Finding Expert Spindle Repair Services Near You

Looking for motor mechanic near me specialized in industrial spindle repair? Here’s a quick guide to finding the best industrial spindle repair technicians in your area:

- Search online directories specifically for industrial spindle repair services

- Check certifications like OEM authorization and years of experience in spindle rebuilding

- Verify expertise with industrial manufacturing spindles for your specific equipment

- Read reviews from other manufacturing companies about repair quality and turnaround time

- Contact multiple providers for quotes and assessment of their technical knowledge

Finding the right industrial spindle repair service is crucial for manufacturing operations. When your production machinery experiences spindle failure, every minute of downtime translates to lost productivity and revenue.

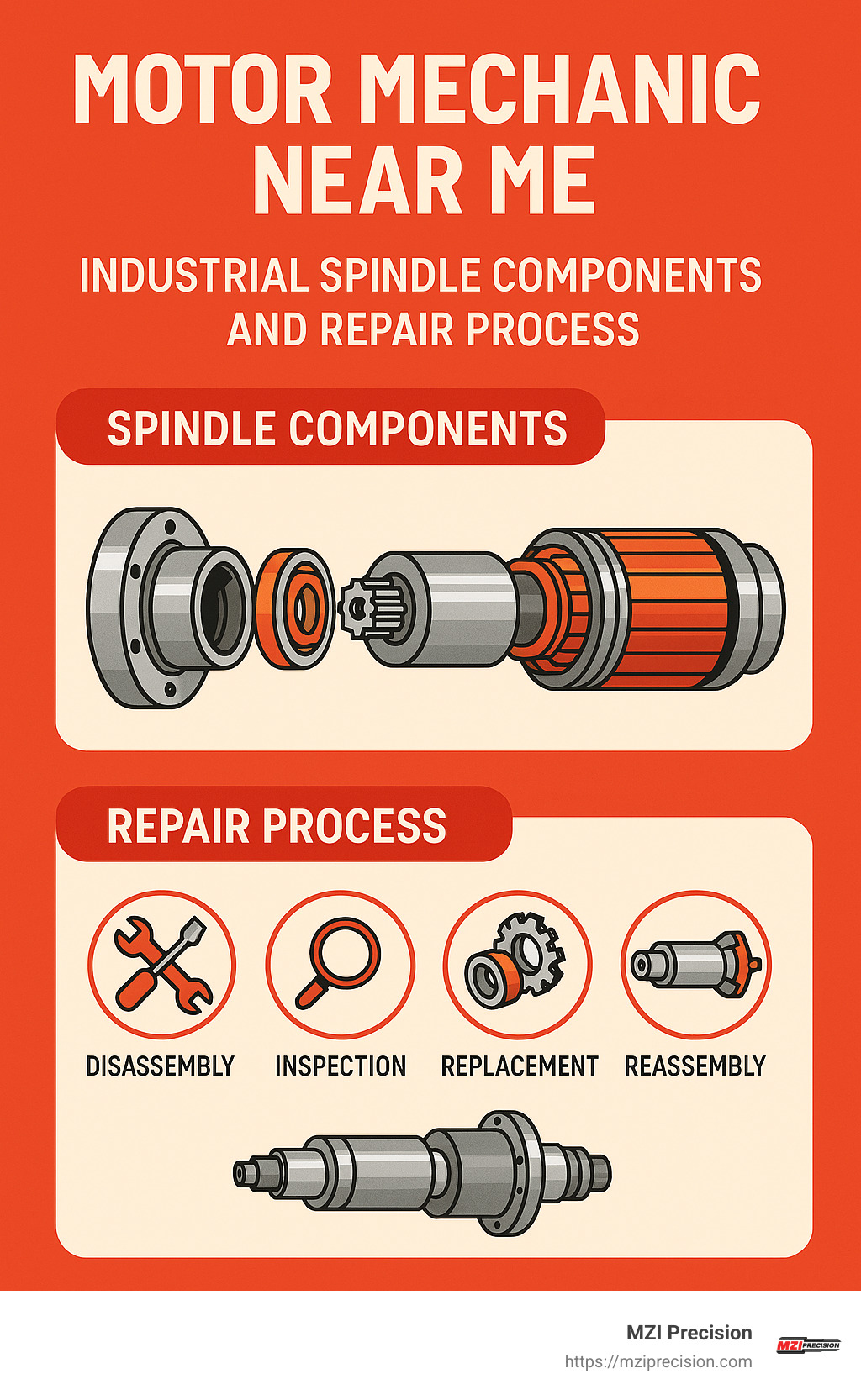

Industrial manufacturing spindles are complex precision components that require specialized expertise to repair and rebuild. Unlike general mechanics, spindle repair technicians need specific training and equipment to handle the high-tolerance requirements of these critical machine tool components.

