Why Industrial Gearbox Rebuilds Matter in California

Gearbox rebuild California services provide a cost-effective solution for manufacturing and industrial businesses facing critical equipment issues. Rather than replacing expensive components, a professional rebuild can restore your system to OEM specifications at a fraction of the cost.

Quick Answer: Why Choose MZI Precision

| Service Feature | MZI Precision Advantage |

|---|---|

| Capacity | Industrial gearboxes up to 50,000 lbs |

| Turnaround | Standard 1–2 weeks; 24–48 hr rush available |

| Statewide Logistics | Free pickup & delivery across California |

| Warranty | 12–24 month comprehensive coverage |

When your industrial operation faces unexpected downtime due to gearbox failure, every hour costs thousands in lost production. California’s manufacturing, agriculture, energy, and aerospace sectors all rely on precision gearbox systems to maintain productivity.

A professional gearbox rebuild involves a complete disassembly, thorough inspection, replacement of worn components, and precision reassembly to restore your equipment to optimal performance standards. This process typically saves businesses 60% compared to purchasing new equipment while extending service life significantly.

Most California gearbox rebuilders offer:

- Free pickup and delivery services statewide

- Emergency 24–48 hour rush options

- Comprehensive warranties (typically 12–24 months)

- AGMA-compliant testing and certification

As one California shop owner notes, “We will not shut our doors until we finish your job,” highlighting the dedication of specialized rebuilders to minimize your downtime.

What Exactly Is a Gearbox Rebuild (and How Is It Different From Repair or Replacement?)

Think of your industrial gearbox like the heart of your operation. When it starts to falter, you have options—but not all solutions are created equal. A gearbox rebuild California service goes far beyond a simple fix-it job.

When we rebuild a gearbox at MZI Precision, we’re essentially giving it a complete rebirth. We dismantle the entire unit down to its smallest components, carefully inspect every gear, bearing, and shaft, then replace worn parts before precisely reassembling everything to meet or exceed original specifications.

“Most folks don’t realize that a proper rebuild often results in a gearbox that performs better than when it first left the factory,” our senior technician often tells clients. “We’re not just restoring—we’re often improving.”

This comprehensive approach follows strict American Gear Manufacturers Association (AGMA) standards, ensuring exceptional quality that frequently surpasses the original build. The result? Extended equipment life and significant cost savings—typically 60% less than buying new.

Core Definitions You Must Know

When discussing your gearbox rebuild California project, these terms will come up:

Precision Machining refers to our ability to create or refurbish components to incredibly tight tolerances—sometimes measuring just microns (that’s thinner than a human hair). This precision is what ensures your rebuilt gearbox runs smoothly and lasts longer.

Bearing Replacement isn’t just about swapping out worn parts. It involves selecting the right bearings, establishing proper preload, and ensuring perfect fit—all critical factors in preventing premature failure and ensuring optimal performance.

Reverse Engineering becomes essential when dealing with older or specialty equipment where original blueprints or replacement parts aren’t available. Our team can analyze, measure, and recreate components with incredible accuracy, breathing new life into systems others might consider beyond salvation.

When Replacement Is Unavoidable

While we pride ourselves on saving equipment others might scrap, sometimes replacement truly is the only option. Here’s when you might need to consider a new gearbox:

Catastrophic Damage occurs when failure has progressed so far that the housing or main structural components are compromised beyond repair. Think of it as the difference between engine repair and a car that’s been totaled.

Obsolete Design issues arise when the original gearbox has fundamental flaws that no amount of rebuilding can overcome. In these cases, upgrading to a newer design often makes more sense both financially and operationally.

Safety Compliance requirements sometimes change over time. When newer regulations demand features that simply cannot be integrated into your existing gearbox, replacement becomes necessary to ensure workplace safety and regulatory compliance.

The good news? In our experience at MZI Precision, roughly 85% of industrial gearboxes that come through our California facility can be successfully rebuilt. This means most of our clients avoid the hefty price tag and extended lead times of new equipment while getting their operations back up and running faster.

