Spindle Replacement Electric Motor: Unfailing 2025

Why Reliable Spindle Replacement Electric Motor is Crucial

When an industrial machine’s spindle motor fails, it halts production. For aerospace manufacturing or other high-precision industries, minimizing downtime is critical. At MZI Precision—headquartered in Huntington Beach, California—we understand that finding the right spindle replacement electric motor quickly and ensuring it performs flawlessly is paramount.

Here’s what you need to know about industrial spindle motor replacement:

- What it does: An industrial spindle motor is the powerful heart of CNC (Computer Numerical Control) machines. It spins cutting tools at high speeds for precise milling, grinding, and turning operations.

- Why replace: Motors fail due to wear, vibration, overheating, or internal electrical issues, leading to poor performance or complete machine shutdown.

- Types: AC induction motors are the most common type used in industrial spindles, though synchronous motors are also found.

- Key factors: When replacing, always match the voltage, power (HP/kW), RPM range, and cooling type to your machine’s specifications.

- Availability: New industrial spindle motors can have long lead times, sometimes months. Rebuilt or repaired options can often get you back up and running faster.

- Repair vs. Replace: For many industrial spindles, specialized repair and rebuilding services can restore your motor to OEM specifications, often more cost-effectively than full replacement.

Precision manufacturing relies on high-performing equipment. When a spindle motor shows signs of trouble, it directly impacts your production quality and schedule. This means identifying the right replacement and installing it correctly are not just maintenance tasks; they are critical decisions for your business.

Spindle replacement electric motor terms explained:

Understanding the Core of Your CNC Machine: Spindle Motor Fundamentals

At the heart of every CNC machine is the spindle motor, a specialized electric motor engineered for the high-speed demands of industrial machining. When discussing a spindle replacement electric motor, we’re referring to the component that powers the cutting tool, enabling the intricate work of modern manufacturing. These motors are critical for machine tool performance, ensuring rotational accuracy, consistent power, and the torque needed for tough cuts. Whether AC or DC, a functioning spindle is essential; without it, your machine cannot operate.

Key Factors for Selecting a Spindle Replacement Electric Motor

Choosing the right spindle replacement electric motor is a decision that impacts your machine’s performance, longevity, and your bottom line. It’s not just about finding “a motor”; it’s about finding the right motor that perfectly matches your machine’s needs and operational demands. This involves a careful assessment of motor specifications, ensuring compatibility with your existing setup, meeting performance requirements, and considering the operational environment for long-term reliability.

Essential Specifications for Your Spindle Replacement Electric Motor

When it comes to replacing a spindle motor, precision is key. We look at several critical specifications to ensure the new motor is a seamless fit and performs optimally:

- Voltage: This must match your machine’s power supply and the VFD’s output. Industrial motors come in a wide range of voltages, from low DC voltages (e.g., 3V, 12V) for smaller applications up to industrial AC voltages like 208V, 230V, 460V, or 575V.

- Power Rating (HP/kW): This indicates the motor’s output capability. Common industrial spindle motors range from fractional horsepower (e.g., 1/4 HP, 1/2 HP) to much larger units (e.g., 5 HP, 10 HP, 20 HP). The power rating determines the motor’s ability to handle cutting loads without stalling.

- RPM Range: Spindle motors are designed for specific speed ranges, from standard industrial speeds (e.g., 1750 RPM, 3450 RPM) to very high-speed applications (e.g., 9000 RPM, 24000 RPM, or even 50000 RPM for specialized tasks). Ensure the replacement can achieve the necessary speeds for your machining operations.

- Frame Size and Mounting Configuration: Motors come in standardized frame sizes (e.g., 56C) that dictate their physical dimensions and mounting bolt patterns. This is crucial for a mechanical fit within your machine’s housing.

- Cooling Type: Spindle motors generate heat, especially at high RPMs. Common cooling methods include air-cooled (often with an integrated fan) and liquid-cooled systems. Matching the cooling type is vital to prevent overheating and premature failure.

- Tool Holding System (if integrated): For spindles with integrated motors, the tool holding system (e.g., CAT, BT, ISO, HSK) must match your existing tooling.

- Compatibility with Existing VFD: If you’re only replacing the motor, ensure it’s compatible with your current Variable Frequency Drive (VFD). The VFD’s output frequency and voltage range must align with the new motor’s requirements.