According to one manufacturer quoted in our research: “When it comes to keeping your production equipment running like a dream, you can always count on specialized spindle repair technicians.” This sentiment echoes throughout the manufacturing industry, where reliable spindle performance directly impacts product quality and operational efficiency.

The best spindle repair services offer comprehensive solutions including failure mode evaluation, precision balancing, and adherence to original OEM specifications. Many established providers have been servicing industrial spindles for decades, with some companies like SETCO operating since 1912 and repairing over 350 different OEM brands.

When searching for spindle repair near you, consider providers that offer advanced technologies like laser cladding for faster turnaround times without sacrificing quality. The right service partner will not only fix immediate issues but help extend the operational life of your manufacturing equipment.

Understanding the Role of Industrial Motor Mechanics

When it comes to keeping your industrial manufacturing spindles running smoothly, skilled motor mechanics are your unsung heroes. Think of them as the doctors for your manufacturing equipment—they diagnose issues, perform necessary repairs, and even offer preventive care to ensure your machinery leads a long, productive life.

Industrial motor mechanics who specialize in spindle repair play a crucial role in the manufacturing world. These talented professionals maintain, rebuild, and repair precision spindle components that power equipment in industries like aerospace, automotive manufacturing, agriculture, solar energy, and defense. Whether you’re crafting precision aerospace parts or manufacturing complex defense equipment, the spindle is at the heart of your operations.

In fact, you could say the spindle is the “heartbeat” of your machine tools—transferring power with precision to shape and form critical materials. When your spindle experiences trouble, your production line quickly comes to a standstill. That’s why finding an experienced motor mechanic near me becomes such an urgent priority: minimizing downtime is vital for your operational efficiency and profitability.

Industrial motor mechanics aren’t your average mechanics—they’re more like highly specialized surgeons. They have deep knowledge of complex mechanical, electrical, and hydraulic spindle systems. Armed with sophisticated diagnostic tools and precision measuring instruments, they combine technical expertise and hands-on experience to quickly pinpoint and resolve spindle issues.

But great mechanics don’t stop at simply fixing what’s broken. They also develop custom preventive maintenance strategies to help extend your equipment’s lifespan, reducing downtime and saving you money in the long run.

As one respected spindle repair service provider proudly states, “With an obsession in providing customers with the highest standard of service and workmanship, we take utmost pride in all our work.” This mentality—focused on excellence and precision—is essential in an industry where tolerances are tight and even tiny errors can lead to major problems down the line.

The Importance of Specialized Technicians

When it comes to industrial manufacturing spindle repair, general mechanical knowledge simply doesn’t cut it (pun intended!). Specialized technicians bring focused expertise that directly impacts your manufacturing efficiency, product quality, and equipment reliability. They’re trained specifically to handle the unique challenges and precise demands of industrial spindle technology.

According to scientific research on technician expertise impact, properly maintained industrial spindles can remain at peak efficiency for decades if serviced by qualified, specialized professionals. Unlike regular mechanics, these specialists undergo rigorous training in areas such as precision balancing techniques (for spindles reaching speeds up to 150,000 RPM!), bearing selection and installation, thermal dynamics affecting spindle performance, vibration analysis, and specialized lubrication systems.

This specialized knowledge makes a tremendous difference. One well-known spindle repair facility proudly notes their team includes “over a dozen degreed engineers in the USA and more than 30 globally,” highlighting just how complex and specialized spindle repairs can become. Their expertise ensures each repaired spindle meets—or even exceeds—the original equipment manufacturer’s (OEM) specifications.

If you’ve ever wondered about the difference between a general technician and a specialized spindle mechanic, think of it this way: a general practitioner might be great for everyday check-ups, but when it comes to heart surgery, you’d trust a cardiologist. In the same way, your industrial equipment deserves a spindle specialist who knows exactly what they’re doing.

At MZI Precision, we see how specialized knowledge translates directly into improved manufacturing uptime and greater peace of mind. Our experienced spindle technicians regularly update their skills through advanced training programs and certifications—ensuring they stay at the cutting edge of industrial spindle technology.

