Spindle Assemblies: Your Perfect Guide 2026

WHY INDUSTRIAL SPINDLE ASSEMBLIES ARE CRITICAL TO MANUFACTURING SUCCESS

Spindle assemblies are the backbone of modern manufacturing, responsible for delivering the torque, speed, and precision required to machine everything from aerospace components to defense equipment. Whether you’re looking to purchase new spindles, rebuild existing ones, or simply understand what makes a quality spindle assembly, here’s what you need to know:

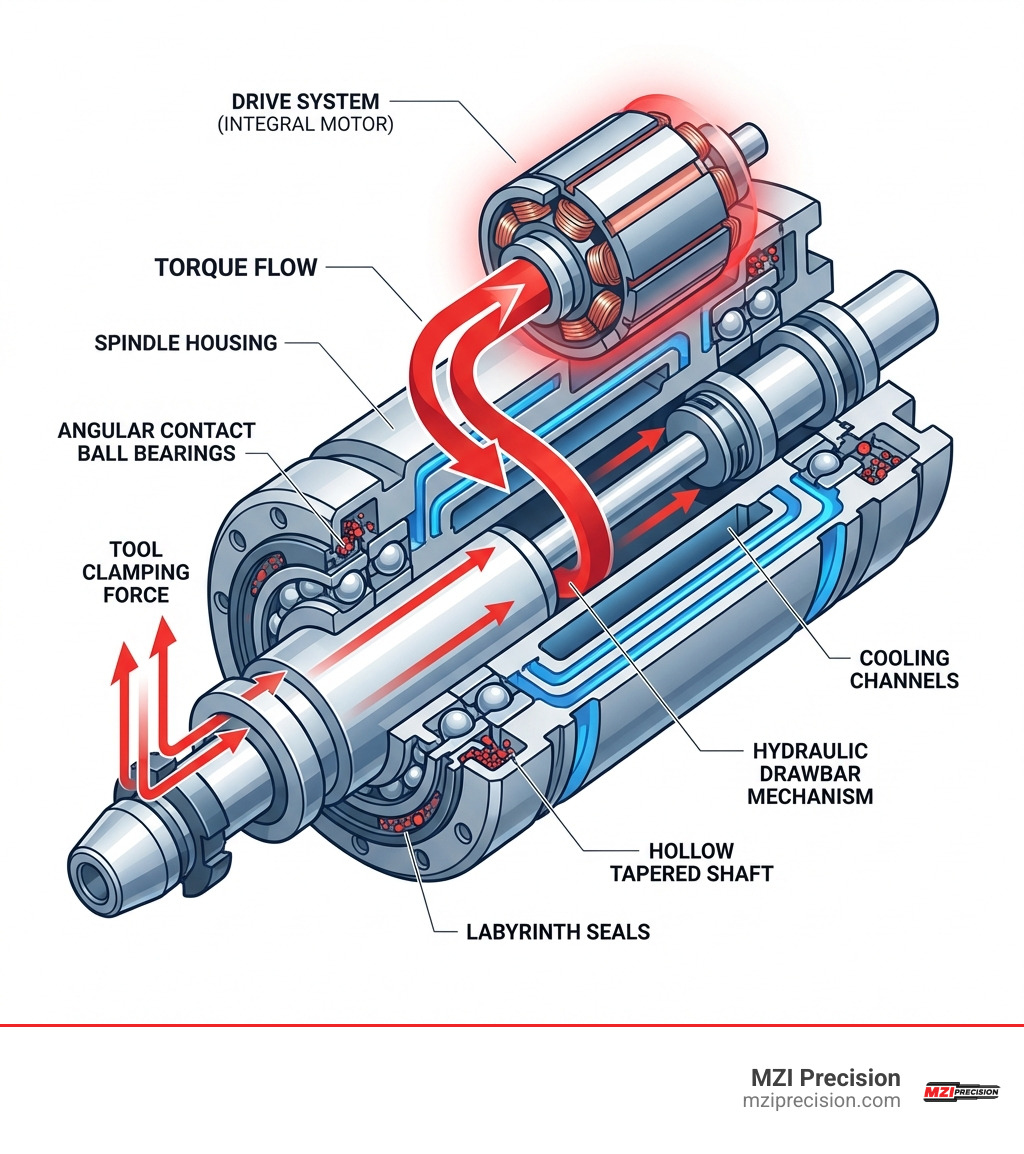

What is a Spindle Assembly?

