Why AC Servo Motors Are Essential for Precision CNC Operations

AC servo motors are the precision powerhouses behind modern CNC machines, delivering the exact control needed for high-quality manufacturing. These closed-loop systems combine electric motors with feedback sensors to achieve positioning accuracy that can detect errors as small as 4 mm over a 40 km rotation.

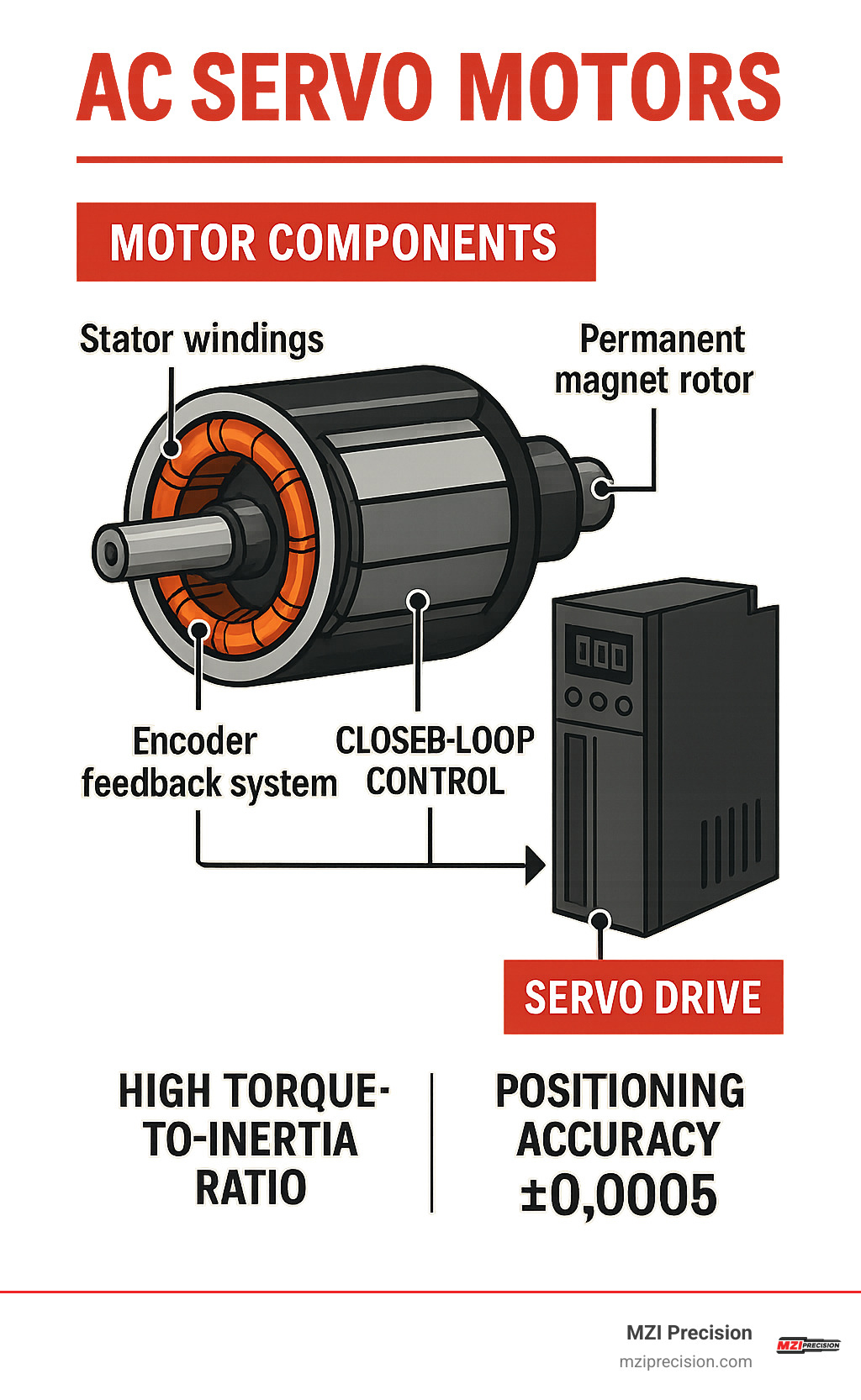

Key Features of AC Servo Motors:

– High torque-to-inertia ratio for rapid acceleration

– Closed-loop feedback control using encoders or resolvers

– 90% efficiency at light loads

– Power range from 50W to 7.5kW

– Speed capability up to 3000 RPM

– Positioning accuracy within 0.0005 inches

AC servo motors outperform stepper motors in precision applications because they continuously monitor and adjust their position through real-time feedback. This makes them ideal for CNC operations where even tiny positioning errors can ruin expensive workpieces.