How to Find the Best Motor Mechanic Near You

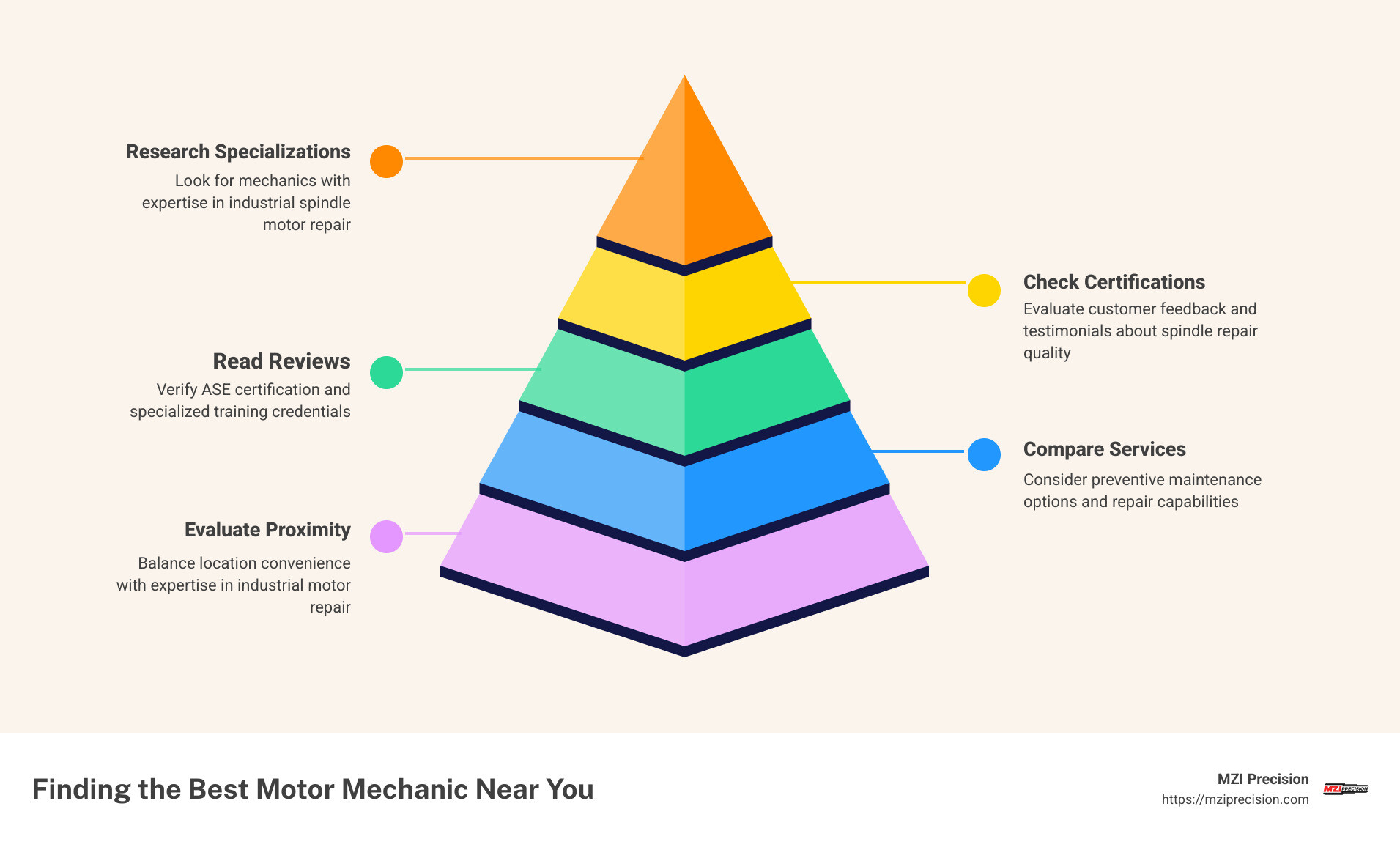

When you’re searching for the right motor mechanic near me for industrial spindle repair, it’s important to approach it strategically. Industrial manufacturing spindles are precision-engineered components, and repairing or rebuilding them requires specialized knowledge, equipment, and experience. Not every mechanic or repair shop has these capabilities, so it’s crucial to find experts who truly understand spindle technology.

First, take a moment to clearly define your spindle repair needs. Are you dealing with an unexpected failure that needs urgent attention, or are you looking for preventive maintenance partners to avoid downtime down the road? Maybe you’re even considering a complete spindle rebuild to restore performance to like-new condition. Knowing exactly what you need helps you filter your options more effectively and find spindle specialists best suited to your situation.

