs, including the CNC machine type, application requirements, and the materials you’re working with. At MZI Precision, we specialize in providing custom solutions to ensure your spindles meet your precise manufacturing demands.

How Machine Spindles Work

Understanding how machine spindles operate is crucial for anyone involved in industrial manufacturing. These components are the heart of CNC machines, determining their torque, speed, and accuracy.

Spindle Drive Systems

Machine spindles rely on different drive systems to meet specific needs:

- Belt-Driven Systems: These spindles are powered by an external motor connected through belts. They are perfect when you need more torque, which is often required in heavy-duty applications. The belt system can adjust torque and speed by changing the pulley ratios. While they offer more power, they usually operate at lower speeds compared to other systems.

- Gear-Driven Systems: Similar to belt-driven spindles, gear-driven ones use a series of gears to transmit power from an external motor. They are robust and can handle high torque loads, making them suitable for demanding machining tasks.

- Integral Motor Systems: In these spindles, the motor is integrated directly into the spindle housing. This design allows for high-speed operations, reaching up to 60,000 RPMs. However, the compact design might limit torque, making it more suitable for applications where speed is prioritized over power.

Importance of Bearings and Seals

Bearings and seals are vital for the smooth operation and longevity of machine spindles:

- Bearings: Bearings support the spindle shaft, allowing it to rotate with minimal friction. The choice of bearing affects the spindle’s performance:

- Angular Contact Bearings: These are ideal for high-speed applications. They can handle both radial and axial loads, ensuring precision and stability. Imagine them as the agile skaters of the bearing world, balancing forces from all directions.

- Roller Bearings: Known for their strength, roller bearings provide greater load capacity and stiffness. They’re like the strong pillars that support heavy loads without giving in.

- Seals: Seals protect the internal components of the spindle from contaminants like dust and debris. There are two main types:

- Contact Seals: Simple and effective, these seals have a lip that touches the shaft. They are easy to install but wear out over time due to friction.

- Non-Contact Seals: These seals use a labyrinth design to keep contaminants out without touching the shaft. They last longer since there’s no direct contact, reducing wear and heat.

Choosing the right combination of drive systems, bearings, and seals is essential for optimizing a spindle’s performance in any industrial setting. Each component plays a role in delivering the torque, speed, and accuracy needed for precise machining tasks.

Next, we’ll explore how to choose the right machine spindle based on your specific application needs.

Choosing the Right Machine Spindle

Selecting the right machine spindle is like picking the right tool for a job. It requires understanding your specific needs and how the spindle will be used. Let’s explore the key factors to consider.

Application Needs

First, think about what you need the spindle for. Are you drilling, milling, or grinding? Each task has its own requirements. For example, milling might need a spindle that can handle heavy loads, while drilling might need high speed for efficiency.

Material Compatibility

The material you’re working with plays a big role. Hard metals like steel require spindles with high torque to cut through them. Softer materials, like certain plastics, might benefit more from high-speed spindles. Knowing your material helps in choosing a spindle that won’t wear out quickly.

Speed and Torque Requirements

Speed and torque are like the speed and strength of a runner. High-speed spindles are great for quick, precise work, while high-torque spindles are better for tough, heavy-duty tasks. Balance is key. You need enough speed to get the job done quickly, but also enough torque to handle the material.

CNC Machine Type

Not all spindles fit all CNC machines. Check your machine’s specifications. Some machines might only work with certain spindle types, like belt-driven or integral motor spindles. Make sure the spindle you choose is compatible with your machine to avoid inefficiencies.

Spindle Application

Consider the specific application of the spindle. Is it for a high-precision task in a clean environment, or a rough task in a dusty factory? This will influence your choice of seals and bearings, which protect the spindle from wear and tear.

Material Use

Finally, think about how often and how long the spindle will be used. If it’s for continuous production, you’ll need a spindle that’s durable and reliable. If it’s for occasional use, you might prioritize cost over longevity.

By considering these factors, you can choose the right machine spindle that meets your needs, ensuring efficient and precise machining. Understanding your application, material, and machine will guide you to a spindle that improves your production capabilities.