- A rotating shaft supported by a bearing system within a housing

- Houses a drawbar mechanism that securely holds cutting tools in place

- Driven by an internal or external motor (belt, gear, or integral motor design)

- Provides precise torque transmission for machining operations

Main Components:

- Drive System – Belt-driven, gear-driven, or integral motor

- Spindle Housing – Supports bearings and provides cooling/lubrication

- Bearing System – The component with the greatest influence on spindle lifetime

- Seals – Prevents contamination (the leading cause of premature failure)

- Shaft – Transmits cutting power and positions the tool

- Drawbar – Clamps and unclamps tools during operation

At the heart of every CNC machine, milling center, or grinding operation is a precision spindle that must withstand enormous machining forces while maintaining micron-level accuracy. The spindle’s characteristics—power, speed, stiffness, and thermal stability—directly impact your production rates, part quality, and operational costs.

The bearing system is particularly critical. As research confirms, “The bearing system is the component with the greatest influence on the lifetime of a spindle.” Yet contamination from moisture and grit remains the primary killer of spindles, which is why proper sealing and maintenance aren’t optional—they’re essential.

For manufacturing operations in aerospace, defense, and other precision industries, choosing the right spindle assembly and maintaining it properly can mean the difference between consistent production and costly downtime.

THE CORE OF PRECISION: ANATOMY OF AN INDUSTRIAL SPINDLE ASSEMBLY

At first glance, a spindle assembly might seem like a simple rotating component. However, beneath its sturdy exterior lies a marvel of engineering, comprising several interconnected parts that work in harmony to deliver the precision and power required in modern industrial manufacturing. Understanding these primary components is crucial to appreciating their collective role in the performance of your machinery. We’re talking about the spindle shaft, housing, bearing system, drive system, seals, and the ingenious drawbar mechanism. Each part plays a vital role, and a weakness in one can compromise the entire operation.

The Spindle Shaft and Housing

The spindle shaft is the central nervous system of the assembly. Its primary function is multifaceted: it acts as a support, a precise positioner for the tool or workpiece, and the rotary drive. Think of it as the unwavering arm of your machine, holding the cutting tool or material with absolute rigidity. As our research highlights, “The spindle shaft must take up any machining forces arising during cutting with the lowest possible deformation response, generate/transmit the cutting power provided by an internal or external drive for machining, and exhibit high positioning and running accuracy.” This means it needs to be incredibly strong to resist bending or flexing under immense cutting forces, all while spinning with pinpoint accuracy and transmitting the necessary torque from the drive system.

Working in tandem with the shaft is the spindle housing. This robust outer shell encases and protects the internal components, particularly the delicate bearing system. Beyond mere protection, the housing plays a critical role in dampening vibration, which is essential for maintaining accuracy and extending tool life. It also often integrates utility systems like lubrication, air pressure, and cooling channels. Spindle housings come in various designs to suit different machine architectures, including integral parts of the machine, block-style designs, or flange-mounted cartridges, each offering specific advantages in mounting and integration.

Bearings, Seals, and Drive Systems

When it comes to the longevity and performance of a spindle assembly, the bearing system is king. As we learned from our research, “The bearing system is the component with the greatest influence on the lifetime of a spindle.” These aren’t just any bearings; they are precision-engineered components designed to handle high speeds, heavy loads, and maintain exceptional accuracy.

