Belt vs Direct Drive CNC: 2025’s Ultimate Guide

Understanding the Critical Choice Between Belt and Direct Drive CNC Systems

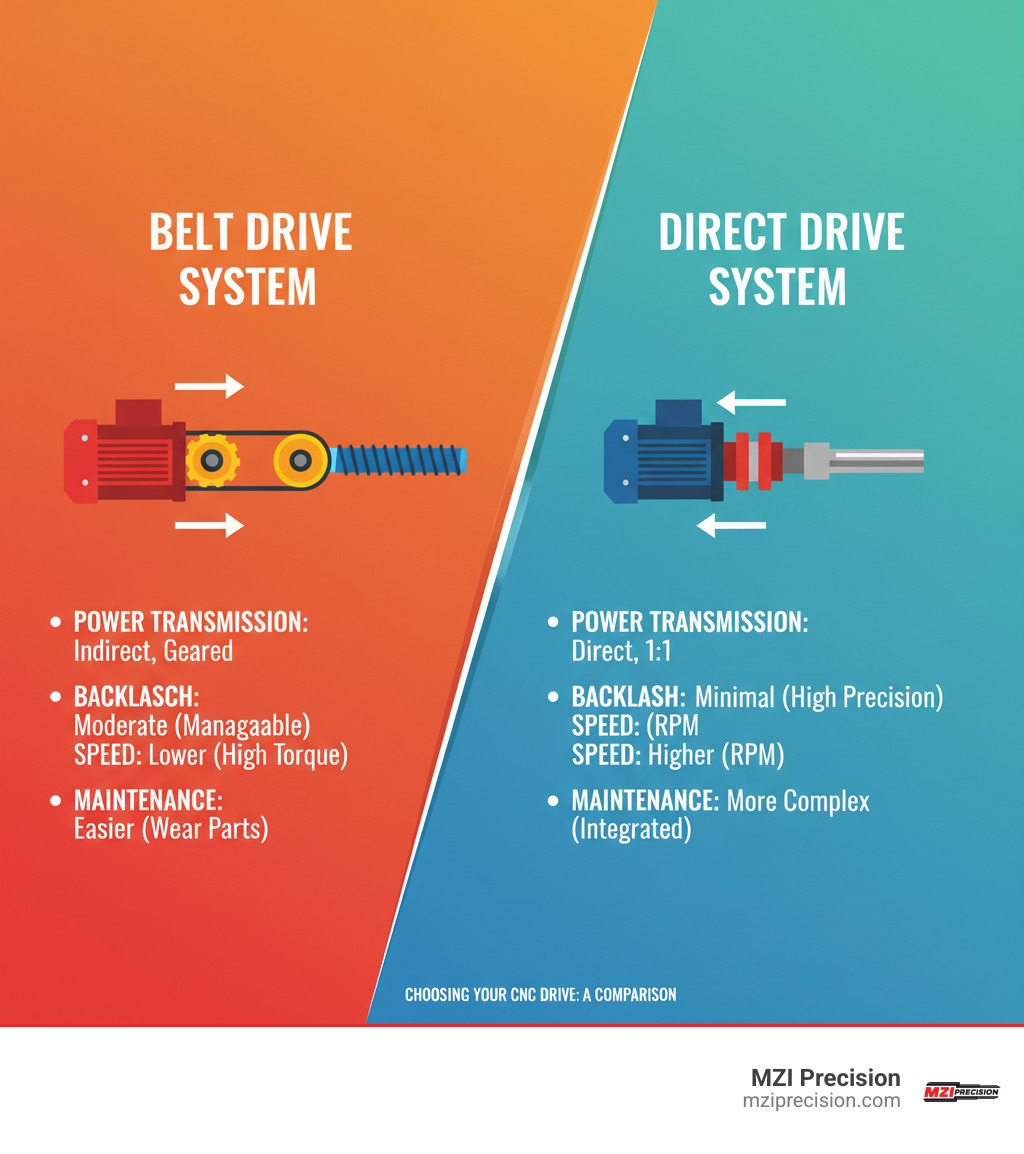

When choosing between belt vs direct drive cnc systems, you are deciding on the core power transmission method for your industrial manufacturing equipment. Belt drive systems use timing belts and pulleys, offering excellent torque, vibration dampening, and cost-effectiveness, making them ideal for heavy-duty machining. In contrast, direct drive systems connect the motor directly to the spindle, providing superior precision and faster response times for high-speed operations above 10,000 RPM, as seen in aerospace and medical manufacturing.

