Milling Spindle Repair: Top 5 Expert Tips

THE HEART OF YOUR INDUSTRIAL MANUFACTURING MACHINE

Milling spindle repair is a critical service that can save manufacturers thousands of dollars in replacement costs while minimizing production downtime. When your industrial manufacturing spindle fails, you face a choice: spend weeks waiting for a replacement or get expert repair in days.

QUICK ANSWER FOR MILLING SPINDLE REPAIR:

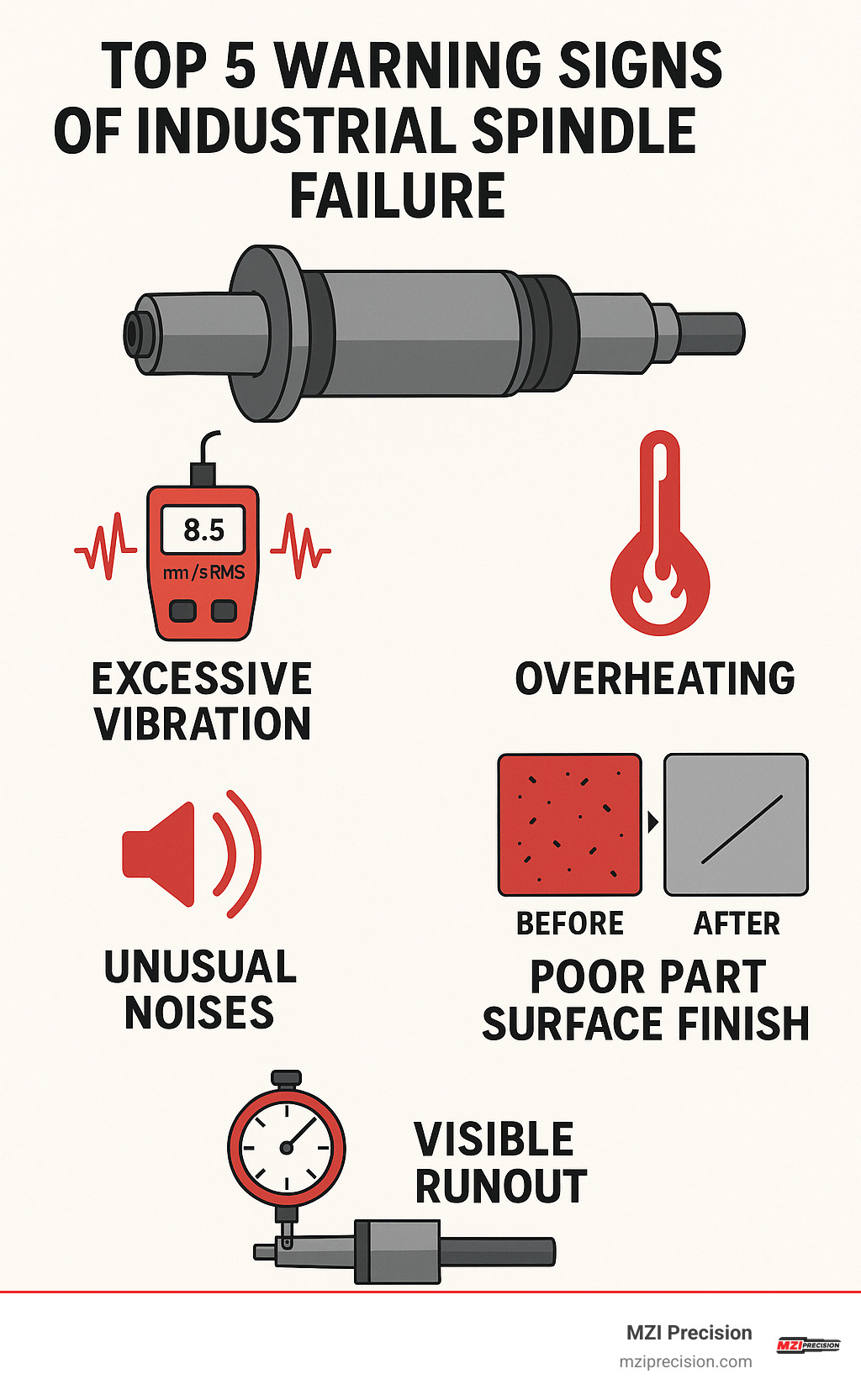

- Common signs: Excessive vibration, overheating, unusual noises, poor part quality

