Why Spindle Runout Checks Are Critical for Precision Manufacturing

METADATA:

TITLE: PRECISION PERFECT: MASTERING SPINDLE RUNOUT CHECKS

DESCRIPTION: LEARN HOW TO ACCURATELY PERFORM A SPINDLE RUNOUT CHECK, UNDERSTAND ITS IMPACT ON INDUSTRIAL MANUFACTURING PRECISION AND TOOL LIFE, AND DISCOVER METHODS FOR CORRECTION AND PREVENTION.

KEYWORDS: SPINDLE RUNOUT CHECK, SPINDLE RUNOUT, RADIAL RUNOUT, AXIAL RUNOUT, TOTAL INDICATED RUNOUT, TIR, SPINDLE MAINTENANCE, TOOL LIFE, PART QUALITY, INDUSTRIAL MANUFACTURING SPINDLES, SPINDLE REPAIR, SPINDLE REBUILDING, DIAL INDICATOR, NON-CONTACT SENSORS

AUTHOR: MZI PRECISION

PRECISION PERFECT: MASTERING SPINDLE RUNOUT CHECKS

Spindle runout check is essential for maintaining machining accuracy and maximizing tool life in industrial manufacturing. When a spindle doesn’t rotate perfectly on its axis, the resulting wobble can destroy precision, damage parts, and break tools.

Quick Answer for Spindle Runout Check:

- Clean spindle taper thoroughly

- Mount a dial test indicator on a magnetic base

- Position indicator tip against a precision test bar

- Rotate spindle manually while recording readings

- Calculate Total Indicated Runout (TIR) as max minus min reading

- Compare against acceptable limits (e.g., 0.0002″ at taper, 0.001″ at 6″)

Spindles have extremely tight tolerances because they spin at high speeds where balance is crucial. As one machining expert notes, “Runout is usually the #1 factor affecting tool life for micromachining.”

Research confirms this: reducing runout on carbide drills from 0.0006″ to 0.00008″ resulted in a 3x improvement in tool life. When runout exceeds 20% of a cutter’s targeted chipload, tool life drops dramatically.

For precision industries like aerospace, even minor runout can lead to expensive scrap. A spindle with runout over 0.001″ is generally unacceptable for high-precision work. Fortunately, most runout issues can be identified and corrected with proper measurement and maintenance.

Understanding Spindle Runout: The Silent Threat to Precision

When an industrial manufacturing spindle has runout, it’s like a drill bit wobbling in its chuck. This seemingly small issue can turn precision machining into an expensive nightmare.

What is Spindle Runout and Why is it a Problem?

