How to grease spindle bearings: Precision 2025

Why Proper Spindle Bearing Lubrication is Critical for Manufacturing Success

Knowing how to grease spindle bearings is essential for any manufacturing operation that relies on precision machinery. For industrial manufacturing spindles, the process is straightforward but critical.

Essential Steps for Greasing Spindle Bearings:

- Clean the grease nipple thoroughly before application.

- Use the correct grease type specified by your OEM.

- Apply grease slowly using a proper grease gun.

- Fill to 20-30% capacity for most industrial applications.

- Purge old grease until fresh grease appears.

- Wipe excess grease to prevent contamination buildup.

- Follow manufacturer schedules for relubrication intervals.

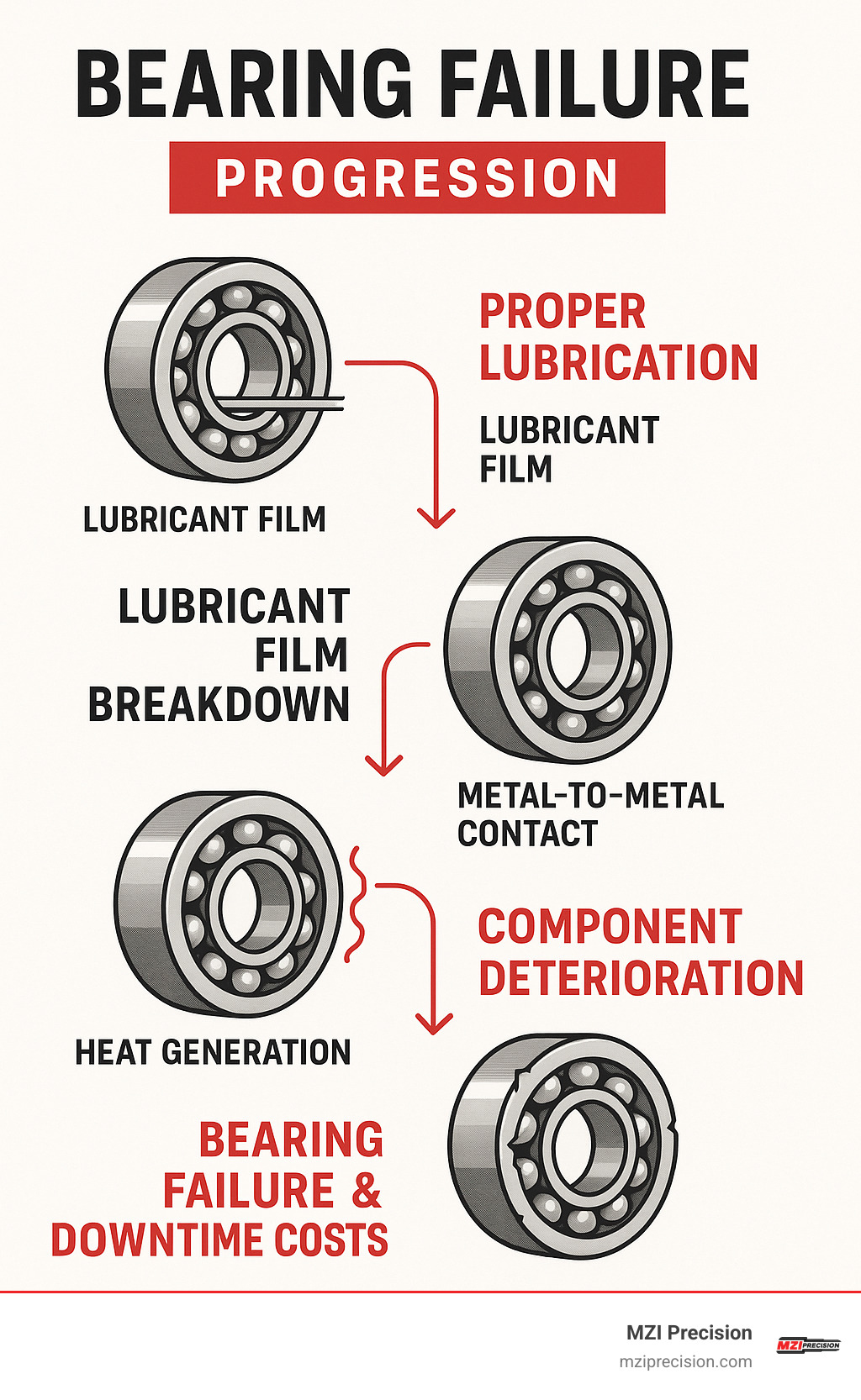

Without proper lubrication, spindle bearings experience direct contact between rolling elements and raceways. This causes heat buildup, component deterioration, and ultimately bearing failure that can shut down your entire production line.

A thin film of lubricant must be maintained between all moving parts. When this film breaks down, the consequences are severe. Precision industries like aerospace cannot afford the unplanned downtime from bearing failures.

For high-speed precision spindles, the stakes are even higher. Over-greasing can cause just as much damage as under-greasing, as excess grease creates churning friction that generates dangerous heat.

Basic how to grease spindle bearings glossary:

Understanding Spindle Bearings and the Critical Role of Lubrication

Spindle bearings are precision-engineered components at the heart of industrial manufacturing equipment like CNC machines. These mechanical components, known as bearings, consist of rolling elements (balls or rollers) that move between machined raceways, enabling smooth and accurate rotation.

Between these moving parts, a microscopic lubricant film is the invisible hero. This thin layer of grease is critical for several reasons:

- Friction Reduction: It prevents direct metal-to-metal contact between rolling elements and raceways, which would otherwise cause rapid wear.

- Heat Dissipation: At high speeds, moving parts generate heat. The grease acts as a coolant, carrying heat away to prevent thermal damage.

- Contamination Barrier: It seals the bearing, keeping dust, moisture, and debris from entering and causing abrasive wear.