Next, consider proximity—but don’t let location limit your choices too much. Having a spindle repair facility nearby is convenient; no one loves paying shipping fees. But keep in mind that industrial spindle repair is a specialized field. As one manufacturing plant manager shared with us, “Quality service is worth traveling for. We initially tried local general mechanics for our spindle issues, but the repairs didn’t last. Switching to a specialized spindle repair service—even though they were further away—ultimately saved us money by providing longer-lasting, higher-quality repairs.”

In fact, many leading spindle repair companies—like us here at MZI Precision—regularly handle shipments from across the country. Our customers have found that shipping their spindles to a specialist often saves more money in the long run by minimizing repeat failures and costly downtime.

Searching Online for “Motor Mechanic Near Me”

Thankfully, the internet has made finding specialized spindle repair services easier than ever. Start your online search by using terms that clearly identify your needs. Instead of just typing in motor mechanic near me, try something more specific like “industrial spindle repair near [your city]” or “OEM spindle rebuild experts.” You can even include your spindle brand or type, such as “precision spindle repair for CNC milling machines,” to further narrow your search results.

In addition to regular search engines such as Google, exploring industry-specific online directories can be incredibly helpful. For example, websites like Thomasnet.com provide comprehensive listings of industrial suppliers and service providers. Manufacturing.net also offers valuable resources specifically for manufacturers looking for specialized services.

Don’t overlook professional networking platforms like LinkedIn, which can give you recommendations from trusted industry colleagues. Industry associations, like the Association for Manufacturing Technology (AMT), often maintain directories or resources highlighting reputable spindle repair providers as well.

Once you’ve found potential spindle repair shops online, visit their websites and look for clear signs of spindle expertise. Check if they mention specific capabilities such as precision balancing, OEM certifications, or expertise with your spindle type. Reviews and testimonials from other manufacturers can also give you a feel for their reliability and quality of service.

Tips for Selecting the Right “Motor Mechanic Near You”

You’ve narrowed down your online search to a few promising candidates—now it’s time to carefully evaluate each one. There are several key factors to consider when choosing an industrial spindle repair partner.

Start with a focus on technical expertise. Does the repair shop specialize in your particular type of spindle application (such as CNC milling, grinding, or boring)? Different spindle types have unique repair challenges, and specialized technicians are essential. Be sure to review their websites or contact them directly to confirm their specific areas of expertise.

The right equipment and facilities are equally important. High-quality spindle repairs require precision machinery like advanced balancing equipment, specialized cleaning systems, and climate-controlled assembly areas for optimal quality.

Another key indicator of a trustworthy spindle repair provider is clear documentation of their repair process. Reliable companies provide detailed reports, including measurements taken before and after repairs, giving you complete transparency and confidence in their workmanship.

Turnaround time is another big consideration—especially if you’re experiencing production downtime. Don’t hesitate to ask potential providers if they offer expedited or emergency services. After all, every minute your production line is stopped can mean lost revenue.

A good spindle repair company will always stand behind their work. Look for providers who confidently offer solid warranty coverage to back up their repairs. One satisfied customer mentioned, “The 24-month warranty gave us confidence in the quality of the repair.” Warranties aren’t just nice to have—they indicate that the company trusts their own work.

Of course, you’ll want to watch out for red flags when choosing your spindle repair specialist. Be cautious if a provider can’t clearly articulate their repair process, lacks proper testing equipment, offers suspiciously low prices without explanation, or refuses to provide references. Trustworthy companies should always be open and transparent, willing to share details of past projects and testimonials to back up their claims.

The best spindle repair service combines efficiency, fair pricing, professionalism, and integrity. Or as another happy customer succinctly described their experience: “Quick, competitive pricing, professional and—most of all—honest.” At MZI Precision, that’s exactly the kind of service and support we strive to provide every day.

Evaluating Certifications and Qualifications

When you’re searching online for a motor mechanic near me who specializes in industrial spindle repair, certifications and qualifications can make all the difference. Think of these as the mechanic’s badge of honor—proof they’ve put in the hard work, time, and dedication to become truly excellent at what they do.

Unlike general mechanics, spindle repair technicians often don’t have just one standardized certification. Instead, they’re recognized through manufacturer authorizations, specialized industry training, and years of hands-on experience.

So, how can you tell if the spindle repair facility you’re considering is truly top-notch?

First, consider how long they’ve been in business. Spindle repair is a highly specialized field, and providers who have stood the test of time—sometimes spanning decades or even a century—are likely doing something right. Longevity indicates they’ve kept pace with changing technology, maintained exceptional service, and consistently satisfied customers.

