Why Dual Spindle CNC Machines Are Revolutionizing Modern Manufacturing

A dual spindle cnc machine combines two spindles in one system to dramatically boost productivity and reduce cycle times. Here’s what you need to know:

Key Benefits:

– 60% faster cycle times compared to single-spindle setups

– 70% less floor space than running separate machines

– 50% energy savings through consolidated operations

– Continuous processing with automatic part transfer

– Reduced part handling improves accuracy and consistency

Main Types:

– Twin spindle – parallel spindles for identical operations

– Sub-spindle – main + secondary for sequential operations

– Multi-spindle – 3+ spindles for high-volume production

In today’s competitive manufacturing landscape, machine shops face constant pressure to increase throughput while maintaining precision. Traditional single-spindle machines often leave operators waiting during tool changes or secondary operations.

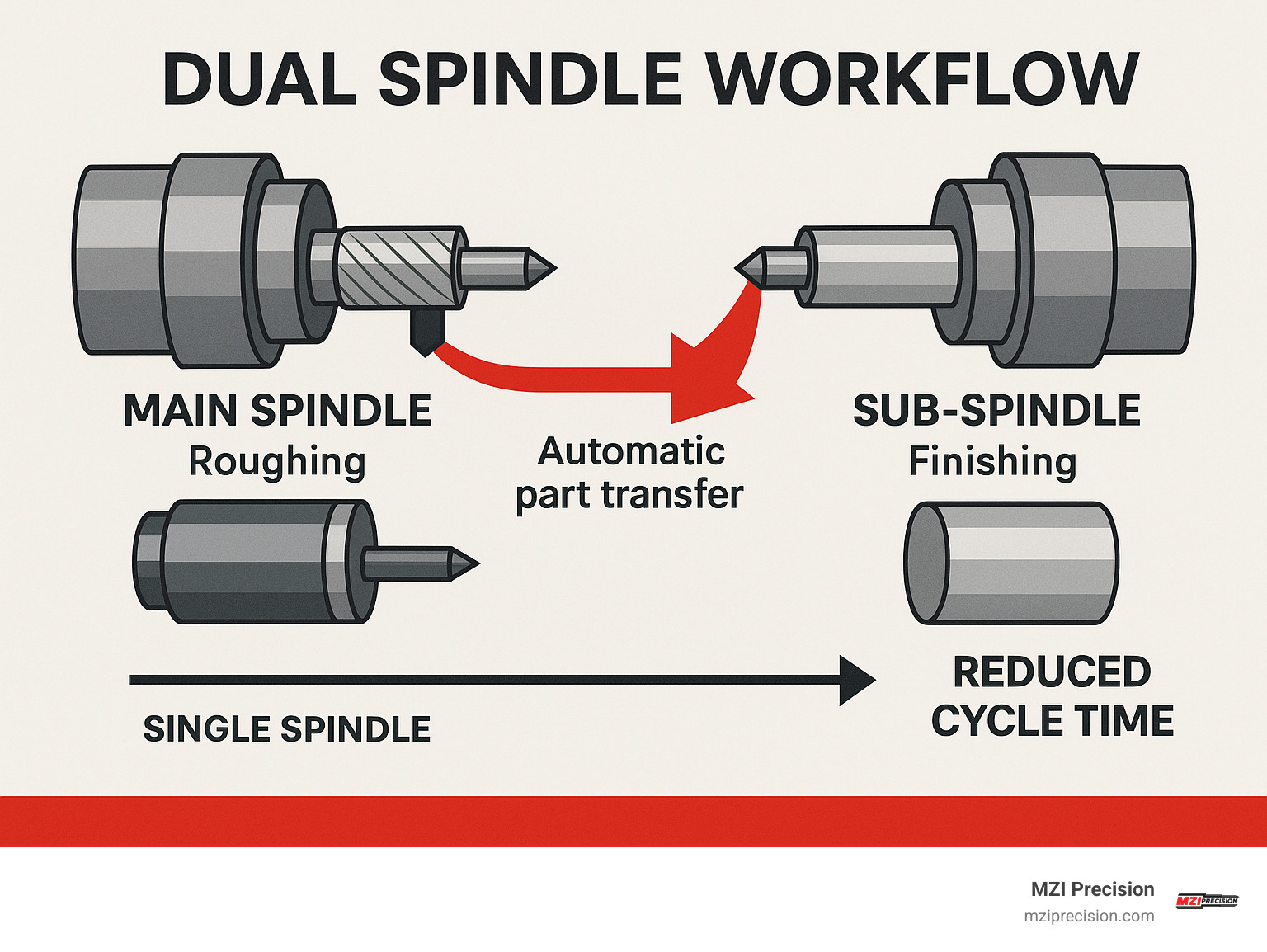

Dual spindle systems solve this by enabling simultaneous machining operations. While one spindle performs rough turning, the second can handle finishing work on a previously machined part. This eliminates idle time and creates a continuous workflow.

The technology has proven especially valuable in aerospace manufacturing, where complex components require multiple operations. As one industry expert noted: “Dual-spindle machines boost productivity by minimizing component handling, allowing automatic transfer of parts from one chuck to another for secondary processes.”

For manufacturers evaluating these systems, understanding the different configurations and their specific advantages is crucial for making the right investment decision.

Essential dual spindle cnc machine terms:

– cnc multi spindle machine

– machine spindle

– maximum spindle speed in cnc machine

What Is a Dual Spindle CNC Machine?

Think of a dual spindle CNC machine as having two expert machinists working on the same part at once – except they never get tired, never make mistakes, and can hand off work with perfect precision. This turning center uses two spindles working together to perform multiple operations either at the same time or in sequence.

Here’s where it gets interesting: while your main spindle is busy roughing out a new part, the sub-spindle (sometimes called the secondary or pick-off spindle) can be finishing the previous part. It’s like having a perfectly choreographed dance where no one steps on anyone’s toes.

The main spindle vs sub-spindle setup creates a powerful workflow. Your main spindle typically handles the heavy lifting – roughing operations, initial turning, and primary shaping. Meanwhile, the sub-spindle focuses on the detail work: finishing operations, back-working, drilling, and tapping.

