Spindle Grinding: Quick Facts

– Service Type: On-site, In-plant

– Key Benefit: Precision restoration of spindle tapers

– Mobile Units Available: Yes

– Locations Served: Continental United States

– Industries: Aerospace, Automotive, Medical, and more

Are you facing constant issues with machine precision, experiencing excessive downtime due to spindle problems? Spindle grinding might just be the solution you’re seeking. Whether it’s wear and tear, taper contact issues, or runout, spindle grinding can bring your machine back to its peak performance with minimal disturbance to your production line.

At MZI Precision, we specialize in providing top-notch spindle grinding services that cater specifically to your needs, ensuring minimal downtime and a swift return to high precision operations. Understanding the critical role spindles play in your machinery, our aim is to offer a service that not only fixes the immediate problem but also enhances your machine’s performance for the long haul.

Understanding Spindle Grinding

Spindle grinding is an essential process in the maintenance and repair of spindles, which are a critical component in many machines used across various industries, including carpentry, metalworking, and manufacturing. This process involves the precise grinding of the spindle, usually to repair damage from wear and tear, improve precision, or restore its original condition. Let’s break down the key aspects of spindle grinding to give you a clearer understanding of its importance and operation.

Function

A spindle’s primary function is to hold and rotate the cutting tools or workpieces at high speeds. In grinding machines, the spindle plays a crucial role by holding the grinding wheel. Over time, spindles can suffer from wear and tear, misalignment, or damage, affecting the machine’s overall precision and functionality.

Use

Spindles are used not only in grinding machines but also in other machine tools such as lathes, milling machines, and CNC machines. Each type of machine relies on the spindle for different purposes, from holding the workpiece in lathes to holding the cutting tool in milling machines.

Carpentry

In carpentry and woodworking, spindles are used in routers, shapers, and other machinery for cutting intricate designs and patterns in wood. The precision of the spindle directly impacts the quality and accuracy of the carpentry work.