- Typical causes: Bearing contamination, inadequate lubrication, mechanical overload

- Repair process: Evaluation → Disassembly → Component replacement → Balancing → Testing

- Timeline: 3-5 days for most repairs vs. weeks for replacement

- Cost savings: Often 50-70% less than buying new

- Warranty: 1-year coverage from reputable repair companies

As one industry expert notes, “Spindle damage is usually synonymous with the total failure of your machine and thus a marked decline in your production capacity.” This reality hits aerospace, defense, and manufacturing companies hard when a critical spindle goes down.

The good news? Professional spindle repair has advanced dramatically. Companies complete repairs within 3-5 days, while specialists perform over 1,000 spindle repairs annually with precision that often exceeds original specifications.

Modern repair facilities use ISO 9001:2015 certified processes, dynamic balancing to G1 tolerances, and comprehensive testing that includes 12-hour runoffs. The result is a spindle that performs like new at a fraction of replacement cost.

TERMS RELATED TO MILLING SPINDLE REPAIR:

IS YOUR INDUSTRIAL SPINDLE FAILING? KEY SIGNS AND COMMON CAUSES

Picture this: your precision CNC machine, the backbone of your production line, suddenly starts acting up. More often than not, the culprit is your industrial spindle – the beating heart of your manufacturing operation. Catching spindle problems early is like spotting storm clouds before the rain hits; it gives you time to take action before disaster strikes.

When milling spindle repair becomes necessary, it’s rarely a surprise to those who know what to look for. The signs usually start small – maybe a slight vibration here, a bit of unusual heat there. But these whispers can quickly become screams if ignored.

Think of your spindle as a high-performance athlete. Even the strongest performer needs attention when something’s off. Excessive vibration might shake your parts loose from precision specs. Overheating tells you something’s working way too hard inside. When your finished parts start looking rough around the edges, your spindle is practically waving a red flag.

Contamination creeps in like an unwelcome guest, bringing coolant mists and debris that slowly eat away at precision. And machine crashes? Well, they’re about as gentle on spindles as a sledgehammer on fine china.

Every minute of downtime hits your bottom line, which is exactly why recognizing these warning signs matters so much.

More info about our industrial spindle repair services

WARNING SIGNS YOUR INDUSTRIAL SPINDLE NEEDS IMMEDIATE ATTENTION

Your industrial spindle normally hums along with quiet efficiency, like a well-tuned engine. When it starts sending distress signals, smart operators listen. These warning signs can save you from major headaches and expensive emergency repairs down the road.

Unusual noises are your first red flag. Any grinding, squealing, rattling, or clunking sounds that break the normal rhythm mean trouble’s brewing. Spindles do make some noise during operation – that’s normal. But sudden changes? That’s your spindle crying for help, usually because bearings are wearing out or internal parts are creating friction where they shouldn’t.

Excessive vibration goes hand-in-hand with noise problems. Some vibration is part of the game, but when levels spike, you’ll feel it in your parts’ quality. Poor surface finishes and shortened tool life follow close behind. Dynamic balancing keeps vibration in check, so when those levels climb, something’s definitely wrong.

Overheating sends a clear message that your spindle is working overtime. If the housing feels unusually hot or your sensors report abnormal temperature readings, internal friction or lubrication problems are likely cooking your components from the inside out.

Visible runout means you can actually see the wobble in your tool’s rotation. When precision measurement tools confirm what your eyes suspect, your spindle’s accuracy is shot. This directly impacts every part you machine.

