Understanding Precision Spindle Rebuilding: The Heart of Machine Performance

A precision spindle rebuild is the comprehensive process of restoring a worn or damaged machine tool spindle to original OEM specifications or better. This specialized service extends spindle life, improves machining accuracy, and saves significant costs compared to replacement.

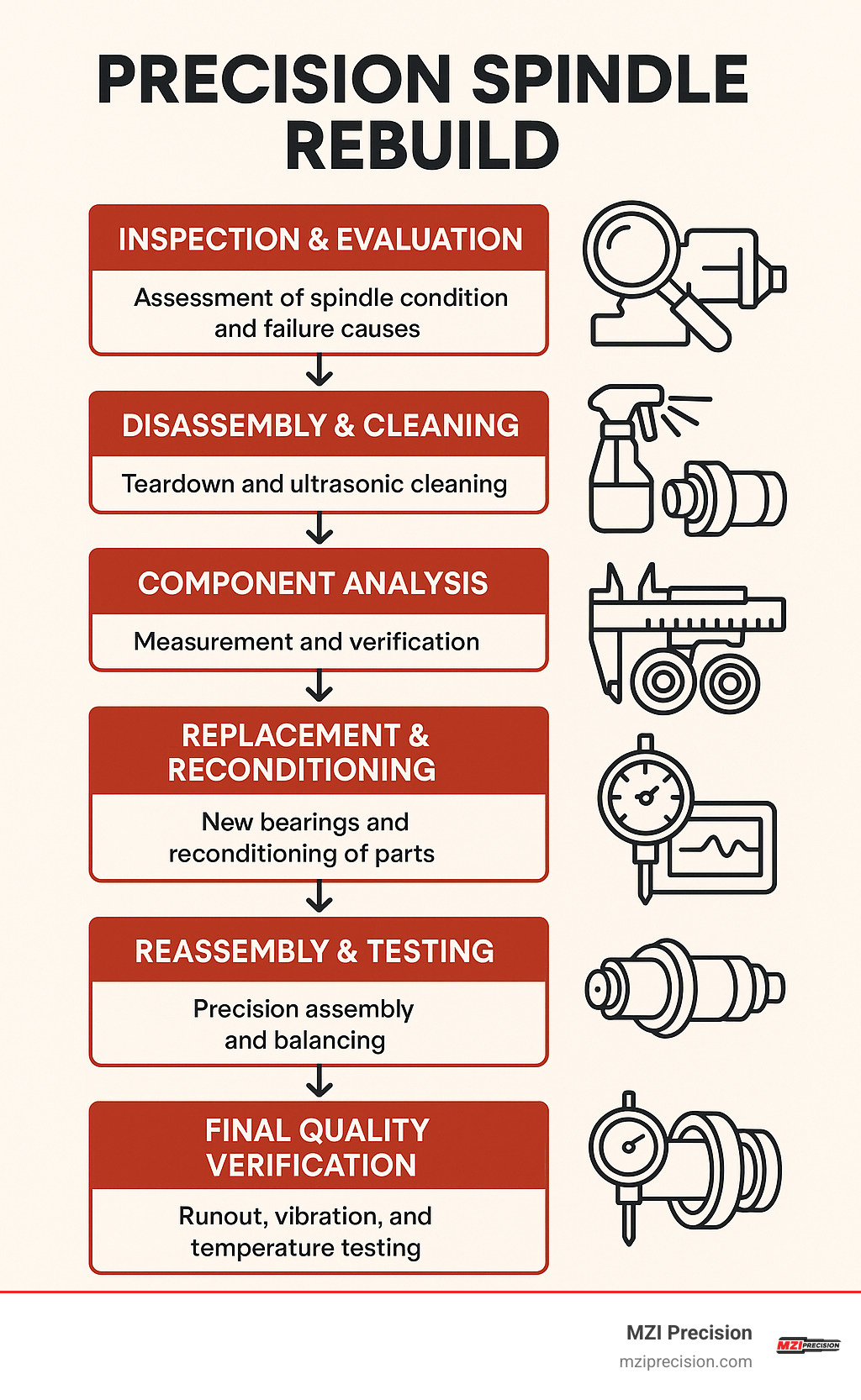

Quick Guide to Precision Spindle Rebuilding:

- Inspection & Evaluation – Complete assessment of spindle condition and failure causes

- Disassembly & Cleaning – Careful teardown and ultrasonic cleaning of all components

- Component Analysis – Measurement and verification of critical dimensions

- Replacement & Reconditioning – Installing new bearings and refurbishing worn parts

- Reassembly & Testing – Precision assembly followed by dynamic balancing

- Final Quality Verification – Runout, vibration, and temperature testing to ensure performance

The spindle is the heart of any machine tool. When a precision spindle fails or shows signs of wear, production stops and part quality suffers. Machine shops, aerospace manufacturers, automotive plants, and other precision industries rely on expert spindle rebuilding services to minimize downtime and maintain critical tolerances.

A professional precision spindle rebuild can restore tolerances to within 2 microns of original specifications – often better than new. This level of precision is essential for aerospace components, medical devices, and other high-value parts where accuracy directly impacts performance and safety.

Most spindle rebuilds are completed in 1-2 weeks, compared to 8-12 weeks for a new replacement spindle. The cost savings are equally impressive, with rebuilds typically running 30-50% of the price of a new spindle while delivering comparable or superior performance with proper warranties.

Precision spindle rebuild word guide:

Precision Spindle Fundamentals: Importance, Failure Signs & Causes

Why Spindles Are Critical to Machine Tool Performance

Think of your machine tool’s spindle as its beating heart. This vital component holds and rotates cutting tools or workpieces with incredible precision, often at speeds that would make your head spin. When your spindle performs at its best, you get perfect parts with smooth finishes and precise dimensions. When it doesn’t… well, that’s when production headaches begin.

A precision spindle isn’t just a simple shaft – it’s a sophisticated assembly of critical components working in harmony:

The foundation is a hardened, ground shaft that connects to ultra-precision bearings (either angular contact or ceramic hybrid). These sit within a housing that includes a carefully calibrated preload system. To keep everything running smoothly, there’s a lubrication system (using grease, oil, or oil-mist), protected by seals that prevent contamination. The business end features a tool interface with taper, face, and pilot surfaces, while power comes from a drive system (belt, gear, or integrated motor).

Common Signs That a Spindle Needs Rebuilding

Your spindle will tell you when it’s struggling – if you know what to listen for. Catching these warning signs early can save you from catastrophic failures and keep repair costs manageable.

When your spindle shows more than 2 microns of radial or axial deviation during rotation (excessive runout), part accuracy immediately suffers. You might also notice unusual vibration – even slight increases can signal bearing problems brewing beneath the surface.

Is your spindle running hot? Thermal issues and uneven heating can cause dimensional variations that ruin parts. And that strange noise you’re hearing? Those grinding, squealing, or rumbling sounds aren’t just annoying – they’re your bearings crying for help.

Watch your parts closely too. When surface finishes start looking rough or you experience unexpected tool chatter, your spindle is likely the culprit. Inconsistent tool life – cutters wearing out faster than normal – often points to spindle problems. And if your drawbar force is weakening, you’re risking dangerous tool pullout during operations.

Primary Causes of Spindle Failure or Degradation

Understanding what kills spindles helps prevent history from repeating after your precision spindle rebuild.

Bearing wear is inevitable – normal fatigue from countless rotation cycles eventually takes its toll. But many failures accelerate due to inadequate lubrication. As noted in research on bearing lubrication procedures, “Low-RPM service does not support the idea that more grease is needed.” The key is using the right amount and type of lubricant for your specific spindle.

Contamination is a silent killer – coolant, chips, and dust sneak past seals and cause premature wear. And nothing damages a spindle faster than a crash – those heart-stopping collisions between tools and workpieces create shock loads that bearings and shafts simply weren’t designed to handle.

