How Servo Motor Torque Determines Performance

Servo motor torque is simply the rotational force a servo motor generates to move or hold a load. Selecting the right torque means your motor can reliably perform its job without stalling or overheating.

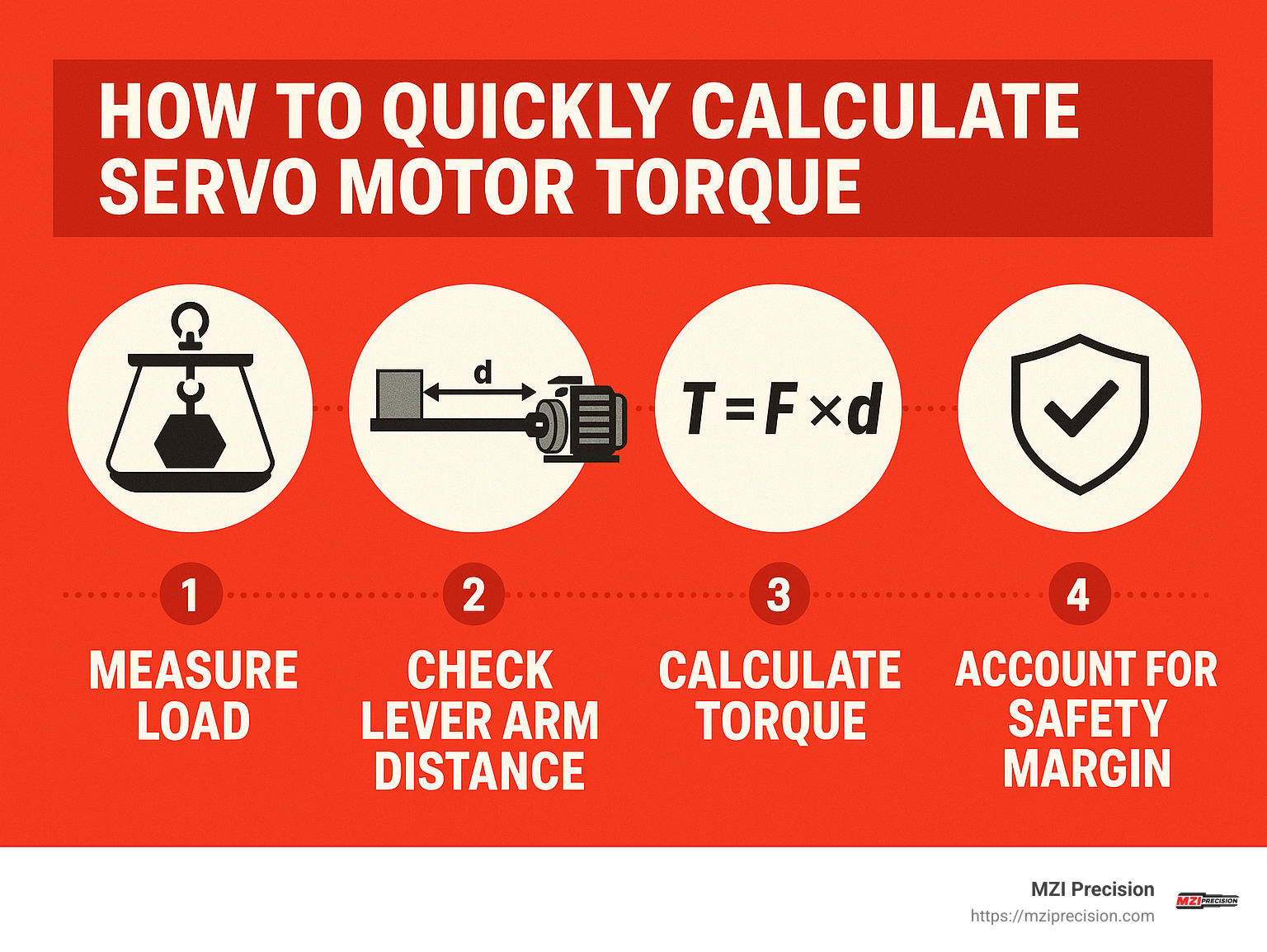

Here’s how to quickly determine your servo motor torque needs:

- Measure Load Weight: Find the heaviest load (in kg or ounces) your servo motor must move or hold.

- Check Lever Arm Distance: Determine the distance (in cm or inches) from the motor’s axis to the point where the load is applied.

- Calculate Torque: Multiply load weight by lever arm distance. (Torque = Force × Distance)

- Account for Safety Margin: Add at least 20% extra torque to allow for friction, acceleration forces, and other unexpected loads.

For example, moving a 2 kg load positioned 3 cm from the motor axis:

Torque Required = 2 kg × 3 cm = 6 kg-cm

With Safety Margin: 6 kg-cm + 20% ≈ 7.2 kg-cm

To visualize this clearly, here’s a simple infographic:

Servo motor torque vocabulary:

– servo motor in cnc

– servo drive

– spindle servo motor

Understanding Servo Motor Torque

When you work with industrial manufacturing spindles and precision machinery, there’s one concept you absolutely can’t ignore: servo motor torque. Simply put, torque is the rotational force a servo motor generates to turn or hold an object around an axis. Think of torque as the muscle behind your servo motor—without the right amount of muscle power, your machinery will struggle or stall.

At MZI Precision, we’ve rebuilt countless industrial manufacturing spindles and seen how crucial torque selection can be. Choosing a servo motor with the correct torque rating can make all the difference between a smooth operation and a frustrating headache—trust us, we’ve been there!