When you compare this to a single-spindle machine, the difference is night and day. Traditional machines can only work on one part at a time, leaving you with dead time during tool changes and setup. Dual spindle systems eliminate this waste by keeping both spindles busy.

The magic happens during simultaneous cutting operations. Industry data shows that well-designed dual spindle systems can reduce cycle times by up to 60% compared to running separate single-spindle machines. That’s not just faster – that’s changeal for your bottom line.

Part transfer between spindles occurs automatically through synchronized movements. The sub-spindle approaches the main spindle, grabs the partially completed part with millimeter precision, and moves it to its working position. This handoff maintains positional accuracy that would be impossible with manual handling.

For manufacturers dealing with complex aerospace components or precision parts requiring multiple operations, this technology represents a significant leap forward. Scientific research on high-speed CNC spindles shows how modern spindle technology enables these systems to maintain exceptional precision even at high speeds.

Core Components of a dual spindle CNC machine

Understanding what makes these machines tick helps you get the most from your investment. Each component plays a crucial role in the synchronized ballet of dual spindle machining.

Spindle motors form the heart of the system. Each spindle gets its own dedicated motor, often with different power ratings custom to their specific jobs. Your main spindle might pack serious horsepower for heavy roughing work, while the sub-spindle could be optimized for precision finishing operations. Modern systems can reach speeds up to 6,000 RPM on the sub-spindle without breaking a sweat.

Chuck systems on both spindles must be perfectly matched – same size, same through-bore capacity, same clamping characteristics. This isn’t just convenience; it’s essential for seamless part transfer. The chucks maintain consistent clamping force during handoff, preventing any part movement that could ruin your precision.

Multiple axes give these machines their versatility. Most dual spindle systems feature Y-axis and C-axis capabilities on both spindles. The C-axis provides rotational positioning for radial operations like cross-drilling, while the Y-axis lets you machine off-centerline features. It’s like having a mill and lathe rolled into one.

Turret and tool changer systems can handle impressive tool loads. Advanced configurations support up to 12 driven tool stations per turret, enabling multiple cutting operations simultaneously. More tools mean fewer interruptions and faster cycle times.

