Exploring Bearing Spindle Assemblies for Industrial Applications

Bearing spindle assembly is a crucial component in manufacturing systems, pivotal for ensuring efficiency and precision. For anyone diving into industrial manufacturing, understanding the role and functionality of these assemblies is essential. Here are the fundamentals:

- Purpose: Bearing spindle assemblies enable smooth, precise rotation in machinery, vital for tasks requiring high accuracy.

- Applications: These assemblies are used broadly across industries, from aerospace to electronics, ensuring components are produced with exact specifications.

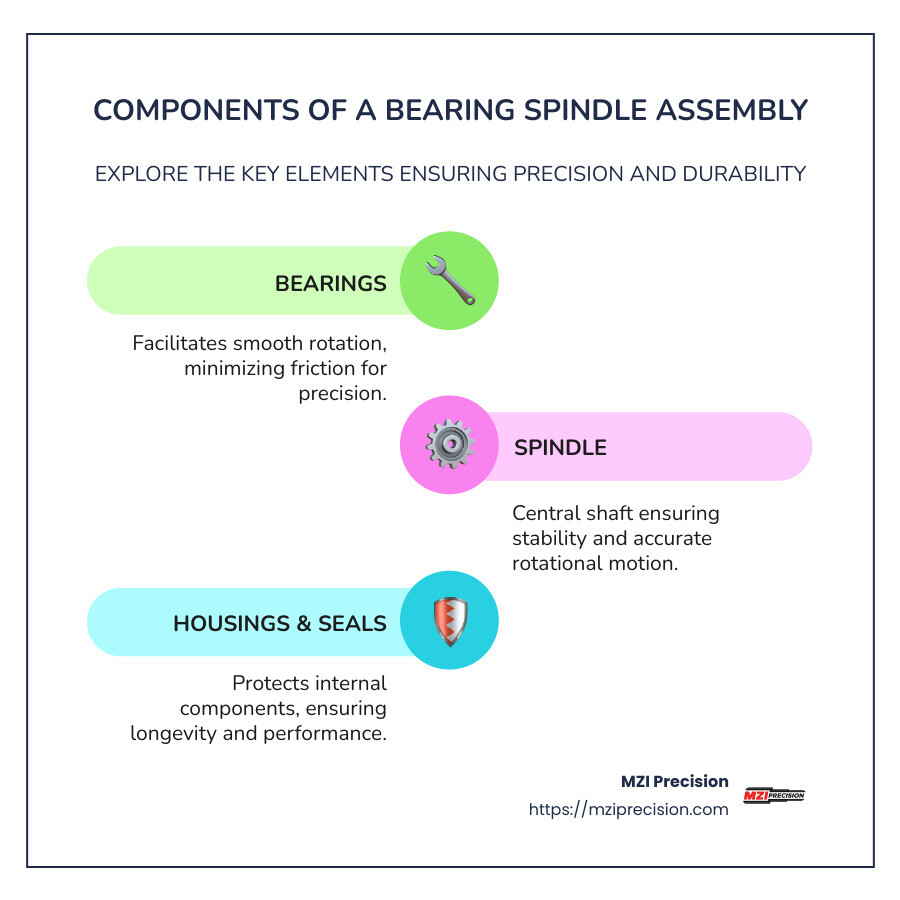

- Components: The assembly consists of bearings, spindles, housings, and seals, each contributing to overall stability and performance.

Manufacturing companies in sectors like aerospace often face challenges when it comes to maintaining or repairing these assemblies. Dependable and expert services, like those offered by MZI Precision, ensure that these critical components function optimally—the key to reducing downtime and maintaining production quality.

Industrial manufacturing thrives on precision and reliability. With countless applications, bearing spindle assemblies provide the necessary rotation with minimal friction, playing a vital role in the production of high-quality goods across various industries.

Understanding Bearing Spindle Assemblies

Bearing spindle assemblies are at the heart of precision machinery, especially in machine tool applications. These assemblies are designed to support and rotate machine components with high accuracy, making them indispensable in industries where precision is paramount.

Spindle Bearings

At the core of every bearing spindle assembly are the spindle bearings. These bearings are engineered to handle both radial and axial loads, ensuring stability and precision during high-speed operations. There are several types of spindle bearings, each suited for specific needs:

- Angular Contact Ball Bearings: Perfect for scenarios where both radial and axial loads are present. These bearings facilitate high-speed movements with precision, essential for high-performance spindles.

- Cylindrical Roller Bearings: Known for managing higher radial loads, these bearings are ideal for heavy-duty applications. Their design ensures even load distribution, crucial for sustaining high-speed operations.