The technology has evolved significantly since Yaskawa invented the first prototype in 1958. Today’s AC servo motors use permanent magnet synchronous designs with advanced digital signal processors (DSP) to optimize control loop performance.

For aerospace manufacturers and other precision industries, choosing the right AC servo motor can mean the difference between meeting tight tolerances and costly rework. The motor’s ability to maintain accuracy while delivering high dynamic response makes it indispensable for modern manufacturing.

AC Servo Motors 101: How They Drive CNC Precision

Think of AC servo motors as the ultimate perfectionist in your CNC machine shop. While other motors might get “close enough,” these precision workhorses obsess over every tiny detail, constantly checking and rechecking their position to make sure everything is exactly where it should be.

What makes them so special? It all comes down to their torque-to-inertia ratio and synchronous operation. Unlike basic motors that can slip and slide under load, AC servo motors lock onto their target speed with zero slip. The rotor spins in perfect harmony with the electromagnetic field, creating the rock-solid precision that aerospace and defense manufacturers depend on.

The secret sauce is in the feedback loop. These motors never work blind—they’re constantly getting updates about their actual position and making split-second adjustments. It’s like having a GPS system that updates thousands of times per second, ensuring you never drift off course.

Working Principle of ac servo motors

The beauty of AC servo motors lies in their closed-loop control system. Picture a conversation happening thousands of times per second between the motor and its control system, where they’re constantly asking “Where are we?” and “Where should we be?”

Here’s how this conversation unfolds: Your CNC controller sends a command signal to the servo drive, which acts like a translator, converting that signal into the right voltage and current for the motor. The stator windings then create a rotating magnetic field that pulls the permanent magnet rotor along for the ride.

But here’s where it gets interesting—high-resolution encoders are watching every move, measuring position down to fractions of degrees. When the system spots even the tiniest error, the PID control algorithms jump into action, making instant corrections faster than you can blink.

This rotor-field interaction combined with encoder feedback creates a system that can detect and correct positioning errors in microseconds. Even when cutting forces try to push the spindle off course, the motor fights back immediately to maintain precision.

Key Components Inside ac servo motors

Open up an AC servo motor and you’ll find some seriously impressive engineering. The stator windings are arranged in precise patterns—usually three phases spaced 120 degrees apart—that create smooth, consistent torque without the jerky motion you might get from simpler motors.

The heart of the system is the permanent magnet rotor, typically made with rare-earth magnets like Neodymium-Iron-Boron. These aren’t your refrigerator door magnets—they’re incredibly powerful and lightweight, which helps achieve that critical high torque-to-inertia ratio that makes rapid acceleration possible.

High-precision bearings keep everything spinning smoothly while handling both radial and axial loads. These aren’t ordinary bearings either—they’re often preloaded and sealed for life, designed to maintain accuracy even after millions of cycles.

The resolver or encoder is like the motor’s eyes and ears, providing position feedback with incredible accuracy. Some systems can detect position changes as small as 1/67 millionth of a full rotation. That’s the kind of precision that lets you machine parts to tolerances measured in thousandths of an inch.

When these components work together, they create a system that doesn’t just move—it moves with purpose, precision, and the kind of reliability that keeps production lines running smoothly day after day.

Product Roundup: Best-in-Class AC Servo Motor Families for CNC

Choosing the right AC servo motors for your CNC machine doesn’t have to be overwhelming. Think of it like picking the right engine for your car—you want something that matches your needs without being overkill (or underpowered).

The servo motor market is huge, with over 500,000 standard models available. That might sound intimidating, but it’s actually great news. This variety means you can find an off-the-shelf solution that performs like a custom unit without the custom price tag or long wait times.

We’ve broken down the top options by power class to make your decision easier. Whether you’re running a small benchtop machine or a massive gantry router, there’s a servo motor family designed for your specific needs.

Compact 400 W–1 kW AC Servo Motors for Benchtop CNC

Small CNC machines need motors that pack serious performance into tight spaces. The 400W to 1kW range hits that sweet spot perfectly, giving you professional-grade precision without taking over your entire workspace.

These compact powerhouses are built for quick acceleration, thanks to specially designed rotors that keep inertia low. Think of it as the difference between accelerating a sports car versus a loaded truck—less rotating mass means faster response times. This design also saves energy during those frequent start-stop cycles that are common in precision work.