This choice impacts precision, speed, maintenance costs, and crash resistance. As one industry expert noted, while direct drive is a common option for high-duty applications, “when efficiency and improved downtime are important, belt drive is a preferred choice.”

Many high-end CNC machines use timing belt drives and can consistently maintain tolerances of 0.0001″ with proper setup. The decision ultimately rests on your specific application requirements, budget, and long-term operational goals. For aerospace manufacturers and precision component producers, understanding these trade-offs is crucial for ensuring reliable spindle performance.

Fundamental Mechanics: How Belt and Direct Drive Systems Work

Every industrial CNC machine must convert motor power into precise, controlled motion. The method of power transmission—the core difference in the belt vs direct drive CNC comparison—defines a machine’s capabilities and shapes its performance. Let’s break down how each system works.

Belt Drive Systems Explained

Belt drive systems are the reliable workhorses of industrial manufacturing. They use a timing belt stretched between pulleys to transfer rotational energy from the motor to a ball screw or spindle shaft.

The genius of this design is its mechanical flexibility. By selecting different pulley sizes, you can easily adjust speed and torque ratios. This gear reduction capability is invaluable for generating high torque for heavy-duty cutting or for optimizing the performance of servo motors. For linear motion, belt drives paired with ball screws are incredibly efficient. The ball screw’s recirculating bearings virtually eliminate friction, helping the entire system achieve around 98% efficiency. This translates to lower power consumption and reduced cooling needs.

A key feature is that the belt acts as a mechanical fuse. In a crash or overload, the belt can slip or snap, absorbing impact energy and protecting the expensive motor and spindle from catastrophic damage.

To dive deeper into these robust systems, check out our detailed guide on Belt Driven Spindle design and applications.

Direct Drive Systems Explained

Direct drive systems eliminate intermediate components for the most direct connection possible. This is done in two ways: direct coupling, where the motor shaft connects straight to the ball screw or spindle shaft, or with integral spindles, where the motor is built directly into the spindle housing, making the spindle shaft the motor shaft.

The primary advantage is the theoretical elimination of backlash and mechanical play. With fewer components, there are fewer sources of error, enabling higher precision and faster response times, especially during rapid acceleration. While ball screws are common, some systems use roller screws for even greater directness.

Direct drive spindles excel in high-speed machining above 10,000 RPM, offering superior control for instant direction changes. However, this direct connection transfers motor heat to the spindle. Integral spindles, in particular, can generate significant heat that may cause thermal drift and impact bearing life, making robust cooling systems critical for maintaining performance.

Understanding these mechanical differences is crucial for making the right choice for your industrial manufacturing needs. Learn more about optimizing direct drive performance on our Direct Drive CNC resource page.

Performance Showdown: Belt vs Direct Drive CNC Metrics

When evaluating a CNC machine, the real question is which drive system will deliver the precision, speed, and reliability your industrial manufacturing operation demands. Let’s break down how these systems perform when the chips start flying.

Precision, Accuracy, and Backlash

Here’s where the belt vs direct drive cnc debate gets interesting. You might assume direct drive wins on precision, and direct drive systems do have a theoretical advantage. With no belt stretch or pulley wear, they can achieve incredible accuracy when perfectly aligned. However, that perfect alignment is critical; any deviation puts stress on bearings and can harm precision over time.

Belt drive systems can be surprisingly accurate. High-quality timing belts—like HTD or GT series—deliver remarkable precision when properly tensioned, and we’ve seen many operations consistently maintain tolerances of 0.0001″. The belt can also absorb minor vibrations and harmonics that might otherwise appear in finished parts.

Backlash is manageable in both systems. Modern timing belts have minimal stretch, and servo tuning can help belt drives achieve near-zero backlash. The key is a control system tuned to compensate for any repeatable patterns.

For more insights into achieving maximum precision, check out our comprehensive guide on CNC Machine Spindle performance optimization.

Speed, Torque, and Power Efficiency

This is where the choice really depends on your goals.

Direct drive spindles are the speed demons of the CNC world. Above 10,000 RPM, they offer superior acceleration and efficient power transfer, making them ideal for high-speed finishing. The trade-off is significant heat generation at the spindle that requires robust cooling.

Belt drives are the torque champions. By adjusting pulley ratios, you can multiply motor torque for heavy-duty cutting. While they don’t spin as fast, they deliver tremendous cutting force and are remarkably efficient—running around 98% efficiency with minimal power loss. This high efficiency often translates to lower overall power consumption and reduced operating costs.