Signs Your Industrial Gearbox in California Needs Attention

Is your industrial gearbox trying to tell you something? Like any sophisticated piece of machinery, gearboxes often give warning signs long before they completely fail. Catching these signals early can be the difference between a planned maintenance event and a costly emergency shutdown.

Unusual vibration is often the first red flag your gearbox waves. When bearings begin to wear or gears develop damage, they create vibration patterns that weren’t there before. Think of it as your gearbox’s way of clearing its throat to get your attention.

Temperature increases are another telltale indicator something’s not right. A properly functioning gearbox maintains a consistent operating temperature. When that temperature creeps upward, it’s often because friction is increasing inside – possibly from inadequate lubrication or components wearing against each other.

Oil quality changes speak volumes about what’s happening inside your gearbox. Finding metal particles in your lubricant is like finding blood in your body – something inside is wearing down or breaking. Regular oil analysis is like a blood test for your equipment.

New noises should never be ignored. That grinding sound? It could be damaged gear teeth. The high-pitched whine? Possibly a bearing issue. The clicking during rotation? Likely a chipped component. Your ears can be outstanding diagnostic tools.

Performance decline might be subtle at first – maybe your equipment needs more power to do the same job, or production numbers are slipping slightly. These efficiency losses often indicate internal issues developing in your gearbox.

Modern manufacturing facilities across California are increasingly adopting sensor-based monitoring systems that can detect these issues before human senses can. As one plant manager told us after avoiding a major breakdown, “Those vibration sensors paid for themselves ten times over in the first year. Instead of an emergency, we scheduled a gearbox rebuild California service during our planned maintenance window.”

Early Warning Indicators Unique to High-Load California Industries

California’s diverse industrial landscape creates some unique challenges for gearbox systems that you won’t necessarily find in other regions:

In agricultural operations, the feast-or-famine nature of seasonal work means equipment often sits idle for months before suddenly running at full capacity. This cycle can be particularly tough on seals and lubrication systems. Smart operators schedule inspections before harvest season begins rather than finding problems when they’re already behind schedule.

The solar energy industry faces extreme temperature challenges, especially in desert installations where daytime highs and nighttime lows create significant thermal cycling. These conditions can quickly degrade standard lubricants and stress seals beyond their design limits. We’ve helped many solar facilities implement specialized high-temperature lubricants and improved cooling systems to protect their critical gearboxes.

For aerospace manufacturing, the precision requirements are among the most demanding in any industry. Even slight increases in backlash or tiny misalignments can affect product quality. When components must be machined to tolerances measured in microns, your gearbox can’t have any play whatsoever.

At MZI Precision, we’ve developed specialized diagnostic protocols for these California-specific applications. Our experience with the unique challenges faced by Golden State manufacturers helps us identify potential issues before they impact your production schedule, saving you both time and money when it comes to gearbox rebuild California services.

Common Industrial Gearbox Types Rebuilt Across the Golden State

California’s industrial landscape is as diverse as its geography, and so are the gearboxes powering its machinery. At MZI Precision, we’ve rebuilt just about every type of industrial gearbox you can imagine. Let’s take a tour through the most common types we encounter in our gearbox rebuild California services.

Planetary reducers are the workhorses of heavy machinery throughout the state. We love these compact powerhouses for their impressive torque capacity, but they demand absolute precision during rebuilding. One micron of misalignment can cascade into major issues down the line.

Helical gearboxes might be the most common sight in our shop. These reliable units run the production lines in everything from food processing to automotive parts manufacturing. They’re generally quiet and smooth operators, but over time, they can develop thrust loading issues that require expert attention.

“Helical gearboxes are like faithful old dogs,” our lead technician often says. “They’ll work forever if you treat them right, but they’ll definitely let you know when something’s wrong.”

Cycloidal drives present unique challenges with their distinctive design. Popular in food processing facilities throughout the Central Valley, these compact units deliver impressive reduction ratios but require specialized tooling and expertise during rebuilding.

When space is tight but power needs remain high, right-angle bevel units are often the solution. These specialized gearboxes experience unique wear patterns where the bevel gears mesh. Our team has developed specific techniques to address these high-stress areas during the gearbox rebuild California process.

