Spindle Repair California is crucial for businesses in the busy industrial manufacturing sector. At the heart of operations, spindles play a key role in powering machinery that produces everything from micro-components to large-scale industrial parts. This essential function makes maintaining them a top priority for any manufacturing company, especially in industries like aerospace, where precision and reliability can make or break an operation.

- Top Features of Spindle Repair California:

- Quick and precise diagnostics to minimize downtime.

- Skilled technicians with industry-specific expertise.

- Use of premium parts and cutting-edge techniques.

In California, where innovation meets industry, companies like MZI Precision ensure that your spindle repair needs are met with best expertise and service. They provide custom solutions, addressing the unique demands of each client. MZI Precision’s commitment to quality and customer satisfaction ensures spindles are not only restored to their original state but often improved for better performance.

Understanding the importance of spindle health, these specialists prioritize innovative repair techniques and consistent communication, allowing clients to make informed choices and keep their manufacturing lines running smoothly.

Understanding Spindle Repair

Spindle Analysis

When it comes to Spindle Repair California, the first step is understanding the spindle’s condition through detailed analysis. This involves examining the spindle’s components to pinpoint the root cause of any issues. Technicians at MZI Precision use cutting-edge diagnostic tools to assess mechanical wear, misalignment, or other potential problems.

Repair Process

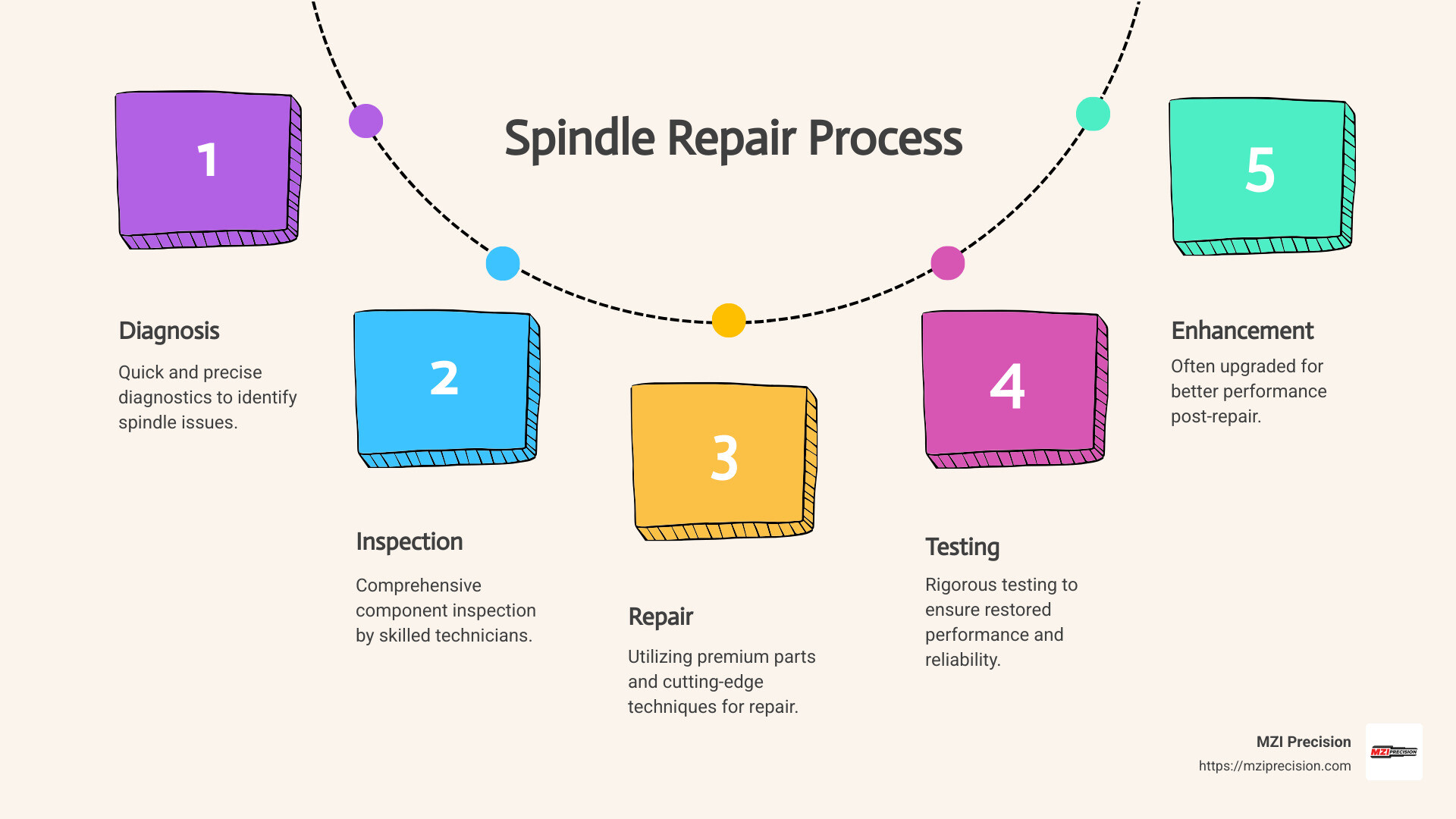

Once the analysis is complete, the repair process begins. This is a meticulous procedure that involves several steps to ensure the spindle is restored to peak performance. Here’s a breakdown:

- Component Inspection: Every part of the spindle is inspected for damage. Technicians look for cracks, wear, and other signs of failure.