For long linear axes, screw whip (vibration at high rotational speeds) can limit maximum RPM. Belt drives can help by allowing you to gear down the motor speed while still achieving necessary linear speeds.

To dive deeper into the efficiency characteristics of different drive systems, explore this detailed resource on drive efficiencies.

Vibration, Noise, and Durability

How a drive system handles stress impacts part quality and machine longevity.

Belt drives can dampen vibration, with the belt acting like a shock absorber for motor vibrations, leading to smoother operation and better surface finishes. But this requires correct belt tension. Too loose, and you get chatter; too tight, and you overload spindle bearings, leading to premature failure. Improper belt tension is a leading cause of spindle damage we see in our repair shop.

Direct drive systems aim for minimal vibration through their rigid connection, but any imbalance is transmitted directly to the cutting tool. Modern direct drive spindles are engineered for smooth, quiet operation when properly maintained.

Durability depends heavily on maintenance for both. Belt drives need periodic belt replacement and tension checks. Direct drives, especially integral spindles, generate more heat that can stress bearings, making effective cooling essential for long bearing life.

If noise is becoming an issue in your operation, our guide on Belt Driven Spindle Noise can help you identify and resolve common sound-related problems.

Application-Specific Recommendations

Choosing between belt vs direct drive cnc systems isn’t about finding a universal winner—it’s about matching the right technology to your specific manufacturing needs. The wrong choice can impact everything from part quality to production costs.

When to Choose a Belt Drive System

Belt drive systems are the reliable workhorses of industrial manufacturing, ideal for high throughput and cost-effective operation. Choose a belt drive for:

- Heavy-Duty Machining: The pulley system naturally multiplies torque, providing the power for deep cuts in tough materials.

- Cost-Effectiveness: Belt drives typically have a lower upfront cost and run at an impressive 98% efficiency, reducing long-term energy bills.

- Design Flexibility: The motor can be placed away from the work area, protecting it from contaminants and allowing for more compact machine layouts.

- Improved Downtime: Belt replacement is a straightforward maintenance task, enabling faster turnarounds compared to more complex repairs.

- Vibration Dampening: The belt absorbs motor vibrations, which can lead to better surface finish quality.

Understanding how to optimize these systems is crucial for success. Learn more about effective Belt Driven Spindle Design to maximize your investment.

When to Choose a Direct Drive System

Direct drive systems are precision instruments for the most demanding applications. Choose a direct drive when you need:

- High-Speed Machining: For operations above 10,000 RPM, direct drives offer instant reverses and superior spooling that belt systems cannot match.

- Exceptional Precision: Essential for aerospace components and medical device manufacturing, the elimination of mechanical play allows for extremely tight tolerances.

- Superior Surface Finish: The rigid, direct connection results in remarkable consistency, making these systems the go-to choice for mirror-like finishes.

- Instantaneous Response: Perfect for applications with rapid direction changes or complex cutting paths where milliseconds matter.

These benefits come with trade-offs, including the need for robust cooling systems and less tolerance for maintenance oversights.

To understand the intricate relationship between motor and spindle performance, explore our detailed guide on How Spindle Motor Works.

Maintenance, Repair, and Cost Implications

Beyond initial performance, the true cost of ownership for an industrial CNC machine is determined by its maintenance requirements, repair complexity, and long-term costs. These factors are crucial when making your selection.

Maintenance and Downtime Comparison for belt vs direct drive cnc

When it comes to keeping your belt vs direct drive cnc system running, each has distinct maintenance needs.

Belt drive systems require regular, but straightforward, attention. The most critical task is belt tensioning and replacement. Belts stretch over time; if tension is too loose, it causes vibrations that ruin part quality. If too tight, it puts excessive stress on spindle bearings, leading to costly failures. The good news is that belt replacement is quick and affordable, with most belts lasting several years with proper care. Linear axes with ball screws also require scheduled lubrication.

Direct drive systems demand more specialized care, with the biggest concern being cooling system maintenance. They generate significant heat at the spindle, so cooling systems need regular checks of coolant levels, filters, and flow rates to prevent thermal drift and premature bearing failure. Alignment checks are also more critical, as the rigid system is less tolerant of misalignment than a forgiving belt.

Proactive maintenance is the key to minimizing unexpected downtime, a core principle of our Spindle Motor Repair services.

Crash Scenarios and Repair Costs

Crashes are an unfortunate reality in industrial manufacturing. How a drive system handles these events can make a huge financial difference.

