High-Speed Spindle Repair is crucial for any company in industrial manufacturing, especially those in aerospace, where precision and reliability can’t be compromised. If your high-speed spindles are acting up, you might wonder how to keep your production line in top gear. Here’s a quick rundown:

- What is it? Repairing high-speed spindles that have become worn or faulty.

- Why does it matter? Proper repair ensures minimal downtime and maintains production quality.

- Who should you trust? Expert services like MZI Precision, where spindle know-how meets advanced technology.

In industrial manufacturing, spindles serve as the backbone of efficient production. These high-speed components — often whirring away at speeds beyond 30,000 RPM — are vital for maintaining the accuracy and efficiency that sectors like aerospace demand. However, intense workloads and continuous operations can lead to spindle wear and failure. When spindles falter, the entire line suffers: downtime spikes, costs mount, and output tumbles.

MZI Precision understands these stakes. With years of expertise, they position themselves as a trusted spindle repair ally, bringing life back into your machinery. They focus on rebuilding and repairing high-speed spindles custom for industrial manufacturers. Ready for solutions that keep your machines running? Dive in to learn how professional repair can make all the difference.

Understanding High-Speed Spindle Repair

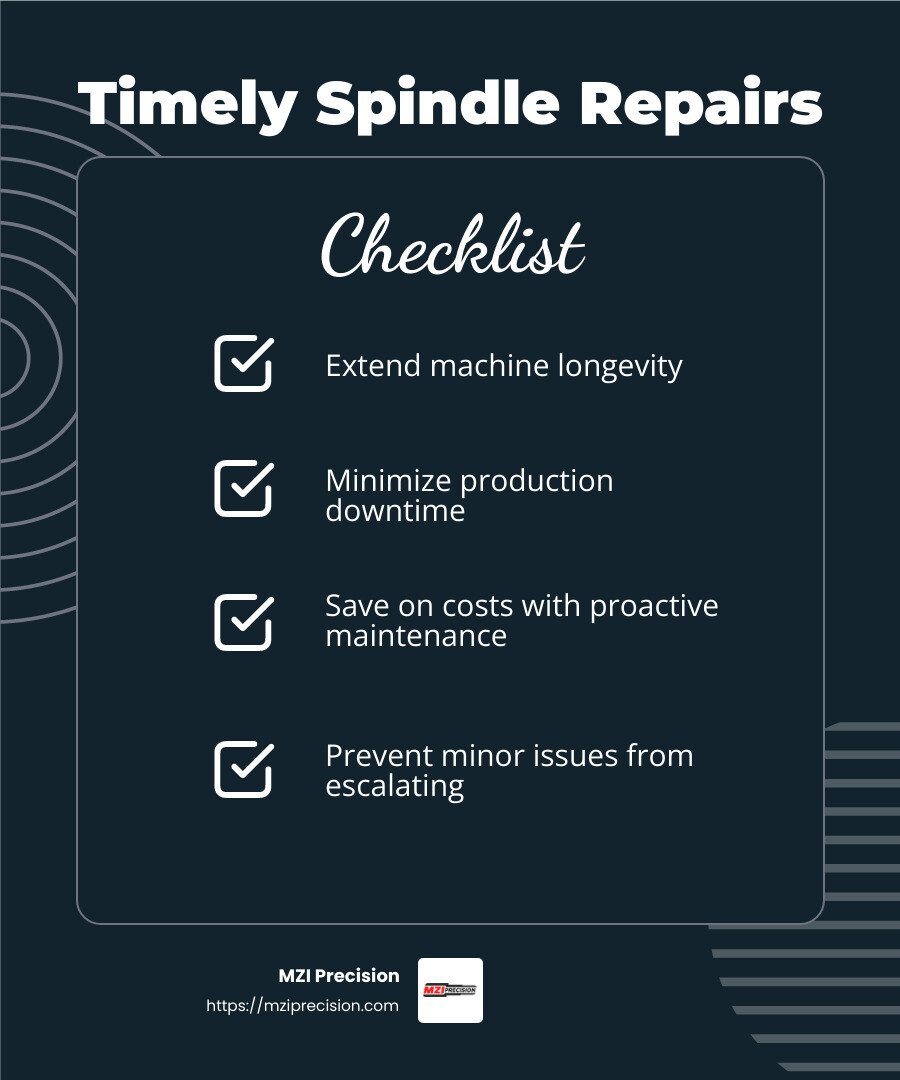

Importance of Timely Repairs

In the world of industrial manufacturing, every minute of machine downtime can translate to significant costs. High-speed spindle repair is essential to ensure your CNC machines operate smoothly without unexpected interruptions.

Here’s why timely repairs are crucial:

-

Machine Longevity: Regular maintenance and prompt repairs extend the life of your spindles. By addressing issues early, you prevent minor problems from escalating into major faults that could lead to costly replacements.

-

Reduced Downtime: When a spindle fails, production halts. Quick and efficient repairs help you get back on track faster, minimizing the impact on your schedule and bottom line.