Synchronization sensors keep everything running safely and precisely. These sensors monitor spindle position, speed, and timing to ensure collision-free part transfer. They’re the safety net that lets these machines run at high speeds without anxiety.

Workflow of a dual spindle CNC machine

The workflow of a dual spindle CNC machine shows why these systems achieve such impressive productivity gains. It’s a continuous cycle that eliminates the start-stop nature of traditional machining.

Loading begins when raw material – often bar stock – feeds into the main spindle chuck. The machine grips the material securely and begins the first phase of operations.

Roughing operations happen on the main spindle. Heavy cutting, initial turning, and primary shaping remove the bulk of excess material. While this happens, the sub-spindle might be finishing the previous part.

Part hand-off is where the magic happens. The sub-spindle approaches the main spindle with choreographed precision, grabs the partially completed part, and transfers it to its own working position. This happens automatically, maintaining perfect positioning.

Finishing work begins immediately on the sub-spindle. Back-working operations, precision drilling, tapping, and final finishing operations complete the part while the main spindle starts fresh with new material.

Unloading completes the cycle as the finished part drops into your collection bin. But here’s the beauty – by this time, the main spindle is already deep into machining the next part, creating a continuous flow of completed components.

This overlapping workflow maximizes machine utilization and eliminates the idle time that plagues single-spindle operations. It’s efficiency in motion.

Types & Configurations of Dual Spindle Systems

When it comes to dual spindle cnc machine configurations, manufacturers have several proven architectures to choose from. Each design serves different production needs, and understanding these options helps you make the right investment decision for your shop.

Twin-spindle machines represent the most straightforward approach. These systems feature two identical spindles working side by side, perfect for producing matching parts or running the same operations simultaneously. Think of them as having two machines in one frame – you get double the productivity without doubling your floor space.

The sub-spindle configuration takes a different approach entirely. Here, you have a powerful main spindle handling heavy roughing work, paired with a smaller, more precise secondary spindle for finishing operations. This setup shines when you need to complete complex parts that require both aggressive material removal and delicate final machining.

Multi-spindle centers push productivity even further by incorporating three, four, or even more spindles. These systems can achieve remarkable cycle time reductions – some four-spindle configurations deliver 60% faster processing while using 70% less floor space than running separate single-spindle machines.

For shops needing maximum versatility, horizontal and vertical combination systems merge different spindle orientations in one machine. This clever arrangement enables five-sided machining in a single setup, eliminating multiple fixtures and the time-consuming setups they require.

Multi-turret systems represent the cutting edge of dual spindle technology. These machines combine multiple spindles with several tool turrets, allowing simultaneous cutting with multiple tools. Advanced configurations can operate up to three turrets at once, creating what engineers call “superimposed machining” – a fancy term for getting a lot more work done in less time.

Twin vs. Sub vs. Multi-Spindle Architectures

Twin spindle systems position their spindles on parallel beds, making them ideal for symmetrical parts or high-volume production of similar components. The parallel arrangement keeps programming straightforward and makes automation integration much easier. If you’re running lots of identical parts, this configuration often provides the best return on investment.

Sub-spindle architectures use an entirely different philosophy. The spindles face each other, enabling direct part transfer without any repositioning gymnastics. This facing arrangement excels at continuous workflow processing and opens up possibilities for back-working operations that single-spindle machines simply cannot handle.

Multi-spindle modules arrange three or more spindles in various patterns – linear, circular, or custom configurations based on your specific needs. These systems target ultra-high volume production where you can machine multiple identical parts simultaneously. Yes, the complexity increases with each additional spindle, but so does your potential for dramatic productivity gains.

Specialty Dual Spindle CNC Machine Arrangements

Bar-fed lathes integrate dual spindles with automatic bar feeding systems, creating a manufacturing setup that can run for hours without operator intervention. These systems excel at lights-out manufacturing of turned components, letting you maximize productivity during off-shifts.

Gantry-loaded cells combine dual spindles with robotic loading systems that create fully automated production cells. The gantry robot loads raw material into one spindle while the other completes machining, maintaining continuous operation without human intervention.