Poor part quality often becomes the most obvious symptom. When your finished products show rough surface finishes, inconsistent dimensions, or chatter marks, a failing spindle is usually the culprit. Inconsistent cutting forces make your machine struggle to maintain steady performance, pointing to problems with spindle rigidity or bearing integrity.

THE ROOT CAUSES OF INDUSTRIAL SPINDLE FAILURE

Understanding why spindles fail helps prevent future problems. These precision workhorses operate under demanding conditions, and like any hard-working equipment, they need proper care to avoid breakdowns.

Bearing contamination tops the list of troublemakers. Coolant mists, dust, and metal chips sneak past seals and wreak havoc on bearing surfaces. Once contamination gets in, it acts like sandpaper, grinding away at precision components. Proper sealing and regular cleaning are your best defenses.

Inadequate lubrication starves bearings of the protection they need. Whether your lubrication system fails or someone uses the wrong lubricant, dry bearings generate heat and wear out fast. It’s like running a car engine without oil – nothing good comes from it.

Mechanical overload happens when operators push spindles beyond their design limits. Excessive feed rates, cutting forces, or speeds create stresses that components weren’t built to handle. This leads to deflection, vibration, and accelerated wear that shortens spindle life dramatically.

Internal friction develops over time as components wear or shift out of alignment. This friction generates heat and accelerates deterioration throughout the spindle assembly.

Bearing wear is inevitable with use, but contamination, poor lubrication, and overloading speed up the process. Worn bearings lose their precision, creating the vibration, noise, and runout that signal trouble.

Thermal stress occurs when rapid temperature changes or prolonged high-heat operation cause components to expand and contract. This constant flexing leads to material fatigue and eventual failure.

Tool connection problems also contribute to spindle issues. Worn tapers, damaged pilots, and faulty clamping mechanisms create imbalance and vibration that stress the entire spindle assembly. When tools don’t seat properly, every revolution compounds the problem.

THE COMPREHENSIVE INDUSTRIAL MILLING SPINDLE REPAIR PROCESS

When your industrial manufacturing spindle starts acting up, you’re not looking at a simple patch job. Think of it more like precision surgery – every step matters, and there’s no room for shortcuts. The milling spindle repair process is a carefully orchestrated dance of diagnostics, disassembly, and reconstruction that brings your machine’s heart back to life.

The goal isn’t just to get your spindle running again – it’s to restore it to OEM specifications using precision components and following strict ISO 9001:2015 quality standards. When done right, your repaired spindle often performs better than it did when new. That’s the beauty of working with specialists who understand that your production line depends on getting this right the first time.

Every repair follows a methodical approach that’s been refined through thousands of successful restorations. From the moment your spindle arrives to the final test run, each step builds on the last to ensure reliability and longevity.

See the repair process in action

STEP 1: EVALUATION, DISASSEMBLY, AND FAILURE ANALYSIS

The repair journey begins with detective work. Your spindle has a story to tell, and experienced technicians know how to listen. The intake inspection starts the moment your spindle arrives, with specialists examining every visible detail for clues about what went wrong.

Vibration analysis comes next, using advanced diagnostic tools to measure exactly how your spindle is misbehaving. This isn’t guesswork – it’s precise measurement that pinpoints problems before any disassembly begins. For spindles with drawbars, the drawbar pull force test reveals whether your tool-holding system is still up to spec.

Then comes the careful disassembly process. This happens in a clean room environment because contamination is often what caused the problem in the first place. Every component gets handled like the precision instrument it is – no rushing, no shortcuts.

During component inspection, each part tells its story. Bearings reveal contamination damage, seals show wear patterns, and the shaft itself displays the stresses it’s endured. The taper, pilot, face, and tool connection points all get scrutinized for problems that might not be obvious at first glance.