Operation

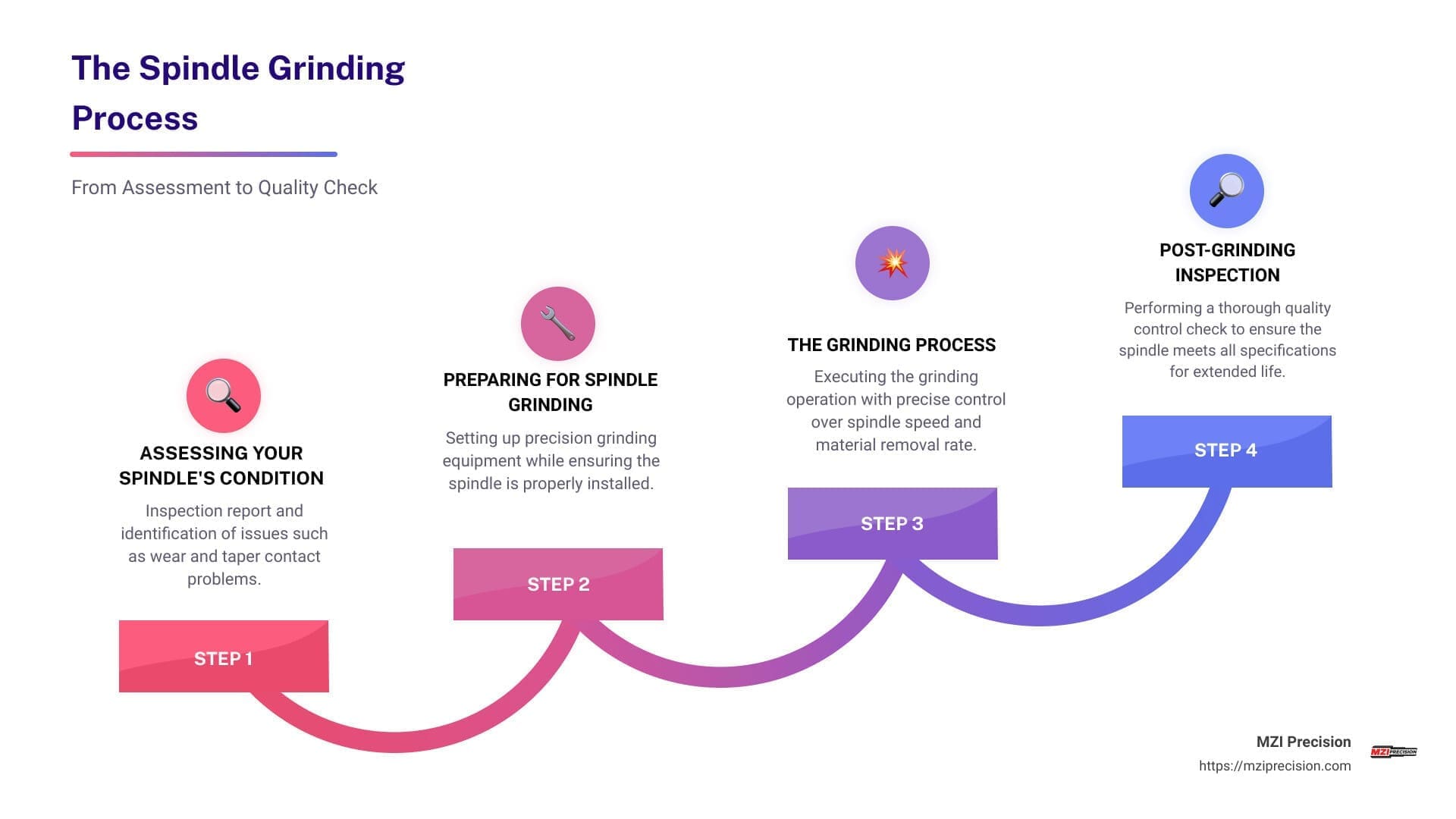

Spindle grinding involves several steps, starting with a detailed assessment of the spindle’s condition. Specialized grinding equipment is then used to remove imperfections and restore the spindle’s surface to its original precision. The process requires a high level of skill and knowledge about spindle geometry and materials.

Spindle Parts

A spindle consists of a body, bearings, a taper (where the tool or workpiece is held), and a drive system (motor). Each part must function correctly for the spindle to operate efficiently. Grinding often focuses on the taper, as this is where most wear and damage occur.

High-Speed Repair and CNC Rebuild

Modern manufacturing demands high-speed spindles for efficient production. Spindle grinding is a critical service for repairing high-speed spindles, ensuring they meet the precision requirements for CNC machining. A well-executed spindle grind can significantly extend the life of the spindle and improve the performance of the CNC machine.

In summary, spindle grinding is a specialized process that restores the precision and functionality of machine spindles. At MZI Precision, we understand the critical role spindles play in your manufacturing operations. Our expertise in spindle grinding, combined with our commitment to quality, ensures that your spindles are in the best hands. Whether you need a high-speed repair or a comprehensive CNC rebuild, we have the skills and technology to meet your needs and exceed your expectations.

Step 1: Assessing Your Spindle’s Condition

Before diving into spindle grinding, thoroughly assess the condition of your spindle. This step is crucial as it helps us determine the right approach to take for repairs and ensures that we address all issues that may affect your spindle’s performance.

Inspection Report

First, we conduct a detailed inspection of your spindle. This involves examining the spindle for signs of wear and tear, such as bellmouthing, which is a common issue where the front of the spindle taper becomes widened over time. This condition can lead to problems with runout, tool chatter, and poor surface finishes.

Taper Contact

We also check the taper contact area. Proper taper contact is vital for effective power transmission and to prevent the tool from slipping during operation. An uneven or worn taper contact can significantly affect the spindle’s performance.

Clamping Pressure

The clamping pressure is another critical factor we assess. Adequate clamping pressure ensures that the tool is securely held in place during operation, preventing it from coming loose and causing damage to the spindle or the workpiece.

Test Bar Runout

We use a test bar to measure runout, which is the amount of wobble in the spindle as it rotates. Excessive runout can lead to poor part finishes and decreased tool life. Assessing the runout helps us to identify any misalignment or balance issues within the spindle.

Wear and Tear

Finally, we thoroughly inspect the spindle for any other signs of wear and tear. This includes checking for spun tools, galling in the taper, and any other damage that may have occurred over time. Identifying and addressing these issues is crucial for ensuring the longevity and performance of your spindle.