For high-speed applications, angular contact ball bearings are the standard choice due to their ability to manage both radial and axial loads with minimal friction. When greater stiffness and load capacity are paramount, often in heavy-duty cutting, roller bearings are preferred. The choice of bearing type, along with factors like lubrication methods, precision levels, and preload amount, is carefully determined by the application’s specific demands. For a deeper dive into selecting the right bearings for your needs, we encourage you to consult resources like the Machine Tool Spindles Selection Guide: Types, Features, Applications.

Next up, let’s talk about seals – the unsung heroes of spindle longevity. We often see that “the leading cause of failure in most spindles is contamination (moisture and grit).” This external contamination, whether it’s metal chips (swarf), coolant, or airborne particles, can wreak havoc on precision bearings. That’s why “seals are required to prevent swarf and other contaminants from entering the bearings.” We use advanced sealing solutions, such as labyrinth seals, which create a complex, tortuous path that contaminants struggle to penetrate. Often, these are combined with positive internal air pressure (purge air) to create an outward flow, actively pushing contaminants away from the bearings. Unlike contact seals, which wear down over time, non-contact labyrinth seals protect bearings with minimal wear and heat, ensuring a longer, more predictable service life for your spindle assemblies.

Finally, the drive system is what gives the spindle its “spin.” It’s responsible for transmitting the power that rotates the shaft. There are three main types:

- Belt-driven systems use an external motor connected to the spindle shaft via belts and pulleys. These are often chosen for applications requiring high torque and can achieve speeds up to 15,000 RPM, offering flexibility in speed and power adjustment.

- Gear-driven systems also use an external motor, but transmit power through a gearbox. They are typically employed for very heavy-duty cutting where maximum torque is needed, often at lower speeds.

- Integral motor designs, also known as motorized spindles, are where the motor’s stator and rotor are built directly into the spindle housing. This design eliminates mechanical transmission elements like belts and gears, leading to reduced vibration, increased rigidity, and higher speeds. As our research indicates, “integral motor designs are normally used in higher speed applications” because they allow for exceptionally high RPMs and compact designs.

A GUIDE TO INDUSTRIAL SPINDLE ASSEMBLIES

Just as there are many different jobs in industrial manufacturing, there are many different types of spindle assemblies, each uniquely suited to specific tasks. From high-speed precision cutting to heavy-duty material removal, the function of a spindle varies significantly depending on the machinery it powers and the application it serves. Understanding these distinctions is key to optimizing your production processes and ensuring the longevity of your equipment.

Common Types of Spindle Assemblies

The evolution of spindle assembly technology has been largely driven by the demand for increased speed, power, and precision in manufacturing. We’ve seen a significant shift towards more integrated and efficient designs.

-

Motorized Spindles: These are the workhorses of high-speed, high-precision machining. As noted in academic research, “Motorized spindles have largely replaced externally driven spindles due to the absence of mechanical transmission elements like gears and couplings.” By integrating the motor directly into the spindle housing, we eliminate vibration and power loss associated with belts and gears. This results in superior accuracy, higher RPMs, and increased production speeds, allowing for faster machining of parts and improved overall productivity. “CNC spindle motors have a higher RPM than conventional motors, which increases production speeds on machined parts, improving the overall productivity of your facility.” These are incredibly versatile, ideal for a wide range of applications from fine engraving to high-speed milling of light alloys.

-

Belt-driven Spindles: While motorized spindles dominate high-speed applications, belt-driven spindle assemblies still hold their ground, especially where high torque is a priority. These systems typically use an external motor that transfers power to the spindle shaft via a belt. This design can be very robust and is often preferred for applications that require significant power for material removal, offering speeds up to 15,000 RPM. They provide flexibility in adjusting speeds by changing pulley ratios and are generally easier to maintain due to the external motor.

-

Gear-driven Spindles: For the heaviest-duty cutting tasks, where raw power and torque are paramount, gear-driven spindle assemblies are often employed. These systems use a series of gears to transmit power from an external motor to the spindle, providing immense torque at lower rotational speeds. They are built to withstand extreme cutting forces and are ideal for machining tough materials where aggressive material removal is required. For a comprehensive overview of various machine tool spindle units, including their designs and applications, you might find the insights from Machine tool spindle units particularly informative.

