Spindle CNC Router: Conquer Precision 2026

WHY THE RIGHT SPINDLE CNC ROUTER MATTERS FOR INDUSTRIAL PRECISION

A spindle cnc router is the core rotating assembly that holds the cutting tool, delivering the speed, torque, and precision essential for accurate machining. In industrial settings like aerospace, the right spindle directly impacts production speed, part quality, and operational costs.

QUICK ANSWER: KEY SPINDLE CNC ROUTER CONSIDERATIONS

- FUNCTION: The heart of a CNC router, rotating the cutting tool at high speeds (up to 18,000+ RPM) with precise torque.

- TYPES: Motorized (integral) for high-speed precision; belt-driven for heavy material removal.

- POWER: Typically 2.2 HP to 9 HP or higher for industrial use.

- COOLING: Air-cooled for general use; liquid-cooled for continuous heavy-duty operations.

- CONTROL: Requires a Variable Frequency Drive (VFD) for power conversion and speed control.

- LIFESPAN: Quality spindles can last 5-8 years with proper maintenance, some reaching 10 years.

The difference between a standard router and a high-frequency industrial spindle is substantial. CNC spindles deliver higher RPM for faster production, maintain greater torque for heavier cuts, and produce less vibration, which improves surface finish and machine longevity. For demanding manufacturing environments, this means less downtime, higher part quality, and more cost-effective operations.

For aerospace manufacturers and other precision-focused facilities, spindle reliability is about meeting exacting tolerances consistently. Whether machining aircraft components or cutting intricate molds, your spindle must deliver precision under continuous loading.

This guide covers spindle types, selection criteria, VFD integration, and maintenance practices to maximize your investment. We’ll also discuss when professional spindle repair or rebuilding is necessary to restore your equipment to OEM specifications.

Common spindle cnc router vocab:

THE HEART OF PRECISION: WHAT IS A CNC ROUTER SPINDLE?