The real value comes in root cause determination. Was it bearing contamination from coolant mist? Inadequate lubrication? Mechanical overload from pushing too hard? Understanding why the failure happened is crucial for preventing it from happening again. You’ll receive a detailed damage report with photographic evidence before any repair work begins.

STEP 2: RECONDITIONING, ASSEMBLY, AND BALANCING

Once you’ve approved the diagnosis, the real craftsmanship begins. This is where experience and precision tools transform worn components back into manufacturing-grade hardware.

Component replacement means every worn bearing, seal, O-ring, and preload collar gets swapped for high-quality parts that meet or exceed OEM specifications. Sometimes original parts aren’t available anymore, which is where reverse engineering expertise comes in handy – creating exact replacements that perform like the originals.

Taper grinding addresses one of the most critical aspects of spindle performance. If your taper is out of spec, tools won’t seat properly, leading to vibration and poor part quality. The “kiss grinding” process corrects runout and restores dimensional integrity with microscopic precision.

Restoring OEM fits ensures every component meshes perfectly. This might involve reconditioning worn parts or machining new ones to exact specifications. It’s meticulous work that pays off in long-term reliability.

Reassembly happens in that same clean room environment where disassembly occurred. Think of it like building a Swiss watch – every component must be perfectly clean and precisely positioned. Contamination at this stage would undo all the careful work that came before.

Dynamic balancing to G1 tolerances is where the magic happens. After assembly, your spindle goes onto specialized balancing equipment that identifies and corrects even tiny imbalances in the rotating components. Many repair facilities exceed OEM balance specifications by 20-40 percent, giving you smoother operation than you had originally.

The final step involves comprehensive testing, including a 12-hour test run that measures bearing temperature, concentricity, vibration levels, and pull-in force. Encoder and sensor positions get verified, speeds are tested, and rotation angles are confirmed. You’ll receive a detailed test report showing your spindle meets or exceeds original specifications.

TYPES OF INDUSTRIAL MILLING SPINDLES WE CAN REPAIR

Industrial manufacturing uses an incredible variety of spindle designs, each engineered for specific applications and performance requirements. Whether you’re running belt-driven spindles with their simple, reliable external motor setup, or motorized spindles with integrated motors for high-speed precision work, the repair approach adapts to the technology.

Direct-drive spindles eliminate belts and gears entirely, providing maximum power transfer and precision for demanding CNC applications. Gear-driven spindles use gearboxes to deliver the perfect combination of speed and torque for heavy cutting operations. High-speed spindles present their own challenges, sometimes spinning at 150,000 rpm or more, requiring specialized balancing techniques and ultra-precise assembly.

The beauty of working with experienced repair specialists is their ability to handle custom spindles designed for unique applications. Whether your spindle serves aerospace manufacturing, defense contractors, or general industrial production, the fundamental principles of precision repair remain the same.

From horizontal machining centers to vertical mills, from grinding applications to specialized cutting operations, milling spindle repair expertise covers the full spectrum of industrial manufacturing needs. A spindle is a rotating axis of a machine tool that deserves the highest level of care and attention during repair.

CHOOSING THE RIGHT INDUSTRIAL SPINDLE REPAIR PARTNER

When your milling spindle repair needs arise, the partner you choose can make or break your production schedule. It’s not just about fixing a broken component – you’re entrusting the heart of your manufacturing operation to someone else’s hands. The right repair partner becomes an extension of your team, understanding that every hour of downtime costs you money and potentially affects your customers.

Think of it like choosing a surgeon for a critical operation. You wouldn’t just pick anyone with a medical degree, right? The same principle applies here. Your spindle repair partner needs the right combination of technical expertise, quality standards, and reliability to get your equipment back to peak performance.

We understand the pressure you’re under when a spindle fails. That urgent phone call to your boss, the scramble to reschedule production, the stress of explaining delays to customers – we’ve heard it all. That’s why choosing a repair partner isn’t just a technical decision; it’s about finding someone who truly gets the urgency and treats your emergency as their own.