Applications in Modern Manufacturing

The industrial spindle assembly is indispensable across a multitude of manufacturing sectors, particularly those demanding high precision and reliability. We see them at the heart of operations in industries that rely on us for their critical components:

-

Aerospace Component Machining: In the aerospace industry, the demands for precision and material integrity are exceptionally high. Our research points out that “Machining large aluminum frames in the aerospace industry requires spindles with high power and high speeds.” This is where high-speed spindle assemblies excel, enabling the rapid and precise machining of complex aluminum and composite parts for aircraft engines, structural components, and interior fittings. The reduced vibration and increased torque output of advanced CNC spindles allow for heavier cuts without sacrificing accuracy, crucial for lightweight yet strong aerospace components.

-

Defense and Military Applications: For defense and military equipment, durability and reliability are non-negotiable. Spindle assemblies are used to machine robust alloys for critical components, from vehicle parts to weaponry systems. These applications often involve heavy-duty alloy machining, requiring spindle assemblies that can handle sustained high loads and deliver consistent performance under challenging conditions.

-

Precision Grinding for Solar Energy Components: The solar energy sector, with its drive for efficiency, relies on incredibly precise components. Spindle assemblies are central to grinding and polishing operations that produce highly accurate surfaces for photovoltaic cells, optical components, and specialized tooling, ensuring optimal performance and longevity of solar energy systems.

-

High-Volume Production in Manufacturing: Across general manufacturing, spindle assemblies are the workhorses enabling high-volume production of diverse components. Their improved reliability leads to less downtime and more cost-effective manufacturing, making them a critical asset in maintaining competitive production rates. The precision of their design means less vibration, leading to a superior surface finish and improved accuracy for all machined parts.

SELECTING THE RIGHT SPINDLE ASSEMBLY FOR YOUR APPLICATION

Choosing the correct spindle assembly is not just a technical decision; it’s a strategic one that directly impacts your productivity, the quality of your output, and your operational costs. It’s about finding the perfect balance between features and benefits that align with your specific machining requirements. As experts in the field, we always advise that companies “correctly identify their machining requirements and make well-informed decisions about which spindle to acquire.” This means diving deep into the critical specifications and considering all the environmental and material factors at play.

Key Specifications for Spindle Assemblies

When we help our clients select a spindle assembly, we focus on several key specifications. These determine the spindle’s capability and suitability for your unique industrial manufacturing processes. “The characteristics of the spindle, such as power, speed, stiffness, bearings, drive methods, or thermal properties, have a huge impact on machine tool performance and the quality of the end product.”

| Feature | Motorized Spindles | Belt-Driven Spindles | Gear-Driven Spindles |

|---|---|---|---|

| Speed (RPM) | Very High (e.g., 20,000 – 80,000+) | High (e.g., 5,000 – 15,000) | Low to Medium (e.g., 1,000 – 6,000) |

| Torque/Power | Medium to High (excellent for constant power at high speed) | High (flexible power delivery) | Very High (maximum torque at low speeds) |

| Load Capacity | Good (precision machining, lighter cuts) | Good to High (versatile for various loads) | Excellent (heavy material removal, aggressive cuts) |

| Vibration | Very Low (direct drive, no transmission elements) | Low to Medium (belt can introduce some vibration) | Medium (gears can introduce some vibration and noise) |

| Complexity | High (integrated motor, advanced controls) | Medium (external motor, belt system) | High (external motor, complex gearbox) |

| Typical Applications | High-speed cutting (HSC), finishing, precision milling | General milling, drilling, versatile machining | Heavy roughing, tough material removal, large tools |

| Thermal Management | Often requires active cooling | Less complex, heat from external motor | Heat from external motor and gearbox |

| Maintenance | Generally lower mechanical wear | Belt replacement, external motor maintenance | Gear inspection, lubrication, external motor maintenance |

- Speed (RPM): This dictates how fast your cutting tool or workpiece rotates. Higher RPMs are crucial for achieving fine finishes, machining small features, and working with certain materials efficiently. CNC spindle motors, for instance, are known for their higher RPMs, boosting productivity.