High-speed spindles represent the precision end of our work. Critical in aerospace manufacturing and medical device production, these specialized gearboxes demand extraordinary balance and alignment during rebuilding—sometimes to tolerances of less than 0.0001 inches.

The mining operations in California’s more remote areas rely on mining crusher gearboxes that handle punishing loads in harsh environments. These massive units often require custom-manufactured replacement parts during rebuilding, something our in-house machining capabilities are perfectly suited for.

California’s renewable energy commitment means wind-turbine gearboxes have become a growing part of our business. These specialized units must withstand highly variable loads and environmental exposure while maintaining peak efficiency.

Sector Snapshot: Industries Driving Demand

The demand for gearbox rebuild California services comes from every corner of our state’s economy. Manufacturing operations concentrated in Los Angeles and the Bay Area typically need precision gearbox rebuilds to keep production lines moving. A single day of downtime can cost hundreds of thousands in lost production.

Power generation facilities—from traditional plants to the sprawling solar installations in the desert—depend on reliable gearbox operation. As one plant manager told us, “When a gearbox fails here, it’s not just machinery that stops—it’s electricity that doesn’t reach homes and businesses.”

California’s massive food and beverage sector presents unique challenges. These gearboxes must not only perform reliably but also meet strict hygiene standards. We’ve developed specialized cleaning and sealing processes to ensure compliance with these requirements.

Defense contractors and aerospace manufacturers in Southern California often come to us with high-precision rebuild needs that must meet exacting military specifications. These projects require detailed documentation and testing beyond standard industrial requirements.

The aggregate and cement industry, particularly in inland areas, relies on heavy-duty gearbox rebuilds for their crushing and conveying equipment. As a cement plant manager in Riverside County recently told us, “When our main crusher gearbox failed, we were looking at 8 weeks for a replacement. The gearbox rebuild California specialist had us back up and running in 10 days, saving us hundreds of thousands in lost production.”

From agriculture to aerospace, California’s industries keep turning thanks to properly maintained and rebuilt gearboxes—and we’re proud to play our part in keeping the Golden State productive.

Reverse Engineering & Parts Manufacturing

For many industrial gearboxes, especially older models, original replacement parts may be unavailable. Our gearbox rebuild California service includes:

- CNC Gear Cutting: We can manufacture custom gears to match or improve upon original specifications.

- 3-D Scanning: For complex components, we create digital models that allow precise reproduction.

- Obsolete Parts Recreation: Our engineering team can reverse-engineer discontinued components.

- Rush Lead Times: For emergency situations, we can manufacture critical components in as little as 24 hours. Download the MZI Precision Gearbox Rebuild & Support Brochure

As one food processing plant manager in the Central Valley told us, “When our 30-year-old mixer gearbox failed, we thought we’d have to replace the entire system. MZI Precision reverse-engineered the obsolete parts and had us back in production in less than a week.”

Cost, Turnaround Times, and Emergency Options

Let’s talk dollars and days – the two things most California plant managers worry about when facing unexpected gearbox troubles. The good news? A gearbox rebuild California service typically saves you around 60% compared to buying new equipment.

When that critical production line gearbox fails, you need solutions fast, not sticker shock. Most of our clients are pleasantly surprised when they see their rebuild quote compared to replacement costs.

What Influences Your Quote in California

Not all gearbox rebuilds are created equal. Your specific situation will determine your final investment:

Gear size and complexity plays a major role – rebuilding a massive mining crusher gearbox naturally costs more than a small conveyor drive. When we’re working with precision gears that measure tolerances in microns, the expertise required affects pricing.

Weight and handling requirements matter too. We’ve rebuilt gearboxes weighing up to 50,000 pounds! These behemoths require specialized lifting equipment and handling procedures that smaller units don’t need.

Industry application significantly impacts your quote. Food processing gearboxes, for instance, often require FDA-compliant materials and special surface treatments that aerospace applications might not. As one bakery maintenance manager told us, “The food-grade requirements added a bit to our rebuild cost, but it was still way less than replacement.”