KEY FACTORS FOR YOUR SELECTION

The difference between a good repair experience and a great one often comes down to a few critical factors that separate the professionals from the rest.

Experience and reputation form the foundation of any trustworthy repair service. Look for a company that’s been around long enough to have seen every type of failure imaginable. When we say “we’ve seen it all,” we really mean it – from simple bearing replacements to complex rebuilds that require reverse engineering obsolete parts. Years of experience translate into faster diagnostics, better solutions, and fewer surprises along the way.

Engineering capabilities matter more than you might think. The best repair partners don’t just follow instructions – they have degreed engineers who can analyze your specific situation, identify root causes, and even suggest improvements. Sometimes a repair isn’t just about fixing what broke; it’s about understanding why it broke and preventing it from happening again.

In-house machining capabilities can be a game-changer, especially when you’re dealing with older equipment or custom applications. When a repair shop can manufacture replacement parts on-site rather than waiting weeks for special orders, your downtime shrinks dramatically. It’s the difference between getting your spindle back in days versus weeks.

Warranty terms tell you everything about a company’s confidence in their work. A comprehensive warranty that covers both parts and labor for a full year isn’t just protection – it’s proof that the repair shop stands behind their craftsmanship. Be wary of limited warranties or companies that seem reluctant to discuss coverage details.

24/7 service availability might seem like overkill until you need it. Manufacturing doesn’t always happen during business hours, and neither do emergencies. Having access to technical support and emergency services around the clock can mean the difference between a minor hiccup and a major crisis.

OEM-CERTIFIED VS. THIRD-PARTY REPAIR FOR YOUR INDUSTRIAL MILLING SPINDLE

When your milling spindle repair is needed, you’ll face a choice that many manufacturers struggle with: should you go with an OEM-certified service or trust a third-party specialist? Both paths have their merits, and understanding the differences helps you make the best decision for your specific situation.

| FEATURE | OEM-CERTIFIED SERVICES | THIRD-PARTY SERVICES |

|---|---|---|

| Use of OEM Parts & Specs | Guaranteed use of original, patented components and factory settings. Rebuilds to true factory original performance. | Uses high-quality equivalent parts that meet or exceed OEM specifications. Often provides improved performance through improved components. |

| Access to Factory Specs | Complete access to proprietary drawings, tolerances, and assembly procedures directly from the manufacturer. | Extensive reverse engineering capabilities and decades of experience with various spindle designs. Often maintains comprehensive databases of specifications. |

| Warranty Coverage | Typically offers standard manufacturer warranty terms, usually 1 year on parts and labor. | Often provides competitive warranty terms, sometimes exceeding OEM coverage with more flexible conditions. |

| Cost Comparison | Generally higher cost due to premium pricing on OEM parts and authorized service fees. | Typically 30-50% less expensive while maintaining comparable quality standards. |

| Technical Support | Direct access to original design engineers and manufacturer technical resources. | Dedicated engineering team with broad experience across multiple spindle brands and applications. |

| Turnaround Time | May require longer lead times due to parts sourcing and scheduling through manufacturer networks. | Often faster turnaround with in-house machining capabilities and readily available inventory. |

The truth is, both options can deliver excellent results when executed properly. OEM-certified services give you the peace of mind that comes with factory-direct support and genuine parts. You know exactly what you’re getting, and there’s comfort in that consistency.

Third-party specialists, on the other hand, often bring a different kind of value. They’ve worked on spindles from dozens of manufacturers over the years, giving them insights that even OEM technicians might not have. They can spot patterns across different brands and sometimes offer improvements that improve performance beyond original specifications.

The decision often comes down to your specific priorities. If you’re working with critical aerospace or defense applications where documentation and traceability are paramount, OEM certification might be worth the premium. But if you’re looking for the best combination of quality, speed, and value, a reputable third-party specialist can often deliver superior results.

What matters most is finding a partner – whether OEM or independent – who understands your industry, respects your timelines, and has the technical expertise to handle your specific spindle repair needs with precision and care.