What is Torque in Servo Motors?

In technical terms, torque is the rotational force causing objects to spin around an axis—often called a “moment of force.” Imagine trying to open a stubborn jar lid: the harder you twist, the more torque you’re applying to get that lid off. Similarly, a servo motor relies on torque to properly rotate or hold your machinery components exactly where you need them.

Engineers calculate torque using a simple formula:

[

\tau = r \times F \times \sin(\theta)

]

Here’s what each part means:

- τ (tau): The torque (or rotational force)

- r: The distance from the rotation axis to the point where force is applied (also called the “lever arm”)

- F: The force you apply

- θ (theta): The angle between the force applied and the lever arm—maximum torque happens when this angle is 90 degrees (perpendicular).

Depending on your region or industry standards, you might measure servo motor torque in different units, including Newton-meters (Nm), ounce-inches (oz-in), or kilogram-centimeters (kg-cm). Sometimes you might need to convert between these units, so here are a couple of handy conversions to remember:

- 1 Nm equals roughly 8.85 pound-force inches (lbf-in)

- 1 Nm equals approximately 10.2 kilogram-centimeters (kg-cm)

Why is Torque Important for Servo Motors?

You might wonder: “Why does torque matter so much?” Well, torque is the heart of servo motor performance. Without enough torque, your spindle or machinery won’t have the strength to handle its tasks effectively.

First and foremost, servo motors need torque to move loads smoothly. Whether your equipment is lifting, rotating, or positioning components, sufficient torque ensures your motor won’t stall or struggle halfway through the job.

Second, torque is critical when your machinery must hold a position. Imagine your servo-controlled spindle holding a precise machining position against outside forces and vibrations. Without enough torque, your spindle could drift or lose its accuracy—not exactly ideal when precision is your goal!

Next, torque directly impacts how quickly your spindle can accelerate and decelerate. High-torque servo motors respond swiftly, enabling your machinery to speed up quickly and slow down smoothly. This responsiveness boosts productivity and helps maintain accurate movement.

Lastly, every mechanical system encounters friction. Your servo motor needs adequate torque to overcome friction and keep things running smoothly. Choosing a motor with a little extra torque ensures your machine can handle friction and unexpected resistance without strain or overheating.

In our spindle rebuilding work at MZI Precision, we’ve found proper torque specification to be absolutely essential. As the saying goes, “Torque is the measure of the force causing an object to rotate—it’s essential for determining the right servo motor for your application.”

Understanding servo motor torque isn’t just engineering jargon—it’s practical knowledge that can greatly improve your spindle’s reliability, accuracy, and lifespan.

How Torque is Measured in Servo Motors

Understanding how servo motor torque is measured is essential when selecting the right motor for your industrial manufacturing spindle applications. Manufacturers may present torque data differently, but the core concepts remain consistent—designed to help you choose the best motor to match your performance requirements.

