Spindle mean: Crucial 2025 Performance Explained

UNPACKING ‘SPINDLE MEAN’: THE FOUNDATION OF INDUSTRIAL PRECISION

The term spindle mean refers to the critical operational and performance characteristics that define an industrial spindle’s effectiveness and reliability in precision manufacturing. For professionals in aerospace and advanced machining, understanding this concept is vital. ‘Spindle mean’ encompasses the average performance metrics (speed, torque, power), precision tolerances (mean runout), expected operational life, and consistent reliability (uptime) of a spindle.

From ancient tools for spinning fibers to the heart of modern CNC machines, the spindle has a rich history. Its etymological roots trace back to the Old English ‘spinel,’ linked to ‘spinnan,’ meaning ‘to spin.’ Over time, this concept of a rotating axis evolved dramatically. Today, in industrial manufacturing, the spindle is a highly engineered component, critical for the precision and efficiency required in aerospace, defense, and other high-tech industries.

The meaning of ‘spindle’ has expanded to encompass sophisticated rotating shafts that serve as the axes for larger, more intricate rotating parts in machine tools. These industrial spindles are the core components that deliver the torque, speed, and accuracy needed for precise material removal.

WHAT IS AN INDUSTRIAL SPINDLE? THE HEART OF THE MACHINE TOOL

An industrial spindle is the rotating axis of a machine tool, delivering the torque, speed, and precision needed to transform raw materials into finished parts. Without this vital component, a CNC machine cannot function.

At its core, an industrial spindle holds and rotates cutting tools or workpieces with incredible accuracy. The spindle mean – its critical performance characteristics – determines whether a spindle delivers consistent results. When machining aerospace components where tolerances are measured in microns, every revolution must be perfect. That’s why at MZI Precision, we treat these components with the respect they deserve.

The spindle is a system of components working together. The shaft transmits power, while precision bearings ensure smooth, accurate rotation. The housing provides a protective shell and structural foundation, and the drive system supplies the power. Finally, the drawbar mechanism securely clamps cutting tools in place.