Space efficiency is where these motors really shine. Most feature slim flange mounting with standardized mounting patterns between 40mm and 80mm. Many even offer both servo and stepper motor mounting holes, making retrofits surprisingly straightforward.

Don’t let the compact size fool you—these motors deliver impressive numbers. You’ll typically see rated torques from 0.6 to 3.8 N·m, with peak torques reaching up to 5.73 N·m. Speed capabilities range from 1500 to 3000 RPM, which is plenty for most precision applications.

These motors excel in PCB drilling, small part machining, and prototype development where every inch of space matters and moderate loads are the norm.

Medium 1 kW–5 kW AC Servo Motors for Production Mills

When you step up to production milling, you need motors that can handle the heat—literally and figuratively. The 1kW to 5kW range is where AC servo motors really show their industrial strength.

High continuous torque is the name of the game here. These motors typically deliver 3 to 15 N·m continuously, with peak torques reaching 45 N·m or higher. That’s enough muscle to power through heavy cutting operations without breaking a sweat.

Safety becomes crucial in production environments, which is why most motors in this class include dynamic braking systems. These electromagnetic brakes kick in automatically when power is cut, preventing dangerous runaway situations on vertical axes. It’s like having an emergency brake that never fails.

The feedback systems get serious upgrades too. Many models feature 25-bit absolute encoders or incremental encoders with over 100,000 counts per revolution. This level of precision lets you position parts to within micrometers—accuracy that would make a Swiss watchmaker proud.

These motors are built tough, with Class F insulation rated for 155°C and IP64 or higher environmental protection. They’re designed to keep running reliably in demanding production environments where downtime costs real money.

Heavy-Duty 5 kW+ AC Servo Motors for Gantry Routers

Large gantry systems don’t mess around, and neither do the AC servo motors that power them. These are the heavyweight champions of the servo motor world, built to handle the massive forces involved in aerospace and heavy manufacturing.

Direct-drive capability becomes a game-changer at this power level. By eliminating gearboxes, these systems eliminate mechanical backlash entirely while reducing maintenance headaches. It’s like having a direct connection between your control system and the cutting tool.

The torque numbers are impressive—continuous torques from 15 N·m up to 96 N·m, with peak torques exceeding 200 N·m. That’s enough power to handle the enormous cutting forces you encounter when machining titanium aerospace components or thick steel plates.

Thermal monitoring becomes critical at these power levels. Built-in sensors continuously monitor winding temperatures and automatically dial back performance if things get too hot. Some systems even include active cooling options for extreme duty cycles where standard air cooling isn’t enough.

For detailed specifications and application guides that dive deeper into these motor families, check out the Downloads on AC servo technology for comprehensive technical documentation.

How to Select and Size AC Servo Motors for Your CNC Build

Getting the right AC servo motors for your CNC build can feel overwhelming with all the technical specifications and calculations involved. But here’s the good news: following a systematic approach makes the process much more manageable and helps you avoid expensive mistakes down the road.

The secret is understanding your application’s unique requirements before diving into motor catalogs. Every CNC machine has different load-inertia characteristics, peak-torque demands, and duty-cycle patterns. Taking time upfront to analyze these factors ensures you select motors that deliver optimal performance without over-engineering (and overspending on) your system.

Think of motor sizing like choosing the right engine for a vehicle. A compact car doesn’t need a truck engine, and a heavy-duty truck won’t perform well with a motorcycle engine. The same principle applies to AC servo motors – matching the motor to your specific load and performance requirements is crucial for success.

Most selection mistakes happen when engineers underestimate peak torque requirements or ignore the importance of safety-factor calculations. Industry experience shows that motors sized too close to their limits often fail prematurely or can’t handle unexpected load variations during actual machining operations.

The wiring-voltage requirements also play a critical role in your selection process. Higher voltage systems typically offer better performance and efficiency, but they may require different safety considerations and electrical infrastructure in your facility.