- Ball Screw Support Bearings: Provide stiff support for ball screws, ensuring axial rigidity and accuracy. They are vital in CNC machinery and high-precision milling applications.

Precision Applications

In precision applications, bearing spindle assemblies play a critical role. They are used in sectors like aerospace and electronics, where even a tiny error can lead to significant consequences. The precision offered by these assemblies ensures that machinery operates smoothly, producing parts that meet exact specifications.

Machine Tool Spindles

Machine tool spindles rely heavily on bearing spindle assemblies for their operation. These spindles are responsible for holding and rotating tools or workpieces, making precise cuts and movements possible. The quality of the spindle assembly directly impacts the machine’s performance, affecting everything from the quality of the finished product to the efficiency of the production process.

In summary, understanding the components and functions of bearing spindle assemblies is vital for anyone involved in industrial manufacturing. These assemblies ensure that machines operate with the precision required to meet the high standards of today’s competitive industries.

Signs of Bearing Spindle Assembly Wear

In industrial settings, the bearing spindle assembly is crucial for maintaining precision and performance. However, like any mechanical component, it can show signs of wear over time. Recognizing these signs early can save you from costly repairs and downtime.

Vibration

One of the first indicators of spindle wear is increased vibration. When a spindle assembly starts to wear, the balance and alignment can be affected. This misalignment causes the machine to vibrate more than usual. Advanced tools like vibration analysis can detect these abnormalities early, predicting potential failures before they lead to significant downtime. Regular monitoring can help in identifying issues and maintaining optimal machine performance.

Noise

Unusual noises are another telltale sign of wear in a bearing spindle assembly. Grinding, screeching, or rumbling noises suggest that the bearings may be failing. These sounds are often a result of worn or damaged bearings that can no longer support the spindle’s smooth rotation. Listening to your machine and identifying these noises can prevent further damage and ensure timely maintenance.

Uneven Cuts

In industries reliant on precision, uneven cuts are a major red flag. If your machine begins producing parts with inconsistent dimensions or finishes, it might be due to a worn spindle assembly. This unevenness can be caused by misaligned or damaged bearings, leading to a loss of precision in machining operations. Regular inspection and maintenance of the spindle assembly can help maintain the accuracy required in industrial applications.

Recognizing these signs of wear is essential for maintaining the efficiency and longevity of your machinery. By addressing these issues promptly, you can ensure that your bearing spindle assembly continues to perform at its best, supporting the high standards of industrial manufacturing.

Bearing Spindle Assembly Maintenance

Maintaining your bearing spindle assembly is key to ensuring its longevity and continued performance in industrial applications. Proper maintenance not only extends the life of your spindle but also minimizes downtime and costly repairs.

Spindle Cover and Protection

A spindle cover is your first line of defense against external contaminants. Dust, debris, and moisture can infiltrate the spindle assembly, leading to premature wear and tear. Ensuring that your spindle cover is intact and properly sealed helps protect the internal components from these harmful elements.

Regularly inspect the spindle cover for any signs of damage or wear. If the cover is compromised, replace it immediately to maintain optimal protection. This simple step can significantly reduce the risk of contamination and extend the life of your spindle.

Longevity Through Routine Maintenance

Routine maintenance is essential for the longevity of your bearing spindle assembly. Here are some key practices to keep in mind:

- Lubrication: Use the correct and filtered oil for your spindle. Proper lubrication reduces friction and wear, ensuring smooth operation. Always check for the right amount of lubricant and inspect for any leaks or contamination.

- Airflow Management: Maintain the proper airflow with clean, dry air. This is particularly important in preventing moisture-related issues that can lead to corrosion or damage.

- Inspection and Cleaning: Regularly inspect the spindle assembly for any signs of wear, damage, or misalignment. Clean the components to prevent the buildup of dust and debris.

- Break-in Procedures: If the spindle has been idle for an extended period, break it in gradually. This helps in redistributing the lubricant evenly and prevents sudden stress on the components.

By following these maintenance practices, you can improve the performance and durability of your bearing spindle assembly. Regular care and attention to detail ensure that your spindle remains a reliable component in your industrial operations, supporting precision and efficiency.

Industrial Manufacturing Spindle Repair and Rebuilding

In the field of industrial manufacturing, spindle repair and rebuilding are crucial services that keep machinery running smoothly. When a spindle begins to falter, it can lead to increased downtime and costly disruptions. This is where MZI Precision excels, offering top-tier solutions for OEMs rebuilt spindles and ensuring exceptional service.