- Torque and Power Requirements: Torque is the rotational force, while power is the rate at which work is done. High torque is essential for heavy material removal and machining tough alloys. Advanced CNC spindles offer increased torque output, allowing for heavier cuts without sacrificing accuracy.

- Load Capacity (Radial and Axial): Spindles must withstand forces acting perpendicular to the shaft (radial loads, like side pressure during milling) and parallel to the shaft (axial loads, like drilling force). Your spindle choice must match the anticipated loads to prevent premature wear or failure.

- Tooling Interface (HSK, SK): The interface system (e.g., HSK, SK) defines how tools are held. It impacts rigidity, tool change speed, and accuracy. Selecting the right interface ensures optimal tool holding and performance.

- Precision and Accuracy Needs: For applications requiring micron-level tolerances, the inherent precision of the spindle assembly itself—its run-out, stiffness, and thermal stability—becomes paramount.

Environmental and Material Considerations

The operating environment and the materials you’re machining play a significant role in spindle assembly design and selection.

- Environmental Conditions: Factors like ambient temperature, humidity, and the presence of contaminants (coolant, chips, dust) directly influence spindle longevity. Robust sealing and effective cooling systems are critical in harsh environments. For instance, in our experience, contamination from moisture and grit is a leading cause of premature spindle failure, underscoring the importance of superior sealing.

- Material Being Machined and Cutting Forces: Different materials generate different cutting forces and heat. Machining tough alloys like titanium or nickel-based materials generates substantial forces, demanding a spindle with high stiffness and torque. Conversely, high-speed cutting of aluminum requires spindles capable of very high RPMs and excellent thermal management. The material selection for the spindle components themselves is also vital. For example, ductile iron offers “greater flexibility and wear, impact, and fatigue resistance” compared to grey iron or aluminum housings, making it a robust choice for demanding industrial applications. We ensure our rebuilt spindles use materials that can withstand the rigors of your specific machining tasks.

MAXIMIZING LONGEVITY: MAINTENANCE, REPAIR, AND FUTURE TRENDS

The life of an industrial spindle assembly isn’t just about its initial design and selection; it’s also about how we care for it throughout its operational life. Proactive maintenance and timely, expert repair are paramount to maximizing longevity and maintaining peak performance. After all, even the most robust components can succumb to wear and tear.

Maintenance and Repair for Spindle Assemblies

Ignoring maintenance is akin to inviting trouble. “Proactive maintenance and repair are crucial for achieving efficiency, safety, and quality,” as our research emphasizes. Regular inspections, cleaning, and proper lubrication are not just good practices; they are essential for preventing costly downtime.

- Importance of Regular Inspections and Cleaning: Simple, routine checks can catch minor issues before they escalate. “Regular cleaning and inspections before use should be mandatory.” This includes checking for unusual noises, vibrations, or excessive heat buildup.

- Lubrication Management: Proper lubrication is vital for bearing health. Over- or under-lubrication can both lead to problems. We ensure our rebuilt spindles have optimal lubrication systems designed for their specific application.

- Recognizing Signs of Wear: Be vigilant for common symptoms of a failing spindle:

- Increased vibration: A subtle hum turning into a noticeable shake can indicate bearing damage or imbalance.

- Excessive heat: A spindle running hotter than usual often points to bearing friction or lubrication issues.

- Unusual noise: Grinding, squealing, or whining sounds are clear distress signals from internal components.

- Poor surface finish on machined parts: Reduced accuracy or inconsistent finishes can be a direct result of spindle run-out or diminished rigidity.

