Lathe spindle repair is crucial for maintaining precision and efficiency in industrial manufacturing. When your equipment’s spindle falters, it can disrupt operations and lead to costly delays.

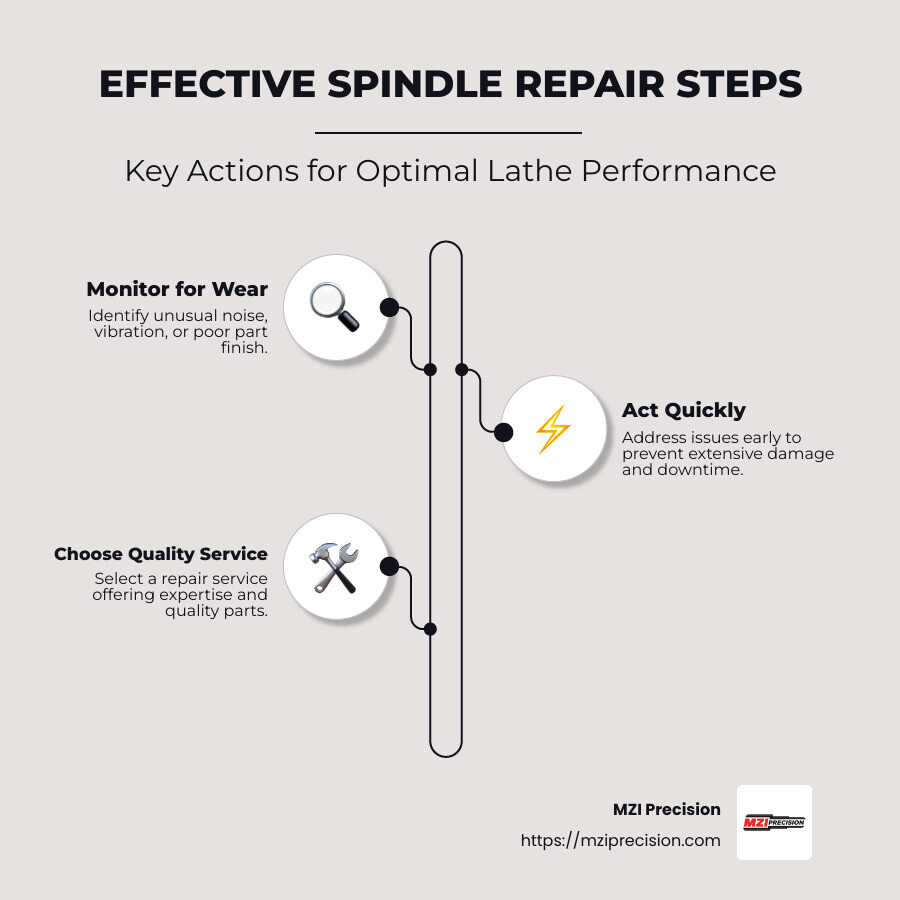

To keep those machines running smoothly:

- Monitor for signs of spindle wear: Look for unusual noise, vibration, or poor part finish.

- Act quickly: Addressing issues early can prevent extensive damage and costly downtime.

- Choose a reliable repair service: Expertise and quality parts are key to long-lasting repairs.

In precision turning, even tiny imperfections can drastically impact performance. Proper spindle care ensures optimal results and operational efficiency. At MZI Precision, we understand the stakes and can help you get back to smooth, precise turning quickly.

Find more about Lathe spindle repair:

Understanding Lathe Spindle Issues

Lathe spindles are critical components in precision machining, and several issues can disrupt their operation. Common problems include bearing failure, spindle damage, poor lubrication, and excessive vibration.

Bearing Failure

Bearings ensure smooth spindle rotation. Failure can result from overloading, inadequate lubrication, or contamination by dust and metal shavings. Regular checks and maintenance are vital to prevent these issues.

Spindle Damage

Damage can occur from accidents or improper handling, indicated by scarring, gouges, or discoloration from overheating. Early intervention is crucial to avoid extensive repairs.

Poor Lubrication

Adequate lubrication reduces wear and prevents overheating. Signs of poor lubrication include unusual noise and increased spindle temperature. Regular checks are essential for maintaining optimal function.

Excessive Vibration

Vibration issues may arise from imbalance, worn components, or misalignment. Early detection and correction are key to maintaining spindle performance and longevity.