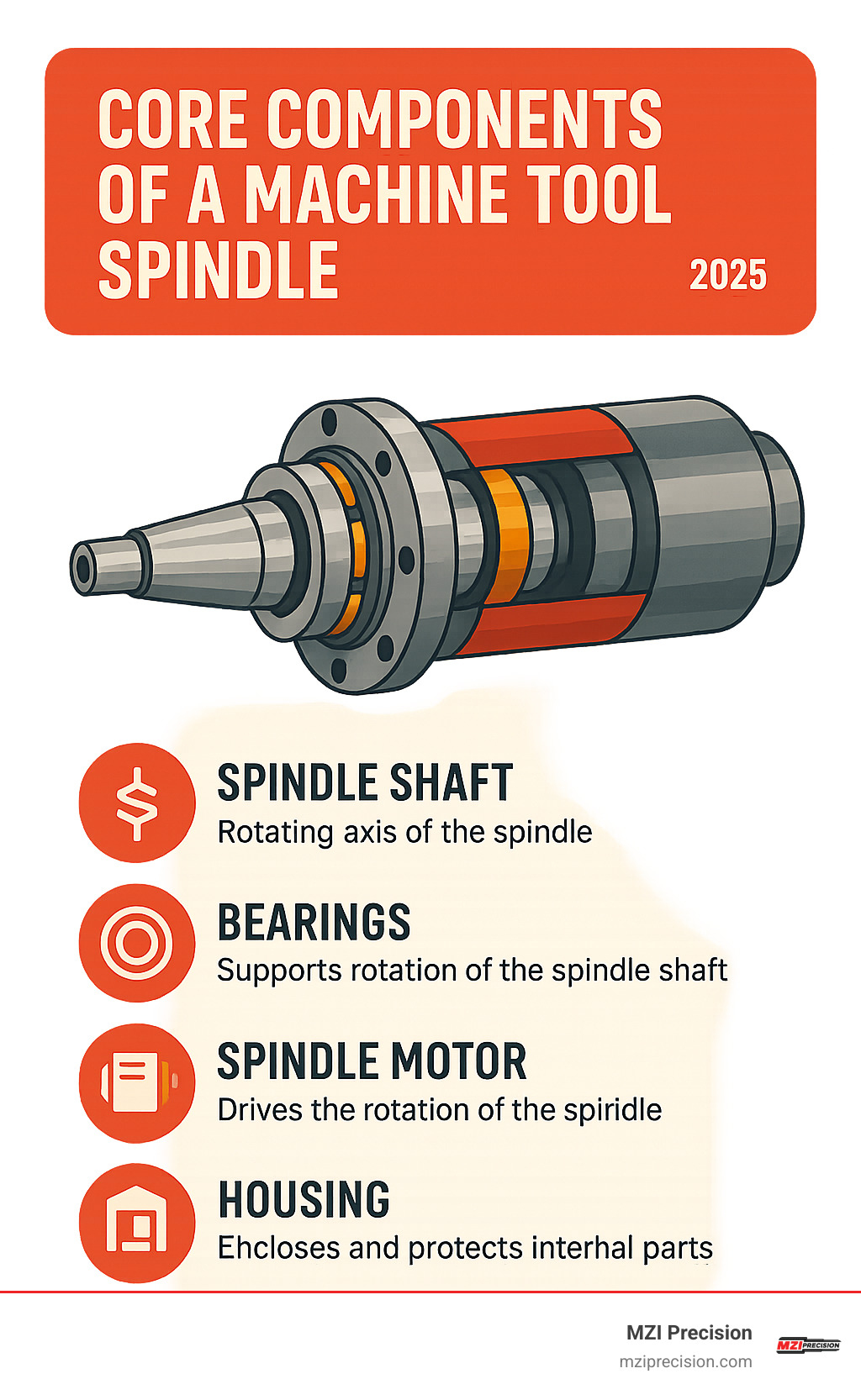

THE PRIMARY COMPONENTS OF A SPINDLE

Each component plays a key role in the spindle’s performance.

The rotating shaft is a precisely engineered component designed to handle massive forces while maintaining perfect balance. Most feature a hollow, tapered design to accommodate tool retention systems.

Your bearing system is where precision lives or dies. Industrial spindle bearings are crafted to determine a spindle’s accuracy and lifespan. Angular contact bearings excel in high-speed applications, while roller bearings handle heavier loads with their robust design.

The spindle housing is a structural foundation that integrates cooling channels, lubrication systems, and air passages to keep contaminants out. It’s engineered to dampen vibrations that could compromise machining precision.

Drive systems come in different types. Belt-driven systems are cost-effective and flexible. Gear-driven systems provide high torque. Integral motor spindles build the motor directly into the housing, delivering higher speeds and better dynamic response.

The drawbar mechanism, hidden inside the shaft, uses hydraulic or pneumatic power to provide the clamping force that keeps cutting tools secure. A properly functioning drawbar ensures consistent tool retention.

Each component must perform flawlessly. That’s why we offer comprehensive spindle rebuilding services – we understand how these intricate parts work together.

HOW SPINDLES POWER MANUFACTURING

Industrial spindles enable the creation of everything from aircraft components to precision medical devices. Their ability to deliver controlled, high-speed rotation makes complex machining operations possible.

- CNC machines: Spindles rotate cutting tools through precise paths, removing material with surgical accuracy.

- Lathes: Spindles rotate either the workpiece or the cutting tool for turning, facing, and boring operations.

- Milling machines: Spindles power various cutting tools for versatile material removal operations.

- Grinding machines: Spindles rotate abrasive wheels at extremely high speeds to achieve superior surface finishes and tight tolerances. Here, spindle mean performance is critical, as any deviation impacts part quality.

The material removal capabilities these spindles enable are essential for high-volume production, especially in aerospace and defense where challenging materials like titanium and Inconel are common. Spindle performance is mission-critical for these applications.

UNDERSTANDING SPINDLE MEAN AND PRECISION PERFORMANCE

When we talk about industrial spindle performance, we’re talking about consistency. The term spindle mean represents a spindle’s ability to deliver reliable, predictable results day after day.

Think of spindle mean as a spindle’s performance average. A spindle that maintains steady performance metrics is invaluable for manufacturers. This consistency covers accuracy, reliability, thermal stability, and the ability to hold precise tolerances. When your spindle maintains a healthy spindle mean, part quality stays high, scrap rates drop, and productivity soars.