Other common culprits include electrical damage (current passing through bearings causes pitting), improper operation (exceeding speed or load ratings), imbalance (unbalanced tooling creates destructive vibration), and improper assembly during previous repairs (incorrect preload or alignment).

At MZI Precision, we’ve examined thousands of failed spindles, giving us the expertise to quickly identify what went wrong. This detective work is crucial – a proper precision spindle rebuild must address not just the symptoms but the underlying causes to prevent recurring problems.

By understanding these fundamentals, you’ll be better equipped to maintain your spindles and recognize when it’s time for professional attention – before small problems become expensive disasters.

The Precision Spindle Rebuild Process

A comprehensive precision spindle rebuild isn’t just a repair—it’s a meticulous art form that breathes new life into the heart of your machine tool. At MZI Precision, we’ve refined this process through years of hands-on experience with countless spindle types across industries from aerospace to woodworking.

Intake, Cleaning, and Evaluation

When your spindle arrives at our facility, our rebuild journey begins with thorough documentation:

We carefully log each spindle with its own unique tracking number—think of it as your spindle’s hospital bracelet during its stay with us. Before we even reach for a wrench, we conduct a hands-on external inspection, checking for visible damage, measuring runout, and feeling for those telltale rough spots when rotating by hand.

The disassembly phase is where our expertise truly shines. Using specialized tools and fixtures developed over thousands of rebuilds, we carefully take apart your spindle without adding any new damage—a bit like archaeological work, but with precision steel instead of pottery.

Ultrasonic cleaning comes next, where we remove every trace of grease, coolant residue, and tiny contaminants that might be hiding in the smallest crevices. This deep cleaning reveals the true condition of all components and prepares them for meticulous inspection.

Once cleaned, each component undergoes dimensional inspection using precision measuring instruments. We’re looking at microns here—measurements so small they’re invisible to the naked eye but make all the difference in spindle performance.

Report & Approval

We believe in transparency, which is why we provide a detailed report before proceeding further:

Our failure analysis pinpoints exactly what went wrong with your spindle—whether it was contamination, bearing fatigue, or perhaps a crash that sent shockwaves through the system. We document the condition of every component with photographs and precise measurements, then outline specific recommendations for repair or replacement.

You’ll receive a clear cost estimate and timeline for completion, allowing you to make an informed decision before we proceed. No surprises, just straightforward expertise.

Assembly, Repair, and Rebuild

Once you give us the green light, the real change begins:

The spindle shaft—the backbone of the entire assembly—may need reconditioning through precision grinding, polishing, or in some cases, complete replacement. Housing reconditioning follows, ensuring that bearing seats and other critical surfaces are perfect.

Bearing replacement is perhaps the most crucial step. We install new precision bearings matched specifically to your application’s requirements. The drawbar system gets equal attention, with reconditioning or replacement of components and verification of proper pull force.

New seals create a fortress against future contamination, while our precision assembly process ensures every component fits together with proper preload and alignment. The correct lubricant, applied in the right amount, completes the mechanical assembly—typically using a 30% fill quantity for grease-lubricated spindles, which research has shown to be optimal for most applications.

Final Tests & Balance

A rebuilt spindle isn’t ready for service until it passes our rigorous testing regimen:

Dynamic balancing to G1 tolerances or better ensures minimal vibration and extended bearing life. This precision balancing makes a world of difference in performance and longevity—imagine the difference between riding in a car with balanced vs. unbalanced tires, but at 15,000 RPM!

The run-in testing phase puts your spindle through its paces at various speeds while we monitor temperature, vibration, and noise patterns. We’re looking for that smooth, quiet operation that indicates everything is working in perfect harmony.

We verify radial and axial runout to ensure they meet or exceed OEM specifications, with our standard being 2 microns radial runout and 1 micron axial runout. For tool-holding spindles, we confirm that the drawbar provides proper clamping force—critical for both safety and precision.

A comprehensive final inspection and complete documentation of test results complete the process, giving you confidence that your rebuilt spindle is ready for its next chapter of service.

