Spindle runout correction: Ultimate 2025 Guide

Understanding Spindle Runout and Its Impact on Manufacturing Precision

Spindle runout correction is essential for maintaining manufacturing precision. Spindle runout occurs when an industrial manufacturing spindle no longer rotates perfectly on its intended axis, causing tools to wobble. This deviation creates two main types of error: radial runout (perpendicular to the axis) and axial runout (parallel to the axis).

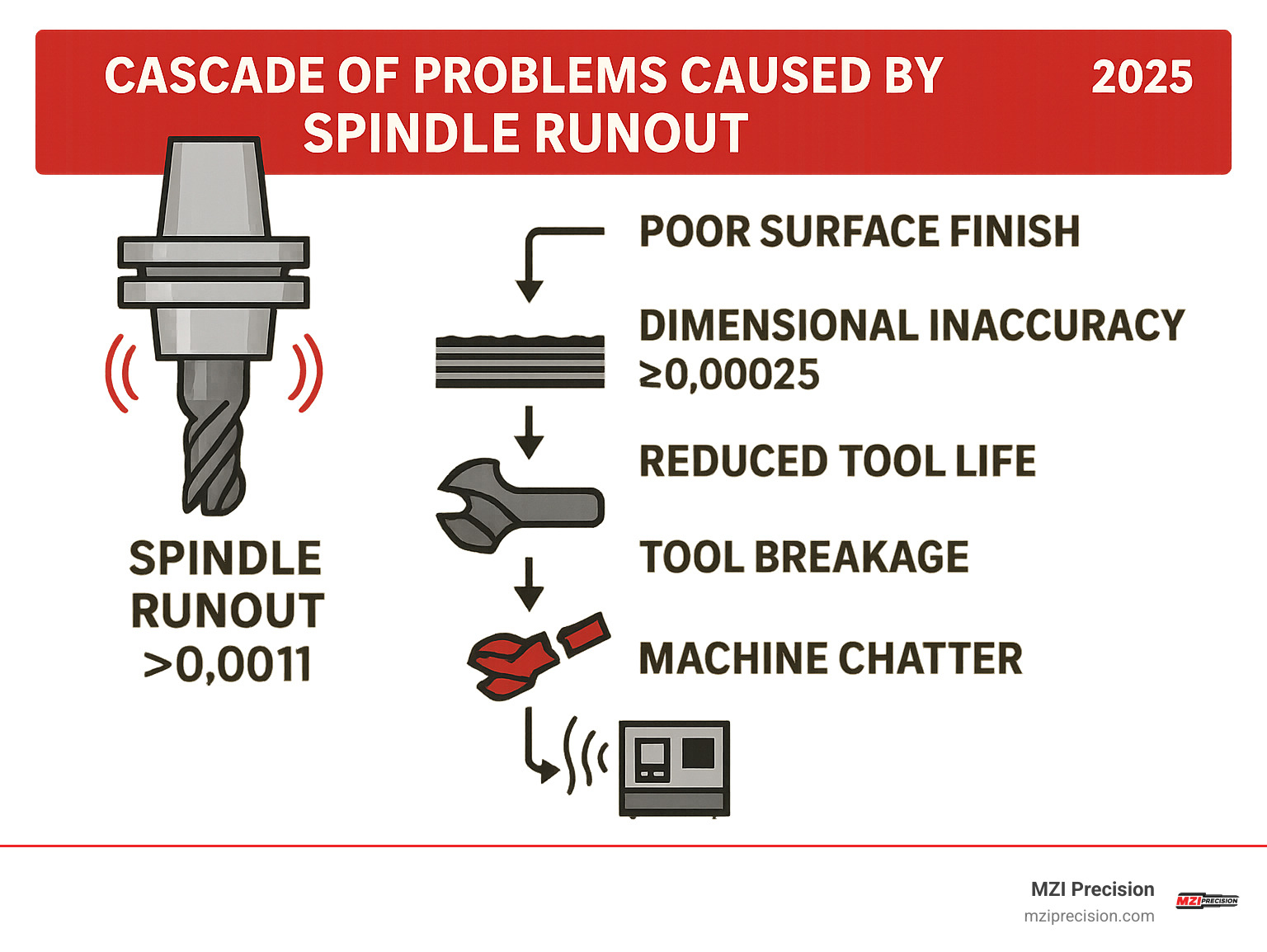

The consequences of uncorrected runout are severe. Research shows that runout greater than 0.001″ is unacceptable for high-speed spindles and can lead to bearing failure. Operations will experience poor surface finishes, dimensional inaccuracies, premature tool wear, and increased tool breakage.