Next, we’ll discuss maintaining and repairing machine spindles to ensure they last and perform well over time.

Maintaining and Repairing Machine Spindles

Keeping your machine spindle in top condition is crucial for maintaining productivity and avoiding costly downtime. Let’s explore how regular maintenance and expert repair services can keep your spindle running smoothly.

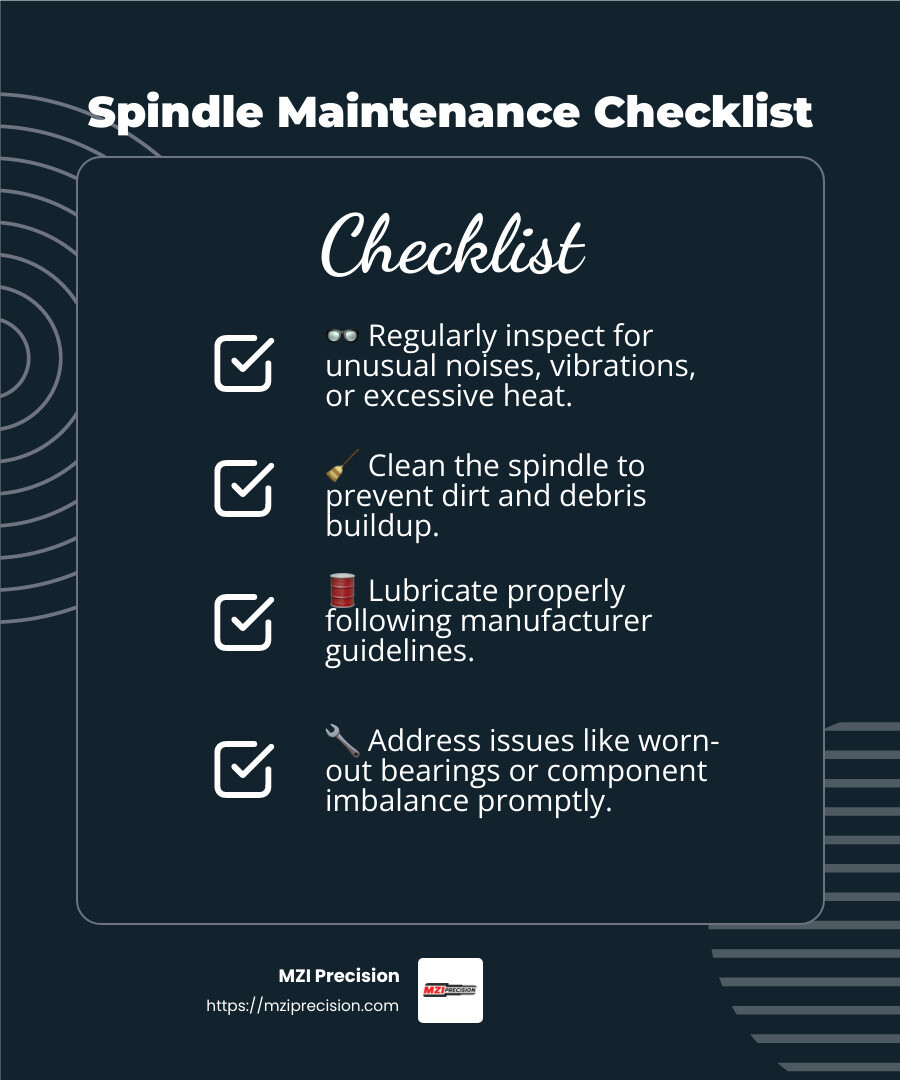

Importance of Regular Maintenance

Preventive maintenance is like a routine check-up for your machine spindle. It helps catch small issues before they become big problems. Here’s how you can keep your spindle in great shape:

- Inspection: Regularly inspect your spindle for signs of wear and tear. Look for unusual noises, vibrations, or excessive heat. These can be early indicators of potential issues.

- Cleaning: Dirt and debris can cause damage over time. Make sure to clean your spindle regularly to prevent buildup that could lead to malfunction.