Step-By-Step Precision Spindle Rebuild Checklist

For those who appreciate the details, here’s our comprehensive precision spindle rebuild checklist:

- Receive and log spindle – We document everything about your spindle’s arrival condition, assign a tracking number, and create its rebuild “medical chart.”

- Initial inspection – Before disassembly, we check for visible damage, measure runout, test rotation by hand, and note any unusual conditions.

- Disassembly – We carefully remove external components and extract bearings, documenting each step and noting any unexpected findings.

- Cleaning – Ultrasonic cleaning removes all contaminants and lubricant residue, revealing hidden damage.

- Component evaluation – We measure shaft dimensions, check bearing seats, inspect sealing surfaces, and evaluate all critical interfaces.

- Failure analysis – We determine the root cause of failure, document findings with photos, and prepare recommendations to prevent recurrence.

- Quote preparation – Based on our findings, we list required parts, calculate labor, estimate lead time, and prepare a detailed quote.

- Customer approval – We submit our findings and recommendations, discuss options, and obtain your approval to proceed.

- Parts procurement – We order precision bearings and source all necessary components, verifying receipt of the correct parts.

- Reconditioning – The shaft and housing are reconditioned as needed, and all components are prepared for assembly.

- Assembly – We install bearings with proper preload, mount seals and components, apply correct lubricant, and assemble with proper torque values.

- Initial testing – We verify smooth rotation, check preliminary runout, and make adjustments as needed.

- Dynamic balancing – The rotating assembly is balanced to G1 tolerance, with documented results.

- Run-in testing – We run the spindle at progressive speeds, monitoring temperature, vibration, and noise.

- Final inspection – All dimensions and specifications are verified, including runout and drawbar force if applicable.

- Packaging and shipping – We clean exterior surfaces, apply corrosion protection, package securely, and include all documentation.

This detailed process ensures that every precision spindle rebuild we perform not only meets or exceeds OEM specifications but also provides the maximum possible service life for your valuable equipment. When your production depends on precision, our rebuild process delivers peace of mind.

Restoring & Upgrading Performance: Technologies, Testing, Industries & Cost Benefits

When we rebuild your spindle at MZI Precision, we’re not just fixing what’s broken – we’re giving you an opportunity to make it even better than when it rolled off the assembly line. Think of it as your spindle getting a spa day with some serious upgrades!

Advanced Technologies in Modern Spindle Rebuilding

The world of precision spindle rebuild has come a long way in recent years. We now have some pretty amazing tech at our fingertips that can take your tired spindle to the next level.

Ever heard of laser cladding? It’s like magic for worn surfaces. We can add a perfectly bonded layer of material to restore dimensions that would otherwise require a complete replacement. This technology doesn’t just fix the problem – it creates a surface that’s often more wear-resistant than the original.

Many of our customers are making the switch to ceramic hybrid bearings during their rebuilds. These bearings combine ceramic balls with steel races for a match made in spindle heaven. They run cooler, faster, and last longer than traditional all-steel bearings. For high-speed applications, they’re absolutely worth considering.

We’re also implementing smarter lubrication systems that deliver precisely the right amount of oil or grease exactly when and where it’s needed. These systems not only extend bearing life but are also better for the environment by reducing waste.

And let’s not forget about keeping the bad stuff out! Modern sealing technologies have improved dramatically, with advanced labyrinth and contact seals that provide superior protection against contaminants that can quickly destroy even the best bearings.

For customers looking toward the future, we can integrate temperature and vibration sensors during the precision spindle rebuild process. These smart monitoring systems give you early warning of potential issues, helping you avoid costly emergency repairs down the road.

Testing and Verification Methods

We’re pretty obsessive about testing at MZI Precision. After all, what good is a rebuild if we can’t prove it’s performing perfectly?

Every precision spindle rebuild undergoes rigorous verification. We check radial runout to ensure it’s within 2 microns and axial runout to within 1 micron – often tighter than original factory specs. Our dynamic balancing brings rotating components to G1 tolerance or better, eliminating harmful vibrations that can damage bearings and ruin surface finishes.