Mill-turn centers merge dual spindle turning capabilities with full milling functions, incorporating Y-axis, C-axis, and live tooling. These versatile systems can complete complex parts that traditionally required multiple machines and setups, consolidating your entire process into one efficient operation.

Productivity, Footprint & Cost Advantages

When manufacturers invest in a dual spindle CNC machine, they’re not just buying faster cycle times – they’re changing their entire production approach. The benefits ripple through every aspect of manufacturing operations, creating value that compounds over time.

The magic happens through simultaneous operations. Picture this: while your traditional single-spindle machine sits idle during tool changes, a dual spindle system keeps cutting metal. One spindle rough-turns a new part while the other finishes the previous piece. This continuous action can slash cycle times by up to 60% compared to running separate single-spindle machines.

Part handling becomes virtually eliminated, and that’s huge for quality. Every time an operator moves a part between machines, there’s risk. Risk of dropping it, risk of positioning errors, risk of contamination. Dual spindle systems grab parts automatically and transfer them with precision that human hands simply can’t match. The result? Better parts and fewer rejects.

Here’s something that surprises many shop owners: single-setup accuracy means complex parts get completed without ever leaving the machine. No more worrying about how well that second setup will align with the first. No more scrapped parts because the operator couldn’t quite get the positioning right. The dual spindle CNC machine holds everything in perfect relationship throughout the entire process.