| Specification | AC Servo Motors | DC Servo Motors |

|---|---|---|

| Efficiency | 90-95% | 75-85% |

| Maintenance | Low (brushless) | Higher (brush replacement) |

| Speed Range | 0-6000 RPM | 0-4000 RPM |

| Control Complexity | Moderate | Simple |

| Initial Cost | Higher | Lower |

| Operating Cost | Lower | Higher |

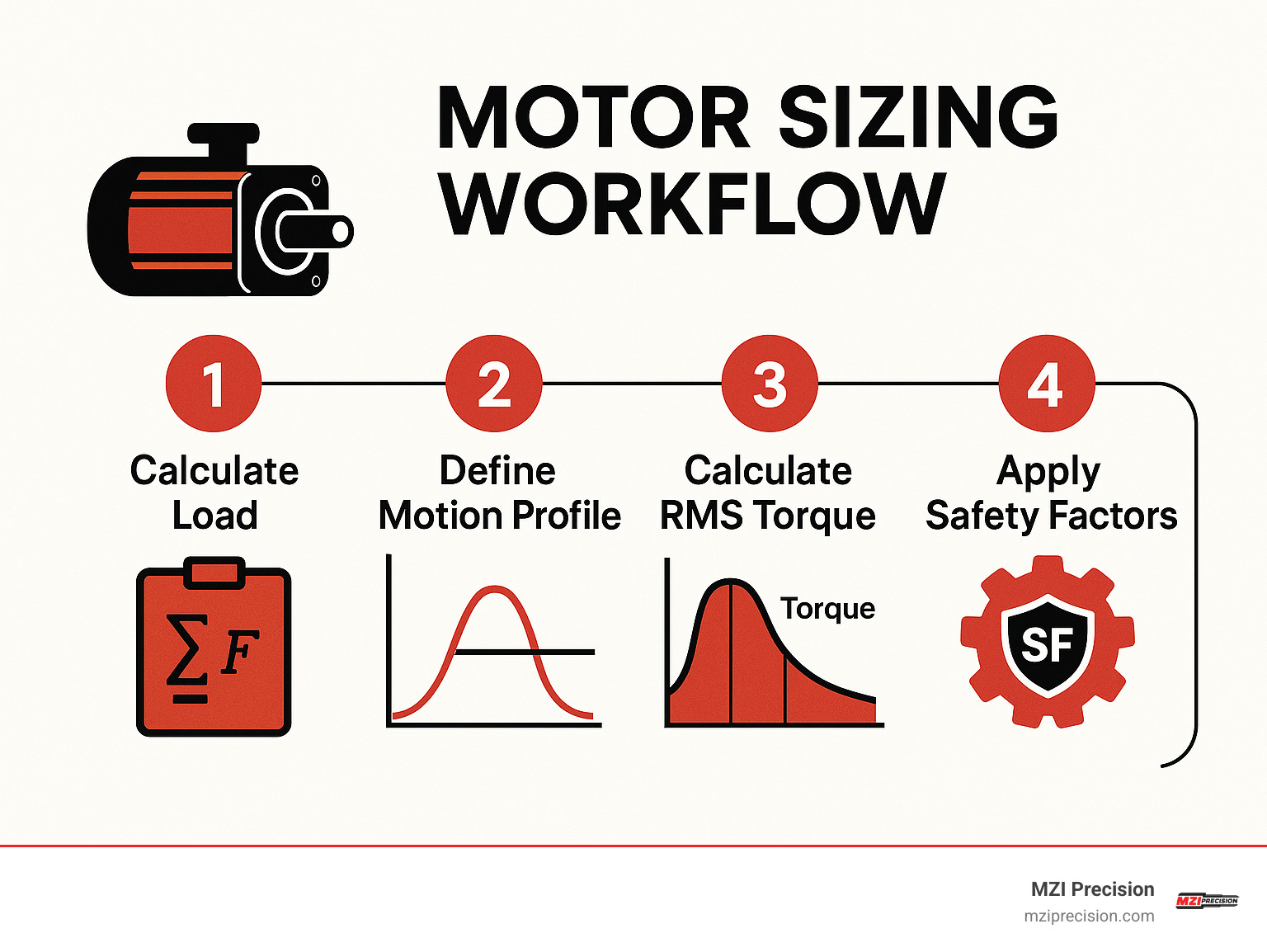

Step-by-Step Motor Sizing Workflow

The motor sizing process becomes straightforward when you break it down into manageable steps. Start by gathering information about your axis-mass and typical machining operations – this foundation data drives all subsequent calculations.

Calculating your total system inertia requires adding up all the rotating and moving masses that your motor will drive. This includes the obvious components like spindles and tool holders, but don’t forget about coupling systems, gearboxes, and the reflected inertia from linear axes. A common mistake is underestimating this total inertia, which leads to sluggish performance and positioning errors.

Defining your acceleration profile means understanding how quickly your axes need to start, stop, and change direction. High-speed machining operations typically require aggressive acceleration rates, while heavy cutting applications may prioritize torque over speed. Your typical feed rates and rapid traverse velocities directly impact motor selection.