During run-in testing, we monitor temperature patterns to identify any potential issues before they become problems. Our sophisticated vibration analysis equipment can detect the slightest irregularities across various operating speeds. And for tool-holding spindles, we verify that the drawbar is providing proper clamping force to prevent dangerous tool pullout.

Industries Served by Precision Spindle Rebuilding

The need for precision spindle rebuild services crosses virtually every manufacturing sector. In aerospace, where tolerances are measured in microns and lives depend on part integrity, our rebuilt spindles help maintain the exacting standards required for flight-critical components.

Defense and military manufacturing relies on spindles that deliver absolute reliability and precision. Automotive manufacturers count on us to keep their production lines moving, producing engine components and transmission parts with tight tolerances day after day.

The medical device industry can’t afford imperfection – when a component might end up inside the human body, there’s zero room for error. Semiconductor manufacturing presents unique challenges with its ultra-precise air bearing spindles, which require specialized expertise to rebuild properly.

From solar energy production to woodworking, from stone cutting to glass processing – each industry has unique spindle requirements, and we’ve developed specialized procedures to address them all. At MZI Precision, we’re proud to serve over 20 different industries with our precision spindle rebuild expertise.

Cost Benefits of Rebuilding vs. Replacement

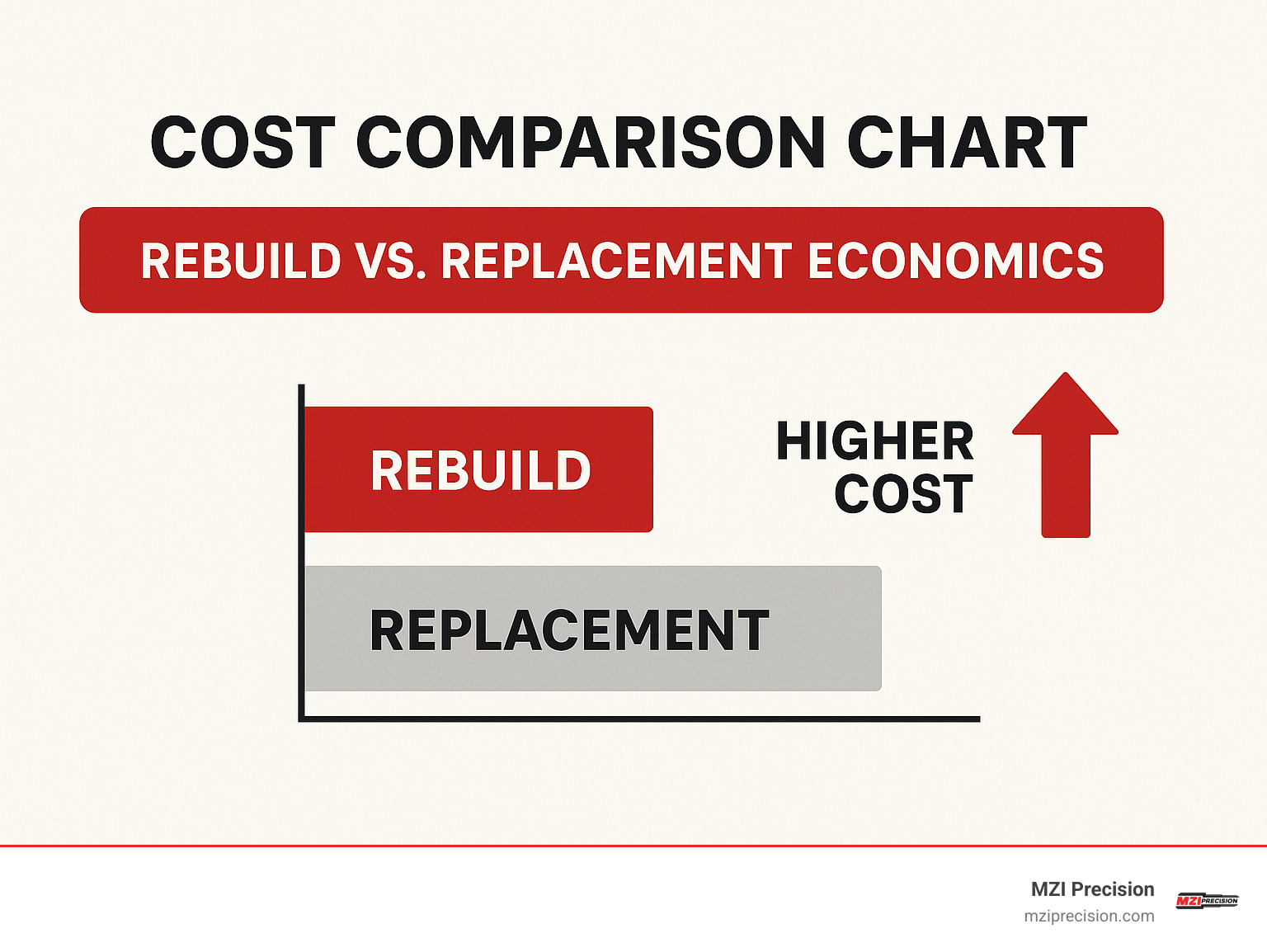

Let’s talk dollars and sense. The financial case for choosing a precision spindle rebuild is compelling. Typically, you’ll pay just 30-50% of what a new spindle would cost. For high-end spindles, we’re talking about potential savings in the tens of thousands of dollars!

But the true cost of a spindle failure isn’t just the replacement part – it’s the downtime. While you might wait 8-12 weeks for a new spindle to arrive from the OEM, we can often complete a rebuild in just 1-2 weeks. That difference can save your company enormous sums in lost production.

What about longevity? A properly rebuilt spindle from MZI Precision can provide the same or better service life than a brand new one. We stand behind our work with comprehensive warranty coverage that gives you peace of mind.