Understanding these specifications is crucial. It’s like finding the right heart for your machine – it needs to be the perfect match to keep everything running smoothly.

Sourcing Your Spindle Replacement Electric Motor: New vs. Rebuilt

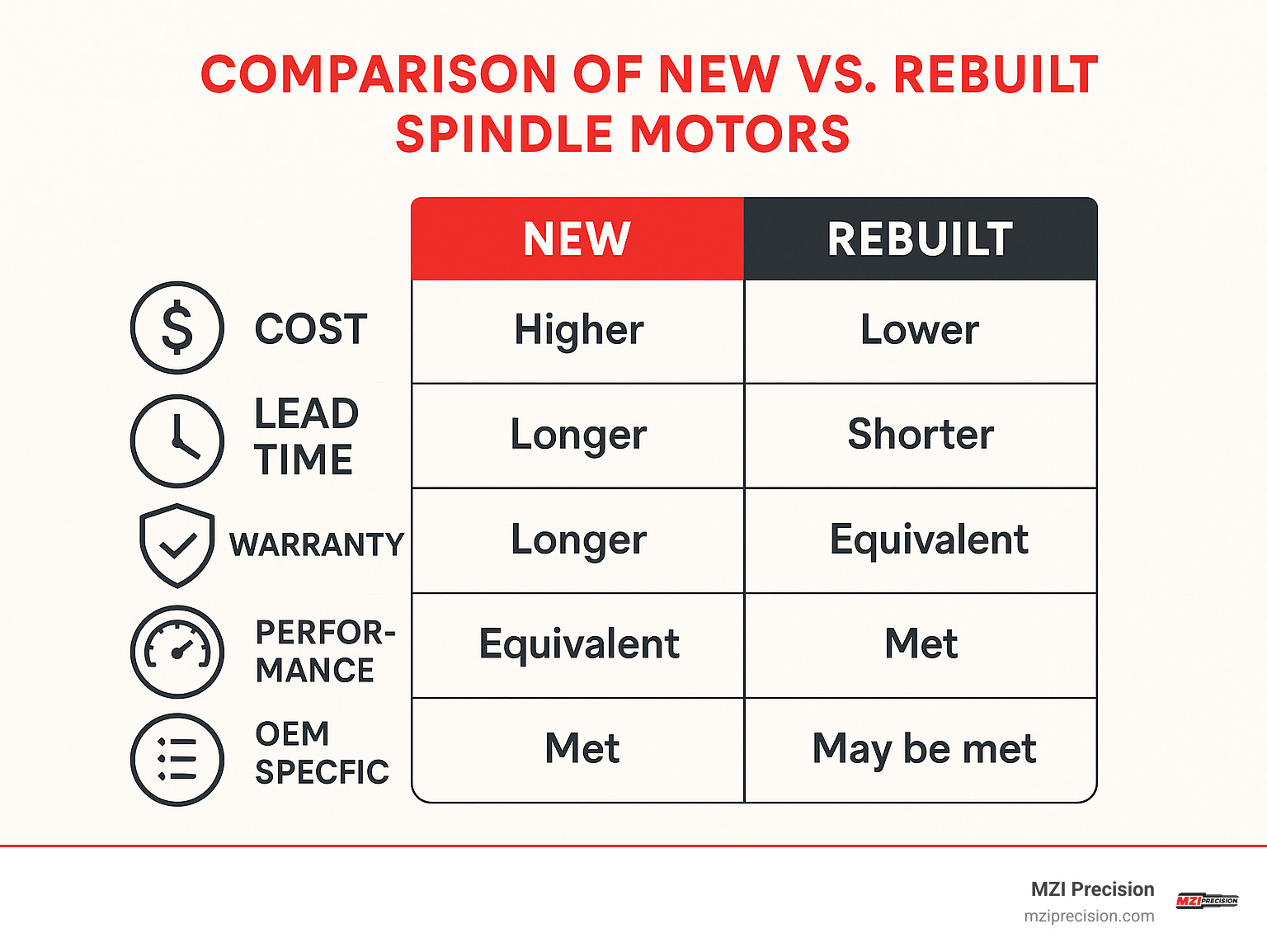

Once you know the specifications, the next big question is where to source your spindle replacement electric motor. You generally have two main options: purchasing a new motor or opting for a professionally rebuilt one. Each comes with its own set of considerations regarding lead time, cost, and long-term value.