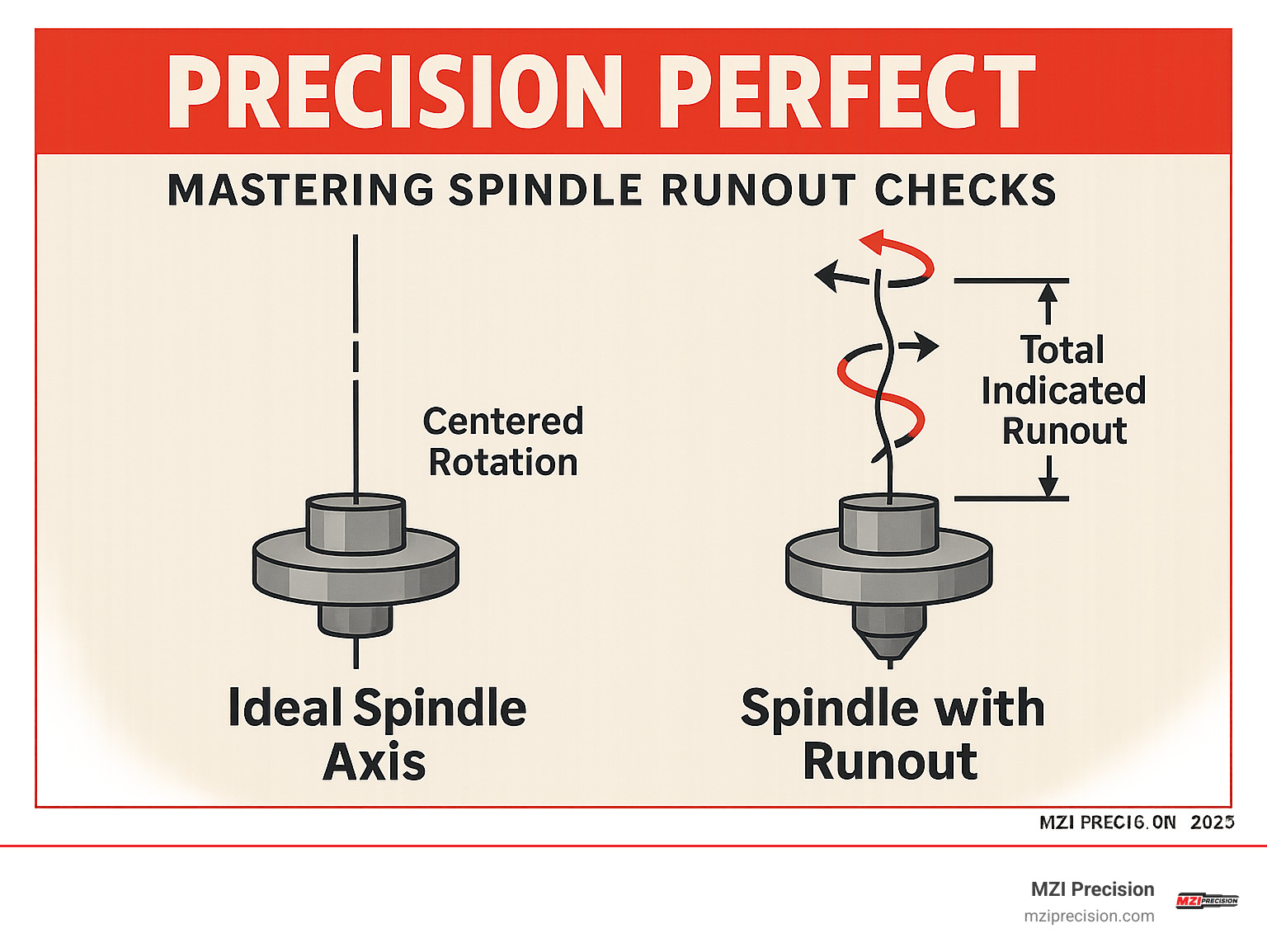

Spindle runout is the deviation of a spindle’s rotation from its intended axis. Instead of spinning perfectly true, it creates a wobble that we measure as Total Indicated Runout (TIR). At thousands of RPM, even a microscopic wobble is magnified, becoming a precision killer.

This deviation has a brutal impact on manufacturing. Cutting tools don’t engage evenly; some edges are overworked while others barely touch the material. As CNCCookbook explains how spindle runout can shorten tool life, these uneven chip loads cause tools to wear out faster, increasing costs and reducing quality.