Another key factor is their relationship with original equipment manufacturers (OEMs). An authorized partnership means the facility meets the manufacturer’s strict standards for training, repair quality, and equipment. Facilities with OEM partnerships often have access to original parts, proprietary specifications, and specialized training, ensuring repairs match or exceed original factory conditions.

You should also look for ISO certifications such as ISO 9001. This internationally recognized standard confirms the repair shop follows documented, quality-driven processes. In other words, they have clear guidelines for consistently excellent results—no guesswork involved.

Don’t forget the qualifications of their technical staff. Top spindle repair shops employ engineers and technicians who have advanced training, specialized education, and extensive hands-on experience. Many even have degreed engineers on their team, guaranteeing a high level of expertise.

Understanding Industry Standard Certifications

While there’s no one-size-fits-all certification specifically for industrial spindle repair, several respected industry qualifications highlight a repair shop’s commitment to quality:

Being an authorized OEM repair facility is a significant badge of trust. It indicates the shop has met rigorous manufacturer standards in training, equipment, and repair processes, giving you peace of mind that your spindle is in capable hands.

ISO 9001 certification is another strong indicator. Facilities with this certification consistently follow proven, documented procedures—no cutting corners, just high-quality results every single time.

Other qualifications you might encounter include a Certified Manufacturing Technology Sales Engineer (CMTSE) certification from the Association for Manufacturing Technology (AMT). While not specifically about spindle repair itself, this certification demonstrates a deep understanding of manufacturing technology and related processes.

Some facilities might also have Professional Engineers (PE) on staff. These engineers carry state-issued licenses, showing a high level of professional expertise and ethical responsibility.

Though, industry insiders agree that formal certifications are valuable—but they’re only part of the picture. As one veteran spindle repair expert noted, “In precision spindle repair, there’s just no substitute for years of hands-on experience.”

That’s why at MZI Precision, we’ve built a rigorous training program that pairs formal education with mentorship from our seasoned specialists. Our technicians continually upgrade their skills, combining cutting-edge knowledge with decades of practical expertise.

Verifying Experience with Spindle Repair

Beyond certifications and credentials, real-world experience is perhaps the single most important criterion when finding a trustworthy motor mechanic near me for industrial spindle repair. After all, not every spindle is created equal—some facilities may excel with high-speed grinding spindles but lack experience with heavy-duty milling spindles.

Make sure to ask about the shop’s experience handling industrial spindles similar to yours. Look for a facility that:

- Has successfully repaired spindles from your specific manufacturer

- Understands your spindle’s unique application requirements

- Is experienced with spindles of comparable speed, power, and precision

- Can provide examples of tough repair problems they’ve effectively solved in the past

You can also gain valuable insights from client testimonials. One manufacturing customer shared their experience this way: “Their expertise in spindle repair saved our production line from prolonged downtime. The repaired spindle has been running flawlessly for over a year now, which is even better performance than we had before the failure.”

Quality spindle repair providers keep meticulous records to document their work, including thorough initial inspections, identified failure modes, before-and-after measurements, balancing data, and final testing results. Not only do these records offer transparency, but they also build trust and confidence that your spindle is in experienced hands.

At MZI Precision, we take pride in our transparent, thorough approach. We’ve spent years building our expertise across multiple industries including aerospace, automotive manufacturing, defense, and more. When your spindle needs care, we’re here with the right certifications, proven qualifications, and hands-on experience to deliver outstanding results.

The Advantages of Using Certified Repair Facilities

Choosing a certified repair facility for your industrial spindle repair needs isn’t just about getting a fancy sticker or certificate—it’s about protecting your manufacturing equipment, maintaining production efficiency, and safeguarding your bottom line.

While an uncertified shop may offer enticingly low prices upfront, that’s often a “too good to be true” situation. In reality, the hidden costs of poor-quality repairs—like repeated downtime and premature spindle failure—can quickly outweigh any initial savings. Certified facilities commit to industry standards, documented processes, and ongoing technician training, ensuring repairs are done right the first time.

One of the biggest advantages of certified shops is the peace of mind from quality assurance. These facilities consistently follow strict documented repair procedures. As one experienced facility manager put it, “We follow the same detailed procedures for every spindle repair, no matter how big or small. That’s the only way to guarantee consistent results.”

Another crucial benefit is advanced equipment. Certified facilities invest heavily in specialized tools and technologies—such as precision balancing machines, vibration analysis tools, and climate-controlled assembly areas—ensuring your spindle meets or exceeds OEM standards upon completion. General repair shops typically don’t possess this specialized equipment, leading to less reliable results.

