The Importance of High-Speed Spindle Repair in Industrial Manufacturing

High-speed spindle repair is vital to maintaining the efficiency and precision of industrial manufacturing. Spindles, powerful components that drive machinery, bear immense responsibilities. A malfunction can halt operations and lift costs. To quickly address this, here are the essential aspects:

- Fast and reliable repair services prevent production downtime.

- Expert technicians ensure high precision repairs.

- Testing and procedures guarantee high-quality performance post-repair.

- Regular maintenance extends spindle lifespan and boosts productivity.

In the competitive world of industrial manufacturing, seamless operations are crucial. A malfunctioning spindle can disrupt production, leading to costly delays. MZI Precision understands these challenges, providing robust repair solutions to keep your machinery running smoothly. With skilled technicians and proven methods, they ensure that your spindle not only meets but exceeds expectations after each repair.

To maintain the highest efficiency in your industry, choosing a trusted spindle repair service that values your production time is essential. At MZI Precision, we are committed to delivering best reliability and precision through our meticulous repair process.

Simple high-speed spindle repair glossary:

– High-speed spindle balancing

– spindle failure analysis

– spindle vibration analysis

Understanding High-Speed Spindle Repair

High-speed spindles are the heart of precision machining in industrial manufacturing. They enable rapid material removal and ensure high precision, operating at speeds exceeding 30,000 RPM. When these spindles malfunction, the impact on production can be significant. That’s why understanding the repair process is crucial.

Spindle Repair Essentials

Repairing a high-speed spindle requires specialized knowledge and tools. The process begins with a thorough evaluation to identify any issues. Technicians disassemble the spindle, examining each component for wear or damage. This step is critical, as even a minor fault can lead to major inefficiencies.

After disassembly, the spindle is cleaned using ultrasonic technology to ensure all parts are free from contaminants. Technicians then replace or refurbish damaged components. For example, bearing replacements are common, as they are vital for smooth spindle operation.

Precision Machining Benefits

Precision machining relies heavily on the spindle’s accuracy. A well-maintained spindle improves product quality and reduces waste. It also ensures that machinery can operate at optimal speeds without risking breakdowns.

Efficiency and Cost Savings

Proactive spindle repair can save significant costs in the long run. By addressing issues early, manufacturers can avoid the expense of complete spindle replacements or extended downtime. Regular maintenance and timely repairs ensure that machinery continues to operate efficiently, supporting continuous production.

In the field of industrial manufacturing, high-speed spindle repair is not just a service—it’s a necessity. By understanding the repair process and its importance, manufacturers can maintain the precision and efficiency that their operations demand.

Key Components of Spindle Repair

When it comes to industrial manufacturing spindle repair, understanding the key components is essential for effective maintenance and longevity. Spindles are complex assemblies with several critical parts, each playing a vital role in the overall functionality. Let’s break down the components and their significance in the repair process.

Mechanical Spindles

Mechanical spindles are the workhorses of many industrial machines. They consist of a rotating shaft, bearings, and a housing. The shaft is the core component, transferring power from the motor to the tool. Bearings support the shaft, allowing it to rotate smoothly at high speeds. The housing encases these parts, providing structural support and protection.

In the repair process, technicians carefully inspect these components. Bearings often require replacement due to wear from high-speed operations. Using high-quality bearings, like ABEC 7 or better, can significantly improve spindle performance and longevity.

Air-Bearing Spindles

Air-bearing spindles are used in applications where precision is paramount. Unlike mechanical spindles, they use a thin layer of air to support the shaft, reducing friction and wear. This design allows for extremely high speeds and precision.

Repairing air-bearing spindles requires specialized skills and equipment. Technicians must ensure the air gap is perfectly calibrated. Even a small deviation can affect performance. The repair process often involves cleaning the air supply system and checking for any blockages or leaks.

Spindle Components

Regardless of the type, spindles share common components that are crucial in the repair process:

- Bearings: As mentioned, they are central to smooth operation. Regular inspection and replacement are key to maintaining spindle health.

- Shafts: Technicians check for wear, cracks, or bends. A damaged shaft can cause vibrations and reduce machining accuracy.

- Lubrication: Proper lubrication is essential to minimize friction and prevent overheating. Technicians ensure the right type and amount of lubricant is used.

- Seals: These prevent contaminants from entering the spindle. Over time, seals can degrade and need replacing to maintain a clean operating environment.

Importance of Component Integrity

Each component’s integrity directly impacts the spindle’s performance. A faulty bearing or misaligned shaft can lead to inefficiencies and increased wear on other parts. By focusing on the state of each component during repairs, technicians ensure the spindle operates at its best.

High-speed spindle repair is a meticulous process that demands attention to detail. By understanding the key components and their roles, manufacturers can appreciate the complexity and importance of professional repair services. This knowledge empowers them to make informed decisions, ensuring their machinery runs smoothly and efficiently.