New industrial spindle motors, especially specialized OEM parts, can have surprisingly long lead times. We’ve seen lead times vary from a few weeks to 6-9 months or even longer for out-of-stock or custom orders. This extended waiting period can translate into significant downtime for your operations, which, as we know, directly impacts your profitability. This is why many manufacturers keep a spare CNC spindle motor on the shelf to minimize costly interruptions.

On the other hand, professionally rebuilt spindle motors offer a compelling alternative. Companies specializing in spindle repair and rebuilding, like us, often have an inventory of older, popular, and hard-to-find models available for exchange. Our expertise in OEMs rebuilt spindles means we can restore your motor to its original specifications, or even better, often at a lower cost and with a much faster turnaround time than acquiring a new one. This approach also aligns with sustainability efforts by extending the life cycle of existing equipment.

Here’s a quick comparison to help you weigh your options:

When considering a rebuilt motor, always look for a reputable service provider that offers a warranty. We, for example, offer a six-month warranty on motorized spindles and a one-year warranty on non-motorized spindles, reflecting our confidence in the quality of our work. The cost savings and reduced lead times offered by professional rebuilding services can be a game-changer for businesses facing unexpected downtime.

Troubleshooting Common Spindle Drive Problems

Even the toughest industrial spindle motors can face issues. Knowing the early warning signs and understanding common problems can save you from big failures and long shutdowns. We focus on clear diagnostics, understanding why things failed, and suggesting ways to prevent problems so your machine keeps running smoothly.

Telltale Signs Your Spindle Motor is Failing

Your machine often has its own way of telling you when its spindle motor is in trouble. Learning to understand these “conversations” can stop small issues from turning into huge, costly repairs. If you spot any of these signs, it’s time to think about your spindle replacement electric motor options or get professional help:

First, listen closely. A healthy spindle motor purrs, but if you start hearing unusual noises like grinding, whining, screeching, or clunking, it’s like your machine is clearing its throat to tell you something’s wrong, often with the bearings. Next, feel your machine. Excessive vibration, especially at certain speeds, is a clear sign that something is unbalanced or bearings are failing. This can even mess up the parts you’re making.

Then, there’s heat. If the motor housing feels super hot to the touch, or if your machine’s sensors start beeping about high temperatures, that’s overheating. It could mean the cooling isn’t working right, or there’s friction from bad bearings, or even electrical problems. If your motor struggles to cut like it used to, or it stalls easily, that’s a loss of power or torque. This might be due to electrical issues inside the motor or just plain wear and tear.

Look at your finished products too. If you suddenly see a poor surface finish on parts, like rough spots or chatter marks, it often points to issues with the spindle’s rotation or vibration caused by the motor. Modern CNC machines are smart, and they often give you direct clues. Watch for PLC error codes related to the spindle, like “Spindle Not Rotating” or “Spindle Not Running at Correct Speed.” These are clear calls for help! If the spindle speed jumps around instead of staying steady, that’s inconsistent RPM, which can be a problem with the motor or its control system. And finally, if your circuit breakers keep tripping or the power frequently cuts out to the spindle, it could signal an electrical overload or a short circuit inside the motor.

For specific steps and detailed manufacturer guidance, you can always See a detailed manufacturer replacement guide. Acting fast on these signs can stop bigger damage and keep your production going strong.

The Critical Decision: Repairing vs. Replacing Your Spindle

When a spindle motor shows signs of trouble, the big question is always: should we fix it or get a new one? This isn’t a simple answer and needs a careful look at costs versus benefits, how much downtime it will cause, and what really broke in the first place.

Why Repair?

For many industrial spindles, especially the complex or super-precise ones, getting professional spindle repair and rebuilding services offers some big wins. When you work with experts like us, with our deep knowledge in OEMs rebuilt spindles, we can:

- Address the Real Problem: We don’t just fix what you see. We dig deep to find the exact reason for the failure. Maybe it was bearing contamination (often from coolant or debris sneaking in), a winding failure inside the motor, or even crash damage from an accident. We’ve seen it all, from brown particles in rear bearings to front covers needing tiny, precise welds.

- Restore to Original Specs: A quality rebuild means we bring your spindle back to its original factory specifications – sometimes even better! This involves replacing worn parts, making sure the spindle is perfectly balanced, and setting the bearings just right.