Custom materials sometimes make sense for improving longevity. We might recommend upgrading to specialty alloys or advanced heat treatments for components that repeatedly fail. These improvements add some cost upfront but pay dividends in extended service life.

Typical Timeline Benchmarks

Time is literally money when production is halted. Here’s what to expect:

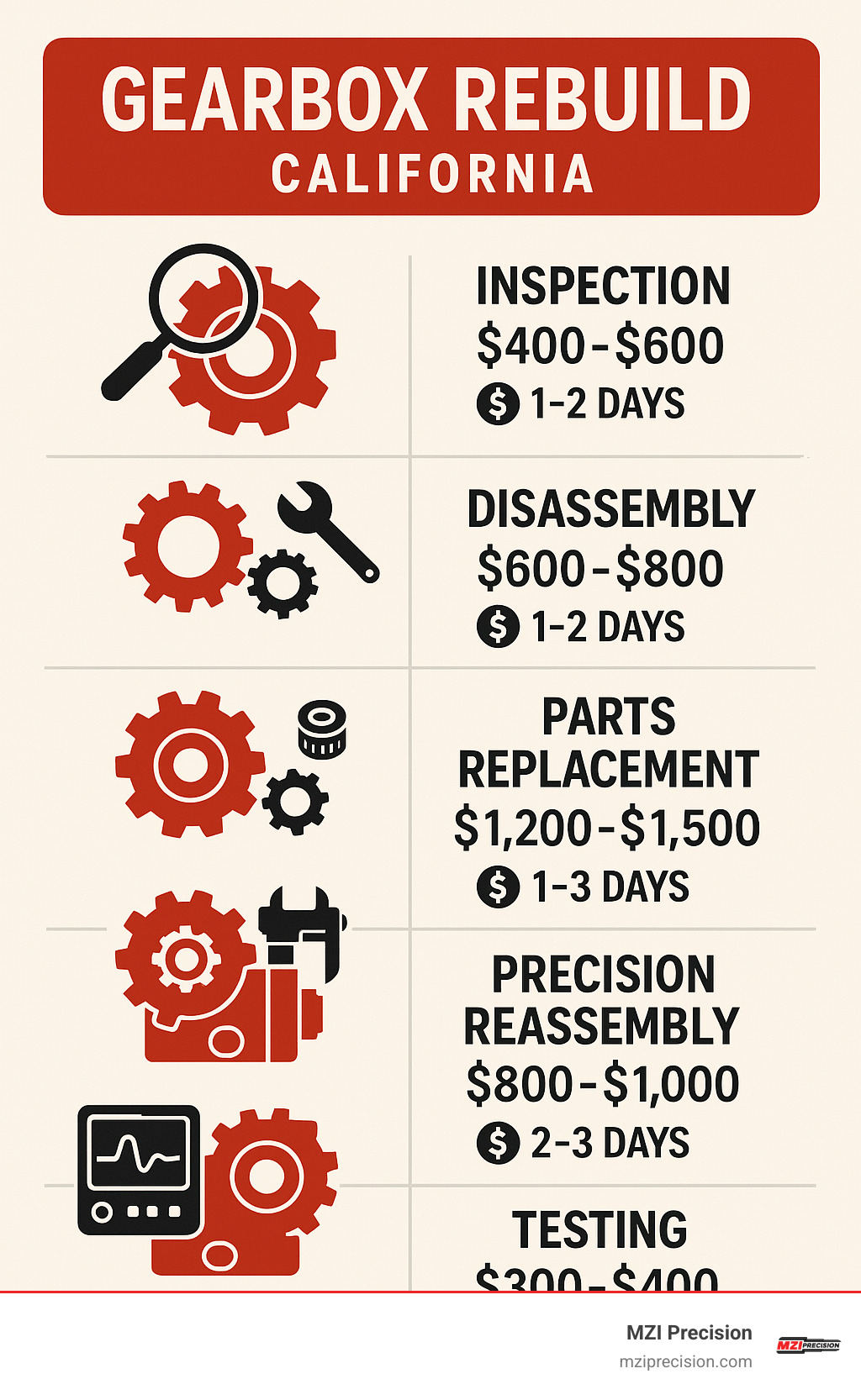

A standard rebuild typically takes 1-2 weeks from door to door for most industrial gearboxes. This includes thorough inspection, disassembly, parts replacement, precision reassembly, and testing.