Here’s how different spindle types typically perform across key metrics:

| Performance Indicator | Belt-Driven Spindle | Direct-Drive Spindle | High-Torque Spindle |

|---|---|---|---|

| Max Speed (RPM) | 12,000-15,000 | 20,000-60,000 | Up to 15,000 |

| Torque Output | Moderate to High | Moderate | Very High |

| Precision/Accuracy | High | Very High | High |

| Thermal Stability | Good | Challenging | Good |

| Maintenance Needs | Higher | Lower | Moderate |

| Best Application | General machining | High-speed finishing | Heavy roughing |

WHAT DOES SPINDLE MEAN IN TERMS OF PERFORMANCE METRICS?

Spindle mean refers to the operational averages that define a spindle’s real-world capabilities. Mean speed and mean torque describe its typical working life. For example, a spindle might have a max speed of 20,000 RPM but a mean speed of 15,000 RPM during machining. These averages provide a realistic foundation for planning jobs and estimating times.

Precision tolerances are where the spindle mean truly shines. A spindle that consistently holds parts within a 5-micron tolerance band demonstrates a stable performance DNA. This reliability impacts everything from chip load distribution to final surface finish. A stable spindle mean leads to longer tool life, better part finishes, and reduced setup times. Industry standards, such as the Axes of Rotation standards from ASME, provide benchmarks for measuring these capabilities.