- Save Money: Rebuilding can often be much cheaper than buying a brand-new spindle replacement electric motor. This is especially true for older or special models where new parts are hard to find or cost a fortune.

- Reduce Downtime: Our repair process is designed to be quick. Plus, we often have parts or even whole exchange units ready, which means your machine can get back to work much faster than waiting months for a new motor from the factory.

- Be Eco-Friendly: Repairing and rebuilding equipment is a smart, sustainable choice. It extends the life of valuable machines and cuts down on waste.

When to Consider Replacement?

While rebuilding is often the best path, sometimes a full replacement might be the way to go:

- Too Much Damage: If the motor’s housing, shaft, or inside parts are so badly broken that fixing them just doesn’t make financial sense (like after a huge crash that bent the whole thing).

- Outdated Tech: If your current motor is super old and they don’t even make parts for it anymore, or if newer technology offers a big jump in performance that your old motor just can’t match.

- Planned Upgrade: Sometimes, replacing the motor is part of a bigger plan to make your machine faster or more powerful, with higher RPMs or more efficiency that your current model can’t deliver.

Our team specializes in complex spindle repairs and rebuilding, and we understand all the fine details of different manufacturer specifications. We’ll give your spindle a thorough check-up and help you make the best choice – one that balances the immediate cost with long-term reliability and how well your machine performs. We’re here to help you get your machine back in top shape, making sure it won’t let you down.

Frequently Asked Questions about Industrial Spindle Motors

We understand that industrial spindle motors can be complex, and you likely have questions beyond just replacement. These hardworking components are critical to your operations, so it’s natural to wonder about their longevity and common issues. Here, we address some of the most common inquiries we receive from our clients, helping you understand these vital machine parts a little better.

How long does a typical industrial spindle motor last?

The lifespan of an industrial spindle motor isn’t a fixed number you can just pick out of a hat. Think of it like a marathon runner – some last longer than others, depending on how they’re treated! While many are designed for years of robust service, their longevity heavily depends on several key factors:

- Operating Hours and Load: Motors that are constantly running under heavy loads will naturally experience more wear and tear than those used intermittently or for lighter tasks. It’s simply a matter of physics and fatigue.

- Maintenance Schedule: This is a big one! Sticking to a strict preventative maintenance schedule, including regular lubrication and cleaning, can significantly extend a motor’s life. Proper lubrication, using the right type and amount of grease or oil, is absolutely paramount for bearing life, which is often the first thing to go.

- Operating Conditions: The environment where your machine operates plays a huge role. Excessive dust, humidity, or extreme temperatures can accelerate wear and lead to contamination inside the motor.

- Contamination: Any rogue coolant, chips, or other debris finding their way into the motor or its bearings is a leading cause of premature failure. It’s like sand in a finely tuned clockwork!

- Bearing Life: Speaking of bearings, they are often the first component to show signs of fatigue in a spindle motor. Their quality, proper installation, and how well they’re protected are critical to the motor’s overall lifespan.

With proper care and attention, an industrial spindle motor can provide many years of reliable service, keeping your production lines humming. Neglect, on the other hand, can drastically shorten its operational life, leading to unexpected downtime and the urgent need for a spindle replacement electric motor.

What are the most common causes of spindle motor failure?

While industrial spindle motors are built tough, designed to withstand the rigors of manufacturing, certain issues tend to crop up more frequently than others. Understanding these common culprits can help you catch problems early and potentially avoid a complete breakdown. These are the main reasons you might find yourself needing a spindle replacement electric motor or professional repair:

- Bearing Failure: This is, without a doubt, the most common reason we see spindles come in for repair. Bearings often fail due to:

- Contamination: Coolant, dust, or metal particles from the machining process can infiltrate and quickly destroy bearings.

- Fatigue: Sometimes, bearings simply reach the end of their designed operational life.

- Improper Lubrication: Too little, too much, or even the wrong type of grease or oil can lead to catastrophic bearing failure.

- Overheating: Excessive friction, electrical issues, or insufficient cooling can cause bearings to overheat and seize.

- Contamination (Beyond Bearings): It’s not just bearings that suffer. Coolant, chips, or other debris can damage windings, sensors, and other crucial internal components of the motor.

- Overheating: Sustained high temperatures are detrimental to any motor. They degrade insulation, bearings, and other parts, leading to premature failure. This can be caused by overloaded operation, inadequate cooling systems, or underlying electrical issues.