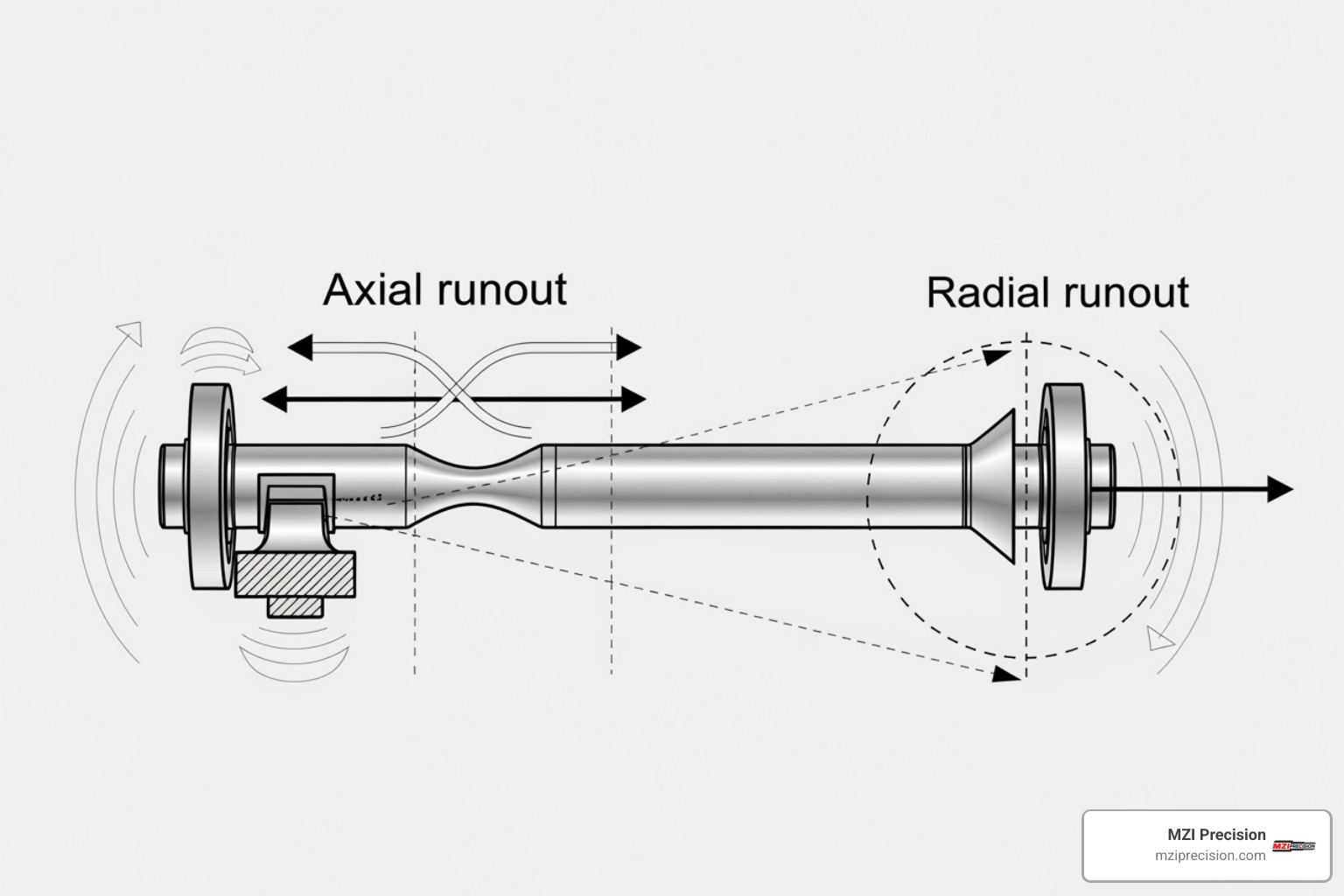

The Two Faces of Error: Axial vs. Radial Runout

Understanding the difference between axial runout and radial runout is key to diagnosing spindle problems.

Radial runout is a sideways shift of the spindle’s axis, causing the tool tip to trace a larger circle than intended. This affects part concentricity.

Axial runout occurs when the spindle axis is tilted, like a wobbling coin. This error worsens with distance from the spindle face and affects the flatness and perpendicularity of machined surfaces.

Both types degrade accuracy, so a proper spindle runout check must measure for both.

Consequences of Excessive Runout

Unchecked runout creates a cascade of expensive problems:

- Poor surface finish: A wobbling tool cannot make consistent cuts, leaving parts rough and requiring extra finishing work.

- Inaccurate tolerances: Hitting tight specifications becomes impossible when the cutting tool isn’t stable, leading to rejected parts and wasted material.

- Reduced tool life: Uneven chip loads cause some cutting edges to do all the work, burning out tools prematurely. The stat showing a 3x improvement in tool life by reducing runout from 0.0006″ to 0.00008″ highlights the financial impact.

