Milling machine spindle repair is crucial for keeping your industrial equipment running smoothly. It helps minimize downtime, improves performance, and extends the life of your milling machines. These spindles are at the heart of manufacturing setups, demanding regular maintenance to avoid costly interruptions.

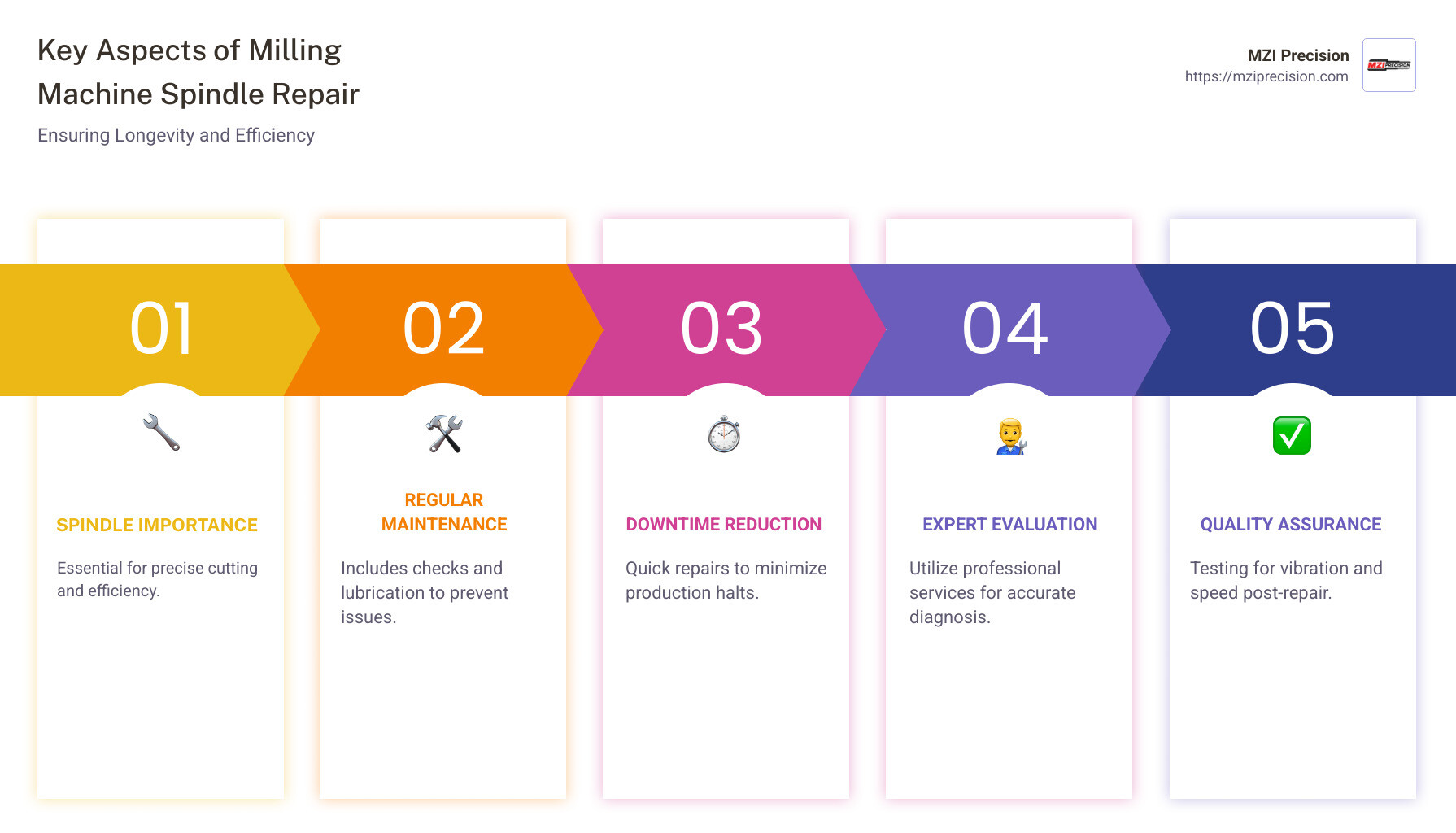

- Spindle Importance: Acts as the machine’s core, essential for cutting accuracy and efficiency.