- Electrical Issues: Problems like winding shorts (often due to insulation breakdown from heat or contamination), open circuits, or issues with the motor’s internal wiring can lead to a motor’s demise. Sometimes, these winding failures can occur quite suddenly, without much warning.

- Operator Error or Machine Crash: Unfortunately, accidents happen. A machine crash or operator error can impart severe shock loads to the spindle, leading to physical damage like bent shafts, damaged bearings, or fractured components.

- Improper Maintenance: Skipping routine maintenance, using incorrect replacement parts, or improper installation during previous repairs can lead to a domino effect of failures down the line.

Understanding these common causes helps us diagnose problems quickly and provides valuable insights for setting up effective preventative maintenance strategies in your facility.

Can a spindle motor be upgraded during replacement for better performance?

Absolutely! Replacing a spindle motor isn’t always just about a like-for-like swap. In many cases, it’s a fantastic opportunity to give your machine a performance boost! When we perform a spindle replacement electric motor or a comprehensive rebuild, we can often incorporate upgrades to significantly improve your machine’s capabilities.

Imagine taking your trusty old machine and giving it a new lease on life with improved precision and speed. Here are some common upgrades we can implement:

- Upgrading Bearings: Swapping out standard bearings for higher precision types (like ABEC 7 or 9) or specialized options (such as ceramic hybrid bearings with Silicone Nitride components) can dramatically increase maximum speeds, improve rigidity, and reduce vibration. This means smoother cuts and better part finishes.

- Higher RPM Capabilities: While always limited by the machine’s overall design and structure, sometimes a motor can be selected or modified to achieve higher RPMs. This can open up new possibilities for faster machining, more efficient material removal, or achieving even finer surface finishes.

- Improved Cooling Systems: Enhancing the motor’s cooling system, whether through more efficient internal designs or external liquid cooling, allows the motor to run cooler. A cooler motor means a longer lifespan and the ability to handle more aggressive machining parameters without overheating.

- Improved Sealing: One of the leading causes of bearing failure is contamination. Implementing more robust sealing mechanisms helps prevent coolant, chips, and other debris from getting into critical internal components.

- Performance Gains: These types of upgrades work together to deliver tangible performance gains. You can expect increased rigidity, better precision, and reduced noise and vibration, all of which directly contribute to improved part quality and overall productivity.

However, any upgrade must be carefully considered for machine compatibility. It’s crucial to consult with a specialist, like us at MZI Precision, who has deep knowledge of spindle mechanics and motor integration. We can assess your specific machine, understand its current limitations, and discuss your desired performance improvements. This allows us to recommend the most effective and safe upgrade path, ensuring that any improvement works harmoniously with your existing setup, providing a seamless transition to a more capable machine.

Conclusion: Ensuring Longevity and Precision in Your Operations

Well, we’ve certainly covered a lot of ground today, haven’t we? From the humming heart of your CNC machine to the tiniest telltale sign of trouble, understanding your industrial spindle motor is key to keeping your operations running smoothly. In industrial manufacturing, precision and reliability aren’t just nice-to-haves; they’re the absolute bedrock of success.

The spindle replacement electric motor truly is the unsung hero, constantly working to deliver the high-speed, high-precision machining your business relies on. We’ve explored how these powerful motors function, the different types that drive your machines, and why getting the specifications just right – voltage, power, RPM, cooling – is so incredibly important when it’s time for a replacement. Whether you’re considering a brand-new motor or the fantastic value of a professionally rebuilt option, each choice impacts your machine’s performance and your bottom line.

And let’s not forget those crucial moments when your machine starts “talking” to you – unusual noises, vibrations, or an unexpected error code. Knowing these signs and understanding when to repair versus when to replace your spindle can literally save you thousands in downtime and lost productivity. Our goal is always to help you make the most informed decision, one that balances immediate cost with long-term reliability and peak machine performance.

At MZI Precision, our commitment goes beyond just fixing a problem. With our deep expertise in OEMs rebuilt spindles, we’re dedicated to being your partner in minimizing downtime and maximizing your productivity. We believe in providing solutions that offer lasting value, ensuring your machines perform at their best, reliably, day in and day out.

So, if you’re facing a spindle challenge, or simply want to ensure your operations are as precise and reliable as possible, don’t hesitate to reach out. We’re here to help you keep your machines humming along beautifully.