- Tool chatter and bearing wear: The uneven forces create vibrations (chatter) that damage part quality and put stress on precision spindle bearings, leading to premature failure, costly repairs, and significant downtime.

A regular spindle runout check is essential protection for your manufacturing operation and your bottom line.

The Step-by-Step Spindle Runout Check Procedure

An accurate spindle runout check requires the right tools and a methodical approach. This health checkup for your spindle can save thousands in damaged parts and broken tools.

Gathering the Right Tools for an Accurate Check

Precision measurement demands precision tools. Your essential toolkit includes:

- Dial Test Indicator (DTI): A “tenths indicator” with a resolution of at least 0.0005″, though 0.0001″ is ideal for high-precision work.

- Magnetic Base: A sturdy base to provide rock-solid mounting for the DTI.

- Precision Test Bar: A perfectly ground cylindrical bar that fits the spindle taper, eliminating variables from actual cutting tools. A calibration blank can work in a pinch.

- Cleaning Supplies: Lint-free cloths and spindle taper cleaner (or isopropyl alcohol) are critical, as even a speck of dust can skew readings.

Performing a Static Spindle Runout Check

Static testing measures runout with the spindle stationary, making it accessible for any shop.

- Clean the spindle taper: This is the most critical step. Use a lint-free cloth and cleaner to ensure perfect metal-to-metal contact. Inspect with a flashlight.

- Insert the test bar: Seat the precision test bar securely in the clean taper.

- Mount the indicator: Secure the magnetic base to a rigid part of the machine (table or column) and position the DTI tip against the test bar. For radial runout, the tip should be perpendicular to the bar; for axial, it should be parallel to the spindle axis.

- Set the indicator: Apply a pre-load of about 0.010″ of deflection to ensure consistent contact. Zero the indicator at the lowest reading point found by slowly rotating the spindle by hand.

- Measure TIR: Manually rotate the spindle 360 degrees. The Total Indicated Runout (TIR) is the difference between the highest and lowest readings. Repeat several times to ensure consistency.

- Measure at multiple points: Take readings near the spindle face and again 4-6 inches down the test bar. A significant increase in TIR at a distance suggests angular misalignment.

Static vs. Dynamic Measurements

A static spindle runout check provides excellent diagnostic data, but it’s important to know its limitations.

- Static testing, performed while stationary, is great for identifying mechanical issues like bent shafts, contamination, or unloaded bearing play. It’s straightforward and uses basic tools.

- Dynamic testing measures runout at operating speed, accounting for real-world conditions like heat effects, vibration, and centrifugal force. It requires specialized equipment like non-contact sensors.

While dynamic testing is more comprehensive, a thorough static check is sufficient for most routine maintenance and troubleshooting in industrial manufacturing. It provides the necessary information to identify significant problems and guide corrective actions.

Interpreting Your Measurements: From Data to Diagnosis

After a spindle runout check, the numbers on your dial indicator tell a story. Understanding them is key to diagnosis.

What Are Acceptable Limits for Spindle Runout?

“Acceptable” runout depends on the application, but general guidelines for precision work are strict.

- Spindle Taper Runout: Less than 0.0002 inches (0.005 mm) measured at the spindle nose. This is the gold standard for spindle precision.

- Gauge Line Runout: Less than 0.0005 inches (0.013 mm) where the test bar sits in the taper. This indicates how well the spindle holds a tool.

- Runout at a Distance: Less than 0.001 inches (0.025 mm) measured 6 inches down the test bar. A large increase from the gauge line measurement points to an angular wobble.

For micromachining, these limits are even tighter, as minimal runout drastically improves tool life. As a rule of thumb, any runout greater than 0.001″ is generally unacceptable for industrial manufacturing spindles and signals an underlying problem.

Common Causes of Excessive Spindle Runout

If your measurements are high, one of these common culprits is likely to blame.

- Bearing Wear: As bearings age, they develop play that causes runout, which often worsens over time or under load.