RMS-torque calculations can seem intimidating, but they’re essential for ensuring your motor can handle the complete duty cycle without overheating. This involves analyzing the torque requirements during acceleration, cutting, deceleration, and holding phases of your typical machining cycle. The RMS value represents the effective continuous torque your motor must provide.

Smart engineers always apply generous safety factors to their calculations. Peak torque requirements should include at least a 2:1 safety margin, while continuous torque calculations benefit from 1.5:1 safety factors. These margins account for unexpected cutting forces, tool wear, and variations in material properties.

Matching Drives, Encoders, and Cables

Selecting the right servo-amplifier is just as important as choosing the motor itself. The drive must handle your motor’s current requirements while providing the control features your application demands. Modern servo drives include sophisticated algorithms that automatically optimize performance, but they still need to be properly matched to your motor specifications.

High-resolution encoders determine your system’s ultimate positioning accuracy. A practical guideline is choosing encoder resolution that’s at least four times finer than your required positioning accuracy. For precision manufacturing applications, this often means selecting encoders with 100,000 or more counts per revolution.

Shielded-cable selection might seem like a minor detail, but improper cabling causes more servo system problems than any other factor. Electromagnetic interference from poorly shielded cables can create mysterious positioning errors that are extremely difficult to troubleshoot. Always use manufacturer-specified cables and maintain proper separation from power conductors.

The integration process becomes much smoother when you work with suppliers who understand the complete system requirements. At MZI Precision, we’ve seen countless projects where careful motor selection and proper integration made the difference between a successful CNC build and months of troubleshooting headaches.

Integrating AC Servo Motors: Control, Feedback & Maintenance

Getting your AC servo motors properly integrated into your CNC system is where the magic really happens. It’s not just about bolting them on and plugging them in—though we wish it were that simple! The real performance comes from careful tuning, smart control setup, and staying on top of maintenance.

Think of it like tuning a high-performance race car. You’ve got all the right parts, but without proper setup, you’re leaving performance on the table. Modern servo systems give you incredible flexibility with position control for those precise positioning moves, speed control when you need constant velocity, and torque control for delicate operations like probing.

The beauty of today’s servo technology is that much of the complex setup work can be automated. But understanding what’s happening behind the scenes helps you get the most from your investment.

Closed-Loop Tuning for ac servo motors

Here’s where modern AC servo motors really shine. Most current servo drives include auto-gain tuning that takes the guesswork out of optimization. The system runs through a series of test moves, measures how your machine responds, and automatically calculates the best settings.

This process involves measuring system response, calculating optimal gain settings, implementing vibration suppression filters, and validating performance across your entire operating range. It’s like having an expert technician tune your system automatically.

Notch filtering is another game-changer. Advanced drives can detect mechanical resonances that might cause vibration or poor surface finish—then automatically suppress them. These adaptive filters continuously monitor your system and adjust filter parameters on the fly.

The goal with overshoot minimization is eliminating position overshoot while keeping fast settling times. This matters especially when you need rapid, accurate positioning between machining operations. Nobody wants their spindle overshooting and having to back up—it wastes time and can affect part quality.

Reliability & Service Tips

Keeping your servo motors running smoothly isn’t rocket science, but it does require attention to detail. Most modern servo motors use sealed bearings, but that doesn’t mean “set it and forget it.” Following the manufacturer’s lubrication schedule prevents those unexpected failures that always seem to happen right before a big deadline.

Typical bearing life ranges from 20,000 to 50,000 operating hours, depending on how hard you’re working them. That’s years of operation for most shops, but keeping track pays off.

Thermal monitoring becomes critical during high-duty-cycle applications. Many motors include built-in thermal sensors that the servo drive can monitor. Think of it as an early warning system—much better to slow down temporarily than to cook your motor windings.

Encoder alignment might sound technical, but it’s really about protecting your feedback system. Even small bumps or cable damage can throw off positioning accuracy. Regular calibration checks ensure your precision stays where it should be.

At MZI Precision, we see how proper maintenance extends equipment life. The same attention to detail that keeps servo motors running smoothly applies to industrial manufacturing spindles—preventive care always beats emergency repairs.

For the latest technical insights and servo system advances, check out these Videos on servo advancements that dive deeper into optimization techniques.

Frequently Asked Questions about AC Servo Motors for CNC

What makes ac servo motors better than stepper motors?

The difference between AC servo motors and stepper motors is like comparing a GPS-guided car to one following a map with no idea where it actually is. Servo motors know exactly where they are at all times, while stepper motors just hope they’re in the right place.

