Why is spindle repair in California a crucial service for industry operations?

Spindle repair is undeniably crucial, especially for industries reliant on CNC machinery for precision tasks. Imagine your spindle as the heart of this sophisticated equipment–if it fails, the entire operation could grind to a halt. This is where timely repair services in California, like those offered by MZI Precision, become indispensable.

A malfunctioning spindle can lead to significant productivity losses, which are not always easy to quantify until they impact deadlines and revenue. In practice, proactive maintenance can prevent these costly breakdowns. From my own experience at MZI Precision, I’ve seen how maintaining a regular repair schedule can save businesses from unexpected downtimes.

Are there instances where you’ve experienced operational setbacks due to machine downtimes? How did you address them?

What are the unique challenges faced during spindle repair in California?

One of the most distinctive challenges in spindle repair relates to the diverse range of machines and industry needs we encounter. Each spindle type has its own set of specifications and operational requirements. For instance, repairing a spindle for aerospace manufacturing demands a higher precision level than those used in woodworking.

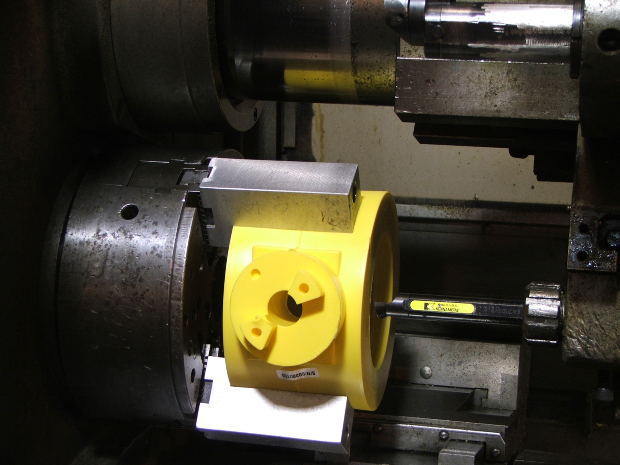

At MZI Precision, we tackle these unique challenges by employing specialized protocols and state-of-the-art diagnostic tools. We understand the nuances of temperature variations and wear-and-tear issues, which require a keen eye for detail and depth of expertise to address effectively.

Have you ever faced a spindle issue that seemed particularly daunting? How did you manage to overcome it?

What situations constitute an emergency spindle repair in California?

An emergency arises when a spindle failure results in a complete operational shutdown, necessitating immediate repair. For businesses, the cost of downtime can be significant, and having a responsive service provider like MZI Precision can make a world of difference.

Our approach involves a structured emergency response: initial remote assessments, on-site diagnostics, and rapid repair and reinstallation. This rapid response system ensures that businesses can get back to full operational capacity without undue delays.

Have you had an experience where immediate repair was essential? What was the impact on your operations?

How are technological innovations transforming spindle repair processes in California?

Technology is indeed revolutionizing spindle repair in remarkable ways. At MZI Precision, we leverage advancements like laser alignment tools and robotic assistance. These tools enhance accuracy and efficiency, reducing human error significantly.

For instance, using real-time monitoring systems allows for predictive maintenance, which means issues can be spotted and addressed before they become major problems. Such innovations not only extend the lifespan of spindles but also optimize overall machine performance.

In what ways have technology and automation benefited your operations or workflow?

How should businesses choose the right spindle repair partner in California?

Choosing the right spindle repair partner is critical, as it can significantly influence operational efficiency. Key considerations include the partner’s expertise, turnaround time, and customer service quality. At MZI Precision, our team’s expertise and dedication stand out.

We encourage potential clients to visit our facilities, engage with our team, and see our state-of-the-art workshop. This interaction can provide invaluable insights into our repair processes and commitment to transparency and excellence. Additionally, testimonials and case studies often offer a glimpse into our track record and reliability.

What factors do you prioritize when selecting a service partner? Have there been experiences that shaped this choice?

Why is expert knowledge essential in the spindle repair industry in California?

Expertise is the cornerstone of effective spindle repair, especially when dealing with diverse and complex machinery. At MZI Precision, our team’s extensive experience across numerous industries allows us to address challenges that might stump less specialized providers.

For example, rebuilding spindles from OEMs like Haas or Mazak requires specific knowledge of their engineering intricacies. Such expertise helps us ensure that repairs not only restore functionality but also often improve machine performance. This is not just about fixing a problem but understanding the root causes and making improvements.

Have you ever worked with an expert in another field and noticed the difference it made? What was that experience like?

The Critical Importance of Spindle Repair

The Critical Importance of Spindle Repair

The Critical Importance of Spindle Repair

The Critical Importance of Spindle Repair Choosing the Right

Choosing the Right