It’s also hard to beat the technical expertise you find at certified facilities. Technicians at these facilities receive ongoing training to stay ahead of evolving spindle technologies. This specialized knowledge enables accurate diagnosis, precise repairs, and reliable performance. You wouldn’t trust your health to an untrained doctor, right? Similarly, your industrial spindle deserves an expert touch.

Certified repair shops also provide comprehensive documentation of every repair. This includes detailed inspection notes, precise before-and-after measurements, balancing data, and final testing reports. Not only is this documentation critical for warranty claims, but it also enables better ongoing maintenance planning. No guesswork needed—just clear, detailed records you can rely on.

And speaking of warranties, quality-certified facilities stand behind their work with meaningful warranty coverage. One customer shared, “The 24-month warranty gave us peace of mind that our repaired spindle would perform reliably.” In short, when a shop confidently backs up their repairs, you know you’re in good hands.

Choosing a certified repair provider isn’t just a short-term investment—it’s a decision that pays dividends over time. Properly repaired spindles run smoother, perform better, last longer, and experience fewer unexpected breakdowns. All these factors translate directly into increased manufacturing productivity and ultimately lower total ownership costs.

For more information on certified spindle repair services and how they can benefit your operation, visit MZI Precision’s services page.

Ensuring Trustworthiness and Reliability

When you entrust your industrial spindle to a repair facility, you’re essentially handing them a critical link in your production chain. The trustworthiness and reliability of your chosen provider directly affect your productivity, reputation, and bottom line. So how can you tell if you’re making the right choice?

First, look for transparent communication. Reliable providers won’t hide details—they’ll clearly explain their findings, recommended repairs, and associated costs. They welcome questions and provide honest answers. If a shop starts dodging tough questions, that’s a big red flag.

Next, check if they offer detailed, itemized quotes. A trustworthy spindle repair facility will clearly break down pricing, showing separate costs for labor, parts, and any additional services required. As one savvy customer advised, “Always get a fixed price quote with a breakdown to avoid surprise fees.”

Realistic timeframes are another indicator of trustworthiness. A reliable provider won’t overpromise just to win your business—they’ll give honest, achievable estimates of repair turnaround times. Experienced facilities understand how downtime impacts manufacturers, and they’ll do their best to meet committed schedules without compromising quality.

Look for providers offering quality guarantees and meaningful warranties. These demonstrate confidence in their work and a commitment to lasting customer relationships. If they’re proud enough of their craftsmanship to back it up with a warranty, you can feel confident too.

Lastly, take note of their industry reputation. Providers with a long history in spindle repair—especially those who’ve been around for decades—have proven their reliability through consistently satisfied customers. Longevity often indicates solid service, repeat clients, and lasting quality.

Here’s a quick comparison to illustrate how certified and non-certified repair shops typically differ:

| Aspect | Certified Repair Facilities | Non-Certified Shops |

|---|---|---|

| Technical Expertise | Specialized training in spindle repair | General mechanical knowledge |

| Equipment | Advanced diagnostic and repair tools | Basic mechanical tools |

| Process Documentation | Detailed procedures and quality checks | Informal or undocumented processes |

| Repair Documentation | Comprehensive reports with measurements | Minimal documentation |

| Warranty | Extended coverage with clear terms | Limited or no warranty |

| Cost | Higher initial investment | Lower upfront cost but potential for costly failures |

Customer reviews can also provide valuable clues about trustworthiness. Keep an eye out for consistently positive feedback, like “Amazing service, perfect quality, and good pricing!” or “Quick, competitive pricing, professional, and most of all honest.” Those are the kinds of testimonials that clearly signal you’ve found a reliable partner.