- Detailed Analysis: Using advanced software, the team conducts a deeper analysis to understand why the spindle failed. This helps prevent future issues by addressing the root cause.

- Precision Repair: The actual repair involves replacing or refurbishing parts. Technicians use high-quality materials to ensure longevity and reliability.

- Balancing and Assembly: The spindle is balanced to ensure smooth operation at high speeds. Then, it’s carefully reassembled in a clean environment to prevent contamination.

- Testing and Quality Control: Before returning the spindle, it undergoes rigorous testing to ensure it meets performance standards.

Component Inspection

A thorough component inspection is crucial to effective spindle repair. Technicians at MZI Precision examine each part, from bearings to seals, to identify wear and tear. This step is essential to ensure that no underlying issues are missed, which could lead to future failures. By using advanced diagnostic equipment, they can detect even the smallest defects that might otherwise go unnoticed.

By focusing on detailed analysis and meticulous repair processes, Spindle Repair California ensures that industrial manufacturing spindles are restored to optimal condition. This commitment to excellence is what sets MZI Precision apart as a leader in spindle repair services.

Spindle Repair California: Key Services

MZI Precision offers a range of services that make them a leader in Spindle Repair California. They focus on three main areas: spindle rebuilds, engineered upgrades, and custom spindle creation. Each service is designed to meet the unique needs of industrial manufacturing clients.

Spindle Rebuilds

A spindle rebuild is like giving your spindle a second life. The process involves taking apart the spindle, inspecting each part, and replacing worn components. MZI Precision’s technicians use high-quality materials to ensure the spindle operates like new. They follow a meticulous procedure that includes:

- Disassembly: Every part is carefully removed and cataloged.

- Inspection: Components are checked against OEM specifications.

- Cleaning: Parts are cleaned to remove any contaminants.

- Reassembly: The spindle is put back together in a clean environment.

- Testing: The spindle undergoes rigorous testing to ensure it meets performance standards.

Engineered Upgrades

Sometimes, a simple repair isn’t enough. That’s where engineered upgrades come in. MZI Precision offers improvements that extend the life of your spindle and improve its efficiency. These upgrades might include:

- Improved Bearings: Using high-quality bearings that reduce friction and wear.

- Improved Cooling Systems: To prevent overheating during high-speed operations.

- Advanced Sensors: For better monitoring and control.

These upgrades not only fix existing issues but also help prevent future problems, making them a smart investment for any industrial setup.

Custom Spindle Creation

In some cases, off-the-shelf solutions won’t do. MZI Precision can create custom spindles tailored to your specific needs. This service is ideal for industries with unique requirements that standard spindles can’t meet. The process involves:

- Design Consultation: Understanding your specific needs and challenges.

- Custom Engineering: Designing a spindle that meets those needs.

- Precision Manufacturing: Crafting the spindle with attention to detail.

- Testing and Validation: Ensuring the custom spindle performs as expected.

By offering these key services, MZI Precision ensures that businesses in California have access to top-tier spindle repair and improvement solutions. This comprehensive approach helps industrial manufacturers maintain efficiency and reliability in their operations.

Industries Benefiting from Spindle Repair

Spindle Repair California is crucial for various industries, especially where precision and reliability are non-negotiable. Let’s explore how spindle repair services, particularly from MZI Precision, are making a difference in some key sectors:

Aerospace

In the aerospace industry, precision is paramount. Aircraft components must meet rigorous standards, and even the slightest error can lead to significant issues. Spindles are used in the machining of these high-precision parts. Spindle repair ensures that these spindles operate flawlessly, maintaining the tight tolerances required.

MZI Precision’s technicians understand the critical nature of aerospace applications. They employ advanced techniques to ensure every spindle not only meets but exceeds OEM specifications. This attention to detail helps aerospace manufacturers maintain the highest standards of safety and performance.

Defense/Military

The defense and military sectors demand equipment that is both reliable and durable. Spindles play a crucial role in the production of military hardware, from vehicles to weaponry. The failure of a spindle in this context can have serious consequences.

Spindle Repair California services, like those provided by MZI Precision, offer the reliability that the defense sector needs. By using predictive maintenance techniques, they can identify potential spindle failures before they occur. This proactive approach minimizes downtime and ensures that military operations continue smoothly.

Solar Energy

As the world shifts toward renewable energy, the solar industry is booming. Manufacturing solar panels involves precise machining processes, where spindles are essential. Any disruptions can delay production and increase costs.

Spindle repair services help solar energy manufacturers maintain productivity. By offering engineered upgrades, MZI Precision ensures that spindles are not just repaired but also improved for better performance. This is vital for an industry that is growing rapidly and demands efficiency.