- Maintenance: Regular checks and proper lubrication prevent small issues from causing bigger failures.

- Downtime Reduction: Quick repairs ensure minimal halt in production, saving time and money.

In manufacturing, particularly in industries like aerospace, the spindle’s role is invaluable. These tiny powerhouse components need care and attention to prevent sudden breakdowns that could paralyze production lines. Experts and precision providers like MZI Precision understand this, offering top-notch milling machine spindle repair services to keep your operations running like clockwork.

Milling machine spindle repair terms explained:

– cnc machine spindle repair

– high-speed spindle repair

– machine spindle

Identifying Spindle Issues

Recognizing spindle issues early can save time and money. Let’s look at the key signs that indicate your milling machine spindle might need repair:

Audible Noise

Unusual noises are often the first sign of trouble. When spindles operate, they should run smoothly and quietly. If you hear grinding, whining, or any unusual sounds, it’s time to investigate. These noises can result from wear and tear, improper installation, or lack of maintenance. Ignoring these sounds can lead to more significant issues down the road, as noted by experts at MZI Precision.

Vibration

Excessive vibration is another red flag. A well-functioning spindle should operate with minimal vibration. When vibration increases, it can affect the precision and quality of your work. This issue might stem from bearing failure or misalignment, both of which require professional attention. Regular checks can catch these problems early, preventing costly repairs or replacements.

Performance Decrease

A drop in performance is a clear indicator that your spindle needs attention. Reduced precision, slower operation, and inconsistent results are common signs. If your projects aren’t turning out as expected, it might be the spindle crying for help. These performance issues often boil down to spindle components like bearings or misalignment. Addressing them promptly ensures your machine operates at its best.

In summary, paying attention to these signs—audible noise, vibration, and performance decrease—can help you catch spindle issues early. By doing so, you can maintain the efficiency and longevity of your milling machines. Next, we’ll explore the detailed process of milling machine spindle repair, from initial inspection to component replacement.

Milling Machine Spindle Repair Process

When your milling machine spindle starts acting up, a structured repair process can bring it back to life. Let’s explore the milling machine spindle repair process, focusing on component inspection, repair, and replacement.