- The Value of Professional Repair vs. Replacement: When a spindle assembly shows signs of trouble, you’re faced with a choice: repair or replace. “Spindle failure leads to machine downtime, and repairs or replacements can cause prolonged delays.” While a new spindle might seem appealing, it often comes with a hefty price tag and a long lead time. This is where professional repair and rebuilding services, like ours at MZI Precision, shine. We specialize in OEM rebuilt spindles, bringing them back to their original specifications, often with faster turnaround times and at a fraction of the cost of a new unit. As the research states, “Repairs and replacements of complex CNC spindles are best left to experts,” and our team of skilled technicians and engineers in California are uniquely equipped to handle the intricacies of industrial spindle repair. For more insights into how we can extend the life of your critical components, please explore our More info about our spindle repair services.

The Evolution and Future of Spindle Technology

The journey of spindle assembly technology has been one of continuous innovation, driven by the relentless pursuit of higher precision and efficiency. Historically, externally driven spindles were common, but advancements in power electronics paved the way for more integrated solutions.

- Historical Development: The significant shift has been towards motorized spindles. These direct-drive systems, free from mechanical transmission elements like gears and belts, offer vastly improved performance. “Motorized spindles have largely replaced externally driven spindles due to the absence of mechanical transmission elements like gears and couplings.” This evolution has been critical in achieving the speeds and accuracies demanded by modern manufacturing.

- Current Trends: Today, the focus in spindle assembly development continues to push boundaries. “The focus has shifted towards higher torque at speeds up to 15,000 rpm, with increased emphasis on reliability, life-cycle, and predictable maintenance.” This means spindles are not just getting faster, but also smarter and more robust.

- Smart Spindles and Sensor Integration: The future of spindle assemblies is increasingly intelligent. Modern spindles are often equipped with integrated sensors that monitor critical parameters like temperature, vibration, and even clamping force. This data is invaluable for condition monitoring, allowing for real-time insights into the spindle’s health.

- Active Balancing: For high-speed applications, even minor imbalances can lead to significant vibration. That’s why “Active balancing systems are being developed for high-speed spindles to reduce vibrations caused by unbalance,” further enhancing precision and extending bearing life.

- Digital Twin Technology: An exciting frontier is the development of “digital twin-driven life health monitoring for motorized spindle” systems. This involves creating a virtual replica of the physical spindle that can simulate its behavior, predict potential failures, and optimize maintenance schedules.

- Predictive Maintenance: All these advancements converge to enable truly predictive maintenance. Instead of waiting for a breakdown or adhering to rigid schedules, “Condition monitoring systems are important for predictive maintenance, allowing the detection of wear, overheating, and imminent failures.” This allows for maintenance to be performed exactly when needed, minimizing downtime and maximizing operational efficiency.

CONCLUSION

We’ve journeyed through the intricate world of spindle assemblies, uncovering their critical role as the backbone of industrial manufacturing. From their fundamental components—the shaft, housing, bearings, seals, and drive systems—to their diverse applications in aerospace, defense, and solar energy, it’s clear that these precision components are indispensable.

The key takeaways are simple yet profound:

- Understanding is Power: Knowing the anatomy and function of each component empowers you to make informed decisions.

- Selection Matters: Choosing the right spindle assembly based on critical specifications like speed, torque, load, and environmental conditions is paramount for your machinery’s performance and output quality.

- Maintenance is Non-Negotiable: Proactive care, regular inspections, and recognizing early signs of wear are vital for maximizing the longevity and efficiency of your spindle assemblies.

- Expertise is Invaluable: When repairs are needed, relying on specialists who understand the nuances of OEM rebuilt spindles can save you significant time and cost, ensuring your equipment returns to peak performance.

At MZI Precision, we pride ourselves on our expertise in industrial manufacturing spindle repair and rebuilding. With our deep understanding of spindle assemblies and our commitment to exceptional service, we help industries across California keep their operations running smoothly and precisely. We understand the demands of your industry and are dedicated to providing solutions that not only meet but exceed your expectations.

Don’t let a failing spindle spin your production out of control. Partner with us to ensure your machinery operates at its best.

Explore our comprehensive bearing and spindle assembly solutions today and find how our precision engineering can benefit your operations.

Have questions or need expert guidance for your spindle assemblies? Contact us for a consultation – our team in California is ready to help you achieve peak performance.