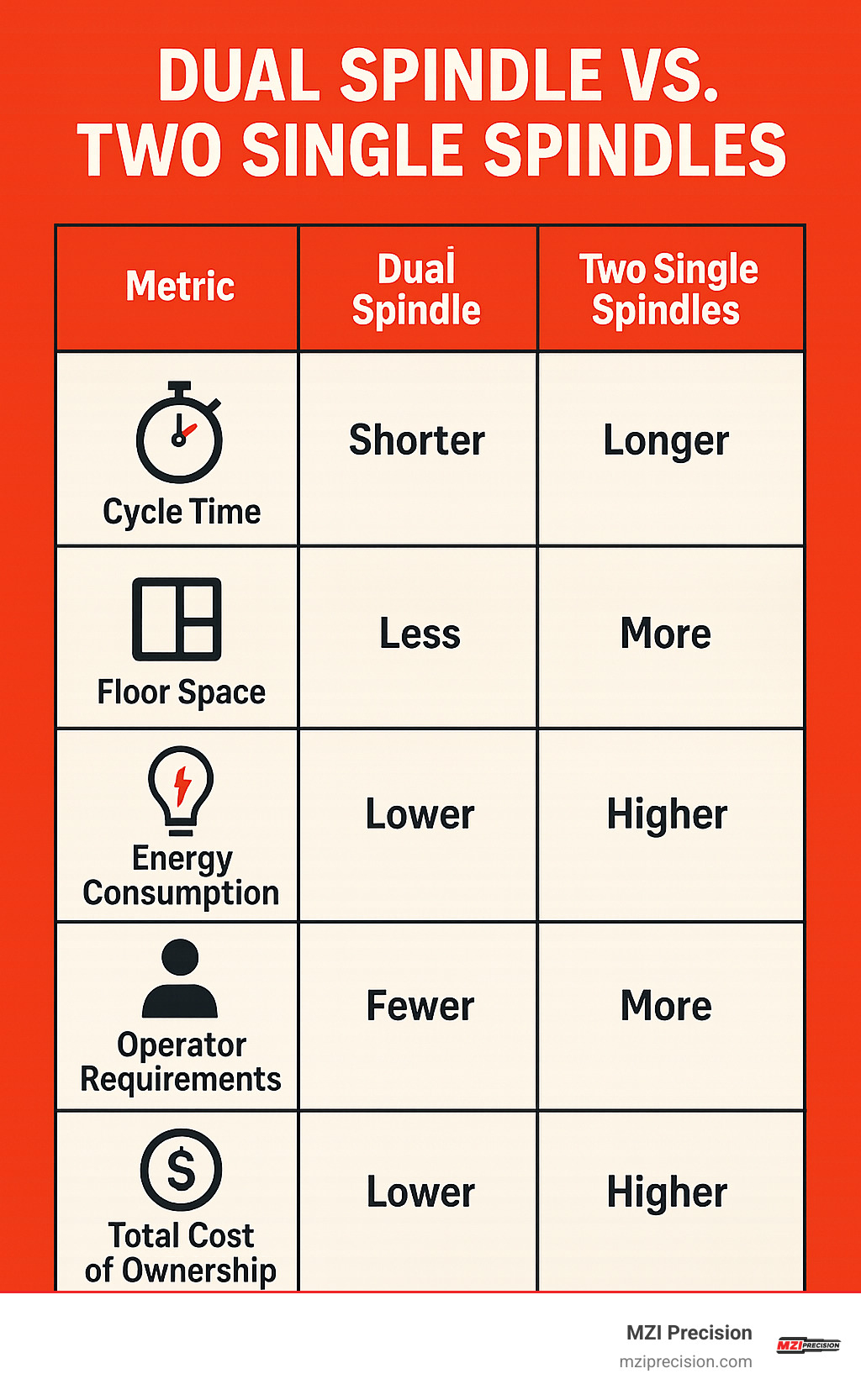

Floor space costs money – sometimes serious money. A four-spindle system uses about 70% less floor space than four separate machines while producing the same output. In facilities where every square foot matters, this efficiency can make or break a project’s economics.

Energy bills tell an interesting story too. Running one consolidated dual spindle system instead of two separate machines typically cuts energy consumption by around 50%. That’s not just good for the environment – it’s money back in your pocket every month.

Quantifying Cycle-Time Gains

Smart manufacturers use balanced cutting to squeeze every second of productivity from their dual spindle systems. While one spindle handles the heavy roughing work, the other performs delicate finishing operations. This prevents bottlenecks and ensures both spindles earn their keep.

Superimposed machining takes things even further. Advanced systems can run three tools simultaneously – imagine cutting with tools on both turrets plus the sub-spindle at the same time. This aggressive approach can reduce cycle times by 40-50% compared to traditional sequential operations.

The real game-changer comes with lights-out production. Dual spindle systems paired with bar feeders can run unattended for entire shifts. Some manufacturers report 16-hour unmanned operations, dramatically boosting overall equipment effectiveness. Your machines work while you sleep – that’s the kind of productivity that changes businesses.

Modern systems like the TTS-46 twin spindle lathe demonstrate just how far this technology has advanced. These machines reach 5,000 RPM in just 1.75 seconds, with acceleration times cut in half compared to older models. Every second saved in acceleration is another second spent cutting metal and making money.

The math becomes compelling quickly. When cycle times drop by 60%, floor space requirements shrink by 70%, and energy costs fall by 50%, the return on investment often justifies itself within the first year of operation.

Programming, Synchronization & Automation

Getting a dual spindle CNC machine to work smoothly feels a bit like conducting an orchestra. You need both spindles to work together perfectly, timing their moves just right while avoiding any collisions. The good news? Modern controls make this coordination much easier than it sounds.

The biggest difference from single-spindle programming is that you’re now managing two separate work areas that need to communicate with each other. Think of it like having two skilled machinists working on the same part – they need to know exactly when to hand off the workpiece and when to stay out of each other’s way.

G-code mirroring simplifies the programming process significantly. Instead of writing completely separate programs for each spindle, you can use special commands like G14 to mirror operations from the main spindle to the sub-spindle. This saves tremendous programming time, especially since the sub-spindle often performs similar operations but from the opposite direction.

Spindle synchronization relies on commands like G199 to keep both spindles perfectly coordinated. Modern CNC controls can synchronize spindles at speeds up to 4,800 RPM, which means you can transfer parts quickly without sacrificing precision. This synchronization is what makes those impressive cycle time reductions possible.

Multi-channel controls give you the flexibility to program each spindle independently while maintaining overall coordination. Advanced systems feature separate channels for each spindle plus additional channels for turret control. This setup enables truly simultaneous operations – imagine having three different cutting operations happening at once.

Toolpath simulation becomes absolutely critical with dual spindle systems. With multiple spindles, turrets, and tools moving simultaneously, the potential for collisions increases dramatically. Modern CAM software includes specialized collision detection designed specifically for dual spindle CNC machine configurations. Running these simulations saves both time and expensive crashes.