By carefully assessing your spindle’s condition, we can provide a tailored solution that addresses all the issues identified. Our goal is to restore your spindle to its optimal performance, ensuring that it meets or exceeds original specifications. This initial step sets the foundation for a successful spindle grinding process, ensuring that we achieve the best possible results for your manufacturing operations.

Step 2: Preparing for Spindle Grinding

Getting ready for spindle grinding is crucial. It’s not just about having the right tools; it’s about making sure everything is set for a precise, efficient job. Here’s how we at MZI Precision prepare for spindle grinding, focusing on ensuring tool life, achieving a permanent repair, and executing spindle taper grinding with precision.

Precision Grinding Equipment

First things first, we make sure our precision grinding equipment is up to the task. This equipment is specially designed for spindle grinding, capable of handling various spindle sizes and types with accuracy. Whether your spindle is part of a large industrial machine or a smaller piece of equipment, we have the right tools for the job.

Spindle Installed

One of the unique aspects of our service is that we grind your spindle taper with the spindle installed in the machine. This approach has several benefits:

– Minimizes Downtime: Since there’s no need to remove the spindle, we can get straight to work, reducing the time your machine is out of action.

– Ensures Greater Precision: Grinding the spindle in its operational position helps to achieve better alignment with the machine’s other components, leading to reduced runout and improved overall performance.

Tool Life

Our spindle grinding process is designed not only to repair your spindle but also to extend its tool life. By restoring the spindle taper to its original specifications, we ensure that tool holders fit correctly, reducing wear and tear on both the spindle and the tools themselves. This means you can go longer between repairs, saving you time and money in the long run.

Permanent Repair

The goal of our spindle grinding service is to provide a permanent repair solution. We don’t believe in quick fixes that leave you facing the same problems down the line. By addressing the root causes of spindle wear and damage, we ensure that once we’ve completed our work, your spindle is as good as new.

Spindle Taper Grinding

Spindle taper grinding is at the heart of what we do. This process involves reshaping the spindle itself to remove any imperfections or wear that have developed over time. It’s a precise, technical procedure that requires the right equipment, skills, and attention to detail – all of which we bring to every job.

By the time we’re done, the spindle taper will meet or exceed its original specifications, ensuring that your machine operates with maximum efficiency and precision. This not only improves your manufacturing operations but also saves you money by reducing the need for future repairs and extending the life of your spindle and tools.

In preparation for spindle grinding, we make sure everything is in place for a smooth, efficient process that delivers results. With MZI Precision, you can trust that your spindle is in expert hands.

Step 3: The Grinding Process

After we’ve thoroughly prepared and ensured your spindle is ready for grinding, we dive into the core of our service – the grinding process itself. This step is critical and demands precision and expertise to ensure the best outcome for your spindle.

Material Removal Rate

At the beginning of the grinding process, we focus on the Material Removal Rate (MRR). This is a measure of how much material is removed from the spindle in a given time. It’s crucial because it affects the efficiency and quality of the grinding. We adjust the MRR based on the condition of your spindle and the desired outcome, ensuring that we remove enough material to address the issue without compromising the integrity of the spindle.

Spindle Speed and Workpiece Rotational Speed

Two more critical factors we adjust are the spindle speed and workpiece rotational speed. The spindle speed refers to how fast the grinding wheel rotates, while the workpiece rotational speed is how fast the spindle being repaired rotates. The right balance between these speeds is crucial for effective grinding without causing damage or unnecessary wear.

Grinding Wheel Inspection

Before the actual grinding begins, we conduct a thorough inspection of the grinding wheel. This step is vital to ensure there are no defects or issues with the wheel that could affect the grinding process. Any imperfections in the wheel could transfer to the spindle, leading to further complications.

Truing and Dressing

The final preparation step before grinding is truing and dressing the grinding wheel. “Truing” involves reshaping the wheel to ensure it’s perfectly round and runs true. “Dressing” cleans the surface of the wheel, removing any debris and exposing fresh abrasive particles. This process is crucial for achieving a high-quality finish and precise dimensions on your spindle.

Once everything is set, we begin the grinding process, carefully monitoring each step to ensure the highest quality results. Our experienced technicians pay close attention to the spindle’s response to the grinding, adjusting the parameters as necessary to achieve the desired outcome.

By the end of this process, your spindle’s surface will be smooth, accurate, and ready for the next steps toward full restoration. With MZI Precision, you can rest assured that your spindle grinding is performed with the utmost care and expertise, aiming for the best possible performance and longevity of your equipment.