-

Cost Savings: Investing in timely repairs can save you money in the long run. Avoiding emergency repairs and replacements helps keep your budget in check.

Common Causes of Spindle Failure

Understanding what leads to spindle failures can help you prevent them. Here are some common culprits:

-

Wear and Tear: Spindles endure immense stress and speed, which can cause wear over time. Regular inspections can catch these signs early.

-

Contamination: Dust, debris, and other contaminants can infiltrate the spindle, leading to malfunction. Proper sealing and maintenance can mitigate these risks.

-

Improper Maintenance: Neglecting routine checks and maintenance can accelerate spindle degradation. Adhering to a regular maintenance schedule is vital.

High-speed spindles are the heart of precision machining, and keeping them in top condition is non-negotiable. MZI Precision excels in diagnosing and repairing these components, ensuring your machines remain reliable and efficient.

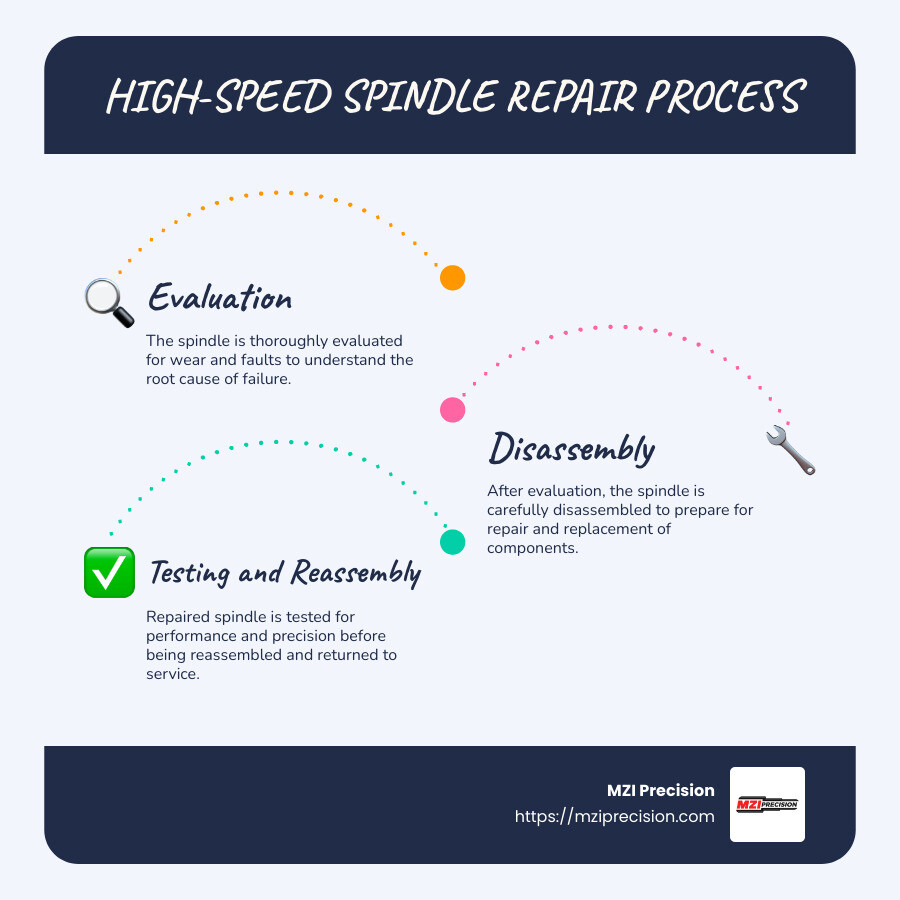

The High-Speed Spindle Repair Process

Detailed Evaluation and Diagnosis

The journey to restoring a high-speed spindle starts with a thorough evaluation and diagnosis. Imagine this as a health check-up for your spindle. Technicians begin by assessing the spindle’s condition to pinpoint the root cause of failure. This step is crucial because understanding what went wrong helps prevent future issues.

During this phase, technicians perform a condition assessment and failure analysis. They carefully examine each component, looking for signs of wear, contamination, or damage. This is akin to a detective solving a mystery, where every clue is vital. By identifying the exact cause of the problem, technicians can tailor the repair process to address specific needs.

Precision Repair Techniques

Once the problem is identified, the spindle moves to the precision repair stage. This is where the magic happens, as technicians carefully disassemble the spindle. Each part is removed with care to avoid further damage. It’s like taking apart a complex puzzle, with each piece needing to be perfectly aligned later.

Bearing replacement is often a key part of this process. Bearings are the heart of spindle functionality, and using high-quality, compatible bearings is essential. Technicians ensure that the new bearings fit perfectly, much like performing a delicate heart transplant.

Next comes balancing. An unbalanced spindle can lead to vibrations, which affect performance and longevity. Technicians use advanced equipment to balance the spindle, ensuring smooth operation at high speeds.