Tool life suffers dramatically when runout exceeds 20% of the programmed chip load. For example, reducing runout on carbide drills from 0.0006″ to 0.00008″ can result in a 3x improvement in tool life. Smaller tools are particularly vulnerable; a 1/8″ endmill with 0.0008″ runout can experience over 100% Total Indicated Runout (TIR) relative to its chip load, leading to immediate breakage.

Understanding and correcting spindle runout is key to protecting your investment in tooling and precision manufacturing capabilities.

Identifying the Root Causes of Spindle Runout

Even precisely engineered industrial manufacturing spindles can develop runout over time. Understanding the root causes is the first step toward effective spindle runout correction.

The most common culprit is worn spindle bearings. After thousands of hours, bearing tolerances can open up, causing the spindle’s axis to wander from its ideal path and create runout.

Spindle damage from crashes is another major cause. A machine crash can shift or damage internal components, immediately throwing the assembly out of alignment.

Sometimes, small issues cause big problems. Contamination in the taper, such as a tiny metal chip or coolant residue, can prevent a toolholder from seating properly. This microscopic debris creates a rocking motion that translates into measurable runout at the cutting tool.

Thermal distortion adds another layer of complexity. As a spindle heats up, metal components expand. If this thermal growth is not uniform, it can cause runout that changes as the machine warms up.

Even worn retention knobs (pull studs) can be a factor. When these wear out, they fail to provide consistent clamping force, allowing movement that appears as runout.

Often, runout stacking occurs when multiple small errors combine. For example, a spindle with 0.0001″ of runout and a toolholder with 0.0003″ can result in 0.0004″ of total indicated runout before even considering the cutting tool.

How Toolholders and Tooling Affect Runout

Your toolholder is the critical bridge between the spindle and cutting tool. The wrong choice can introduce significant runout.

ER collets are versatile and affordable, typically delivering runout between 0.0004″ and 0.0008″. Maintaining cleanliness and replacing worn collets is key to preserving accuracy.

Side lock holders use set screws to grip tools. This mechanism pushes the tool slightly off-center, resulting in around 0.0005″ runout. They offer excellent holding power but are not ideal for high-precision work.

Hydraulic holders use fluid pressure for uniform clamping, offering better runout performance than conventional systems.

Shrink-fit holders provide the highest precision. The heating and cooling process creates a tight, concentric grip that can achieve runout levels around 0.0001″. They are often essential for high-precision work.

The effect of tool stickout cannot be overstated. Runout at the spindle taper is amplified at the tool tip. A spindle with 0.0002″ runout might show 0.0008″ at a tool extending 4 inches. Minimizing stickout is fundamental to precision machining.

For comprehensive solutions, explore our professional services: More info about our spindle services.

Common Spindle Runout Warning Signs

Recognizing runout symptoms early can prevent costly damage and downtime.

Excessive tool wear is a top indicator. Uneven cutting loads cause one or two flutes to do most of the work, leading to rapid wear.

Unexplained tool breakage, especially with smaller tools, often points to runout. Varying chip loads stress individual flutes beyond their limits, causing sudden failure.

Poor surface finish provides immediate visual feedback. Runout creates a rough or chattered appearance as the tool wobbles through the cut.

Audible chatter during cutting is an unmistakable sign of unstable cutting conditions, often caused by runout.

Inconsistent part dimensions can plague shops with runout issues, as measurements may drift over a production run.

Increased machine vibration affects part quality and overall machine health. Unbalanced cutting forces from runout stress spindle bearings and other components, potentially leading to broader reliability issues.

How to Accurately Measure Spindle Runout

Before you can perform spindle runout correction, you must get an accurate measurement. Guessing is not an option in precision manufacturing.

Your measurement toolkit needs three essential items: a dial test indicator, a precision test bar, and a magnetic base. The indicator reveals tiny deviations, while the test bar provides a perfectly straight and concentric reference point.

Cleaning is the critical first step. A microscopic chip or speck of dust can completely throw off your readings. Thoroughly wipe down the spindle taper and your test bar.

The measurement procedure is straightforward. Securely mount the precision test bar in the spindle taper. Position the magnetic base on a stable part of the machine, like the table for mills or the cross-slide for lathes. Set up the dial indicator to make light contact with the test bar.

To measure, first check the spindle taper by placing the indicator directly against it. Slowly rotate the spindle 360 degrees by hand. This Total Indicated Runout (TIR) reading reveals the taper’s accuracy and should be within 0.0002″.