- Lubrication: Just like oil in a car, lubrication reduces friction and wear. Use the right type of lubricant and follow the manufacturer’s guidelines to keep everything running smoothly.

Repair and Rebuilding Services

Even with the best maintenance, spindles can still fail. When this happens, professional repair services can save the day.

Common Issues: Spindle failure can occur due to worn-out bearings, imbalanced components, or overheating. These issues can lead to reduced accuracy and efficiency, affecting your entire production line.

Professional Repair: At MZI Precision, we specialize in repairing and rebuilding spindles to restore them to optimal performance. Our expert technicians conduct thorough inspections to identify the root cause of failure. We then repair or replace damaged components, ensuring your spindle runs like new.

Rebuilding Services: Sometimes, a spindle needs more than just a repair. Our rebuilding services involve a complete overhaul of the spindle, replacing all worn parts with high-quality components. This not only fixes the problem but can also extend the life of your spindle significantly.

By prioritizing regular maintenance and knowing when to seek professional repair services, you can ensure your machine spindle remains reliable and efficient. This proactive approach will keep your production running smoothly and avoid unexpected downtime.

Next, we’ll answer some frequently asked questions about machine spindles to further clarify their role and benefits in CNC machines.

Frequently Asked Questions about Machine Spindles

What is a machine spindle?

A machine spindle is a key component in CNC (Computer Numerical Control) machines. It acts like the heart of the machine, holding and spinning the cutting tools. This spinning action is crucial for cutting, drilling, and milling materials with precision. Inside the spindle, you’ll find a rotating shaft, which is powered by either an internal or external motor. This setup allows the spindle to handle high speeds and torque, making it essential for many industrial manufacturing processes.

How do spindles function in CNC machines?

In CNC machines, spindles convert digital instructions into physical actions. Here’s a simple breakdown of how they work:

- Rotation: The spindle rotates the attached tool or workpiece. This rotation is controlled by computer commands, ensuring precision and consistency.

- Cutting and Shaping: As the spindle spins, it cuts, drills, or mills the material according to the programmed design. This process is highly accurate, allowing for complex shapes and fine details.

- Speed and Torque: The spindle’s speed and torque are adjustable, which means it can be custom to work with different materials and machining requirements. This flexibility is crucial for achieving the desired finish and efficiency in production.

What are the benefits of high-speed spindles?

High-speed spindles offer several advantages that make them a popular choice in industrial settings:

- Accuracy: These spindles provide precise control, resulting in high-quality finishes and intricate details.

- Versatility: High-speed spindles can handle a wide range of materials and temperatures, making them suitable for various applications.

- Durability: Designed to withstand routine wear and tear, high-speed spindles are built to last, reducing the need for frequent replacements.

- Cost-Effectiveness: While they may require a higher initial investment, their precision and longevity can lead to cost savings over time by minimizing waste and downtime.

- Low Maintenance: High-speed spindles are designed for efficiency, needing less maintenance compared to other types, which helps keep operating costs down.

These frequently asked questions highlight the critical role of machine spindles in CNC machining and underscore their benefits in enhancing production efficiency and precision. Next, we’ll dig into the various types of machine spindles and their specific applications.

Conclusion

At MZI Precision, we understand the critical role that machine spindles play in industrial manufacturing. Our expertise in spindle repair and rebuilding ensures that your spindles perform at their best, maximizing both efficiency and precision in your operations.

Our team of skilled technicians is dedicated to providing top-notch service, focusing on extending the longevity of your spindles. By emphasizing regular maintenance and timely repairs, we help prevent costly downtime and ensure your machines are always ready for action.

Choosing MZI Precision means choosing reliability and excellence. We pride ourselves on our commitment to quality and our ability to address any spindle issues you might encounter. Whether it’s routine maintenance or a complete rebuild, we have the experience and knowledge to keep your operations running smoothly.

Explore our CNC Machine Spindle Services to learn more about how we can assist you in maintaining peak spindle performance. Trust us to be your partner in achieving operational excellence and ensuring the longevity of your machine spindles.