The best part? Many of our customers find that their rebuilt spindles actually perform better than they did when new. By addressing design weaknesses and incorporating strategic upgrades, we often send spindles back that outperform their original specifications.

Precision Spindle Rebuild Cost Breakdown

Understanding what goes into the cost of a precision spindle rebuild helps our customers make informed decisions.

About half of your rebuild cost typically goes to parts. Precision bearings usually account for 20-30% of the total price – and these aren’t components where you want to cut corners! Seals, O-rings, and other smaller components make up another 15-20%. If your shaft needs repair or replacement, that might add another 10-20% to the parts cost.

The other half of your investment goes toward skilled labor. Our technicians spend time on careful disassembly and inspection, thorough cleaning and preparation, precision machining and reconditioning, and meticulous assembly and testing. Each step requires specialized knowledge and experience that can’t be rushed.

Sometimes additional services make sense for your situation. Need it back in a hurry? Our expedited service can get your spindle rebuilt faster for a 10-30% premium. Want design modifications to address a recurring issue? We can customize solutions based on your specific needs.

When you compare the total cost of a precision spindle rebuild to buying new, you’ll typically find the rebuild costs 30-50% of replacement. Factor in the reduced downtime, warranty protection, and potential performance improvements, and rebuilding becomes the clear winner for most applications.

Choosing a Rebuild Partner, Maintenance Best Practices & FAQs

Finding the right partner for your precision spindle rebuild isn’t just about price—it’s about finding a team you can trust with the heart of your machine. At MZI Precision, we’ve seen how the right rebuild partner can make all the difference between a quick return to production and weeks of headaches.

Key Criteria for Selecting a Spindle Rebuild Partner

When your production line is down, you need confidence in your rebuild partner. Look beyond the sales pitch and evaluate potential partners on what really matters.

Technical expertise is the foundation of quality rebuilds. At MZI Precision, we’ve rebuilt spindles for over 50 different machine brands, giving us the knowledge to handle virtually any spindle challenge that comes through our doors.