- Extending Operational Life: Proper lubrication directly contributes to the longevity and reliability of your spindle bearings.

For high-speed applications and precision machining, this lubricant film is what allows your equipment to maintain the accuracy your customers demand.

Why Proper Lubrication is Non-Negotiable

Poor lubrication inevitably leads to bearing failure, which causes unplanned downtime—a manufacturer’s worst nightmare. When a spindle seizes, production halts, leading to immediate production loss and significant repair costs that often extend beyond the bearing itself.

Even before a complete failure, inadequate lubrication compromises accuracy. Increased vibration and uneven wear reduce the precision of finished parts, turning valuable components into scrap. This is especially critical in industries like aerospace where tolerances are minute.

Furthermore, grease provides essential wear resistance and corrosion prevention, protecting against rust in humid environments. Proper lubrication isn’t just maintenance; it’s insurance for your entire operation, ensuring your production stays on schedule and your costs remain predictable.

How to Grease Spindle Bearings: Methods and Systems for Industrial Machinery

When learning how to grease spindle bearings, there are two main approaches: manual greasing with grease guns and automated centralized lubrication systems. For both methods, extreme cleanliness and contamination control are paramount. Introducing even tiny particles of dirt into a spindle bearing is like throwing sand into a finely-tuned watch.

Manual Greasing Techniques for Precision Spindles

Manual greasing offers direct control, using a grease gun to apply lubricant through grease nipples (zerks). It requires attention to detail but is effective when done correctly.

Follow these steps for precision industrial spindles:

- Clean the grease nipple thoroughly before attaching the grease gun. Any dirt on the zerk will be pushed directly into the bearing.

- Use only the OEM-specified grease type. The wrong grease can cause more harm than good, as spindles are engineered for specific lubricant properties.

- Apply grease slowly and steadily. Rushing can build excessive pressure and damage seals.

- Watch for the purge of old grease. Seeing fresh, clean grease emerge indicates that old, contaminated lubricant is being expelled. Avoid over-pressurizing, which can damage seals.

- Wipe away all excess grease afterward. External grease attracts dirt that can eventually contaminate the system.