Types of Torque Specifications

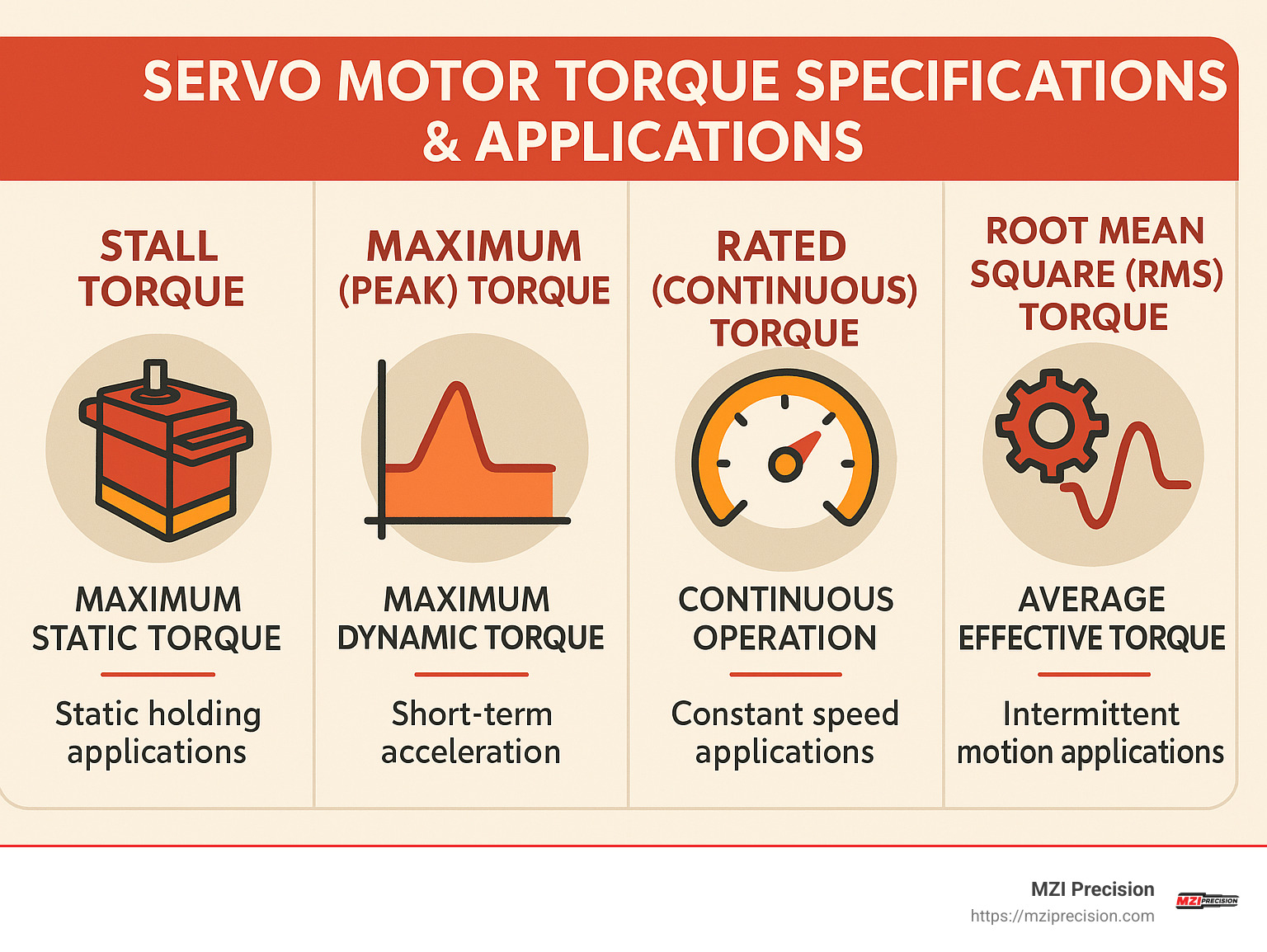

Servo motor datasheets often include several torque specifications. Knowing how to interpret these is key to proper motor selection.

Stall torque is the motor’s maximum torque when energized but not moving—think of it as the motor giving its strongest push without turning. This torque value is important because it tells you the absolute limit before the motor stalls.

Peak torque (maximum torque) refers to the highest possible torque the servo motor can generate in short bursts (usually milliseconds). It’s like that quick extra push you give when starting to move something heavy. Peak torque is crucial if your spindle application involves rapid accelerations or sudden, short-term load spikes.

On the other hand, rated torque (continuous torque) is perhaps the most critical specification for most industrial spindle applications. This is the torque your motor can consistently deliver without overheating or slowing down. In other words, it’s the dependable, steady pulling power your servo motor provides during ongoing operation. As industry research notes, “Rated torque is the maximum continuous torque available at rated speed without overheating.” This specification often guides motor selection for demanding spindle applications.

Another important measure is Root Mean Square (RMS) torque, which reflects the motor’s effective torque across the entire operation or duty cycle. RMS torque considers load variations over time and is especially important if your spindle experiences fluctuating loads during operation.

Here’s a helpful infographic summarizing the main torque specifications visually:

Understanding Torque Curves

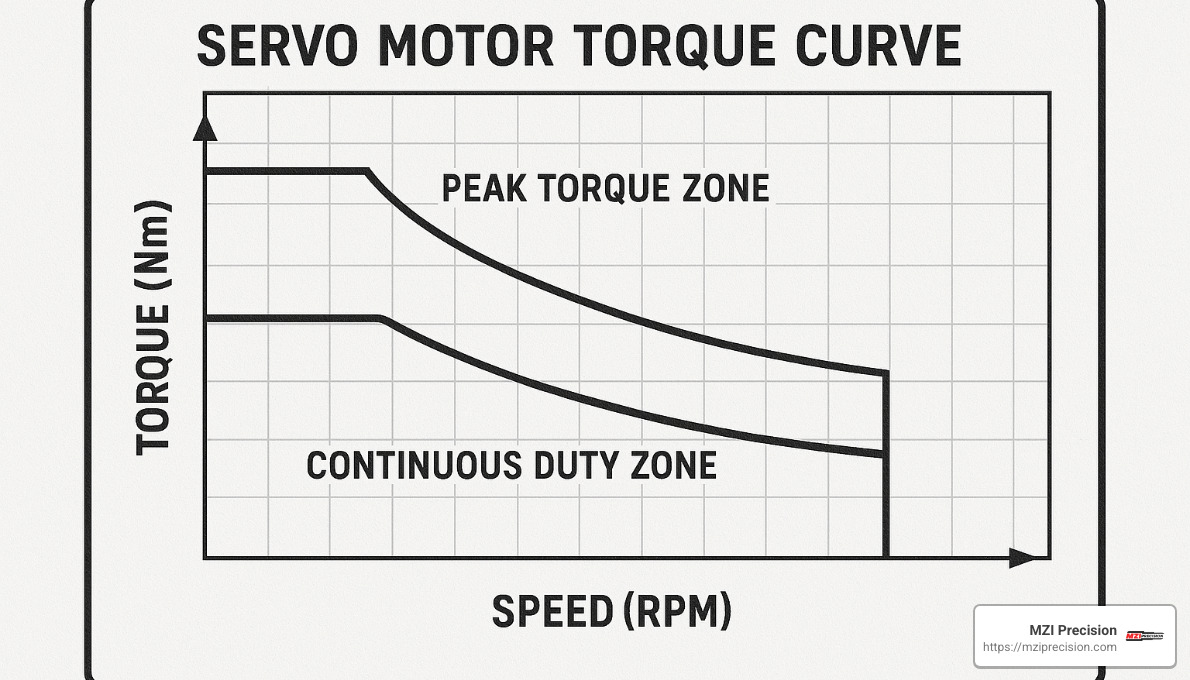

Beyond these specifications, torque curves are one of your best friends in understanding servo motor torque. A torque curve visually illustrates how torque changes as motor speed varies—think of it as a road map showing how much power your motor can deliver at any given speed.