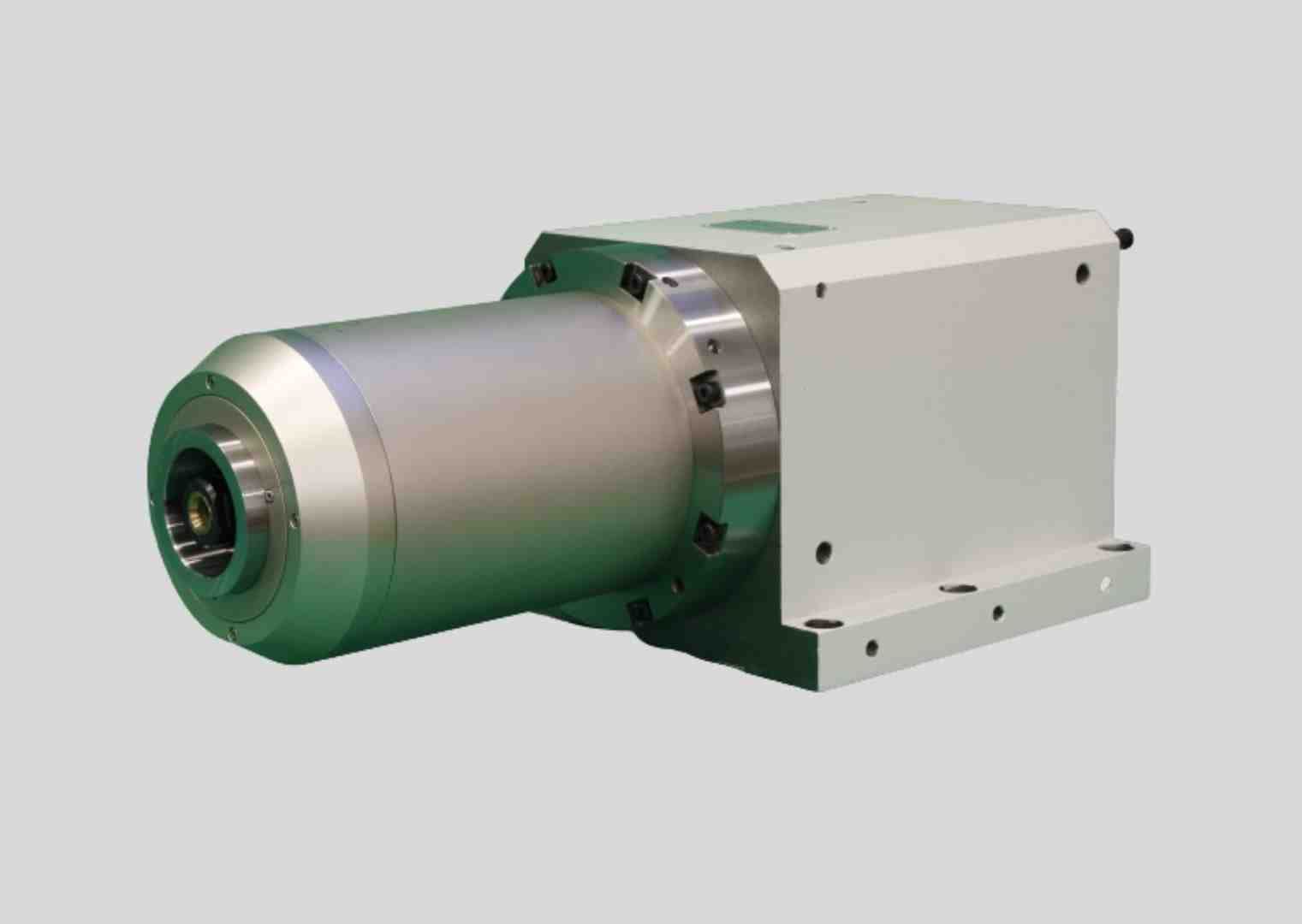

At its core, a spindle cnc router is the rotating assembly that holds and spins the cutting tool in a CNC machine. It acts as the engine, converting rotational energy into the precise, high-speed motion needed for cutting, drilling, and engraving industrial materials. The spindle’s stability and repeatability under load are what enable the tight tolerances and pristine surface finishes demanded by industries like aerospace and medical device manufacturing. A well-functioning spindle is the backbone of efficient, high-quality production.

KEY COMPONENTS EXPLAINED

A spindle cnc router is an advanced assembly of interconnected parts working in harmony to deliver precision.

- DRIVE SYSTEM: The power source, either an integral motor (motorized) or an external motor with belts (belt-driven), that determines the spindle’s RPM and torque.

- SPINDLE HOUSING: The robust outer casing that protects internal components and integrates utility systems like air lines, lubrication channels, and cooling passages.

- BEARING SYSTEM: The most critical component for precision, these bearings support the rotating shaft, minimize runout, and withstand high speeds and heavy loads.

- SHAFT: The main rotating component, connecting the drive system to the tool holder. It must be perfectly balanced to minimize vibration.

- DRAWBAR: In spindles with automatic tool changers, this mechanism pulls the tool holder securely into the spindle taper, ensuring rigid clamping.

- COLLETS: Precision sleeves (e.g., ER11 collets) that fit into the tool holder and grip the cutting tool’s shank, minimizing runout and improving stability.

- TOOL HOLDER: Interfaces with the spindle’s taper and holds the collet and cutting tool, ensuring proper alignment.

HOW A HIGH-FREQUENCY SPINDLE DIFFERS FROM OTHER MOTORS

A spindle cnc router is engineered for demanding CNC tasks, making it profoundly different from a standard woodworking router or general-purpose motor.

High-frequency spindles operate at much higher RPMs, increasing production speeds. They also boast superior torque output, allowing for heavier cuts in challenging materials without losing accuracy. A key advantage is their precision design, which results in far less vibration. This improves surface finish quality and extends the life of machine components and tools. Unlike standard routers that can bog down, high-frequency spindles maintain full torque at lower RPMs, ensuring consistent power delivery.

Furthermore, spindles use precision bearings that reduce run-out for smoother, more accurate cutting. These durable bearings last significantly longer under continuous industrial use, leading to less downtime and more cost-effective manufacturing. Finally, high-frequency spindles are considerably quieter, contributing to a safer work environment.