Need it faster? Our weekend service teams work when others don’t. As our shop foreman likes to say, “We will not shut our doors until we finish your job.” That commitment has saved countless production schedules across California.

For absolute emergencies, our 24-hour tear-down report gives you quick answers about what’s wrong and what it’ll take to fix it. This helps you make informed decisions fast.

If your gearbox needs custom part manufacturing, expect an additional 2-5 days depending on complexity. Our in-house machining capabilities help minimize these delays, unlike shops that outsource this critical work.

At MZI Precision, we understand that logistics shouldn’t add to your headaches. That’s why we offer free pickup and delivery throughout California. Our specialized transport team ensures your valuable equipment arrives safely at our facility and back to yours without adding complications to your already stressful situation.

One operations manager from a Fresno manufacturing plant summed it up perfectly: “The rush fee was nothing compared to what we would have lost in downtime waiting for a new gearbox. MZI had us running again in 36 hours when the OEM quoted us six weeks for replacement.”

How to Choose a California Gearbox Rebuild Partner

Finding the right gearbox rebuild California partner isn’t just about price shopping – it’s about finding a team that treats your equipment like their own. The choice you make directly impacts your operation’s uptime, productivity, and bottom line.

“I’ve learned the hard way that not all rebuilders are created equal,” shares Tom, a maintenance supervisor at a Fresno food processing plant. “What separates the professionals from the amateurs becomes crystal clear when your production line is down and you’re losing thousands every hour.”

When evaluating potential partners, focus on these critical qualities:

Look for shops with proper certifications and standards compliance. A legitimate gearbox rebuild California specialist will follow AGMA class tolerances and maintain ISO 9001 certification. These aren’t just fancy certificates – they represent a commitment to documented quality processes.

In-house manufacturing capabilities are a game-changer. When your rebuilder can manufacture custom parts on-site rather than outsourcing, you’ll see dramatically reduced turnaround times. At MZI Precision, our CNC machining center enables us to reproduce even obsolete components within days, not weeks.

Testing facilities tell you everything about a rebuilder’s confidence in their work. A shop without comprehensive load testing equipment simply cannot verify that your rebuilt gearbox will perform under real-world conditions. Our full-load testing protocols simulate your exact operating conditions before any unit leaves our facility.

Industry-specific experience matters tremendously. Different sectors – from solar tracking systems to food processing to aerospace – each present unique gearbox challenges. A rebuilder who regularly works in your industry will anticipate issues others might miss.

Finally, pay attention to their communication protocols. The best gearbox rebuild California partners provide clear, consistent updates throughout the process. If they can’t communicate effectively during the sales process, imagine how frustrating it will be when your equipment is in pieces on their shop floor.

Questions to Ask Before Signing a PO

Before committing to any rebuilder, arm yourself with these critical questions:

“What warranty do you offer on rebuilt gearboxes?” The industry standard ranges from 12-24 months, but the specifics matter. Is labor included? What about removal and reinstallation if issues arise?

“What testing protocols do you use before returning the gearbox?” Listen carefully to this answer – it reveals whether they’re truly confident in their work or just hoping for the best.

“Do you recommend keeping any spare parts on hand for this gearbox?” A thoughtful answer here demonstrates forward-thinking and genuine concern for your operation’s continuity.

“What improvements can be made to the original design?” This question separates true rebuilders from mere parts-replacers. At MZI Precision, we often identify design improvements that make rebuilt gearboxes perform better than they did when new.

“Can you provide references from similar applications?” Any hesitation here should raise immediate concerns.

Red Flags to Avoid

Watch out for gearbox rebuild California providers who show these warning signs:

No load testing is perhaps the biggest red flag. A visual inspection alone cannot confirm proper operation under real-world conditions. Every gearbox we rebuild undergoes rigorous load testing that simulates your specific operating environment.