Automation integration transforms these machines from simple lathes into complete manufacturing cells. Bar feeders supply raw material continuously while robots or gantry systems handle part removal. This integration enables the extended unattended operation that makes dual spindle systems so attractive for high-volume manufacturing.

Programming Tips for a Dual Spindle CNC Machine

Programming these systems successfully requires understanding a few key differences from traditional single-spindle work. The most important concept to grasp is how the positive Z orientation works on the sub-spindle.

While the main spindle uses negative Z values for cutting moves (moving toward the chuck), the sub-spindle typically uses positive values due to its reversed orientation. This reversal catches many programmers off guard initially, but it becomes second nature with practice.

Tool offset mapping ensures accurate positioning when operations transfer between spindles. Each spindle requires its own tool offset tables, and you must account for any differences in spindle positioning or chuck runout. Taking time to properly map these offsets prevents positioning errors that could scrap expensive parts.

Safety interlocks prevent collisions between spindles, turrets, and tooling. Modern controls include built-in collision avoidance, but programmers still need to understand the machine’s work envelope and potential interference zones. A good rule of thumb: if you’re not sure whether something will clear, simulate it first.

The most successful dual spindle programs follow a systematic approach. Start by establishing timing relationships between spindles, verify clearances throughout the entire cycle, and test programs thoroughly using simulation before running any production parts. This methodical approach prevents costly mistakes and builds confidence in your programming.

Automation Road Map for Dual Spindle CNC Machine Users

Unattended shifts represent the ultimate goal for most dual spindle installations. Achieving this level of automation requires reliable bar feeding, automatic part removal, and robust process monitoring. Many manufacturers successfully run 16-hour unattended shifts with properly configured systems.

The path to full automation typically follows a logical progression. Start with basic dual spindle operation to master the fundamentals. Next, integrate bar feeding to eliminate manual material loading. Then add part removal automation to handle finished components. Finally, implement process monitoring and quality control systems for complete lights-out capability.

Part conveyors integrate seamlessly with dual spindle systems to create complete production lines. Parts move automatically from the machine to secondary operations like deburring, washing, or inspection without any manual handling. This automation eliminates bottlenecks and keeps production flowing smoothly.

In-process gauging enables real-time quality control without stopping production. Modern systems can measure critical dimensions during machining and automatically adjust tool offsets to maintain tolerances throughout extended production runs. This capability is especially valuable during unattended operation when operators aren’t available to make manual adjustments.

The beauty of this automation roadmap is that each step builds on the previous one. You don’t need to implement everything at once – you can gradually add capabilities as your comfort level and production requirements grow. This staged approach makes the investment more manageable while still delivering meaningful productivity improvements at each level.

Selecting, Specifying & Maintaining Your Dual Spindle Investment

Investing in a dual spindle CNC machine is like choosing a business partner – you want someone reliable who’ll grow with you over the years. The decision you make today will shape your production capabilities, floor space efficiency, and operational costs for decades to come.

Think of spindle specifications as the heart of your machine. Main spindles typically pack more punch with 30 HP motors designed for heavy roughing work, while sub-spindles operate with 15-20 HP focused on precision finishing. It’s like having a powerlifter and a surgeon working side by side – each excels at what they do best.

Speed matters, but it’s not everything. Modern systems reach 6,000 RPM on sub-spindles and 4,500 RPM on main spindles, but the real magic happens in the torque delivery. Direct-drive motors eliminate belts and provide consistent power across the entire speed range, giving you smooth performance whether you’re roughing steel or finishing aluminum.

Y-axis and C-axis capabilities transform your turning center into something much more versatile. The Y-axis lets you mill slots and perform off-centerline operations, while the C-axis enables radial drilling and tapping. Suddenly, your lathe becomes a complete mill-turn center that can handle complex parts in a single setup.

Don’t overlook thermal management – it’s the unsung hero of precision machining. Heat isolation systems separate hot components from precision elements, while spindle chillers maintain thermal stability. Without proper thermal control, your spindles will grow with heat, throwing off dimensional accuracy just when you need it most.