Step 4: Choosing the Right Grinding Service

Choosing the right service for spindle grinding is like picking a partner who will determine the success of your project. It’s crucial. Not all services are created equal. Here’s how to make sure you choose the best one for your needs.

Understand Your Needs

First, understand exactly what you need. Are you looking for on-site taper grinding, or do you need a custom spindle built? The specifics of your project will guide your choice.

Look for Experience and Expertise

Experience counts. Services like SPS Spindle Parts, Capellini Electrospindles, and Locher Inc have proven track records. They’ve been in the game for years and have the expertise to show for it. We, at MZI Precision, pride ourselves on our deep understanding and specialized experience in spindle grinding. Our technicians are trained to handle a variety of spindle types and conditions.

Consider On-Site Services

Downtime can be costly. Services that offer on-site spindle taper grinding, like Locher Inc, can be a lifesaver. This option reduces your machine’s downtime significantly, as the spindle doesn’t need to be removed and shipped for repairs.

Customization Options

Sometimes, off-the-shelf solutions won’t cut it. If you need custom spindles, ensure the service provider can accommodate your requirements. Capellini Electrospindles, for example, is known for its ability to produce high-quality custom spindles.

Quality and Precision

Precision is non-negotiable in spindle grinding. Look for services that emphasize the importance of precision grinding equipment and quality control measures. We ensure that our grinding operations are climate-controlled and our equipment can grind to precise tolerances. This attention to detail ensures the longevity and performance of your spindle.

Certifications and Standards

Certifications like ISO 9001:2015, ISO 13485, and AS9100D indicate a provider’s commitment to quality and reliability. Xometry’s vetted network, for example, showcases their adherence to high standards.

Post-Service Support

The relationship shouldn’t end after the service is completed. Opt for providers who offer post-grinding inspection and maintenance advice. This ongoing support can help prevent future breakdowns and extend the life of your spindle.

Conclusion

Choosing the right spindle grinding service is crucial for the success of your repair or rebuild project. Look for providers that match your specific needs, offer on-site services, provide customization options, and adhere to high quality and precision standards. At MZI Precision, we strive to exceed these criteria, ensuring that our clients receive the best possible service and support.

The right partner not only fixes your current issue but also helps prevent future problems. Choose wisely.

Step 5: Post-Grinding Inspection and Maintenance

After the spindle grinding process, it’s crucial not to jump straight back into operations. To ensure the longevity and efficiency of your spindle, a thorough post-grinding inspection and maintenance routine is essential. Here’s how we at MZI Precision handle this vital step:

Quality Control Check

Immediately after grinding, we conduct a comprehensive quality control check. This involves:

- Inspecting the spindle taper for precision: We ensure that the taper meets the original manufacturer’s specifications to guarantee optimal performance.

- Checking for runout: Any deviation from the true rotational axis is corrected to prevent future operational issues.

- Verifying clamping pressure: Adequate clamping pressure is essential for tool retention and performance. We ensure it’s within the recommended range.

- Reviewing the surface finish: A smooth surface finish is crucial for the spindle’s interaction with tool holders and workpieces.

This meticulous inspection ensures that every aspect of the spindle meets our high standards and your operational requirements.

Extended Spindle Life

The aim of spindle grinding and subsequent checks is not just to repair but to extend the spindle’s life. Here’s what we recommend to achieve this:

- Regular lubrication: Proper lubrication reduces wear and protects against corrosion.

- Avoiding overload: Operating within the spindle’s capacity prevents premature wear.

- Routine checks: Regularly inspecting the spindle for signs of wear or damage can catch issues before they escalate.

Adhering to these practices can significantly increase the time between necessary repairs or replacements.

Routine Maintenance

Consistent maintenance is key to preventing future breakdowns. Our routine maintenance includes:

- Cleaning: Keeping the spindle clean prevents the build-up of contaminants that can cause wear.

- Vibration monitoring: Excessive vibration can be an early warning sign of potential issues. Regular monitoring helps prevent damage.

- Temperature checks: Overheating can indicate lubrication problems or excessive friction. Monitoring spindle temperature helps identify issues early.

Prevent Future Breakdowns

Finally, to prevent future breakdowns:

- Train operators: Educating those who work with the spindle on proper use and early signs of trouble can help avoid mishaps.