Each of these industries benefits from spindle repair in unique ways, ensuring that their operations remain smooth and efficient. By focusing on precision, reliability, and innovation, MZI Precision supports these sectors in achieving their goals.

Innovative Techniques and Tools

In Spindle Repair California, staying ahead of the curve means embracing the latest techniques and tools. MZI Precision is at the forefront, using cutting-edge methods to ensure top-notch spindle performance. Let’s dig into some of these innovative approaches:

Predictive Maintenance

Predictive maintenance is like having a crystal ball for your spindles. It uses advanced technology to predict when a spindle might fail. This means issues are addressed before they cause downtime.

MZI Precision employs predictive maintenance software that analyzes spindle performance data. By monitoring vibrations, temperatures, and other key metrics, they can foresee problems and fix them proactively. This not only reduces unexpected failures but also extends the life of the spindle.

Failure Analysis

Understanding why a spindle fails is crucial to preventing future issues. Failure analysis is a methodical approach to identifying the root cause of spindle problems. MZI Precision’s technicians are skilled in this process.

They begin by inspecting the spindle’s components, looking for signs of wear or damage. Advanced diagnostic tools help them pinpoint the exact cause of failure. Once identified, they implement solutions to prevent recurrence, ensuring the spindle operates smoothly.

Advanced Technology

Using advanced technology is key to effective spindle repair. MZI Precision invests in state-of-the-art tools and equipment to deliver precise repairs. This includes automated diagnostic tools that improve accuracy and speed.

These tools allow technicians to perform repairs with best precision, ensuring the spindle meets the highest standards. Additionally, MZI Precision is exploring digital solutions like augmented reality for remote diagnostics and support, making the repair process even more efficient.

By integrating these innovative techniques and tools, MZI Precision ensures that Spindle Repair California remains at the cutting edge. This commitment to innovation not only improves spindle performance but also improves the overall customer experience, leading seamlessly into the next section on frequently asked questions about spindle repair.

Frequently Asked Questions about Spindle Repair

How much does it cost to fix a spindle?

The cost of fixing a spindle can vary significantly. At MZI Precision, prices typically range from a few hundred to several thousand dollars. The final cost depends on several factors:

- Extent of Damage: Minor repairs, such as replacing bearings, are less costly than fixing severe damage.

- Custom Modifications: If your spindle requires specific upgrades or custom modifications, this can increase the cost.

- Type of Spindle: Different spindles have varying complexities, impacting the repair cost.

For an accurate estimate, it’s crucial to have the spindle assessed by experts who can provide a detailed quote based on the specific needs of your spindle.

Can a spindle be repaired?

Yes, spindles can often be repaired, restoring them to optimal functionality. At MZI Precision, the repair process involves several key steps:

- Component Inspection: Technicians disassemble the spindle and inspect each part, such as bearings and seals, to identify the root cause of the failure.

- Advanced Techniques: Using cutting-edge methods, they address underlying issues, ensuring the spindle operates like new.

Repairing a spindle is often more cost-effective than replacing it, saving both time and money while maintaining equipment performance.

How long does a spindle replacement take?

The timeline for spindle replacement varies based on several factors:

- Diagnostics: Initial diagnostics are crucial to understanding the problem and planning the replacement.

- Parts Procurement: Availability of necessary parts can impact the timeline. MZI Precision works efficiently to source parts quickly.

- Replacement Process: On average, replacements can take from a few days to a couple of weeks.

MZI Precision excels in minimizing downtime, ensuring your operations continue smoothly. Their expertise and streamlined processes help complete replacements efficiently, allowing you to get back to business with minimal disruption.

Conclusion

At MZI Precision, our commitment to customer satisfaction is at the heart of everything we do. We understand that when it comes to Spindle Repair California, our clients need reliable, efficient, and high-quality service. Our dedicated team works tirelessly to ensure that every spindle repair meets the highest standards of excellence.

Customer Satisfaction

We believe that communication is key. Our clients are kept informed throughout the entire repair process. We provide regular updates and feedback, making sure you know exactly what is happening with your equipment. This transparency builds trust and ensures that you feel confident in the decisions being made. Our goal is to make sure every client feels valued and understood.

Operational Excellence

Our reputation for operational excellence is not just a claim; it is a reality we strive for every day. With quick turnaround times and efficient service, we minimize downtime and maximize productivity for our clients. Our skilled technicians bring years of experience to the table, diagnosing and resolving issues swiftly and accurately. This expertise is vital in reducing service disruptions and ensuring that your operations continue with minimal interruption.

At MZI Precision, we are not just about fixing spindles; we are about building lasting relationships with our clients. Our dedication to quality, reliability, and customer satisfaction sets us apart in the industry. Whether you are in aerospace, defense, or solar energy, we are here to meet your spindle repair needs with professionalism and care.

Thank you for choosing MZI Precision for your spindle repair needs. We look forward to serving you with the same excellence and dedication that has earned us our reputation as leaders in the field.