Clean room facilities are non-negotiable for proper spindle assembly. Microscopic contaminants can doom even the most careful rebuild, which is why we perform all assembly work in our ISO-certified clean room environment.

The proof is in the testing. Without comprehensive testing equipment, how can anyone guarantee performance? Our testing protocol includes dynamic balancing, detailed runout measurement, and thermal analysis to ensure your spindle performs exactly as specified.

When your machine is down, every hour costs money. That’s why turnaround time matters so much. We’ve developed efficient processes that maintain quality while minimizing downtime, and we offer expedited service when you’re in a production crunch.

A meaningful warranty shows a rebuilder stands behind their work. We’re not interested in quick fixes—we want lasting partnerships built on trust and quality, backed by our comprehensive warranty coverage.

Don’t just take our word for it—ask for customer references. Happy customers are always eager to share their positive experiences, and our testimonials reflect our commitment to excellence in every rebuild.

On-site capabilities can save precious time. Our team can perform on-site spindle runout testing and removal services, preventing additional damage during the critical removal phase.

Engineering expertise adds tremendous value. Beyond simple repairs, our engineering team can identify and implement design improvements during the rebuild process, often resulting in spindles that perform better than when they were new.

Preventive Maintenance Best Practices

The best spindle rebuild is the one you can postpone through proper maintenance. A few smart practices can dramatically extend spindle life:

Regular vibration analysis serves as an early warning system for developing problems. By establishing baseline measurements and monitoring trends, you can often catch issues before they lead to catastrophic failure.

Proper lubrication is critical. Follow manufacturer recommendations carefully—research shows that “a 30% grease fill is the correct practice for AC high-precision bearings in machine tools.” Too much lubricant can be just as damaging as too little.

Tool balance directly impacts spindle health. Even slightly unbalanced tooling creates vibration that transfers to spindle bearings, accelerating wear. Invest in quality balancing equipment or services for all tooling.

Contamination is a silent killer of spindles. Keep your coolant systems clean and properly maintained, and consider upgrading filtration if contamination has been an issue in the past.

Operator training pays enormous dividends. Well-trained operators who understand how to recognize unusual noise, vibration, or performance changes can prevent minor issues from becoming major failures.

For critical applications, consider scheduled preventive rebuilds rather than waiting for failure. This approach allows for planned downtime rather than emergency shutdowns.

A spare spindle program eliminates virtually all spindle-related downtime. Having a rebuilt spare on hand means you can swap it in immediately when problems arise, then rebuild the removed spindle without production pressure.

How Dynamic Balancing Ensures Precision Spindle Rebuild Success

Dynamic balancing might seem like just another step in the precision spindle rebuild process, but it’s actually one of the most critical factors in determining long-term performance.

When a spindle rotates at thousands of RPM, even tiny imbalances create forces that damage bearings and affect machining precision. The balancing process identifies these imbalances and corrects them through precise addition or removal of material at specific locations.

The benefits extend far beyond the spindle itself. Properly balanced spindles produce better surface finishes on machined parts by eliminating the tiny vibrations that transfer to cutting tools. They also run more efficiently, consuming less power and generating less heat during operation.

Perhaps most importantly, balanced spindles dramatically extend bearing life. Since bearing replacement is the most common reason for spindle rebuilds, this directly impacts your maintenance costs and production uptime.

At MZI Precision, we balance all rotating components to G1 tolerance or better—a precision that ensures optimal performance and longevity for your rebuilt spindle.

Frequently Asked Questions about Precision Spindle Rebuild

Q: Why should I rebuild my spindle instead of replacing it?

A: A precision spindle rebuild typically saves you 50-70% compared to buying new, while providing comparable performance and reliability. Plus, rebuild lead times are usually weeks shorter than new spindle delivery, getting you back to production faster. The math makes rebuilding the clear choice for most situations.

Q: What is the typical turnaround time for a spindle rebuild?