Servo motor torque curves usually have two clear zones:

- The continuous duty zone is the safe area where your servo motor can run indefinitely. Staying in this zone ensures reliable, long-term operation without overheating.

- The intermittent (peak) duty zone sits between the continuous and peak torque lines. It’s like the motor’s temporary “turbo boost” zone—your motor can operate here briefly for short-term needs like quick accelerations or transient load surges.

Unlike stepper motors, servo motors typically maintain stable torque over a wide speed range. As one industry expert puts it, “Servo motors can achieve higher speeds and torques than stepper motors, especially at higher rpm.” This consistent performance makes servo motors ideal for high-precision, demanding applications like industrial manufacturing spindles.

At MZI Precision, we carefully evaluate torque curves whenever we repair or rebuild industrial manufacturing spindles. This ensures that our spindle solutions deliver the exact torque needed for peak performance and reliability in every application.

To learn more about torque curves and how they affect servo motor performance, check out this helpful resource: Servo Motor Torque Curves: What You Need to Know.

Factors Influencing Torque Requirements in Applications

Let’s talk about what really matters when choosing the right servo motor torque for your application. This isn’t just about picking the biggest motor available—it’s about finding that sweet spot where your system runs efficiently and reliably.

Calculating the Torque Needed for Your Application

When we’re rebuilding spindles at MZI Precision, one of the most common questions we hear is, “How much torque do I actually need?” It’s a great question, and the answer involves a bit of math—but don’t worry, we’ll break it down into manageable pieces.

Think of torque requirements as having several ingredients that all need to be mixed together:

First, you’ve got your static load torque—this is what’s needed just to hold your load against gravity. Using the formula τ_static = m × g × r (where m is mass, g is gravity, and r is the distance from the rotation axis), you can calculate this base requirement.

Then there’s dynamic load torque, which comes into play when you need to speed up or slow down. This is calculated as τ_dynamic = J × α, where J represents moment of inertia and α is the angular acceleration. This is particularly important in applications where quick movements are needed.

Don’t forget about friction torque! Every system has some friction that needs to be overcome—from bearings, sliding components, and other mechanical elements. This can sometimes be tricky to calculate precisely, but experienced engineers can provide good estimates based on similar systems.

Finally, add these all together and include a safety margin (we usually recommend 20%), and you’ve got your total torque required.

Let me share a real-world example we encountered:

A customer came to us with a robotic arm application that needed to move a 2 kg payload positioned 30 cm from the axis. The system needed to accelerate at 2 rad/s². Here’s how we broke it down:

- Static torque: 2 kg × 9.8 m/s² × 0.3 m = 5.88 Nm

- Dynamic torque (with moment of inertia of 0.2 kg·m²): 0.2 kg·m² × 2 rad/s² = 0.4 Nm

- Friction torque (estimated based on similar systems): 0.5 Nm

- Raw total: 5.88 Nm + 0.4 Nm + 0.5 Nm = 6.78 Nm

- With our 20% safety margin: 6.78 Nm × 1.2 = 8.14 Nm

This approach of working from the outside in—adding up all torque contributions from payloads, links, and joints—gives us a reliable figure to work with when selecting the appropriate motor.

Effects of Operating Voltage on Servo Motor Torque

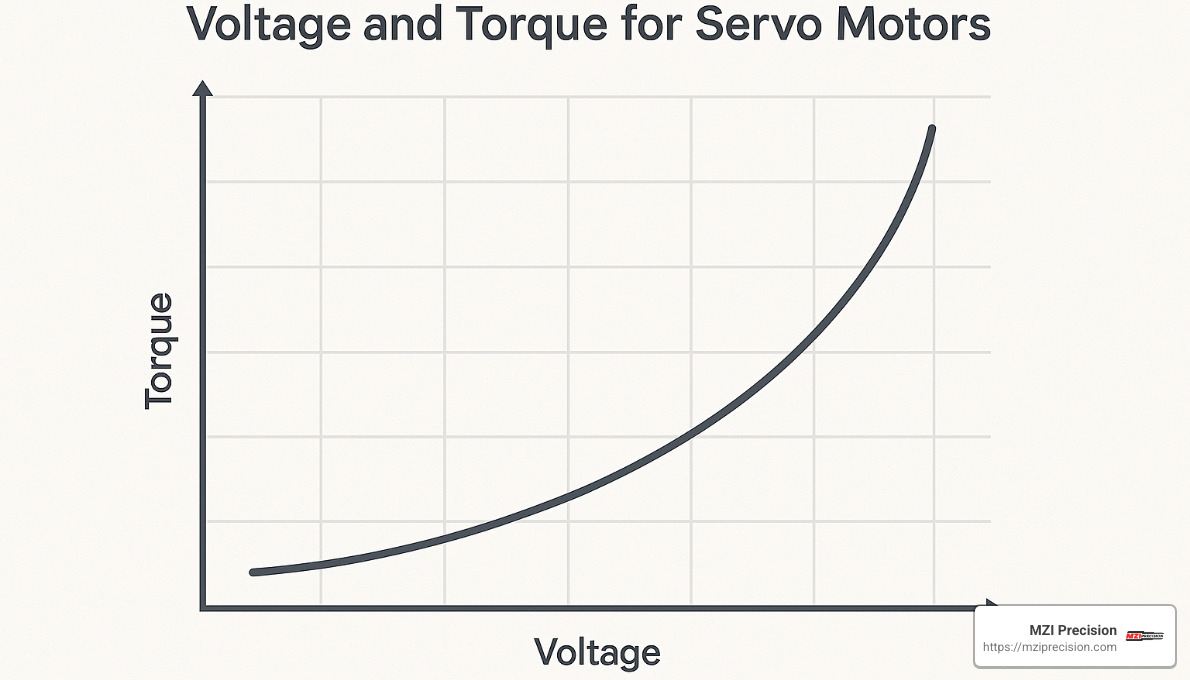

Here’s something many people overlook: the voltage you run your servo at makes a big difference in the servo motor torque you’ll actually get. It’s like the difference between driving your car on regular or premium fuel—same car, different performance.