An Overview of Centralized Lubrication Systems

For large operations or complex machinery, centralized systems automatically deliver controlled amounts of grease from a central reservoir. They excel at providing consistent, precise lubrication at optimal intervals, eliminating the human error associated with manual greasing.

These systems are ideal for high-precision applications, as automated delivery reduces the risk of over-greasing and minimizes contamination. However, they have a higher initial cost and require their own maintenance for pumps, lines, and reservoirs. Troubleshooting can also be more complex than with manual systems.

| Feature | Manual Lubrication | Centralized Lubrication Systems |

|---|---|---|

| Control | Relies on technician’s judgment and consistency | Automated, precise, and consistent delivery |

| Cost (Initial) | Low (grease gun, zerks) | High (pump, reservoir, distribution lines) |

| Application | Individual points, smaller machines | Multiple points, complex machinery, production lines |

| Precision | Variable, depends on skill | High, metered amounts |

| Contamination | Higher risk if zerk/gun are not clean | Lower risk (sealed system) |

| Labor | High (requires regular manual intervention) | Low (monitoring and reservoir refills) |

| Downtime | Less for lubrication, but higher if missed/improper | Minimal, often done during operation or short breaks |

| Common Use | General industrial equipment, initial filling | High-volume production, critical precision spindles |

The choice between manual and centralized systems depends on your application, budget, and operational priorities. Both are effective when implemented correctly.

Precision is Key: Grease Quantity and Relubrication Frequency

Properly learning how to grease spindle bearings means understanding that both quantity and frequency are critical. Too much grease can be as damaging as too little.

A spindle bearing has a specific amount of internal free space, and only a percentage of that should be filled. For low-speed precision bearings, the ideal fill is 20-30%. For high-speed applications, the fill should be under 30% to prevent churning, which generates excessive heat.

How Much Grease is the Right Amount?

Many believe more grease equals better protection, but this is false for industrial spindles.

- Over-greasing causes the grease to churn, creating friction and heat that breaks down the lubricant. The excess pressure can also blow out bearing seals, leading to contamination and grease leakage. The spindle will also consume more power as it fights the excess grease.

- Under-greasing allows direct metal-to-metal contact between rolling elements and raceways. This generates heat, causes rapid wear, and leads to catastrophic bearing failure. It also leaves the bearing vulnerable to moisture and corrosion.

Determining the Optimal Relubrication Interval

Relubrication timing is a science based on operating conditions. Always start with manufacturer specifications, but adjust based on the following:

- Operating Speed: High-speed spindles need smaller, more frequent grease applications. The speed factor (nDm) helps calculate these intervals.

- Load and Temperature: Heavy loads and high temperatures accelerate grease breakdown, requiring more frequent relubrication.

- Vibration: Excessive vibration can degrade lubricant and cause it to migrate away from critical areas.

- Operating Environment: Dirty, humid, or contaminated environments demand more aggressive maintenance schedules than clean, climate-controlled facilities.

After relubrication, especially for high-speed spindles, use a run-in period. Start the spindle at a reduced speed to allow the grease to distribute evenly before gradually increasing to full speed. Monitoring bearing temperature provides real-time feedback on your lubrication program’s effectiveness.

Selecting the Best Grease and Understanding Bearing Types

Choosing the right grease is as important as knowing how to grease spindle bearings. Grease is an engineered mixture of a base oil, a thickener, and additives. Its NLGI grade indicates its consistency. Using the wrong grease can lead to premature bearing failure.

Key Factors in Industrial Grease Selection

Several factors guide grease selection for precision spindles:

- Base Oil Type: Mineral oils are suitable for standard applications (-30°C to +110°C). Synthetic oils are better for extreme temperatures and high speeds, offering superior oxidation resistance and longevity.

- Thickener Type: Lithium thickeners are common and versatile. Polyurea thickeners excel in high-speed, high-temperature applications. Calcium sulfonate thickeners offer excellent water resistance and extreme pressure protection.

- Operating Conditions: Consider the full operating temperature range. For heavy loads, use greases with Extreme Pressure (EP) additives. For humid environments, prioritize water resistance.