Component Inspection

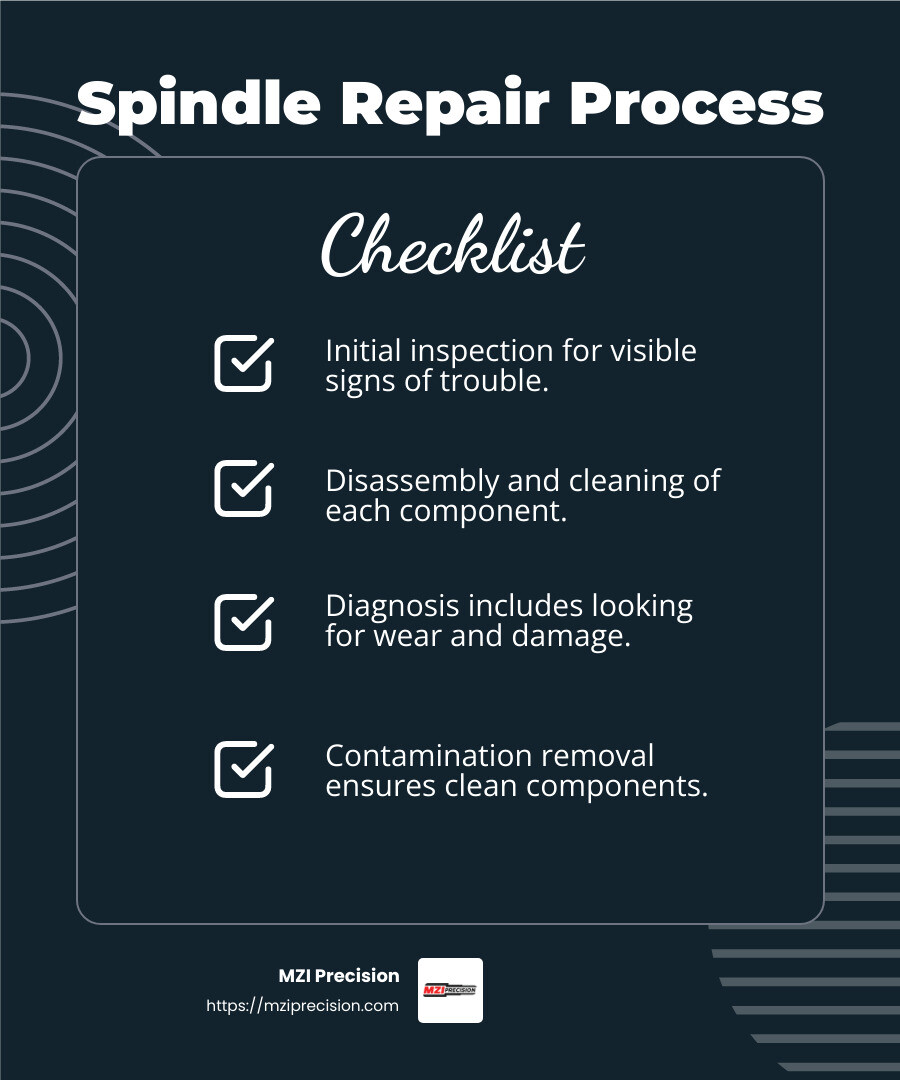

The first step in the repair journey is a thorough inspection. Once the spindle arrives at the repair facility, technicians begin with an initial inspection. This involves carefully examining the spindle to note its condition and any obvious signs of trouble.

Disassembly and Cleaning

Next, the spindle is disassembled piece by piece. This allows technicians to inspect each component individually. During this stage, every part is carefully cleaned to remove contaminants like dirt and grease. Clean components make it easier to spot issues like wear, damage, or contamination.

Diagnosis

With a clean slate, technicians can perform a detailed diagnosis. They look for signs of wear, such as grooves or scratches, which often indicate prolonged use or improper maintenance. Damage might include cracks or breaks in components, while contamination could involve foreign particles that have entered the spindle.

Repair and Replacement

Once the inspection and diagnosis are complete, the next step is deciding whether to repair or replace faulty components.

OEM Specifications

Technicians aim to restore the spindle to its original condition by adhering to OEM (Original Equipment Manufacturer) specifications. This ensures that all parts function as intended, maintaining the machine’s performance and reliability.

Faulty Components

Faulty components are either repaired or replaced based on their condition. For instance, worn bearings might be swapped out for new ones, while damaged shafts could be repaired through precision machining. The goal is to get the spindle back to its optimal state.

By following these meticulous steps, technicians ensure that your spindle is ready for action. The process is all about precision and care, guaranteeing that your milling machine can perform its essential role with reliability and accuracy.

In the next section, we’ll explore the importance of testing and quality assurance to ensure your spindle is in top-notch condition before it returns to service.

Testing and Quality Assurance

After the repair and replacement phase, it’s crucial to ensure that the spindle is ready for its demanding role in industrial manufacturing. This is where testing and quality assurance come into play.

Precision Balance

The first step in testing is achieving precision balance. This means ensuring that all rotating components of the spindle are perfectly balanced. An unbalanced spindle can lead to excessive vibration, which not only affects performance but can also cause further damage over time.

To address this, technicians use specialized equipment to measure and adjust the balance of the spindle. This ensures smooth operation, reducing wear and tear and extending the spindle’s lifespan.