The Importance of Professional Spindle Repair

Professional spindle repair is essential for maintaining the precision required in industrial manufacturing. Key aspects include tight tolerances, OEM parts, and spindle rebuilding.

Tight Tolerances

Maintaining tight tolerances is crucial for high-quality output. Professional services ensure spindles meet these precise standards.

OEM Parts

Using OEM parts guarantees compatibility and performance, crucial for effective repairs. MZI Precision uses only high-quality OEM parts for durability and reliability.

Spindle Rebuilding

Comprehensive rebuilding can significantly extend a spindle’s lifespan. MZI Precision’s process includes thorough disassembly, inspection, and replacement of worn parts, followed by detailed balancing and testing.

Lathe Spindle Repair Process

Understanding the spindle repair process highlights the care and precision involved. Key steps include disassembly, inspection, testing, and reassembly.

Disassembly

Technicians carefully disassemble the spindle, ensuring no further damage occurs. Each component is meticulously examined.

Inspection

Each part is inspected using specialized tools to identify any wear or damage. This step is crucial for diagnosing the failure and planning effective repairs.

Testing

Testing includes checks for radial load, axial compliance, and thermal stability to ensure the spindle meets performance standards.

Reassembly

Reassembly is performed with precision, ensuring all components are correctly aligned and functional. The spindle undergoes final testing before returning to operation.

Benefits of Timely Spindle Repair

Timely spindle repair offers significant advantages, including minimized downtime, reduced operational costs, and extended equipment life.

Minimize Downtime

Quick repairs reduce production interruptions, helping maintain schedules and customer satisfaction.

Lower Operational Costs

Efficient repairs prevent further damage and reduce energy consumption, lowering overall operational costs.

Extend Spindle Life

Regular maintenance and timely repairs enhance spindle reliability and performance, extending its operational lifespan and improving cost-efficiency.

Frequently Asked Questions about Lathe Spindle Repair

Can a spindle be repaired?

Absolutely, a spindle can be repaired, and it’s often a wise choice compared to buying a new one. Lathe spindle repair involves several steps to ensure the spindle returns to optimal performance. One key aspect is bearing replacement. Bearings are crucial for smooth spindle operation, and worn-out bearings can cause vibrations and damage. At MZI Precision, we use high-quality OEM parts to ensure your spindle meets original specifications and performs reliably.

What are the symptoms of a bad spindle bearing?

Identifying a bad spindle bearing early can save you from more significant issues down the line. Look out for:

- Scarring and Gouges: These are visible marks on the bearing surface, indicating wear and tear.

- Discoloration: This can be a sign of overheating, which often results from poor lubrication or excessive friction.

If you notice these symptoms, it’s time to consider professional repair to prevent further damage.

How to check lathe spindle bearings?

Checking your lathe spindle bearings regularly can help you catch issues before they become severe. Here are some simple methods:

- Indicator Test: Use a dial indicator to measure any runout or deflection in the spindle. This test helps detect misalignment or bearing wear.

- Deflection: Gently apply pressure to the spindle and observe any movement. Excessive deflection can indicate a problem with the bearings.

Regular checks with these methods help maintain spindle health and ensure smooth operation.

By understanding these FAQs, you can better maintain your lathe spindles and ensure they continue delivering precise, reliable performance. Up next, we’ll conclude with how MZI Precision’s expertise can support your spindle repair needs.

Conclusion

At MZI Precision, we pride ourselves on delivering exceptional service and leveraging our deep OEM expertise to meet your industrial manufacturing spindle needs. Our commitment to quality and precision ensures that every spindle we repair or rebuild performs as if it were brand new.

Our team of highly skilled technicians understands the intricacies of lathe spindle repair. We use only top-notch OEM parts, ensuring that your spindle maintains the tight tolerances required for precision turning. This focus on quality not only restores your spindle’s performance but also extends its lifespan, providing you with better value over time.

Choosing MZI Precision means minimizing downtime and reducing operational costs. We know that every minute of unplanned downtime can impact your productivity and bottom line. That’s why we work fast and efficiently, without compromising on quality, to get your machines back up and running.

Our comprehensive repair process includes thorough disassembly, detailed inspection, precise testing, and careful reassembly. This meticulous approach guarantees that each spindle meets our high standards and exceeds your expectations.

Experience the MZI Precision difference and keep your industrial manufacturing operations running smoothly. Visit our Precision Spindle Service page to learn more about how we can support your spindle repair needs and improve your machinery’s performance.