Vague quotes that lack component-level detail suggest either inexperience or a desire to cut corners. Detailed quotes with specific component replacement listings indicate thoroughness and transparency.

Limited tooling severely constrains what a rebuilder can accomplish. Advanced machinery isn’t just for show – precision rebuilding requires specialized equipment like dynamic balancers, gear grinders, and coordinate measuring machines.

Can’t provide references from your industry or application? That’s a conversation ender. Established rebuilders proudly showcase their successful projects and satisfied customers.

No root cause analysis means you’re likely to face the same failure again. Simply replacing worn parts without identifying why they failed creates a costly repair cycle rather than a lasting solution.

At MZI Precision, we’ve built our reputation on transparency and meticulous attention to detail. Every gearbox rebuild California project includes comprehensive documentation, testing results, and recommendations for preventing future issues – because we’re not just fixing your equipment; we’re becoming your long-term precision partner.

Extending Gearbox Life After Rebuild: Maintenance & Monitoring

After investing in a quality gearbox rebuild California service, protecting that investment becomes your next priority. Think of your newly rebuilt gearbox like a restored classic car—regular care keeps it running smoothly for years to come.

“Most catastrophic failures we see could have been prevented with basic monitoring,” says our lead technician at MZI Precision. “It’s like ignoring that check engine light until your car breaks down on the freeway.”

Today’s condition-based monitoring approaches have revolutionized industrial maintenance. Instead of changing parts based solely on calendar dates, smart sensors track your gearbox’s actual performance. This means you’ll catch problems while they’re still small whispers rather than expensive shouts.

The best monitoring systems combine wireless sensors, trend analysis, and regular oil sampling. These tools work together to give you a complete picture of your gearbox health. Our California clients who implement these systems typically see a 70% reduction in unexpected downtime—a massive return on a relatively small investment.

Predictive Technologies Available in California

California’s industrial operations have access to cutting-edge monitoring tools that were science fiction just a decade ago:

VibePro Sensors have become the gold standard for gearbox monitoring throughout the state. These compact wireless devices detect tiny vibration changes that human senses would miss completely. One manufacturing client told us, “The sensors caught a developing bearing issue three weeks before it would have caused a line shutdown. That single save paid for our entire monitoring system.”

Thermography provides another window into your gearbox’s soul. Regular thermal imaging scans can spot hot spots that indicate friction problems or misalignment long before they cause damage. Many gearbox rebuild California specialists now offer quarterly thermal scanning as part of their maintenance packages.

Oil Particle Counters continuously monitor your lubricant for metal fragments and other contaminants. When properly integrated with your control systems, these devices can alert maintenance teams the moment contamination exceeds acceptable levels.

Service Packages You Should Consider

At MZI Precision, we’ve developed maintenance programs that complement our gearbox rebuild California services. Here’s what works best for most operations:

Routine Audits provide professional eyes on your equipment at regular intervals. Our technicians often spot developing issues that even the best sensors might miss. Think of these visits as check-ups with your doctor—prevention is always cheaper than emergency treatment.

Baseline Resets become crucial after any process change. If you modify production speeds, change materials, or alter operating conditions, your gearbox’s “normal” operating parameters will shift. Establishing new baselines ensures your monitoring system remains accurate.

Operator Training might be the most underrated maintenance tool available. Your floor team interacts with the equipment daily and can often sense problems through subtle changes in sound or feel. We offer specialized training to help operators recognize early warning signs and communicate effectively with maintenance teams.

One food processing plant manager in the Central Valley put it perfectly: “After our gearbox rebuild California project was complete, MZI helped train our operators to recognize normal sounds and vibrations. Six months later, one operator reported something ‘just didn’t sound right.’ That early catch saved us from a major failure during our busiest season.”

Extending gearbox life isn’t just about technology—it’s about creating a culture where equipment health becomes everyone’s responsibility.

For more detailed information about industrial gearbox maintenance best practices, check out this excellent resource from Machinery Lubrication.