At MZI Precision, we’ve rebuilt countless spindles from dual spindle machines across aerospace, defense, and industrial manufacturing. We’ve seen how proper specification and maintenance directly impact long-term performance and reliability.

Key Specification Checklist

Your work envelope needs to accommodate not just today’s parts, but tomorrow’s opportunities too. Standard configurations handle parts up to 10″ chuck diameter with 3″ bar capacity, but don’t box yourself in if your business might grow into larger components.

Bar capacity affects both the parts you can make and material waste. Larger bar capacity means longer parts and less cutoff waste, but it also means more floor space and higher machine costs. Balance your current needs with realistic growth projections.

Turret stations determine your tooling flexibility. The TTS Series features 12 driven tool stations, which sounds like a lot until you start planning complex operations. More stations mean fewer tool changes, but they also increase turret size and complexity. Count the tools you typically use and add a buffer for future needs.

Modern controller features can make or break your productivity. Built-in collision avoidance, spindle synchronization, and simulation capabilities aren’t luxuries – they’re necessities for efficient dual spindle operation. Make sure your controller supports the automation features you’re planning to implement.

Common Challenges & Solutions

Let’s be honest – dual spindle programming is more complex than single-spindle work. You’re coordinating multiple axes, timing operations, and preventing collisions. The solution isn’t to avoid the complexity, but to accept it with proper CAM software designed for dual spindle machines. G-code mirroring features can simplify programming by automatically adapting main spindle programs for sub-spindle use.

Tool interference keeps many operators awake at night, especially when multiple turrets operate simultaneously. The key is careful tooling selection and thorough simulation before cutting your first chip. Modern controls include interference checking, but they can’t replace good planning and common sense.

Heat management becomes critical when multiple spindles generate heat simultaneously. This is where our experience at MZI Precision really shows its value. We’ve seen what happens when thermal management fails – spindles lose accuracy, tool life suffers, and maintenance costs skyrocket. Proper coolant systems and thermal barriers aren’t optional extras.

Chip evacuation might seem simple, but it’s surprisingly challenging with multiple cutting operations happening at once. Design your chip flow paths carefully and ensure adequate coolant flow. Nothing stops production faster than chips jamming up the works.

The good news? These challenges are entirely manageable with proper planning. The key is understanding them during specification rather than finding them after your machine arrives on the shop floor. That’s why we always recommend working with experienced partners who understand both the opportunities and pitfalls of dual spindle technology.

Frequently Asked Questions about Dual Spindle CNC Machines

What operations can run simultaneously?

The beauty of a dual spindle cnc machine lies in its ability to keep both spindles busy while you’re producing parts. Think of it like having two skilled machinists working on different stages of the same project at once.

Turning operations represent the most straightforward simultaneous work. Your main spindle tackles the heavy roughing cuts on fresh material while the sub-spindle performs precision finishing on a part that’s already been roughed. This eliminates those frustrating moments when expensive equipment sits idle.

Drilling and tapping work particularly well on the sub-spindle during simultaneous operations. While your main spindle continues primary turning, the sub-spindle can drill cross-holes, tap threads, or create radial features. This capability proves invaluable for hydraulic components and complex fittings that need multiple hole patterns.

Milling operations become possible when both spindles feature live tooling. One spindle might cut keyways while the other machines flats or slots on a different part. The versatility transforms your turning center into a complete machining solution.

Secondary operations like back-working, chamfering, or threading happen naturally on the sub-spindle while the main spindle starts fresh material. This continuous workflow maximizes your machine investment by eliminating traditional setup and handling time.

The secret to success lies in balancing cycle times between spindles. When both spindles finish their work at roughly the same time, you maintain that smooth, continuous workflow that makes dual spindle systems so productive.

How does part transfer affect accuracy?

Many manufacturers worry that transferring parts between spindles might introduce accuracy problems. The reality is quite the opposite – modern dual spindle cnc machine systems actually improve accuracy compared to manual part handling.

Synchronized RPM control ensures both spindles rotate at identical speeds during transfer, typically up to 4,800 RPM. This synchronization prevents any relative motion that could damage parts or create positioning errors. It’s like two dancers moving in perfect harmony.