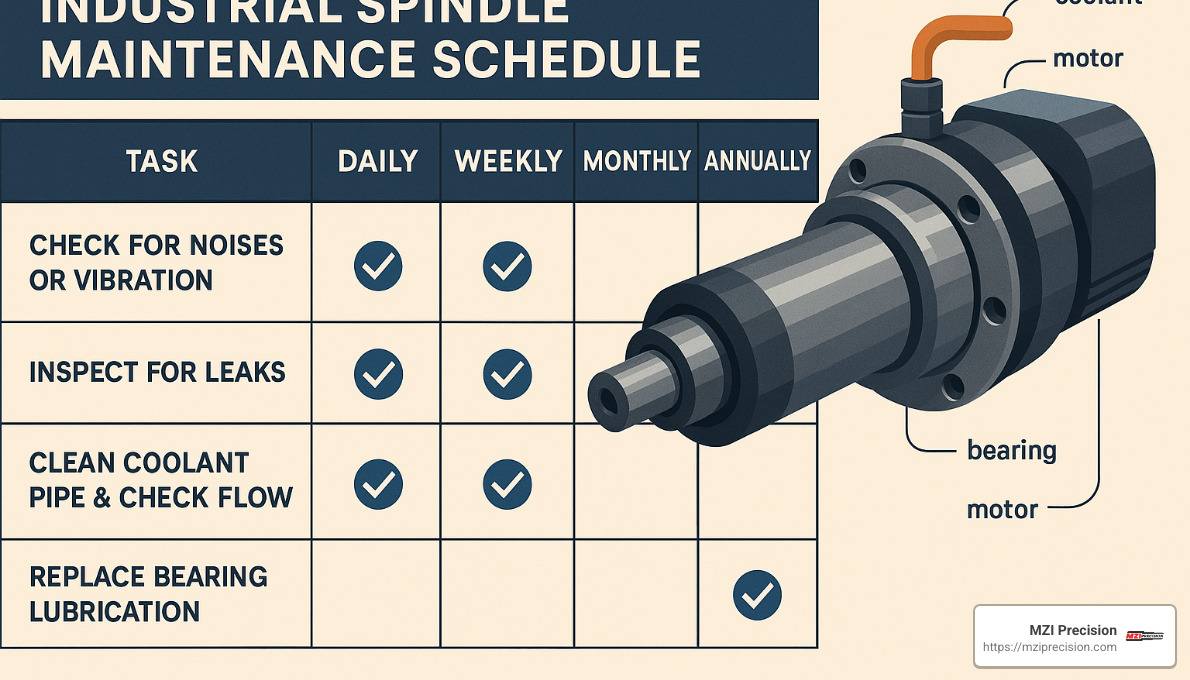

Importance of Regular Maintenance Scheduling

When it comes to your industrial manufacturing spindles, waiting until there’s a problem isn’t exactly a great plan. Regular maintenance scheduling is one of those things that’s easy to overlook—but trust us, your machinery will thank you later.

Regular, planned maintenance offers real benefits that significantly extend your spindle’s lifespan and productivity. For starters, well-maintained spindles simply last longer—often two to three times longer than those left to chance.

Regular maintenance also means consistent performance. A spindle that’s regularly checked and serviced will deliver predictable, reliable results. Better spindle performance translates directly to improved product quality, reduced waste, and fewer production headaches.

Another big advantage is reduced downtime. With maintenance scheduled ahead of time, you can easily plan around your production needs—far better than dealing with the chaos of an unexpected spindle failure. Planned maintenance is much cheaper than emergency repairs, especially when you factor in lost production time.

Furthermore, routine maintenance is cost-effective. Compared to emergency repairs, preventive care typically costs just a fraction—especially considering the potential losses from sudden equipment breakdowns. Think of regular maintenance as insurance: a small investment now saves you from much bigger expenses down the road.

Lastly, regular maintenance helps improve safety. Predictable, properly serviced equipment is far less likely to experience sudden failures, reducing the risk of accidents on your production floor. Employee safety always comes first, and proactive spindle care is a big part of maintaining a safe work environment.

A comprehensive spindle maintenance program usually includes regular vibration checks, temperature monitoring, lubrication services, visual inspections, and performance tests. These preventive measures help catch potential issues early, stopping small problems before they turn into expensive repairs.

As one spindle repair expert humorously put it: “Regular maintenance is like dental flossing for your spindle—nobody gets excited about doing it, but you’ll definitely regret skipping it!”

At MZI Precision, we’re passionate about helping manufacturers establish customized maintenance programs that match their specific machinery, working conditions, and production schedules. Regularly scheduled care keeps your spindles healthy, reliable, and running at peak efficiency—saving you money and downtime headaches in the long run.

Frequently Asked Questions about Finding a Motor Mechanic Near You

Finding the right motor mechanic near me for industrial spindle repair can leave you with plenty of questions. To help simplify things, here are clear, straightforward answers to some common questions manufacturers often ask.

What certifications should I look for in an industrial motor mechanic?

When you’re looking for a trustworthy mechanic to handle your spindle repairs, certifications and qualifications matter a lot. A great place to start is by looking for OEM authorization, which means the repair facility is approved by the original equipment manufacturer. That approval tells you they’ve met strict standards and have access to genuine parts and specifications.