- Spindle Crash Damage: Even a minor crash can bend the spindle shaft, damage bearings, or deform the taper.

- Contamination: A tiny chip or dried coolant in the taper can prevent proper toolholder seating, causing significant runout.

- Toolholding Issues: Problems can stem from improper toolholder installation, worn drawbar components, or poor-quality toolholders and collets with inherent runout.

Isolating the Source of Your Runout Problem

Systematically eliminate variables to find the true cause:

- Start with the spindle taper. Measure with a precision test bar in a clean, empty spindle. If this is within spec, the spindle’s core is likely fine.

- Check toolholders. Measure runout on the toolholder itself with a test pin to see if it’s adding to the problem.

- Test individual components. Swap in new, high-quality collets or check the retention knob and drawbar for wear.

- Re-check cleanliness. Always double-check that the spindle and toolholder tapers are spotless.

This methodical approach helps you determine if you have a spindle issue, a toolholding problem, or a simple cleanliness concern.

Correcting and Preventing Excessive Spindle Runout

Nobody likes dealing with runout problems, but the good news is that many issues can be fixed quickly and prevented entirely with the right approach. Think of it like maintaining your car – a little regular care goes a long way toward avoiding expensive breakdowns.

Immediate Fixes and Adjustments

When your spindle runout check reveals numbers that make you wince, don’t panic. Many runout problems have surprisingly simple solutions that you can tackle right away.

Thorough cleaning is your first line of defense and often the most effective fix. It’s amazing how often a microscopic chip or a tiny speck of dried coolant can throw off your entire operation. Take the time to carefully clean both the spindle taper and toolholder taper with a lint-free cloth and appropriate cleaner. You’d be surprised how many “serious” runout issues disappear with nothing more than a good cleaning.

Re-seating toolholders is another quick win. Sometimes a toolholder gets installed slightly crooked during a hurried tool change. Remove it completely, inspect the taper for any damage or contamination, give it another thorough cleaning, and reinstall it carefully. Make sure it seats fully and correctly – rushing this step often creates the very problems we’re trying to solve.

Investing in high-quality toolholders makes a real difference. Those bargain toolholders with set screws or older drill chucks might seem like a good deal, but they often have inherent runout that adds to your spindle’s natural deviation. Upgrading to precision ER collet chucks or hydraulic holders can dramatically reduce runout at the tool tip, even if your spindle has some acceptable runout of its own.

Minimizing tool stickout is a simple but powerful strategy. The further your tool extends from the toolholder, the more any existing runout gets magnified at the cutting edge – it’s basic physics. Always keep tool stickout to the absolute minimum required for your operation. This also improves tool rigidity and reduces chatter, giving you multiple benefits for one simple change.

Don’t forget about replacing worn collets or pull studs. Collets are consumable items that wear out over time, losing their gripping force and sometimes deforming enough to introduce runout. Replace them regularly, especially if you notice inconsistent runout with the same toolholder. Pull studs (retention knobs) can also wear out, preventing proper toolholder seating.

Long-Term Strategies for Maintaining Precision

Prevention beats reaction every time. These long-term strategies will keep your industrial manufacturing spindles running smoothly and consistently passing every spindle runout check.

Establishing a regular maintenance schedule is crucial. Monthly runout checks work well for most operations, but adjust the frequency based on your specific situation. Machines running abrasive materials or ultra-precision work might need more frequent attention. The key is logging these measurements over time – this creates a valuable trend line that can alert you to gradual wear before it becomes a crisis.

Proactive component replacement saves money and headaches. Don’t wait for complete failure. If your runout measurements show a gradual but consistent increase over time, that’s often an early warning sign of bearing wear or other internal issues. Planning for component replacement or spindle rebuilding before catastrophic failure occurs can save significant downtime and repair costs.

Operator training is your first line of defense. Make sure everyone who touches your machines understands the importance of spindle cleanliness, proper toolholder handling, and how runout affects their work. Well-trained operators prevent more problems than any fancy monitoring system ever could.