DECODING SPINDLE TYPES AND THEIR ADVANTAGES

Choosing the right spindle cnc router requires understanding the main types: motorized (integral) and belt-driven spindles, each suited for different operational demands.

| Feature | Motorized (Integral) Spindles | Belt-Driven Spindles |

|---|---|---|

| MAX RPM | Very High (e.g., 18,000 – 60,000+ RPM) | Moderate to High (e.g., up to 15,000 – 24,000 RPM) |

| TORQUE | Consistent across a wide RPM range, lower at very low RPMs | High torque at lower speeds, can be very powerful |

| VIBRATION | Very low due to compact, integrated design and precision balance | Slightly higher due to belt mechanics, but still very low in industrial models |

| NOISE | Quieter (motor integrated, fewer moving parts) | Can be slightly louder due to belt noise |

| MAINTENANCE | More complex to repair due to integrated motor, typically serviced by specialists | Easier bearing replacement, belt changes are straightforward |

| FOOTPRINT | Compact, smaller overall size | Can be larger due to external motor and belt housing |

| APPLICATIONS | High-speed machining, precision finishing, intricate details, hard materials | Heavy material removal, roughing operations, large-scale cutting, softer materials |

| COST | Generally higher initial cost | Often more cost-effective, especially for high-power applications |

MOTORIZED (INTEGRAL) SPINDLES

Motorized spindles are the workhorses of high-precision CNC machining. The motor is built directly into the spindle housing, creating a compact, efficient system. This integrated design allows for extremely high speeds (18,000+ RPM), crucial for rapid material removal and achieving fine finishes. The compact design also minimizes vibration, leading to superior surface quality and extended tool life. Their versatility and consistent power delivery make them ideal for applications demanding the highest accuracy and speed, from intricate mold work to cutting aerospace components.

BELT-DRIVEN SPINDLES

Belt-driven spindles offer distinct advantages, especially where robust construction and high torque at lower speeds are critical. In this system, an external motor powers the spindle shaft via a belt and pulley. This design excels in applications requiring substantial material removal and roughing operations, as it delivers high torque at lower speeds for cutting tough materials. Maintenance, such as bearing or belt changes, can be simpler and more cost-effective. These spindles can still achieve impressive speeds, with some industrial models reaching up to 15,000 RPM.

HOW TO CHOOSE THE RIGHT SPINDLE CNC ROUTER FOR YOUR APPLICATION

Selecting the ideal spindle cnc router is a crucial decision that impacts your manufacturing efficiency, quality, and costs. The best choice for your facility, whether in Huntington Beach or Los Angeles, depends on your specific materials and operational demands. You must match the spindle’s capabilities to your material requirements, balancing power, speed, and torque.

Consider the materials you machine. Hard metals like titanium demand higher torque, while softer materials benefit from higher speeds for cleaner cuts. The material thickness and depth of cut also influence the required power. A thorough assessment of your application’s needs will guide you to the optimal spindle.

KEY SPECIFICATIONS FOR YOUR SPINDLE CNC ROUTER

To make an informed decision, consider these key specifications:

- POWER (HP/KW): Indicates the spindle’s strength, with industrial units typically ranging from 2.2 HP to 12 HP or more. Options like HSD 2.2HP, HSD 4HP, or Colombo 5 HP spindles are common. Higher power allows for more aggressive cuts.

- SPEED RANGE (RPM): Critical for material compatibility and finish. Industrial spindles often run from 0 to 18,000 RPM, with some exceeding 60,000 RPM for specialized tasks.

- TORQUE OUTPUT: The twisting force, vital for large tools and tough materials. Industrial spindles maintain full torque at much lower RPMs compared to standard routers.

- COLLET TYPE AND CAPACITY: Determines the tool shank diameters the spindle can hold. Common types like the ER series (ER11, ER20, ER25, ER32) minimize runout and ensure secure clamping.

- COOLING METHOD (AIR VS. LIQUID): Air-cooled spindles are simple and use a fan, while liquid-cooled spindles use a circulating coolant for more efficient cooling in continuous, heavy-duty operations.

COMMON APPLICATIONS FOR A SPINDLE CNC ROUTER

The versatility of a spindle cnc router makes it indispensable across many industrial sectors. The development of modern tools focuses on speed and precision, and CNC spindle makers enable manufacturers to meet evolving industry demands with higher quality, more reliable outcomes.

Common applications include:

- Aerospace Component Manufacturing: Machining tough alloys with tight tolerances for engine parts, wing structures, and brackets, ensuring flight safety and performance.

- Precision Metal Cutting: Cutting metals like aluminum and stainless steel with exceptional speed and accuracy, achieving smooth finishes and dimensional precision.