HOW TO REDUCE SPINDLE RUNOUT AND MAINTAIN THE SPINDLE MEAN

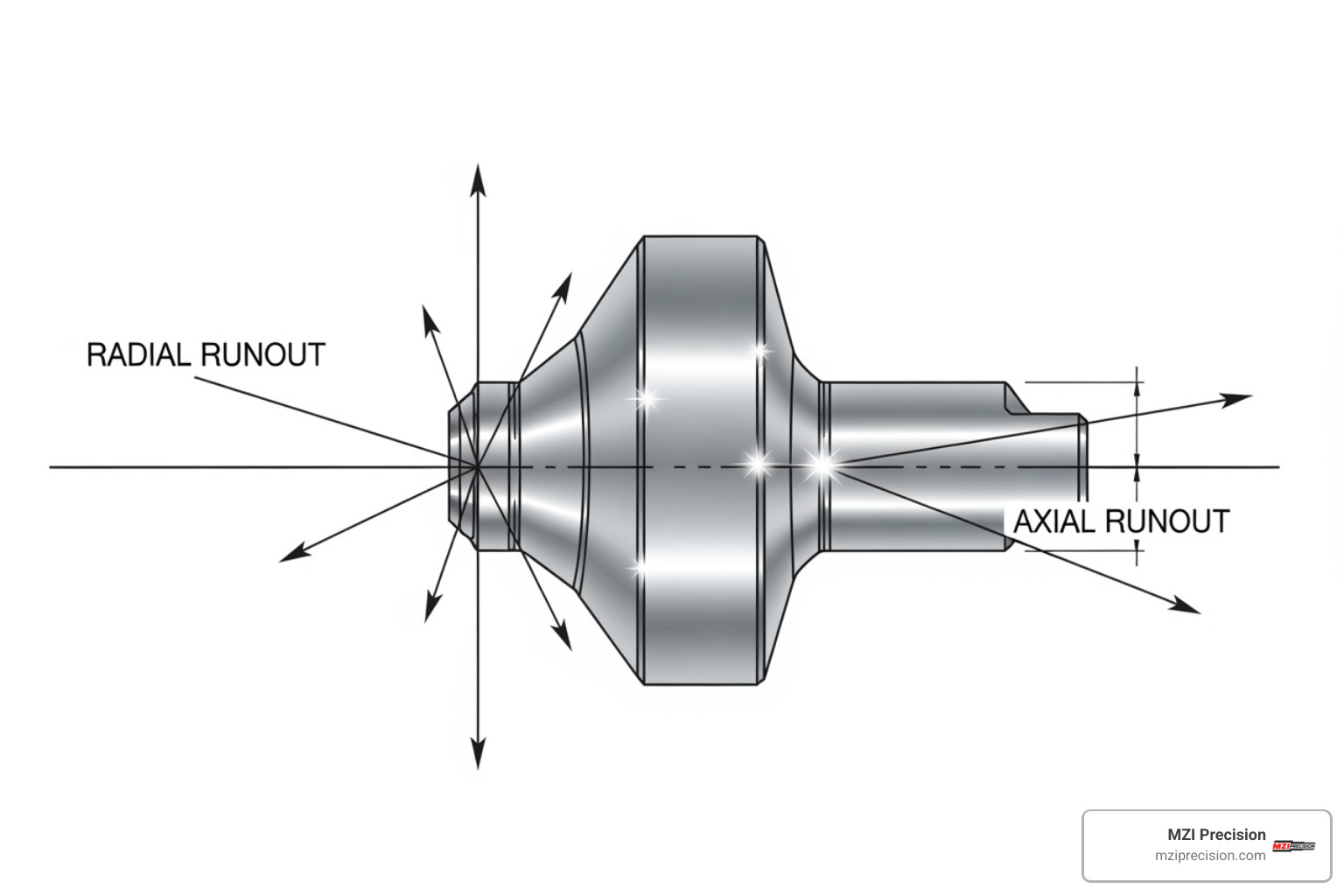

Nothing threatens your spindle mean quite like runout—a tiny wobble that can cause big problems.

Runout comes in two forms. Axial runout is the up-and-down movement along the spindle’s axis, creating inconsistent cutting depths. Radial runout is the side-to-side wobble, causing oversized features and loose tolerances. The effects include accelerated tool wear, rough part finishes, and machine chatter. Your spindle mean performance declines, impacting productivity.

Catching runout early is key. A dial indicator is a simple and reliable tool for measurement. For more advanced analysis, non-contact sensors can account for heat and dynamic forces during operation.

Professional expertise is invaluable here, as the root cause could be worn bearings, a bent shaft, or assembly issues. Our technicians at MZI Precision diagnose and eliminate the true cause of runout. Our rebuilding process restores your spindle to OEM specifications, with every component balanced to micron tolerances. This meticulous work brings your spindle mean back to its optimal level. You can find More info about our spindle repair process on our website.

TYPES OF SPINDLES IN MODERN MANUFACTURING

Modern manufacturing facilities use a variety of industrial spindles, each engineered for specific tasks. The spindle mean performance characteristics vary dramatically between types, making the right choice critical for success. Spindles are classified based on their application, power source, and power transmission method.

Modern industrial spindles can handle everything from delicate aluminum aerospace components to tough titanium alloys used in defense. Whether working with steel, composites, advanced ceramics, or specialized polymers, there’s a spindle designed for the material and precision required.

BELT-DRIVEN VS. DIRECT-DRIVE SPINDLES

Choosing between belt-driven and direct-drive spindles depends on the application’s needs.

Belt-driven spindles use an external motor that sends power through a belt and pulley system. This design is cost-effective to purchase and maintain. The separate motor simplifies cooling and provides natural vibration isolation. A key safety feature is that the belt can slip under overload, preventing damage to expensive components. However, they are typically limited to 12,000-15,000 RPM, and the belt can introduce slight vibrations and requires periodic replacement.

Direct-drive spindles (or integral motor spindles) are at the cutting edge of spindle technology. The motor is built directly into the spindle housing, with the rotor on the spindle shaft. This direct connection allows for remarkable speeds, often 20,000 to 60,000 RPM or higher. With no belts to cause vibration, they deliver superior precision and dynamic performance, ideal for high-speed operations with tight tolerances. The trade-offs include a higher price, more complex servicing, and heat generation that requires sophisticated cooling systems.

HIGH-SPEED AND HIGH-TORQUE SPINDLES

Beyond the drive mechanism, spindles are designed for either speed or torque, a crucial distinction for maintaining optimal spindle mean performance.

High-speed spindles excel at rapid material removal with small cutting tools and can achieve excellent surface finishes. Operating at speeds often exceeding 20,000 RPM, their design focuses on managing the challenges of extreme velocity. They use high-precision angular contact bearings, advanced lubrication, and robust liquid-cooling systems to manage heat. Precise balancing is critical to prevent vibrations that would ruin precision.