Using spindle orientation consistently can help manage existing runout. While features like the M19 code on some machines don’t reduce runout, they ensure any existing runout is always in the same rotational position when you load a tool. This consistency allows you to compensate using wear offsets, making the runout predictable and manageable for critical features.

For high-volume or ultra-precision operations, considering a spindle monitoring system makes sense. These systems track runout and vibration in real-time, providing immediate alerts and historical data for predictive maintenance. This proactive approach helps you plan for spindle replacement services before costly failures occur.

When to Call for Professional Spindle Repair

While many runout issues respond to the fixes we’ve discussed, some problems signal deeper issues that need expert attention. Knowing when to call in the professionals protects your investment and keeps your production schedule on track.

Runout that exceeds correctable limits is a clear signal. If you’ve done meticulous cleaning, re-seating, and checked all external components, but your spindle runout check still shows TIR values consistently above acceptable limits (like more than 0.001″ at the taper), you’re likely dealing with internal damage that requires professional repair.

Suspected bearing damage needs immediate professional attention. Warning signs include increased noise (whining or grinding sounds), excessive heat from the spindle nose, or vibration that gets worse with speed. These indicate failing spindle bearings that need replacement in a proper cleanroom environment.

Post-crash verification is absolutely critical, even if the machine seems fine afterward. Crashes can cause microscopic damage to the spindle shaft or bearings that doesn’t immediately show up as obvious runout but leads to premature failure later. A professional assessment determines the extent of any damage and prevents nasty surprises down the road.

Persistent quality issues often point back to spindle problems. If you’re consistently struggling with poor surface finish, inaccurate dimensions, or tool breakage despite optimizing everything else, excessive spindle runout is likely the culprit. When you’ve exhausted all other troubleshooting steps, it’s time for professional diagnosis.

Some manufacturers opt for preventative rebuilding at set intervals, even before failure occurs. For critical production machines, this proactive approach ensures consistent performance and avoids unexpected downtime.

At MZI Precision, we specialize in industrial manufacturing spindle repair and rebuilding. Our expertise in OEM rebuilt spindles ensures your equipment gets restored to original factory specifications – often performing better than new. We understand how critical spindles are to your production and we’re committed to exceptional service and support. Learn more about our services and how we can help keep your operations running smoothly.

Conclusion

Mastering the spindle runout check isn’t just about ticking boxes on a maintenance schedule—it’s about taking control of your industrial manufacturing operation’s precision and profitability. Throughout this guide, we’ve explored how something as seemingly small as a microscopic wobble can cascade into major headaches: rough surface finishes, blown tolerances, tools that snap when they should be cutting smoothly, and spindle failures that bring production to a grinding halt.

The beauty of understanding spindle runout check procedures lies in their simplicity and power. With basic tools like a dial test indicator and precision test bar, you can peer into the heart of your spindle’s health. You can catch problems while they’re still whispers rather than screams—when a thorough cleaning might solve what could otherwise become a costly bearing replacement.

We’ve seen how the difference between acceptable and excessive runout often comes down to thousandths of an inch. Those tiny measurements tell big stories about bearing wear, crash damage, contamination, or simply the need for better toolholders. When you know how to read these signs, you transform from reactive maintenance to proactive precision management.

The immediate fixes we discussed—thorough cleaning, proper toolholder seating, investing in quality components—can often restore your spindle’s accuracy quickly and affordably. But the real value comes from the long-term strategies: regular monitoring, trend analysis, operator training, and knowing when professional intervention is needed.

Industrial manufacturing spindles are the beating heart of your precision operations. They deserve the same attention you’d give any critical component. A consistent spindle runout check routine turns runout from a hidden enemy into a trusted performance indicator that guides your maintenance decisions.

Don’t wait for quality issues or catastrophic failures to force your hand. Take charge of your spindle health today. At MZI Precision, we understand the critical role these components play in your success, and we’re here to help when professional spindle rebuilding becomes necessary. Contact us for expert spindle rebuilding and let our expertise keep your industrial manufacturing operations running with the precision and reliability your customers expect.