Next, move to measuring at the gauge line on the test bar. Repeat the rotation and record the TIR. This measurement should not exceed 0.0005″.

Finally, measure at a distance of about 6 inches from the gauge line. This reading amplifies any runout, making it easier to quantify. At this distance, TIR should be under 0.001″.

For authoritative measurement standards, many professionals reference guidelines from organizations like ASME: Authoritative standards for measurement.

Understanding Acceptable Runout Limits

“Acceptable” runout is not a single number; it depends entirely on the application.

Total Indicated Runout (TIR) limits vary by measurement location. At the spindle taper, the foundation of your accuracy, aim for no more than 0.0002″.

Using a test bar, the limits are more generous further from the spindle. At the gauge line, 0.0005″ is typically acceptable. At 6 inches out, up to 0.001″ can still allow for good machining performance.

However, application-specific tolerances can be much tighter. In micromachining, even 0.0002″ of runout can be disastrous. For these demanding applications, the goal is often 0.0001″ or less.

The most critical factor is the runout vs. chipload ratio. When TIR exceeds about 20% of your tool’s intended chip load, tool life begins to drop rapidly. For example, if a small endmill has a programmed chip load of 0.002″ per tooth and runout is 0.0004″, you are at the 20% threshold. This is why smaller tools are so sensitive to runout; their small chip loads make even tiny runout values a huge percentage of the intended cut.

A Guide to Spindle Runout Correction Methods

Once runout is diagnosed, it’s time to fix the problem. Many issues can be resolved at the machine, while more stubborn problems may require advanced solutions to restore your industrial manufacturing spindle to peak performance.

Spindle runout correction involves systematically eliminating potential causes, from simple cleaning to advanced toolholder adjustments.

On-Machine Adjustments for Spindle Runout Correction

Start with corrections you can make at your machine to optimize the spindle-toolholder interface.

- Thorough cleaning of the taper is often the solution. Even a microscopic chip can prevent proper seating and cause runout.

- Toolholder inspection is crucial. Look for nicks, scratches, or wear that could indicate damage. A bent toolholder will always introduce runout.

- Collet inspection and replacement is vital. Collets are consumables that wear out, losing spring tension and accuracy. Replace them on a regular schedule.

- Retention knob replacement should not be overlooked. Worn threads or damaged surfaces on pull studs prevent consistent clamping force, leading to inconsistent runout.

- “Clocking” toolholders can partially cancel runout. By orienting the high spot of the spindle 180 degrees from the toolholder’s high spot, the errors can offset each other.

- Adjustable toolholders, like the RA Holder, offer mechanical compensation to dial out runout directly at the machine, potentially reducing it by a factor of ten (e.g., from 0.0008″ to 0.00008″).

Advanced Spindle Runout Correction and Compensation

When basic adjustments are insufficient, advanced methods offer higher precision.

High-precision toolholders are a significant upgrade. While an ER collet may have 0.0004″ to 0.0008″ of runout, a shrink-fit holder can consistently achieve under 0.0001″. The upfront cost is often justified by extended tool life and improved part quality.

| Toolholder Type | Typical Runout (TIR) | Cost Factor | Application |

|---|---|---|---|

| ER Collet | 0.0004″ – 0.0008″ | Low | General machining, versatile |

| Side Lock | ~0.0005″ | Low | Heavy milling, strong grip |

| Hydraulic | 0.0002″ – 0.0004″ | Medium | Precision machining, vibration damping |

| Shrink-Fit | <0.0001″ | High | High-precision, high-speed, long tool life |

| Adjustable | 0.00008″ (RA Holder) | High | Precision drilling/reaming, runout compensation |

CAM software compensation provides a software-based fix. By adjusting the tool diameter in your CAM program to account for measured runout, you can improve dimensional accuracy. This helps with part dimensions but does not fix the underlying mechanical issue causing uneven chip load and vibration.

Correcting Runout on Different Industrial Machines

Different machines present unique challenges for runout correction.

- Milling machines: Correction focuses on the spindle taper, toolholder selection, and tool management. Clean tapers and high-quality toolholders are key. After a crash, inspect the spindle taper carefully for damage.

- Lathes: Headstock bearing preload is critical. Loose bearings increase runout. Chuck mounting also requires attention. A toolholder should fit correctly, with at least 75% contact, confirmed by using high-spot paste.

For more measurement techniques, consult resources like this tutorial on runout measurement.

When on-machine corrections fail, or if you suspect bearing wear or internal damage, it’s time for professional spindle repair or rebuilding services.