Clamp force control maintains the delicate balance between secure holding and part distortion. The receiving spindle applies just enough force to hold the part securely without causing deformation. Modern systems monitor and adjust this force automatically throughout the transfer.

Positional repeatability in quality dual spindle systems reaches ±0.0000787″ or better. This precision means parts maintain accurate positioning throughout the entire transfer process. Compare this to manual part handling, where human variability can introduce much larger positioning errors.

Thermal compensation addresses the reality that spindles heat up during operation. Advanced systems monitor thermal growth in both spindles and compensate automatically, maintaining accuracy even during extended production runs.

The automatic transfer actually eliminates the quality variations that occur with manual part repositioning. No more wondering if the operator positioned the part correctly – the machine handles it with consistent precision every time.

What automation options fit dual spindles best?

Choosing the right automation for your dual spindle cnc machine depends on your production volume, part complexity, and budget. The good news is that dual spindle systems work exceptionally well with various automation approaches.

Bar feeders represent the most popular first step into automation. These systems supply continuous raw material, enabling those coveted lights-out shifts that maximize your equipment investment. The continuous workflow of dual spindle machines makes bar feeders particularly effective – there’s no wasted motion or idle time.

Gantry robots provide ultimate flexibility for complex automation needs. These systems handle raw material loading, finished part removal, and can even perform secondary operations like deburring or basic inspection. Gantry systems work well with dual spindle machines because they can efficiently service both spindles without interference.

Collaborative robots offer an affordable entry point for smaller operations. These cobots can safely work alongside operators, handling part loading and unloading while adapting to different part mixes. Their flexibility makes them ideal for job shops running varied work on dual spindle systems.

Pallet pool systems suit specialized applications where complex workpieces require multiple setups. While less common with turning operations, some dual spindle mill-turn centers benefit from pallet automation for prismatic parts.

The best automation choice depends on your specific situation. Many successful installations start with basic bar feeding and gradually add more sophisticated automation as production volumes justify the investment. At MZI Precision, we’ve seen how proper automation transforms dual spindle machines into highly productive manufacturing cells that run reliably for extended periods.

Conclusion

Dual spindle CNC machines have fundamentally changed how smart manufacturers approach production challenges. These sophisticated systems deliver impressive results – 60% faster cycle times while taking up 70% less valuable floor space than traditional setups.

The real magic happens when you match the right configuration to your specific needs. Twin spindle systems excel at high-volume identical parts, while sub-spindle configurations shine with complex multi-operation components. Getting this match right transforms your entire production capability.

Yes, programming these systems requires more thought than single-spindle machines. But modern controls and CAM software have eliminated most of the traditional headaches. The upfront investment in proper setup and training pays back quickly through dramatically improved throughput and reduced operator babysitting.

Here’s where things get serious: maintenance becomes absolutely critical with dual spindle CNC machines. The complexity means downtime costs more, but it also means prevention pays bigger dividends. Precision uptime isn’t just a nice phrase – it’s the difference between profit and frustration.

At MZI Precision, we’ve rebuilt spindles from dual spindle systems across aerospace, defense, and manufacturing facilities. We understand that when one spindle goes down, your entire productivity advantage disappears. That’s why industrial manufacturing spindle repair and rebuilding expertise matters so much with these investments.

The spindles in dual spindle systems work harder and longer than their single-spindle cousins. They need proactive care to maintain the precision these systems promise. Service life depends on catching problems early and addressing them with proper expertise.

Whether you’re evaluating your first dual spindle machine or maximizing an existing installation, having single-source support for spindle services protects your investment. We’ve seen too many shops struggle with downtime because they didn’t plan for comprehensive spindle maintenance.

The manufacturing landscape increasingly rewards efficiency without compromising quality. Dual spindle CNC machines deliver both advantages, making them essential for manufacturers who want to stay competitive.

For more information about keeping your dual spindle system running at peak performance through expert industrial manufacturing spindle rebuilding services, visit our More info about our CNC spindle services page. Our team brings decades of hands-on experience to help you maximize every aspect of your dual spindle investment.

The future belongs to manufacturers who work smarter, not just harder. Dual spindle technology represents that evolution – and proper spindle support ensures you realize every benefit these remarkable machines offer.