- Intricate Mold and Die Work: Creating complex molds and dies that require fine detail and superior surface finishes, where high RPM and low runout are critical.

- Friction Stir Welding (FSW): This solid-state joining process requires spindles with high thrust capacity and robustness to withstand continuous loading.

- Robotics Integration: Mounting a spindle to a robot allows for automated, intricate applications, reducing manufacturing costs and human error.

INTEGRATION AND CONTROL: VFDS AND SPINDLE CONTROL SYSTEMS

The power and precision of a spindle cnc router depend on sophisticated control systems. Variable Frequency Drives (VFDs) and dedicated spindle control boards act as the brain, allowing precise management of the spindle’s performance.

UNDERSTANDING THE VARIABLE FREQUENCY DRIVE (VFD)

A Variable Frequency Drive (VFD), or inverter, is an electronic device essential for powering and controlling a high-frequency spindle cnc router. Its main function is to convert standard electrical power into a variable frequency, three-phase output to run the spindle motor. Because an AC motor’s speed is proportional to the power frequency, the VFD enables precise control over the spindle’s RPM.

Beyond speed control, VFDs provide programmable acceleration and deceleration ramps to prevent mechanical shock. They also protect the spindle motor from electrical issues like overcurrent and overheating, extending its lifespan. A VFD display provides real-time feedback on the spindle’s running status.

SPINDLE CONTROL BOARDS AND CNC INTEGRATION

While the VFD handles power, the spindle control board is the intermediary between the CNC controller and the VFD. This board integrates the spindle cnc router into the overall CNC system, enabling software-driven control.

The control board connects to the CNC controller and is wired to the VFD, allowing the CNC software to send commands dictating the spindle RPM. Using G-code, an operator can program the machine to automatically adjust spindle speed for different tool paths or materials. This optimizes cutting conditions and extends tool life without manual intervention.

System compatibility between the CNC controller, control board, and VFD is paramount. Most industrial CNC systems are designed for seamless integration, allowing full software control of all spindle functions.

ENSURING LONGEVITY: PROACTIVE SPINDLE MAINTENANCE AND REPAIR

For any industrial facility, the spindle cnc router is a critical investment. Ensuring its longevity through proactive maintenance and timely repair is essential for profitability. A robust maintenance schedule prevents costly downtime, maximizes the spindle’s lifespan, and ensures consistent part quality.

When your spindle requires expert attention, MZI Precision specializes in industrial manufacturing spindle repair and rebuilding. We restore your equipment to OEM specifications, ensuring it performs reliably. More info about our expert repair services is available on our website.

ROUTINE MAINTENANCE CHECKLIST

Implementing a routine maintenance checklist is a non-negotiable step to prolong the life of your spindle cnc router. Regular cleaning and inspections are mandatory.

Here are essential tasks:

- CLEAN SPINDLE AND TOOL HOLDER: Keep the taper, collet, and tool holder free from contaminants that cause runout and premature wear.

- INSPECT FOR VIBRATION OR NOISE: Pay attention to unusual sounds or vibrations during operation, as they can indicate bearing wear or imbalance.

- CHECK COOLING SYSTEM: Ensure the cooling system is operating effectively. Keep air-cooled fins clear and check coolant levels and filters on liquid-cooled systems.

- VERIFY COLLET AND DRAWBAR: Regularly inspect collets for wear or cracks. Ensure the drawbar provides adequate clamping force and replace worn components as needed.

- MONITOR LUBRICATION: If required, follow the manufacturer’s lubrication schedule. Monitor automatic systems for proper dispensing.

- CHECK AIR PRESSURE: For air-purged spindles, verify that air pressure is within the specified range to prevent contaminants from entering the bearings.

RECOGNIZING SIGNS OF SPINDLE FAILURE

Even with good maintenance, a spindle cnc router will eventually show signs of wear. Recognizing these indicators early can prevent an emergency shutdown.

- INCREASED VIBRATION OR CHATTER: A sudden increase in vibration or chatter marks on parts often points to bearing wear or imbalance.

- UNUSUAL NOISES: Grinding, whining, or rattling sounds are strong indicators of internal issues, most commonly bearing failure.

- DEGRADED SURFACE FINISH: A consistent decline in the surface quality of parts can be due to excessive runout or instability in the spindle.