Finally, the spindle is carefully reassembled. Every component is put back with precision, ensuring alignment and functionality. Think of this as the final touches on a masterpiece painting, where every detail matters.

Once reassembled, the spindle undergoes rigorous testing. Technicians check for vibration, temperature, and speed to ensure everything functions within specified limits. This testing phase is like a test drive for a newly repaired car, confirming that it’s ready for action.

By following this structured repair process, MZI Precision ensures that your high-speed spindles return to optimal performance, keeping your operations running smoothly.

Benefits of Professional Spindle Repair Services

Long-Term Performance and Reliability

When it comes to high-speed spindle repair, having expert technicians on your side makes all the difference. These are the folks who know their way around spindles like the back of their hand. They use advanced equipment to ensure each spindle is repaired to meet high standards. With their expertise, your spindles can achieve machine efficiency and contribute to production success.

Reliability is key. A professionally repaired spindle means fewer unexpected breakdowns and a smoother production line. This reliability translates to long-term performance, where your machines run efficiently and consistently. It’s like having a well-oiled machine that just keeps going, reducing the risk of costly interruptions.

Cost-Effectiveness and Warranty

Investing in professional spindle repair services is not just about fixing what’s broken—it’s about smart cost management. A detailed cost proposal is usually provided, helping you understand the investment needed for repairs. This transparency ensures you’re not caught off guard by hidden costs.

A strong warranty coverage is another crucial benefit. It acts as a safety net, providing peace of mind that your repaired spindle will perform as expected. A robust warranty also speaks volumes about the confidence the repair service has in their workmanship. It’s like getting a seal of assurance that your spindle is ready to handle the demands of your production line.

By choosing professional spindle repair services, you’re not just fixing a part; you’re investing in the future performance and reliability of your machinery. This proactive approach helps maintain the efficiency and success of your production operations, ensuring you stay ahead in the world of industrial manufacturing.

Frequently Asked Questions about High-Speed Spindle Repair

What are the signs of spindle failure?

Recognizing spindle failure early can save you time and money. Here are some common signs:

-

Unusual Noises: Grinding, screeching, or rattling sounds often indicate problems like bearing failure. If your machine starts making these noises, it’s time for a check-up.

-

Increased Vibration: Excessive vibration can be a sign of worn-out bearings or imbalance. Watch for chatter marks on machined parts, which suggest vibration issues.

-

Poor Part Finish: If the quality of your machined parts declines, it might be due to spindle issues affecting precision.

-

Temperature Rise: An overheating spindle can signal lubrication problems or bearing failure.

How long does a typical spindle repair take?

The time needed for spindle repair can vary based on the complexity of the issue and the service provider’s capabilities. However, most standard repairs are completed within 1-3 weeks. This timeframe includes:

- Initial Evaluation: Assessing the spindle’s condition and identifying issues.

- Repair Process: Disassembly, repair, and reassembly of the spindle.

- Testing: Running tests to ensure the spindle operates efficiently post-repair.

Emergency services are available if you need quicker turnaround times, but thorough repairs take time to ensure quality and reliability.

What is the warranty period for repaired spindles?

A strong warranty is a hallmark of a reputable spindle repair service. Most professional services offer warranties that cover a significant period post-repair, often up to one year. This coverage includes:

- Performance Assurance: Ensures the spindle performs as expected.

- Peace of Mind: Protects against potential failures, giving you confidence in the repair quality.

A robust warranty reflects the repair service’s confidence in their work, ensuring that your spindle can handle the demands of industrial manufacturing with ease.

Conclusion

At MZI Precision, we pride ourselves on delivering exceptional service and expertise in OEM spindle repair. Our commitment to quality ensures that your industrial manufacturing spindles receive the best care, enhancing their performance and longevity.

Our Expertise

With years of experience in spindle repair and rebuilding, we understand the intricacies involved in maintaining high-speed spindles. Our team of expert technicians is equipped to handle a wide range of spindle issues, ensuring that your machinery operates at peak efficiency.

-

Advanced Techniques: We employ state-of-the-art methods for bearing replacement, balancing, and reassembly. This ensures that your spindle performs like new after repair.

-

Comprehensive Evaluation: Our detailed evaluation process includes condition assessment and failure analysis, allowing us to pinpoint and address the root causes of spindle failure.

Exceptional Service

We believe in providing not just a service, but a solution that goes beyond immediate repair needs. Our focus on long-term performance and reliability means that you can count on us to keep your machines running smoothly.

-

Customer Support: Our commitment to exceptional customer service means we’re here to assist you every step of the way. From diagnosis to post-repair support, we ensure your satisfaction.

-

Warranty Assurance: Our robust warranty coverage reflects our confidence in the quality of our repairs. You can trust that your spindle is in good hands with MZI Precision.

For more information on our services and how we can assist with your spindle repair needs, visit our Machine Tool Spindle Repair California page. Let us help you keep your operations running smoothly with our expert spindle repair solutions.