Benefits of Professional Spindle Repair Services

In industrial manufacturing, high-speed spindle repair is not just about fixing what’s broken. It’s about ensuring precision, reliability, and reduced downtime for your operations. Let’s explore why professional spindle repair services are so vital.

Precision

Precision is the cornerstone of any manufacturing process. When spindles operate at high speeds, even the smallest error can lead to significant production issues. Professional spindle repair services ensure that your spindles are restored to their optimal condition, enhancing the accuracy of your machinery.

An example of this meticulous attention to detail comes from a case where MZI Precision provided spindle repairs that resulted in a performance better than new, achieving tolerances within 2 microns. Such precision is crucial for maintaining the quality and efficiency of your production line.

Reliability

Reliability in manufacturing means less stress and more productivity. A well-maintained spindle is a reliable spindle. By entrusting your spindle repair to experts, you ensure that each component is thoroughly inspected and repaired or replaced as necessary. This attention to detail extends the lifespan of your spindles and keeps your machinery running smoothly.

Technicians at MZI Precision focus on component integrity, ensuring each part functions seamlessly. For example, bearings are often replaced with high-quality alternatives to withstand the demands of high-speed operations. This dedication to quality ensures that your spindles are dependable, reducing the risk of unexpected failures.

Reduced Downtime

Downtime is the enemy of productivity. When a spindle fails, it can bring your entire production line to a standstill. Professional repair services minimize this risk by addressing potential issues before they escalate. Regular maintenance and timely repairs keep your spindles in top shape, preventing costly interruptions.

A real-world illustration of this benefit is seen in the experience of a company that used a Spindle Health Monitoring System. This system provided real-time data on spindle conditions, allowing them to schedule maintenance proactively and avoid catastrophic failures. As a result, they significantly reduced downtime and improved their production efficiency.

In summary, professional spindle repair services offer more than just a quick fix. They provide the precision, reliability, and reduced downtime that are essential for maintaining smooth and efficient manufacturing operations. With expert repair services, you can keep your machinery running at its best, ensuring consistent quality and productivity.