Frequently Asked Questions About Gearbox Rebuild California

How much does an industrial gearbox rebuild cost in California?

If you’re wondering about the investment required for a gearbox rebuild California service, you’ll be pleased to know it’s typically 40-60% of what you’d pay for a brand new unit.

For perspective, that $10,000 replacement gearbox might only cost $4,000-$6,000 to rebuild professionally. Every situation is different though – costs vary based on your gearbox size, complexity, and which components need replacement.

Need it done yesterday? Emergency rush services are available throughout California, though they’ll add about 25-50% to your bill. Still, when your production line is standing idle, that premium often pays for itself within hours through avoided downtime costs.

“We had a critical gearbox fail during peak harvest season,” shares one Central Valley food processor. “The rush rebuild cost us an extra $1,500, but saved us nearly $30,000 in lost production. That math was pretty simple.”

Can obsolete gearboxes still be rebuilt if parts are unavailable?

Absolutely! This is where skilled gearbox rebuild California specialists truly shine.

Using a combination of reverse engineering techniques, advanced 3D scanning technology, and precision CNC machining, qualified rebuilders can recreate virtually any obsolete component. Our team at MZI Precision regularly breathes new life into gearboxes that original manufacturers declared “unrepairable” years ago.

The silver lining? These newly manufactured components often improve upon the original designs. We can incorporate modern materials and manufacturing techniques that simply weren’t available decades ago when your gearbox was first built. Many customers find their rebuilt “obsolete” gearboxes actually perform better than when they were new!

What warranty should I expect on a rebuilt gearbox?

Any reputable gearbox rebuild California service should stand firmly behind their work with a solid warranty. Most quality rebuilders offer 12 to 24 months of coverage on both parts and workmanship.

Some providers, including MZI Precision, offer extended warranty options for additional peace of mind. Just be aware that warranties typically cover failures related to the rebuild work itself, not issues caused by improper installation, lubrication neglect, or operational errors.

Always get your warranty terms in writing and make sure you understand any maintenance requirements that might affect your coverage. A good rebuilder will clearly explain what’s covered and what’s not without the fine-print runaround.

As one of our long-time customers puts it: “The warranty on our rebuilt gearboxes has never been an issue because they simply don’t fail when rebuilt properly. But knowing it’s there gives our management team confidence when choosing rebuild over replacement.”

Conclusion

When your industrial gearbox starts making those worrying noises, you don’t have to panic about replacement costs. Here in the Golden State, gearbox rebuild California services offer a smart alternative that keeps your operation running without breaking the bank.

Think of a rebuild as giving your gearbox a second life—often better than its first. At MZI Precision, we take pride in restoring industrial spindles and gearboxes to their original glory (and sometimes even improving them) for California’s manufacturing powerhouses across aerospace, agriculture, automotive, defense, and renewable energy sectors.

Our customers tell us they appreciate our approach: we pick up your equipment anywhere in California (yes, for free!), get to work immediately (especially when you’re facing costly downtime), and apply our engineering expertise to solve even the trickiest challenges with obsolete components. Every rebuild meets rigorous AGMA standards, undergoes thorough testing, and comes backed by our comprehensive warranty.

“The MZI team saved us thousands and had our production line back up in half the time a replacement would have taken,” one food processing plant manager told us recently. That’s the kind of feedback that makes our work worthwhile.

Choosing a rebuild over replacement isn’t just good for your budget—it’s also kinder to our California environment by reducing industrial waste and conserving valuable resources. It’s a win-win that makes good business sense.

Remember though, even the best rebuild deserves proper care afterward. Think of your rebuilt gearbox like a high-performance vehicle—regular check-ups and modern monitoring tools will help you spot small issues before they become big problems. Our team can help you develop a maintenance program that protects your investment for years to come.

Want to learn more about how our gearbox rebuild California services can help keep your operation running smoothly? Our team of friendly specialists is just a phone call away, ready to discuss your specific needs and answer any questions.

For more information about our California rebuild program or to schedule a no-obligation assessment of your gearbox needs, contact our team of specialists today.