High-torque spindles are the powerhouses designed for tough materials and heavy cuts. While slower, they deliver the substantial turning force needed for serious material removal. These robust machines feature larger, stiffer shafts and often use roller bearings to handle heavy loads. They are built for power and stability, enabling deep cuts in challenging materials like titanium or superalloys without flinching. Matching the spindle type to your manufacturing needs is key to success.

THE IMPORTANCE OF SPINDLE MAINTENANCE AND REBUILDING

An industrial spindle is the heart of your manufacturing operation, but it operates under incredible stress. High-speed rotation, heavy loads, coolant, and debris eventually take their toll. Without proper care, the spindle mean performance will drop, leading to inaccurate parts, rough surface finishes, and costly downtime.

A solid maintenance routine, including regular lubrication and cleaning, can significantly extend a spindle’s life. However, components will eventually wear out. This is where professional spindle rebuilding becomes essential, restoring your spindle to its original performance specifications.

At MZI Precision, we see rebuilding as a smart investment that restores accuracy, extends equipment life, and ensures consistent quality. When you’re ready to learn more, check out More info about our spindle repair process.

COMMON CAUSES OF SPINDLE FAILURE

Understanding common failure modes is key to prevention.

- Bearing contamination: This is the number one cause of failure. When seals wear out, coolant, metal chips, and dust enter the bearing system, causing abrasive wear.

- Improper lubrication: Too little lubricant causes overheating and seizure. Too much can also create excessive heat and damage seals. Using the wrong type is also a recipe for disaster.

- Overloading: Pushing a spindle beyond its design limits for speed or torque causes stress and premature wear on bearings, the shaft, and other components.

- Crashes: A tool collision can cause shock loads that bend shafts, damage bearings, or fracture components instantly.

- Vibration issues: Unbalanced tooling, worn bearings, or misalignment create vibrations that accelerate wear on all components, gradually degrading the spindle mean performance.

- Lack of maintenance: Neglecting routine inspections allows small issues like seal degradation or low lubrication to grow into major failures.

WHY PROFESSIONAL SPINDLE REBUILDING IS CRUCIAL

When a spindle fails, professional rebuilding offers compelling advantages over simple replacement.

Restoring OEM specifications is what separates true rebuilding from basic repair. We completely disassemble the spindle, inspect every component, and replace anything that doesn’t meet original manufacturer standards. This brings your spindle back to a like-new condition, ensuring it delivers the intended spindle mean performance.

Micron tolerances are critical for precision. Rebuilding to these exacting standards requires specialized equipment and expertise. Every bearing journal and housing bore is ground and polished to prevent runout and premature failure.

Balancing the entire rotating assembly is essential. We perform dynamic balancing to minimize vibration at high speeds, which is the enemy of precision and longevity.

Professional rebuilding extends equipment life, maximizing your return on investment. It also reduces downtime, as our streamlined process is often faster than waiting for a new spindle. Most importantly, it ensures precision, allowing your rebuilt spindle to deliver the consistent accuracy your operations depend on. This means higher quality parts, fewer rejects, and the confidence to meet the demands of precision industries.

CONCLUSION

From a simple tool for spinning wool, the spindle has evolved into the sophisticated heart of precision manufacturing, powering everything from aircraft components to defense systems. Throughout this article, we’ve defined spindle mean as the consistent, reliable performance characteristics that are the hallmark of exceptional manufacturing.

We’ve explored the intricate system of components—the shaft, bearings, housing, and drive system—and how choices between belt-driven, direct-drive, high-speed, or high-torque designs shape a spindle’s ability to maintain its intended spindle mean performance.

Proper care is essential. Industrial spindles are precision instruments that require attention to prevent contamination, avoid overloads, and recognize when professional rebuilding is needed. When performance suffers due to wear, contamination, or a crash, professional rebuilding is the key to restoring the micron tolerances and perfect balance that modern manufacturing demands.

At MZI Precision, we understand that your spindles are the foundation of your operation’s success. Our expertise in rebuilding industrial spindles ensures we’re here when precision matters most. For aerospace, defense, or other high-tech manufacturing operations that require peak performance, we are ready to help.

Your success depends on spindles that deliver reliable, precise performance. Don’t let worn or failing spindles compromise your quality or timeline. Contact us for your spindle service needs and find how MZI Precision can keep your operations running smoothly.