Crucially, never mix different grease types unless confirmed compatible by the manufacturer. Incompatible greases can react chemically, destroying their lubricating properties. When in doubt, flush the old grease completely.

How to Grease Spindle Bearings Based on Their Type

Proper technique depends on the bearing configuration:

- Open Bearings: These have no shields or seals. They are often lubricated by other means (e.g., oil baths), but if greased manually, the grease must be worked thoroughly into all rolling elements.

- Shielded Bearings (Z or ZZ-type): Non-contact metal shields offer some protection but allow for relubrication. In harsh environments, periodic greasing helps flush out contaminants. Apply grease slowly until old grease purges, then clean the excess.

- Sealed Bearings (RS or 2RS-type): These have rubber contact seals and are typically “greased for life” from the factory. Do not attempt to add more grease, as this can damage the seals and cause premature failure.

Always identify the bearing type before starting. A grease fitting (zerk) usually indicates the bearing is relubricable, but always confirm with the equipment manual to avoid costly mistakes.

Common Mistakes and Best Practices for Greasing Spindle Bearings

Most catastrophic bearing failures are preventable. The difference between a long-lasting spindle and a failed one often comes down to following best practices and avoiding common mistakes.

Best Practices

- Maintain Extreme Cleanliness: Contamination is the biggest enemy. A tiny speck of dirt acts like sandpaper inside a precision bearing. Always clean the grease nipple and surrounding area before connecting a grease gun.

- Use Dedicated and Clean Tools: Use separate, clean grease guns for different grease types to prevent cross-contamination. Use clean implements to extract grease from bulk containers.

- Follow a Strict Schedule: Perform preventative maintenance based on OEM recommendations and operating conditions. Don’t wait for signs of distress.

- Document Everything: Keep detailed records of when each spindle was greased, the type and quantity of grease used, and any observations. This data is invaluable for troubleshooting.

- Proper Grease Storage: Keep grease containers sealed tightly in a cool, dry, clean environment to prevent contamination of your supply.

Common Mistakes to Avoid

- Using the Wrong Grease Type: Automotive grease has no place in a high-precision industrial spindle. Use only the grease specified for the application’s speed, load, and temperature.

- Mixing Incompatible Greases: This can cause a chemical reaction that destroys the lubricant’s properties. Always ensure compatibility or completely purge the old grease first.

- Over-greasing or Under-greasing: Both extremes lead to failure. Over-greasing causes heat and seal damage, while under-greasing causes metal-to-metal contact and wear.

- Introducing Contaminants: Dirty tools, an unclean work area, or failing to clean the grease nipple can introduce abrasive particles that accelerate wear.

- Ignoring Manufacturer Recommendations: OEM guidelines on grease type, quantity, and frequency are based on extensive testing. Ignoring them can void warranties and cause preventable failures.

- Failing to Purge Old Grease: In relubricable bearings, failing to purge leaves old, contaminated lubricant inside to continue causing damage.

- Greasing “Sealed for Life” Bearings: Attempting to force grease into a sealed bearing will damage the seals, leading to rapid failure.

Conclusion

Mastering how to grease spindle bearings transforms a maintenance program. It’s a fundamental skill that separates successful manufacturing operations from those plagued by downtime. Each time you properly lubricate a bearing, you are extending your machinery’s life and preventing emergency failures.

The principles are simple, but the consequences of error are severe. Over-greasing can cause just as much damage as under-greasing. The key is using the right grease, in the right amount, at the right time.

Our experience in industrial manufacturing spindle repair shows that most bearing failures are preventable. The fundamentals are universal across all industries, from aerospace to agriculture: maintain extreme cleanliness, follow manufacturer specifications, and never mix incompatible greases.

At MZI Precision, we’ve rebuilt spindles for every sector, including defense and solar energy. The longest-lasting spindles consistently come from facilities that prioritize proper lubrication. This practice is not just about preventing downtime; it’s about maximizing your spindle’s lifespan and return on investment.

When you grease a spindle, you are actively protecting your bottom line and ensuring production continuity. It’s the hallmark of a proactive and thriving manufacturing operation.

For expert spindle repair and maintenance services, contact us today.