OEMs Rebuilt Spindles

At MZI Precision, we specialize in rebuilding OEM spindles to their original specifications. Our team has a deep understanding of the intricacies involved in these complex components. We use state-of-the-art equipment to restore spindles to peak performance, addressing issues such as noisy or contaminated bearings and increased vibration.

- Precision Grinding and Machining: Our facility is equipped with advanced precision grinding and machining capabilities. This allows us to handle a variety of spindle issues with accuracy and efficiency.

- High-Quality Spare Parts: We use only the highest quality spare parts, ensuring that each rebuilt spindle meets stringent industry standards. This commitment to quality guarantees the longevity and reliability of the spindles we service.

Exceptional Service at MZI Precision

MZI Precision is committed to delivering exceptional service and support to our clients. Our process begins with a thorough diagnosis of the spindle issues, followed by meticulous repairs. But our dedication doesn’t stop there.

- Quality Control and Testing: Before a spindle leaves our facility, it undergoes rigorous quality control tests. This ensures that the spindle operates efficiently and reliably, giving our clients peace of mind.

- Swift Turnaround Times: We understand the importance of minimizing downtime. That’s why we strive to provide fast turnaround times without compromising the quality of our work.

- Ongoing Support: Our service doesn’t end with the repair. We offer ongoing support to ensure the continued efficiency and longevity of your equipment.

By choosing MZI Precision for your spindle repair needs, you’re opting for a partner that values precision, quality, and exceptional service. Our expertise in OEMs rebuilt spindles makes us a trusted choice for industrial manufacturing operations seeking reliable and efficient solutions.

Frequently Asked Questions about Bearing Spindle Assemblies

What is a bearing spindle assembly?

A bearing spindle assembly is a critical component in industrial machinery. It consists of the spindle itself, which is a rotating axis, and the bearings that support and stabilize it. This assembly is essential for the smooth operation of machine tools, ensuring they can perform high-precision tasks efficiently. In many ways, it’s the backbone of machinery, allowing for precise movements and operations. In some contexts, you might hear it referred to as a “mandrel assembly,” especially when discussing applications involving cutting or shaping materials.

How do I know if my spindle bearings are bad?

Recognizing the signs of failing spindle bearings is vital to prevent costly downtime. Here are some key indicators:

- Vibration: If you notice unusual vibrations during machine operation, it could signify worn or damaged bearings. Advanced tools like vibration analysis can help detect these issues early by identifying abnormalities in the spindle’s operation.

- Noise: Listen for any grinding or screeching sounds coming from your machine. These noises often point to bearing failure or internal issues, indicating that maintenance or replacement might be needed.

- Performance Issues: Poor performance, such as uneven cuts or imprecision, can also be a sign that your spindle bearings need attention. The bearings are crucial for maintaining the machine’s accuracy, so any deviation from expected performance should be investigated.

What is the role of spindle bearings in industrial applications?

In industrial settings, spindle bearings play a pivotal role in ensuring that machine tools operate with the precision required for demanding tasks. They are designed to handle high speeds and loads, providing stability and accuracy in operations. This is especially important in sectors like aerospace and automotive, where even the smallest error can have significant consequences.

By maintaining the precision of machine tool spindles, these bearings help achieve exact measurements and movements, essential for high-quality manufacturing processes. Their durability and performance improve the overall capability and output of machinery, making them indispensable in industrial applications.

By understanding these critical aspects of bearing spindle assemblies, you can ensure your machinery operates at its best, with minimal downtime and maximum efficiency.

Conclusion

At MZI Precision, we pride ourselves on our expertise and unwavering commitment to support our clients in industrial manufacturing. Our focus is on bearing spindle assemblies, which are the backbone of precision machinery across various industries.

Expertise is at the core of what we do. With our skilled technicians and state-of-the-art facilities, we ensure that every spindle we repair or rebuild meets the highest standards of accuracy and performance. Our dedication to precision is not just a promise but a principle that guides every facet of our work. We understand that in industries like aerospace, automotive, and defense, even the smallest error can have significant consequences. That’s why we strive to deliver nothing but excellence.

Our support extends beyond just providing high-quality spindle repair and rebuilding services. We offer a customer-first approach, ensuring that you receive the guidance and assistance you need at every step of the process. Whether you’re facing signs of wear in your spindle bearing assembly or looking to preempt potential issues through regular maintenance, we are here to help.

By choosing MZI Precision, you are not just opting for a service provider; you are partnering with a company that values precision and understands the critical role that bearing spindle assemblies play in your operations. Experience the MZI Precision difference and let us support your spindle repair and rebuilding needs with our exceptional expertise and service.