When we look at servo motor datasheets, they typically specify torque ratings at different voltage levels. For smaller servos, these might be 4.8V and 6.0V, while industrial servo motors often have higher voltage ratings.

The relationship is pretty straightforward: higher voltage generally means higher torque output—within limits, of course. A typical servo might deliver 20-25% more torque when operated at 6.0V compared to 4.8V. This can make a significant difference in borderline applications where you need just a bit more power.

However, there’s always a trade-off. Running at higher voltages makes the motor run hotter, which can affect its lifespan if you’re operating near thermal limits. We’ve seen this when customers push their systems too hard—what seems like a performance boost in the short term can lead to premature failure down the road.

Another factor to consider is back EMF (electromotive force). At higher speeds, back EMF reduces the effective voltage available to the motor, which can limit torque output just when you might need it most. This is why torque curves typically show a drop-off at higher speeds.

As one of our engineers likes to say, “Higher operating voltage is like giving your servo a shot of espresso—it’ll work harder and faster, but don’t expect it to keep that pace forever.”

At MZI Precision, when we’re rebuilding industrial manufacturing spindles, we carefully balance voltage considerations with the expected duty cycle and operating environment to ensure you get optimal performance without sacrificing reliability. That sweet spot is different for every application, which is why custom solutions often outperform off-the-shelf options.

For more in-depth information about torque in servo motors, check out this excellent resource from Heidenhain.

Advantages and Disadvantages of High Torque Servo Motors

When you’re diving into industrial automation, understanding the trade-offs of high torque servo motors can save you considerable headaches down the road. At MZI Precision, we’ve helped countless customers steer these choices for their industrial manufacturing spindles, and we’ve seen how the right torque selection makes all the difference.

Advantages of High Torque Servo Motors

High torque servo motors shine in demanding industrial applications. They excel at handling larger loads that would stall lesser motors, which is particularly valuable in heavy-duty manufacturing processes. One of our aerospace clients recently upgraded to higher torque motors and immediately noticed how their production line handled materials with greater confidence.

Improved acceleration and deceleration is another significant benefit. When your manufacturing process demands rapid movement followed by precise positioning, that extra torque provides the muscle needed to change speeds quickly without losing accuracy. This translates directly to faster cycle times and increased productivity.

Better stability under varying conditions is something we see customers appreciate daily. That extra torque reserve acts like insurance against unexpected load variations or external disturbances. Think of it as having extra horsepower in reserve – you might not need it all the time, but when you do, you’ll be glad it’s there.

Many of our industrial clients have also found that high torque motors can reduce or eliminate gearboxes in certain applications. This simplifies the mechanical system by removing components that can introduce backlash or require additional maintenance. The result? More precise motion control and fewer mechanical headaches.

Finally, that extra torque helps overcome static friction (also called “stiction”), ensuring smooth starts from a standstill position. This is particularly important in precision manufacturing applications where jerky movements can damage materials or reduce quality.

Disadvantages of High Torque Servo Motors

Let’s be honest – nothing in engineering comes without trade-offs. Higher costs are perhaps the most obvious drawback of high torque servo motors. The premium materials and construction needed for these powerhouses come with a price tag to match. One of our customers recently compared two options and found the high torque version cost nearly 40% more.

Size and weight concerns are real considerations in many applications. High torque motors generally require larger housings and more substantial internal components. When you’re designing a compact manufacturing system with tight space constraints, these larger dimensions can create genuine design challenges.

Power consumption is another factor that deserves careful thought. Those extra newton-meters of servo motor torque require additional electrical input, which means higher energy bills over the life of your equipment. In continuous operation environments, this can add up significantly over time.

Heat is the enemy of precision and longevity in industrial manufacturing spindles. Greater heat generation in high torque motors often necessitates more robust cooling solutions. We’ve helped customers implement everything from improved passive cooling to sophisticated liquid cooling systems to manage thermal issues in high-performance applications.

Finally, don’t overlook the increased complexity that often comes with high torque systems. As one of our manufacturing clients finded, “These motors require more sophisticated controllers and drives than simpler alternatives.” This added complexity means more potential points of failure and more specialized knowledge required for maintenance and troubleshooting.

At MZI Precision, we work closely with customers to find the sweet spot between performance and practicality. Sometimes the highest torque option isn’t necessarily the best choice – it’s about finding the right balance for your specific industrial manufacturing spindle application. We pride ourselves on helping you steer these decisions with clarity and confidence, ensuring you get the performance you need without paying for capability you’ll never use.

Choosing the Right Servo Motor Based on Torque Requirements

Finding the perfect servo motor—particularly when it comes to servo motor torque—can seem overwhelming at first, but it doesn’t have to be. At MZI Precision, we’ve worked with countless customers facing the same challenge: matching the right servo motor to their specific industrial manufacturing spindle application. The key is taking it step by step, focusing on what really matters.

Step-by-Step Selection Process

Start by clearly defining your application needs. Understand exactly what your servo motor must accomplish. This means identifying the heaviest load it will handle, how far that load is positioned from the motor’s axis, required acceleration rates, duty cycle (how often and for how long the motor runs), and environmental factors like temperature and humidity. Each of these elements directly impacts the torque your servo motor must generate.