Closed-loop control is the game-changer here. While stepper motors operate blindly and can lose steps without knowing it, AC servo motors continuously monitor their position through encoder feedback. If a heavy cutting load tries to push the motor off position, the servo system instantly detects this and corrects it. No lost steps, no wondering if your part is still accurate.

Speed is another major advantage. Stepper motors start strong but lose torque quickly as speed increases—kind of like a weightlifter who’s great at slow movements but struggles to move fast. AC servo motors maintain their torque much better at higher speeds, allowing for faster rapids and more efficient machining cycles.

The efficiency difference is dramatic too. Servo motors can reach 90% efficiency at light loads, while steppers typically struggle to hit even 50%. This means less heat, lower power bills, and cooler running machines. Your spindle repair intervals might even stretch longer when the whole system runs cooler.

How often should encoder feedback be calibrated?

Think of encoder calibration like tuning a precision instrument—how often you do it depends on how precise you need to be and how hard you’re using it.

For high-precision manufacturing like aerospace components, monthly calibration checks make sense. When you’re holding tolerances tighter than a few microns, even tiny encoder drift can cause expensive scrap. These applications often use laser interferometry to verify positioning accuracy.

Most general manufacturing operations do well with quarterly verification and annual comprehensive calibration. This catches any gradual drift before it affects part quality. The key is tracking trends—if you notice positioning accuracy slowly degrading, it’s time for calibration regardless of the schedule.

Environmental factors can accelerate the need for calibration. Machines in harsh environments with temperature swings, heavy vibration, or contamination may need more frequent attention. Smart manufacturers implement condition monitoring that watches positioning accuracy continuously and alerts when calibration is needed.

The good news is that modern encoders are remarkably stable. Many can maintain accuracy for years with proper care and protection from damage.

Can one servo drive multiple axes?

While it’s technically possible to run multiple axes from one drive, it’s usually not the best approach for CNC machines. It’s like trying to steer a car while someone else controls the gas pedal—things can get complicated quickly.

Single-axis drives are the gold standard for CNC applications. Each axis gets its own dedicated drive that can be tuned independently for optimal performance. This approach also provides better fault isolation—if one axis has problems, it doesn’t affect the others.

Multi-axis drives do exist and work well for certain coordinated motion applications, but they require careful consideration of power sharing and control complexity. The tuning becomes more challenging when axes interact through a shared drive system.

For industrial manufacturing spindle applications, the reliability and performance benefits of individual drives per axis usually outweigh any cost savings from shared drives. When your spindle repair schedule and part quality depend on precise, reliable motion control, the extra investment in dedicated drives pays dividends in uptime and accuracy.

Conclusion

When you’re looking to take your CNC operations to the next level, AC servo motors are the precision upgrade that makes all the difference. These remarkable motors don’t just improve accuracy—they transform your entire manufacturing process with their lightning-fast response times and rock-solid reliability.

The journey to servo motor success starts with making smart choices. Getting the right motor for your specific needs, sizing it properly, and integrating it correctly sets the foundation for years of trouble-free operation. It’s like building a house—get the foundation right, and everything else falls into place.

But here’s something many people don’t realize: your AC servo motors are only as good as the complete motion system they’re part of. That’s where the real magic happens. At MZI Precision, we’ve seen countless manufacturing operations where perfectly good servo motors were held back by worn-out industrial manufacturing spindles.

Think about it this way—your servo motor might be delivering precise positioning commands, but if your spindle has worn bearings or damaged components, you’re not getting the precision you paid for. It’s like having a Formula 1 engine in a car with wobbly wheels.

Our expertise in industrial manufacturing spindle repair and rebuilding perfectly complements servo motor technology. Whether you’re running aerospace parts that demand submicron accuracy or defense components with zero tolerance for failure, we understand how all the pieces work together.

The companies that really succeed are the ones that think about their entire motion control system. They invest in quality AC servo motors and they maintain their spindles properly. They don’t wait for breakdowns—they plan ahead.

The numbers speak for themselves. Better part quality, fewer rejected pieces, and machines that keep running when you need them most. That’s what happens when precision motors meet expert maintenance and support.

Ready to see what your CNC systems can really do? Our team has been helping manufacturers across aerospace, defense, automotive, and other precision industries open up their full potential for years. We’d love to show you how proper spindle care can maximize your servo motor investment.

For more information about our comprehensive CNC spindle services and how we can support your precision manufacturing needs, visit More info about CNC spindle services.