- Schedule regular professional inspections: Having experts like us at MZI Precision inspect your spindle can help identify and mitigate potential issues before they become serious.

- Implement a predictive maintenance program: Using data to predict when maintenance should be performed can prevent unexpected failures.

By following these steps, you ensure not only the restoration of your spindle to its peak condition but also its sustained performance and longevity. At MZI Precision, we’re committed to providing the support and expertise needed to keep your spindles running smoothly, efficiently, and without unexpected downtime.

Frequently Asked Questions about Spindle Grinding

In our journey to understand spindle grinding better, we’ve encountered some common questions. Let’s address these to help clarify the process and its benefits further.

What is the function of a spindle in a grinding machine?

A spindle in a grinding machine is akin to the heart in our bodies—it’s crucial for the machine’s operation. It holds the grinding wheel and provides the rotation needed to cut or grind various materials. Without the spindle, there’s no grinding, no shaping, and no finishing. It’s that essential.

How does a spindle work?

Imagine a top spinning smoothly across your table—that’s the spindle in action, but on a much more sophisticated level. Powered either by electricity or air, the spindle rotates at high speeds. This rotation, controlled precisely by either manual inputs or computer commands, allows the spindle to carry out its mission: grinding, cutting, or shaping the workpiece with exceptional accuracy. It’s all about controlled motion and precision.

What are the advantages of spindle grinding?

Spindle grinding offers a myriad of benefits, making it a preferred method for many machining tasks. Here are some key advantages:

- Precision: Spindle grinding can achieve incredibly precise tolerances, essential for high-quality manufacturing processes.

- Versatility: Whether it’s metal, ceramics, or another material, spindle grinding can handle it. This adaptability makes it invaluable across various industries.

- Surface Finish: The method is capable of producing superior surface finishes, from smooth and reflective to textured, depending on the project’s needs.

- Cost-Effectiveness: With its high material removal rate and the ability to automate the process, spindle grinding is both time-efficient and cost-effective.

- Extended Equipment Life: Properly maintained, a grinding spindle can have a long operational life, ensuring sustained production capabilities without the need for frequent replacements.

At MZI Precision, we understand the importance of spindle grinding in the manufacturing process. It’s not just about shaping materials—it’s about precision, efficiency, and reliability. We’re here to ensure those are the standards you can expect when you choose us for your spindle grinding needs.

Conclusion

Precision, Cost-Effectiveness, Extended Equipment Life, Improved Performance

In manufacturing, particularly in high-demand sectors like aerospace, the significance of spindle grinding cannot be overlooked. It’s a process that goes beyond mere functionality—it embodies the pursuit of perfection in every piece produced. At MZI Precision, our commitment is not just to meet your expectations but to exceed them, ensuring that every project we undertake is a testament to our dedication to precision, cost-effectiveness, extended equipment life, and improved performance.

Precision is at the heart of everything we do. We understand that in industries where every micron matters, there’s no room for error. Our spindle grinding services are designed to restore your equipment to its peak performance, ensuring that your operations run smoothly and efficiently.

Cost-effectiveness is another cornerstone of our approach. We believe in providing solutions that not only solve your immediate problems but also offer long-term value. By choosing our spindle grinding services, you’re investing in a solution that will save you money in the long run through reduced downtime and extended equipment life.

Speaking of extended equipment life, it’s a direct benefit of our expert spindle grinding services. Regular maintenance and timely repairs can significantly prolong the lifespan of your machinery. This means you can get more out of your existing equipment, delaying the need for costly replacements and keeping your production lines moving.

Finally, improved performance is the ultimate goal of our spindle grinding services. A well-maintained spindle not only operates more efficiently but also produces better-quality products. This can give you a competitive edge, helping you to meet and exceed industry standards and customer expectations.

Choosing MZI Precision for your spindle grinding needs means partnering with a team that understands the challenges and demands of your industry. We’re not just service providers; we’re your partners in achieving excellence. With our expertise, state-of-the-art technology, and commitment to customer satisfaction, we’re here to support you every step of the way.

For more information on how we can assist you with your spindle grinding and repair needs, please visit our services page. Let us help you enhance your manufacturing process, ensuring precision, cost-effectiveness, extended equipment life, and improved performance.