Next, carefully calculate your required torque. Begin with static torque, the torque needed simply to hold your load in place against gravity. Then factor in dynamic torque, the force needed to accelerate your load quickly and smoothly. Don’t forget to include friction torque, the extra effort needed to overcome friction in your system. Once you’ve totaled these numbers, always add a safety margin—typically between 20% and 50%—to account for unexpected conditions. Trust us, your servo motor will thank you later!

After addressing torque requirements, consider your speed needs. Look closely at your required maximum operating speed and make sure the servo motor you choose provides sufficient torque at that speed. Servo motors have torque curves that show torque at various speeds, so use these graphs to confirm the motor can meet your application’s specific demands.

Once you have clear torque and speed requirements, evaluate available motor options. Compare continuous (rated) torque and peak torque ratings carefully. Use manufacturer-provided torque curves to ensure the motor maintains sufficient torque at your required operating speeds. Also, verify thermal performance: Can the motor handle your duty cycle without overheating or needing constant maintenance?

Finally, select the appropriate drive and control system for your servo motor. Make sure the drive and controller you choose match the voltage, current, and torque capabilities of your selected motor. Consider control features needed for your specific application—like positioning accuracy or feedback sensors—to achieve smooth, reliable spindle performance.

To help visualize these steps clearly, here’s a helpful infographic summarizing the servo motor selection process based on torque requirements:

It’s like Bill Lackey once wisely noted: “It is an engineering truism that there is no such thing as a perfect solution—just the best solution for the problem at hand.” At MZI Precision, we live by this principle every day, helping customers find the right servo motor solution without overcomplicating things.

Practical Selection Example

Let’s walk through a quick real-world example. Imagine you’re selecting a servo motor for an industrial manufacturing spindle with the following requirements:

Your spindle needs to handle a load of 10 kg, positioned 15 cm from the motor’s axis. It must accelerate at 5 rad/s² and operate at a speed of 3000 RPM. The duty cycle is pretty demanding: 80% on, 20% off, and the ambient temperature is around 35°C.

Here’s how you’d approach the torque calculation for your spindle application:

- Static torque is calculated first: 10 kg × 9.8 m/s² (gravity) × 0.15 m (lever arm distance) = 14.7 Nm.

- Dynamic torque, assuming your load has a moment of inertia of approximately 0.5 kg·m², works out to 0.5 kg·m² × 5 rad/s² = 2.5 Nm.

- Factoring in estimated system friction of about 1.5 Nm, that brings the total torque requirement to 18.7 Nm (14.7 + 2.5 + 1.5).

- To be safe (and smart!), add a 30% safety margin, giving a final required torque of roughly 24.3 Nm.

With these numbers in hand, you’d want to choose a servo motor that can comfortably deliver a continuous torque rating of at least 24.3 Nm at 3000 RPM. Additionally, confirm the selected motor can handle your 80% duty cycle and 35°C ambient temperature without overheating. Don’t forget to check peak torque ratings as well—this ensures your motor can manage unexpected load spikes without issues.

At MZI Precision, we’ve seen how the right servo motor torque selection can drastically improve spindle performance and longevity. With careful consideration and the right calculations, you’ll confidently pick the ideal servo motor, ensuring your spindle runs smoothly, efficiently, and reliably for years to come.

Common Applications of Servo Motors with Varying Torque Specifications

Servo motors show up everywhere in modern industry, from tiny precision devices to huge machinery. At MZI Precision, we’ve seen how understanding servo motor torque requirements can significantly impact the success of industrial manufacturing spindles in various applications. Let’s explore some common use cases, grouped by their torque needs, to help you better match torque ratings with your specific industrial spindle application.

Low to Medium Torque Applications (1-10 Nm)

When you think of lower torque applications (ranging from about 1 to 10 Nm), consider tasks that require precision, accuracy, and smooth motion—but aren’t moving enormous loads. In industrial manufacturing spindles, these motors are ideal for lighter-duty processes where delicate control is crucial.

For example, precision positioning systems like optical alignment stages, smaller robotic arms, and camera positioning equipment rely on lower torque servo motors to deliver pinpoint accuracy. They’re also popular in laboratory and medical equipment, such as automated lab sample handlers, medical imaging devices, and diagnostic machines that demand precise motion control.

Additionally, you’ll often find these motors at work in light assembly automation—like electronic component insertion, delicate pick-and-place operations, or packaging machines that handle lighter products with care and finesse.

Medium to High Torque Applications (10-100 Nm)

Stepping up to medium and high torque ranges (about 10 to 100 Nm), we encounter servo motors designed to handle heavier-duty operations. These motors are the workhorses in many industrial manufacturing spindle applications, providing robust power and reliability for more demanding tasks.

In the machining world, CNC machine tools—including milling machine axes, lathe spindles, drilling equipment, and grinding machines—rely heavily on servo motors with strong torque ratings. These motors ensure smooth yet powerful spindle motion and accurate positioning, critical for precise metalworking and production.

Similarly, industrial robots performing welding, automated assembly line tasks, palletizing operations, or material handling frequently depend on these higher torque servos. These motors handle heavier payloads, overcome mechanical friction, and provide rapid acceleration and deceleration.

Heavy manufacturing equipment such as metal forming presses, injection molding machines, extrusion lines, and cutting or shearing machinery also benefit greatly from servo motors in this torque range. At MZI Precision, we specialize in repairing and rebuilding industrial manufacturing spindles equipped with these medium-to-high torque motors, keeping production lines running smoothly.