A: Most rebuilds take 1-2 weeks, depending on complexity and parts availability. When production demands it, our expedited service can sometimes reduce this to just a few days. We once rebuilt a critical aerospace production spindle in just four days when the customer faced contract penalties for missed deadlines.

Q: How long do rebuilt spindles last?

A: A properly rebuilt spindle should match the service life of a new one. With good maintenance practices, this typically means thousands of production hours. We’ve seen properly maintained rebuilt spindles last 5+ years in demanding environments.

Q: Can you improve upon the original spindle design during rebuilding?

A: Absolutely! We often identify and address design weaknesses during rebuilds. This might include improved sealing systems, upgraded bearing arrangements, or improved lubrication delivery. These improvements can make your rebuilt spindle perform even better than it did when new.

Q: What types of spindles can be rebuilt?

A: Nearly any industrial spindle can be rebuilt, including belt-driven, motorized, high-speed, air bearing, and specialized types. At MZI Precision, we’ve successfully rebuilt spindles for over 50 different machine brands across dozens of applications.

Q: What warranty do you offer on rebuilt spindles?

A: We stand confidently behind our precision spindle rebuild work with a comprehensive warranty. Specific terms depend on spindle type and application, but we’re committed to your satisfaction and long-term success.

Q: How do I know if my spindle needs rebuilding?

A: Watch for warning signs like increased vibration, unusual noises (especially ones that change with speed), declining surface finish quality, dimensional inconsistencies in parts, overheating, or visible damage. When in doubt, our diagnostic services can provide definitive answers.

Q: Can you perform emergency spindle rebuilds?

A: Yes! We understand that downtime is incredibly costly. Our expedited service includes weekend work when necessary because we know your production can’t always wait for standard turnaround times.

Q: Do you provide on-site services?

A: We offer on-site spindle runout testing and removal services to help diagnose problems and safely extract damaged spindles. This can prevent additional damage during removal and provide valuable information for the rebuild process.

Q: How do I prepare my spindle for shipping?

A: Original packaging works best if you still have it. Otherwise, secure the spindle in a sturdy container with ample padding. Remove any tooling, and if possible, lock the spindle to prevent rotation during shipping. Give us a call for specific instructions custom to your spindle type—a few minutes of preparation can prevent shipping damage.

Conclusion

The art of precision spindle rebuilding combines engineering know-how, careful craftsmanship, and cutting-edge technology into something truly special. When done right, a rebuild doesn’t just fix a failed spindle – it often makes it better than it was when new.

Think about what you’re really getting with a professional precision spindle rebuild:

Your spindle gains a new lease on life, typically matching or even outlasting a brand-new unit. The math makes perfect sense too – at just 30-50% of replacement cost, rebuilding delivers exceptional value without cutting corners on quality. And let’s face it, time is money in manufacturing. With significantly faster turnaround than waiting for a new spindle, you’ll minimize those painful production interruptions that eat into your bottom line.

Peace of mind comes standard with every rebuild at MZI Precision. Our comprehensive testing and quality control processes ensure your rebuilt spindle meets or exceeds original specs. Plus, the rebuild journey creates a perfect opportunity to address any design weaknesses and incorporate improvements that will serve you better in the long run.

We’ve spent years refining our precision spindle rebuild process across dozens of industries. Our customers stick with us because they know our commitment to quality, attention to detail, and customer-first approach makes us a reliable partner when spindle performance directly impacts their success.

Whether you’re dealing with an unexpected spindle failure or smartly planning preventive maintenance, choosing the right rebuild partner matters enormously. Look for a provider with deep technical expertise, proper facilities, specialized equipment, and an unwavering commitment to quality that matches your operational demands.

A spindle isn’t just another component – it’s the beating heart of your machine tool and the foundation of your manufacturing quality. Investing in a professional precision spindle rebuild is really an investment in productivity, part quality, and profitability.

Want to learn more about our precision spindle rebuild services and the many industries we serve? Visit our Industries Served page or reach out to our team of experts. We’re here to keep your production running smoothly with spindle solutions custom to your specific needs.