Preventative Maintenance and Knowing When to Call a Professional

Preventative maintenance is your best defense against spindle runout, helping you catch problems before they become expensive disasters.

The foundation of good spindle care is regular cleaning. We recommend monthly inspections of your spindle taper, or weekly for high-production shops. A clean taper is essential for cutting accuracy and surface finish.

After cleaning, apply a light coat of all-purpose machine oil for proper lubrication. This prevents corrosion and ensures smooth operation.

For milling machines, regularly check drawbar force measurement. Insufficient force can allow the toolholder to pull out, creating dangerous conditions and runout issues.

Your toolholder and collet inspection routine should be second nature. These components wear out and should be replaced proactively to avoid failures.

However, there are times when maintenance isn’t enough. Knowing when to call a professional can prevent a moderate problem from becoming a catastrophic failure.

- Post-crash assessment is critical. Even a minor collision can cause internal damage that is not immediately visible.

- Inconsistent runout readings that vary with each rotation or from day to day likely indicate internal bearing issues that require expert repair.

- Excessive noise or heat from the spindle signals a serious internal problem, typically related to the bearings.

- When runout consistently exceeds acceptable limits despite your best efforts at spindle runout correction, the spindle itself is likely the root cause.

At MZI Precision, we understand that calling for professional help is a smart business decision. Our expertise in industrial manufacturing spindle repair and rebuilding serves industries from aerospace to defense and solar energy. We are located in the United States, with facilities in Huntington Beach and Los Angeles, California, ready to restore your spindle to manufacturer’s tolerances.

Frequently Asked Questions about Spindle Runout

Here are answers to the most common questions we receive about spindle runout correction.

Can I completely eliminate spindle runout?

Achieving absolute zero runout is practically impossible. Every rotating mechanical system will have some measurable deviation. The goal is not elimination but minimization.

We focus on reducing runout to a level where it does not negatively impact your machining operations. Using high-precision components and proper maintenance, we can achieve runout levels that are negligible for most applications. Acceptable tolerances vary by need; general machining may tolerate 0.0005″, while micromachining may require 0.0001″ or less.

How much does tool life improve by reducing runout?

The improvement can be dramatic. Reducing runout leads to transformative changes in efficiency and cost.

When runout is present, cutting flutes wear unevenly because the workload is not shared. The overworked flutes fail quickly, ending the tool’s life prematurely.

Real-world data shows significant improvement. For example, reducing runout on carbide drills from 0.0006″ to 0.00008″ can result in a 3x tool life increase. This means fewer tool changes, less downtime, and more parts per tool. The improvement comes from balancing the runout-to-chipload ratio. When all cutting edges share the load equally, you get reduced flute wear and predictable performance.

Is runout more harmful to smaller or larger tools?

Runout is unquestionably more detrimental to smaller tools. This is due to the higher TIR to chipload ratio.

A small 1/8″ endmill might have a target chip load of just 0.0006″. If your spindle has 0.0008″ of runout, that’s over 130% of the intended chip load. One flute is forced to do more than double its designed work, making the risk of breakage extremely high.

Larger tools, with their more robust chip loads, can tolerate the same amount of absolute runout much better because it represents a smaller percentage of their cutting action. This is why spindle runout correction is absolutely critical in micromachining and other applications that use delicate cutting tools.

Conclusion: Achieving Precision by Managing Spindle Runout

We’ve explored spindle runout correction, from its causes to the methods that restore precision. Runout’s impact is significant, leading to poor part quality, premature tool failure, and increased costs. When your industrial manufacturing spindle isn’t running true, the entire operation suffers.

Accurate measurement is the foundation of any correction effort. Using precision test bars and dial indicators provides the data needed to diagnose the problem correctly.

Many runout issues can be fixed with systematic correction methods, such as cleaning the spindle taper, replacing worn collets, or investing in high-precision and adjustable toolholders. Proactive maintenance is also key, as regular cleaning and inspection can prevent problems from escalating.

However, when the problem is internal—worn bearings or damage from a crash—professional expertise is required. Attempting to rebuild a precision spindle without the right tools and cleanroom environment can make the problem worse.

At MZI Precision, our expertise in industrial manufacturing spindle repair and rebuilding can restore your equipment to manufacturer specifications. The investment in proper spindle runout correction pays for itself through longer tool life, better part quality, and reduced downtime. While zero runout is a theoretical goal, achieving the precision your application demands is entirely possible with the right approach.

Contact us for professional spindle repair services and let us help you achieve the precision your industrial manufacturing operations deserve.