Very High Torque Applications (100+ Nm)

Once you cross into servo motors providing torque of 100 Nm or greater, you’re talking about some seriously heavy-duty industrial applications. These powerful motors are essential for moving large loads, overcoming significant resistance, and handling tough environments. They’re the muscle behind some of industry’s toughest jobs.

For instance, heavy machinery like massive industrial presses, heavy-duty material handling systems, mining equipment, and construction machinery use high torque servo motors for strength and reliability. Likewise, transportation systems—including elevator drives, heavy-duty conveyors, automated guided vehicles (AGVs), and crane positioning systems—need substantial torque to safely and efficiently move heavy loads.

In the energy and utilities sectors, servo motors provide crucial torque for wind turbine pitch control, precise tracking of solar panels, valve actuators handling large pipeline flows, and heavy-duty pumps. These applications demand consistent, powerful torque output under challenging conditions, and servo motors in the very high torque range are up to the task.

At MZI Precision, we’ve seen how well-maintained servo motors with the right torque rating can make or break an industrial manufacturing spindle’s performance. Our team provides specialized servo motor repairs and rebuilds, ensuring your spindle delivers the powerful, reliable torque your operation demands—no matter what your application requires.

As our research highlights, servo motors are capable of impressive torque levels—up to 250 ft-lb—making them a versatile solution for industrial manufacturing spindles across nearly every industry imaginable.

Environmental Factors Affecting Servo Motor Torque

When selecting a servo motor for industrial manufacturing spindles, servo motor torque isn’t determined solely by motor specs and load calculations. In real-world applications, the environment itself can have a big impact on your servo motor’s performance. Let’s explore how temperature, humidity, altitude, and air pressure can influence torque, and how you can ensure your spindle operates reliably in various environments.

Temperature Effects

Temperature can be a bit of a wildcard when it comes to servo motors. It directly influences the amount of torque a motor can produce without overheating or failing prematurely.

Servo motors generate heat as they operate, and they rely on cooling methods like natural convection, forced air, or even liquid cooling to manage that heat. When the ambient temperature is higher than the motor’s rated conditions, cooling becomes less efficient. As a general rule, for every 10°C increase above rated temperatures, you might have to reduce (or “derate”) your motor’s continuous torque by about 10%–15%. So, if your spindle is running in a warm factory environment, double-check your torque requirements and add extra margins when selecting a motor.

Operating temperature inside the motor matters too. Most industrial servo motors have insulation rated for maximum winding temperatures between 130°C and 155°C. Exceeding these limits can damage insulation, reduce motor life, or even cause motor failure. Thankfully, modern servo drives and controllers often have built-in temperature sensors or thermal models to prevent overheating—keeping your industrial manufacturing spindle running smoothly.

As one industry source puts it, “Higher ambient temperatures can cause the motor to reach its thermal limit faster, requiring a derating of continuous torque, while lower temperatures can allow a higher continuous torque rating.” So, keep an eye on your spindle’s operating environment, and ensure proper thermal management for reliable performance.

Humidity and Moisture

Humidity and moisture might seem harmless enough, but they can quietly sabotage your servo motor torque and the longevity of your spindle.

High humidity can degrade electrical insulation properties and increase the risk of condensation inside the motor, potentially causing electrical shorts or permanent damage. To protect against moisture intrusion, consider servo motors with IP-rated enclosures that provide better moisture resistance.

Humidity also accelerates corrosion, especially in sensitive components like bearings and internal connectors. Increased corrosion leads to higher friction, higher resistance, and ultimately, reduced available torque from your servo motor. Choosing servo motors with sealed bearings and protective coatings can help your spindle withstand humid conditions.

Moisture issues get trickier when combined with temperature fluctuations. Frequent temperature cycling in humid environments can cause condensation—even inside motors that seem well protected. If your spindle operates in such conditions, selecting motors specifically designed for tough environments becomes absolutely essential.

Altitude and Air Pressure

Believe it or not, altitude can also impact your servo motor’s torque capabilities! At higher altitudes, the air is thinner, meaning servo motor torque can be affected simply because there’s less air available to cool the motor.

Lower air density reduces the efficiency of natural and forced-air cooling methods. As a result, motors running at higher altitudes can reach their thermal limits more quickly, requiring additional torque derating or improved cooling solutions. This might mean choosing a more powerful servo motor or investing in specialized liquid cooling systems to maintain reliable performance in your industrial manufacturing spindle.

In addition to cooling concerns, lower air pressure at high altitudes can affect electrical insulation properties due to reduced dielectric strength. If you’re operating servo motors in high-voltage spindle applications at liftd altitudes, consider motors and drives specifically designed with insulation rated for reduced air pressure conditions.

At MZI Precision, we know how important these environmental factors are when rebuilding industrial manufacturing spindles. We always take temperature, humidity, altitude, and air pressures into consideration to ensure your servo motors deliver the reliable torque and performance you expect.

For more detailed information on servo motor torque curves and how environmental factors may influence them, you can check out this helpful resource: Servo Motor Torque Curves: What You Need to Know.

Frequently Asked Questions about Servo Motor Torque

What is the difference between stall torque and rated torque?

This is a great question we often hear at MZI Precision, and understanding it clearly can mean the difference between a successful industrial manufacturing spindle application and a costly mistake.