- SPINDLE OVERHEATING: An excessively hot spindle housing is a serious warning sign of failing bearings, poor lubrication, or a malfunctioning cooling system.

- INCREASED TOOL RUNOUT: If you measure an increase in tool runout, it points directly to issues with bearings, the collet system, or the shaft, leading to part inaccuracies.

- FREQUENT TOOL BREAKAGE: A sudden increase in unexplained tool failures can sometimes be traced to excessive spindle vibration or runout.

When you observe persistent issues that routine maintenance doesn’t resolve, it’s time to contact experts for professional repair.

FREQUENTLY ASKED QUESTIONS ABOUT CNC ROUTER SPINDLES

We understand that investing in and maintaining a spindle cnc router can raise many questions. Here are some of the most common inquiries.

WHAT ARE THE MAIN ADVANTAGES OF A HIGH-FREQUENCY SPINDLE?

High-frequency spindles are crucial for industrial manufacturing, offering several key advantages:

- HIGHER PRODUCTION SPEEDS: A significantly higher RPM range allows for faster material removal and shorter cycle times, increasing facility productivity.

- GREATER TORQUE OUTPUT: Industrial spindles maintain substantial torque even at lower RPMs, enabling heavier cuts in tough materials without sacrificing accuracy.

- IMPROVED FINISH AND LONGEVITY: Precision design leads to less vibration, which improves surface finishes and extends the life of cutting tools and spindle components.

- IMPROVED RELIABILITY: Built for demanding, continuous industrial applications, these spindles result in less downtime and more cost-effective manufacturing.

HOW DO I KNOW WHEN MY SPINDLE NEEDS PROFESSIONAL REPAIR?

You should seek professional repair for your spindle cnc router when you observe persistent issues that routine maintenance doesn’t fix. Key signs include increased vibration, unusual noises (grinding, whining), a degraded surface finish on parts, or increased tool runout. Any sudden change in performance, like a drop in power, overheating, or a catastrophic failure (e.g., seizing), requires immediate expert assessment to prevent further damage. Attempting complex repairs without specialized tools can cause more severe problems.

WHAT IS A VFD AND WHY IS IT ESSENTIAL FOR A HIGH-FREQUENCY SPINDLE?

A VFD (Variable Frequency Drive) is an electronic device that converts standard electrical power into the variable frequency power required by a high-frequency spindle cnc router. It is essential for several reasons:

- PRECISE SPEED CONTROL: The VFD allows for exact and continuous control over the spindle’s RPM, which is critical for optimizing cutting for different materials and tools.

- OPTIMAL PERFORMANCE: It ensures the spindle motor receives the correct power profile at all speeds, maximizing torque and efficiency.

- MOTOR PROTECTION: VFDs include protective features that safeguard the motor from electrical issues like overcurrent, extending its lifespan.

- SOFT START/STOP: By enabling a gradual ramp-up and ramp-down of speed, VFDs reduce mechanical stress on bearings and other components, improving longevity.

Without a VFD, a high-frequency spindle cannot operate correctly, severely limiting the CNC router’s versatility and precision.

CONCLUSION

The journey to finding and maintaining the ideal spindle cnc router for your industrial manufacturing needs is a critical one. We’ve explored how the spindle acts as the precision heart of your CNC machine, delivering the speed, torque, and accuracy vital for quality output in demanding sectors like aerospace. Understanding the distinct advantages of motorized versus belt-driven spindles, and carefully matching their specifications to your specific materials and applications, is paramount for optimizing performance and profitability.

Furthermore, we’ve highlighted how the seamless integration with Variable Frequency Drives (VFDs) and spindle control boards empowers automated, precise control over your machining processes. Yet, even the most robust spindles require diligent care. A proactive maintenance regimen, coupled with the ability to recognize early signs of wear, is essential for ensuring longevity and preventing costly downtime.

At MZI Precision, we understand the intricate demands placed on industrial manufacturing spindles. Our expertise lies in providing expert spindle repair and rebuilding services, carefully restoring your equipment to OEM specifications and ensuring it performs with the precision your operations require. Whether you’re in California, from Huntington Beach to Los Angeles, we are your trusted partner in maintaining the critical components that drive your success.

Explore our industrial spindle motor solutions today to find how we can support your manufacturing excellence. For a personalized assessment of your spindle needs or to discuss repair options, don’t hesitate to contact us for a consultation on your spindle needs.