Belt drive systems have a built-in advantage. In a crash, the belt acts as a sacrificial component—a mechanical fuse that absorbs much of the impact. The belt may slip or snap, preventing destructive force from reaching the expensive spindle and motor. A broken belt means downtime, but replacing it is a quick, inexpensive fix compared to rebuilding a spindle. This crash protection can save thousands of dollars.

Direct drive systems lack this buffer. During a crash, the force travels directly through the spindle shaft to the motor’s rotor and bearings, often resulting in more severe damage. Repair complexity is higher, and integral spindles can be particularly expensive to repair or replace. Our Spindle Rebuilding expertise can often restore these complex units to OEM specifications, offering a cost-effective alternative to full replacement.

Overall Cost and Complexity in the belt vs direct drive cnc choice

The true cost of your belt vs direct drive cnc choice involves more than the initial purchase.

Initial investment typically favors belt drives. Their components (motors, belts, pulleys) are generally less expensive and more standardized, leading to lower upfront machine costs. Direct drive systems, especially those with high-performance integral spindles, represent a higher initial investment due to advanced technology and cooling systems.

Component availability and costs also differ. Belt drive replacement parts are widely available and affordable. Direct drive components can be more proprietary, leading to higher costs and longer lead times from the original manufacturer.

Design flexibility is another factor. Belt drives allow motors to be placed away from the work area, enabling more compact machine footprints. Direct drives require the motor to be in-line, which can make machines longer. While belt drives are simpler to integrate mechanically, direct drives require more precision during implementation and more sophisticated thermal management. Understanding these factors is key to choosing the right Machine Tool Spindle for your business.

Frequently Asked Questions about CNC Drive Systems

We understand that choosing the right drive system is a significant decision. Here are answers to some of the most common questions we encounter regarding belt vs direct drive cnc systems in industrial manufacturing.

Which system is more accurate, belt or direct drive?

While direct drive systems are theoretically more accurate because they eliminate backlash from belt stretch, the real-world answer is more nuanced. A high-quality, properly tensioned timing belt system on a rigid machine can achieve comparable, near-zero backlash and consistently hold tolerances of 0.0001″ when set up correctly. For most industrial tasks, a well-engineered belt drive delivers the required precision without the higher cost and complexity of a direct drive.

Does a belt drive offer protection in a CNC crash?

Yes, and this is a major practical advantage. In a crash, the timing belt can act as a mechanical “fuse.” The belt may snap or slip, absorbing a significant portion of the impact energy. This protects the more expensive spindle and motor from catastrophic failure. Replacing a belt is a quick and inexpensive fix compared to the extensive repairs a damaged direct drive spindle might require.

Is a direct drive spindle always better for high-speed machining?

Generally, yes. Direct drive spindles excel at speeds above 10,000 RPM, offering faster acceleration, smoother operation, and greater stability. This makes them ideal for finishing passes and machining materials like aluminum, where high spindle speeds are crucial for optimal material removal and surface finish. While belt drives can achieve high speeds, they can be limited by belt durability and potential vibrations at extreme RPMs. For applications demanding both high speed and exceptional finish, direct drives have a clear performance edge.

Conclusion

The belt vs direct drive cnc decision is about choosing the right partner for your manufacturing goals. There is no single winner, only the best fit for your specific needs.

Direct drive systems are the precision instruments of the industrial world. They excel when you need lightning-fast responses, mirror-like surface finishes, and the ability to operate at speeds above 10,000 RPM. If you’re manufacturing aerospace components or medical devices that demand perfection, direct drives deliver. However, they require robust cooling systems and a higher investment.

Belt drive systems are the reliable workhorses that keep industrial manufacturing running. They offer impressive torque for heavy-duty cutting, act as protective “fuses” during crashes, and deliver remarkable precision when properly maintained. With efficiency ratings around 98% and the ability to hold 0.0001″ tolerances, they prove that a tried-and-true approach is often the right one.

Your choice depends on your priorities: maximum speed and ultimate precision versus robust performance and cost-effectiveness. Both systems, however, demand proper maintenance and expert care when things go wrong. At MZI Precision, our expertise covers the full spectrum of industrial manufacturing spindle technologies, ensuring your operations run smoothly.

Ready to ensure your spindle systems perform at their peak, regardless of drive type? Explore our expert spindle services to keep your operations running flawlessly. Because in industrial manufacturing, downtime isn’t just inconvenient—it’s expensive.