Speed Analysis

Next, we look at speed analysis. A spindle must operate efficiently at various speeds, especially if you’re considering increasing your machine’s RPM for future upgrades. During speed analysis, technicians test the spindle at different speeds to ensure it performs consistently and reliably.

By doing this, they can identify any issues that might arise at higher speeds, such as overheating or instability. This step is vital for those planning to upgrade their machines for higher productivity.

Vibration Analysis

Lastly, we conduct a vibration analysis. Vibration is a critical factor that affects the accuracy and quality of machining. Using tools like accelerometers and piezoelectric sensors, technicians measure the spindle’s vibrations in real-time.

These sensors detect even the slightest vibrations, helping identify any underlying issues. By addressing these vibrations, technicians can ensure the spindle operates smoothly, improving the overall quality of the machining process.

Through these rigorous testing procedures, MZI Precision ensures that your spindle is not just repaired, but optimized for peak performance. This comprehensive approach minimizes downtime and maximizes the reliability of your milling operations.

In the following section, we’ll address some frequently asked questions about milling machine spindle repair, helping you make informed decisions about maintaining your equipment.

Frequently Asked Questions about Milling Machine Spindle Repair

Can a spindle be repaired?

Absolutely, a spindle can be repaired. Milling machine spindle repair involves identifying and fixing the specific issues affecting the spindle’s performance. This process can include replacing worn components, cleaning, and rebalancing the spindle. Using OEM parts during repairs ensures that the spindle meets the original specifications, providing better fit and longevity. OEM parts are typically more reliable than aftermarket alternatives, which can significantly improve the spindle’s performance and lifespan.

How much does it cost to fix a spindle?

The cost of fixing a spindle varies widely based on several factors. These include the extent of the damage, the type of spindle, and whether OEM parts are used. For minor repairs, costs might be a few hundred dollars. However, extensive rebuilds or repairs involving high-end parts could run into thousands. It’s always best to get a detailed quote from the service provider. This quote should include parts, labor, and any additional services or upgrades you might consider.

What causes a spindle to go bad?

Several factors can lead to spindle failure. Damage from mishandling or accidents is a common cause. Poor lubrication is another culprit, leading to increased friction and wear. Over time, this can cause the spindle components to degrade. Contamination from dust or debris can also affect performance. Regular maintenance and proper handling are crucial to prevent these issues and extend the spindle’s life.

Understanding these aspects can help you make informed decisions about milling machine spindle repair and maintenance. In the next section, we’ll wrap up with why MZI Precision is your go-to choice for spindle services, thanks to their exceptional service and industry expertise.

Conclusion

When it comes to milling machine spindle repair, choosing the right service provider can make all the difference. At MZI Precision, we pride ourselves on delivering exceptional service and leveraging our extensive industry expertise. Our commitment to quality ensures that your spindles not only get repaired but also perform optimally for a long time.

Why Choose MZI Precision?

Exceptional Service: We place a significant emphasis on customer satisfaction. Our team works closely with you to understand your specific needs and provide custom solutions that ensure minimal downtime and maximum efficiency.

Industry Expertise: With years of experience in spindle repair and rebuilding, our skilled technicians are equipped to handle a wide range of spindle issues. Our expertise in dealing with OEMs rebuilt spindles guarantees that your equipment receives the highest standard of care.

Quality Assurance: Every spindle that comes through our doors undergoes a rigorous inspection and repair process. We use state-of-the-art equipment to ensure precision in balancing, speed analysis, and vibration analysis. This meticulous approach helps us deliver results that meet or exceed your expectations.

For those seeking reliable and efficient milling machine spindle repair, MZI Precision stands out as a trusted partner. Our dedication to quality, combined with our industry know-how, ensures that your spindles are in the best hands.

To learn more about our services and how we can help you optimize your CNC machine performance, visit our CNC Machine Spindle Services page. Let us help you keep your machines running smoothly and efficiently.