Stall torque is the highest torque a servo motor can produce when its shaft isn’t turning—think of it as the motor’s maximum strength at a standstill. While it’s impressive, stall torque is only sustainable for very short periods. Holding it too long can cause the motor to quickly overheat, damaging your precious equipment.

On the other hand, rated torque (also known as continuous torque) is the torque a servo motor can deliver all day, every day, without overheating or harming its internal components. This is the reliable, steady-state torque you want to consider when choosing a servo motor for continuous use.

In short, stall torque gives you a glimpse into the motor’s maximum power for brief moments, while rated torque reflects its true ability to handle consistent workloads. As we often remind our customers, rated torque provides a realistic baseline to size motors correctly for industrial manufacturing spindle applications, ensuring performance and longevity.

How does temperature affect servo motor torque?

Temperature plays a bigger role in servo motor torque performance than you might think. At MZI Precision, we’ve seen how temperature variations can impact industrial manufacturing spindle performance.

When ambient temperatures rise above the motor’s rated operating conditions, it becomes harder for the motor to dissipate heat. This means you’ll need to reduce—or “derate”—the continuous torque specification to avoid overheating. Typically, continuous torque capacity drops by about 10-15% for every 10°C increase above rated temperature.

It’s not just about external temperature either. Inside the motor, copper windings get hotter and their resistance goes up. This reduces efficiency, making the motor work harder to deliver the same torque output.

Also, the permanent magnets inside servo motors lose some strength at higher temperatures, directly lowering the motor’s torque-producing capability.

Modern servo drives often include built-in thermal protection, automatically limiting current if the motor gets too hot. While this safety feature prevents costly damage, it also means less torque available when you might need it most.

At MZI Precision, we always stress the importance of good thermal management practices. Keeping your servo motors within proper temperature ranges ensures steady torque output, reliability, and a longer life for your industrial manufacturing spindles.

Can increasing operating voltage boost the torque output of a servo motor?

Yes, boosting the operating voltage can indeed increase the torque output of your servo motor—but don’t reach for that dial just yet! There’s a bit more to it, and you’ll want to tread carefully to avoid damaging your equipment.

When you increase the operating voltage (within the manufacturer’s specified limits), your servo motor can draw more current, creating stronger magnetic fields and boosting torque output. For example, many servo motors can deliver around 20-25% more torque when operated at 6.0V compared to 4.8V.

However, there’s a catch: exceeding the manufacturer’s voltage limits can lead to insulation breakdown, excessive heat, and reduced motor lifespan. Also, higher voltage means higher speeds at no-load, so it changes the motor’s entire torque-speed characteristic. Be sure this aligns with your application’s needs.

Higher voltage operation also generates more heat, so you’ll need solid thermal management to keep your motor cool under these conditions.

At MZI Precision, we advise sticking closely to your servo motor manufacturer’s voltage recommendations. When rebuilding industrial manufacturing spindles, we’ve seen that operating at slightly higher—but still within-limit—voltages can safely boost performance. Just make sure your power supply and motor specifications match to avoid any unpleasant surprises.

If you’re ever unsure about how voltage changes might impact your industrial manufacturing spindle performance, reach out to our experienced team at MZI Precision. We’re here to help you find the sweet spot between performance and reliability.

Conclusion

Selecting the right servo motor with the appropriate servo motor torque is a critical step for ensuring your industrial manufacturing spindle operates smoothly and reliably. Throughout this guide, we’ve explored everything from the basics of torque and how it’s measured, to calculating your torque needs accurately and choosing the perfect motor for your application.

Servo motor torque isn’t just a number on a datasheet—it’s the rotational muscle your spindle depends on to move loads, maintain precision, and keep production humming along. Proper torque selection considers static load, dynamic acceleration needs, frictional forces, and always factors in a healthy safety margin. And since no spindle operates in a vacuum (unless you’re manufacturing in space, in which case, call us, we’d love to chat!), environmental factors such as temperature, humidity, and altitude must be taken seriously to avoid unexpected downtime.

Every industrial spindle application is unique. Low to medium torque servos work wonders in precision positioning and small assembly tasks. Medium to high torque motors are your workhorses in CNC machining centers, robotic arms, and heavier manufacturing environments. And if you’re swinging huge loads around, well, very high torque servos have got you covered—just remember, bigger isn’t always better. Higher torque servos can handle heavier loads and quicker accelerations, but they also mean higher costs, larger sizes, more heat, and trickier control systems.

At MZI Precision, we specialize in industrial manufacturing spindle repair and rebuilding services across diverse sectors—including aerospace, agriculture, defense/military, solar energy, and beyond. Our expertise in OEM spindle rebuilds and extensive experience with servo motor systems mean we know exactly how important the right torque selection is. We’ve seen how the proper motor choice boosts your spindle’s performance, extends its lifespan, and reduces costly interruptions.

Whether you’re setting up a new spindle application or repairing existing equipment, our dedicated team is ready to support you every step of the way. Downtime is frustrating and expensive—that’s why we focus on delivering top-notch service and speedy, dependable solutions. Our California-based facilities are packed with state-of-the-art equipment and skilled technicians eager to tackle your spindle and servo motor challenges.

If you’re curious about our detailed servo motor repair services, visit our servo motor repairs page. And hey, if you’re still scratching your head about servo motor torque calculations, don’t hesitate to reach out—we’d be happy to walk you through it personally!

Choosing the right servo motor torque isn’t just about meeting minimum specs; it’s about enhancing performance, ensuring reliability, and maximizing the long-term health of your industrial manufacturing spindle. At MZI Precision, we’re here to help you achieve exactly that.