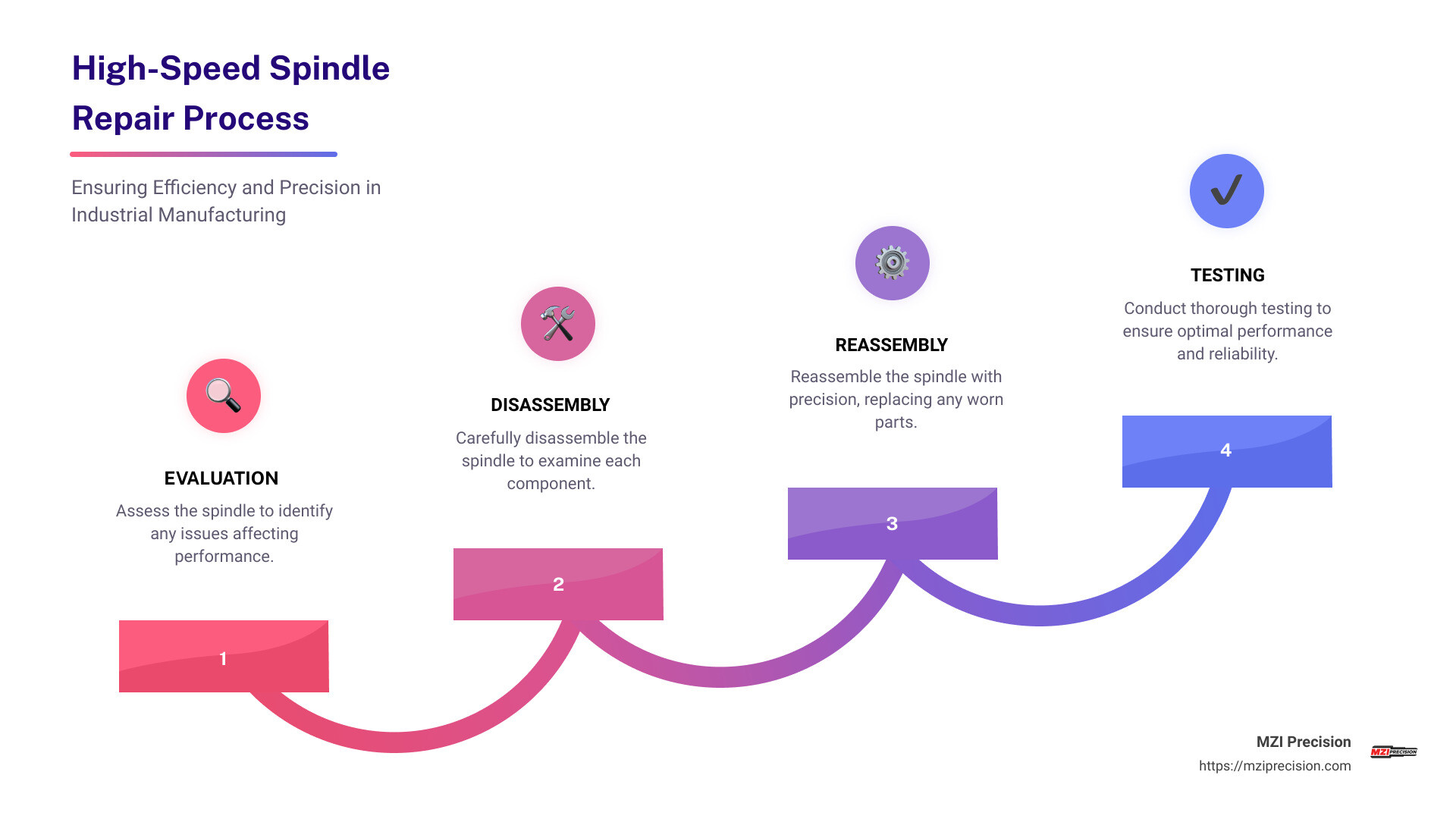

High-Speed Spindle Repair Process

High-speed spindle repair is a meticulous process that involves several critical steps to ensure your industrial manufacturing operations run smoothly. Here’s a breakdown of the key stages: evaluation, disassembly, reassembly, and testing.

Evaluation

The repair process begins with a thorough evaluation. This step involves inspecting the spindle to determine its condition and identify the root cause of any failure. Technicians document their findings in a detailed repair report, which includes photographs and observations. This comprehensive evaluation helps in creating a custom repair plan that addresses specific issues.

Disassembly

Once the evaluation is complete, the spindle is carefully disassembled. During this phase, each component is examined for wear and damage. Parts are cleaned using advanced methods, such as hot ultrasonic cleaning, to ensure all residues are removed. This step is crucial for identifying which parts need replacement or refurbishment.

Reassembly

After disassembly and cleaning, the reassembly process begins. New parts and high-speed bearings are installed following precise procedures. This ensures that the spindle is restored to its original specifications or better. For instance, the spindle rotor shaft is rebalanced to less than a G1 level, ensuring optimal performance.

Testing

The final stage of the repair process is testing. The spindle undergoes rigorous tests, including run-in, balancing, and vibration testing, to confirm its functionality. This step ensures that the spindle can withstand the demands of high-speed operations and delivers consistent performance. MZI Precision’s commitment to quality means that each spindle is tested to meet the highest industry standards before it is returned to the customer.

The high-speed spindle repair process is designed to restore and improve the performance of your spindles, ensuring they meet the demanding requirements of industrial manufacturing. With careful evaluation, precise disassembly and reassembly, and thorough testing, you can trust that your spindles will operate with precision and reliability.

Frequently Asked Questions about High-Speed Spindle Repair

What are the signs that a spindle needs repair?

A spindle in need of repair often shows some clear signs. Increased noise during operation is a common indicator. If you notice unusual sounds like grinding or squealing, it might be time to check the spindle. Vibration is another warning sign. Excessive vibration can lead to poor machining quality and damage other machine components. Reduced precision and efficiency in machining tasks can also point to spindle issues. If your machine isn’t performing as it used to, the spindle might be the culprit.

How long does a typical spindle repair take?

The time it takes to repair a spindle can vary. Typically, a standard spindle repair might take anywhere from a few days to a couple of weeks. The duration depends on the complexity of the repair and the availability of replacement parts. At MZI Precision, we aim to minimize downtime and provide a quick turnaround without compromising on quality. Our streamlined processes ensure that your spindle is back in action as soon as possible.

What is the cost range for spindle repair services?

Repair costs for spindles can vary widely based on several factors. The extent of the damage, the type of spindle, and the specific repairs needed all influence the final price. Generally, spindle repair costs can range from a few thousand dollars to over ten thousand dollars. At MZI Precision, we focus on providing cost-effective solutions. Our team evaluates all repair options before considering a complete replacement, helping you save money in the long run.

Conclusion

At MZI Precision, we understand that when your spindle is down, your production is impacted. That’s why we are committed to delivering exceptional service and expertise in high-speed spindle repair. Our team of skilled technicians and engineers is dedicated to restoring your industrial manufacturing spindles to peak performance.

With a deep understanding of OEM spindles, we ensure that every repair meets or exceeds original specifications. Our thorough and meticulous approach allows us to not only fix your spindle but sometimes even improve its performance beyond its original state. This level of expertise means you can trust us to handle the most complex repairs with precision and confidence.

Our service doesn’t stop at repair. We offer comprehensive support and a full one-year in-service warranty for all units tested and repaired by our team. This commitment to quality and customer satisfaction ensures that your operations run smoothly with minimal downtime.

Choosing MZI Precision means opting for a partner who brings a wealth of technical expertise and a genuine commitment to your success. Our passion for spindle technology and dedication to delivering reliable, high-quality repair services make us the ideal choice for your industrial manufacturing spindle repair needs.

Learn more about how we serve various industries and keep your operations at the forefront of precision machining by visiting our industries served page. Let us help you maintain efficiency and productivity across your manufacturing processes.