Another important credential is ISO 9001 certification, an international standard that shows the company follows documented processes to ensure quality. You can trust that every repair gets done consistently and properly when a shop meets ISO standards.

Pay attention to the credentials of the technical staff as well. Ideally, the best spindle repair providers employ degreed engineers with specialized training in spindle technology. Their advanced knowledge and expertise translate into accurate diagnosis and reliable repairs.

Experience is another big factor—even if it isn’t exactly a certificate hanging on a wall. Ask potential providers to share their experience with your specific type of industrial spindle. Don’t hesitate to request references or examples of similar repairs they’ve successfully completed.

Lastly, involvement with professional organizations like the Association for Manufacturing Technology (AMT) can also speak to a company’s professional commitment and ongoing education.

At the end of the day, an industry expert summed it up best: “In industrial spindle repair, there’s no substitute for a mix of formal training, manufacturer authorization, and real-world experience.”

How can I tell if a repair shop is trustworthy?

Handing over critical equipment like an industrial manufacturing spindle can feel a bit like dropping your kid off on their first day of school—you want to make sure they’re in good hands. Fortunately, there are some clear indicators of a repair shop’s trustworthiness and reliability.

Start with transparent communication. A reliable provider doesn’t leave you feeling confused about what they’re doing or how much it’ll cost. Instead, they’ll explain clearly what’s wrong, their recommended solutions, and all associated costs—no hidden surprises.

Another strong indicator is detailed documentation. A reputable spindle repair provider will gladly share comprehensive reports detailing their inspection findings, what repairs were performed, and the results of their testing. Great documentation shows confidence in their workmanship.

Don’t underestimate the power of real-world customer references. Ask to speak with manufacturers who have similar equipment or applications. Listening to their experiences can provide valuable insight into how the repair facility treats customers and handles projects.

If you’re able to visit the facility in person, do it! Seeing a clean, organized workspace with advanced equipment can tell you a lot about the shop’s attention to detail and commitment to quality. While you’re there, ask questions—great providers are happy to walk you through their processes.

Pay attention to the warranty they offer. Reliable repair shops aren’t afraid to back their work with meaningful warranty coverage. As one satisfied customer advised, “A trustworthy mechanic stands behind their work with a solid warranty. That’s how you know they’re confident in the quality of their repairs.”

Most importantly, be cautious of providers who promise unrealistic turnaround times or drastically lower prices than competitors. Quality spindle repair requires precision and specialized technical expertise—it simply can’t be rushed or done cheaply without compromising quality.

Should I choose a local mechanic or an authorized service center?

This is a question we hear a lot: Should you pick a local general mechanic or go with an authorized spindle repair center? While each option has its own pros and cons, for industrial manufacturing spindle repair, specialized expertise usually wins out.

Local general mechanics might be quick to respond and generally offer lower hourly rates. They can handle some simple mechanical tasks effectively. However, most general mechanics lack the highly specialized knowledge, advanced equipment, and access to genuine OEM parts needed for precision spindle repairs.

On the other hand, authorized spindle service centers specialize exclusively in spindle technology. Their technicians are trained and equipped to address complex spindle issues accurately, and they typically have direct access to original parts and manufacturer specifications. You benefit from detailed documentation, thorough quality control processes, and strong warranty coverage.

It’s true that authorized service centers sometimes come with higher hourly rates and might be located further away. But think about the long-term reliability and lifespan of your spindles—going with a specialized repair service can often save you money in the long run by reducing downtime and extending equipment life.

One manufacturing plant manager shared it like this: “We initially tried saving some money with local mechanics, but those spindle repairs didn’t hold up. Once we switched to a specialized spindle repair service, we saw much longer-lasting repairs and fewer repeat breakdowns. It actually lowered our overall maintenance costs.”

That many leading spindle repair companies, like MZI Precision, make it easy for you by offering streamlined shipping services. You can simply pack up your spindle, ship it to them, and get it back expertly repaired—often faster than repeated attempts by less-qualified local providers.

Choosing an authorized service center gives you peace of mind knowing your equipment is in the best hands possible, ensuring your critical industrial manufacturing spindles remain reliable and productive.

Conclusion

Choosing the best motor mechanic near me for industrial spindle repair is more than just another maintenance decision—it’s a critical choice that influences your entire manufacturing operation. The right spindle technicians keep your machines running smoothly, protect your investment, and help maximize productivity. On the other hand, a wrong choice can lead to frustrating downtime, costly repairs, and compromised product quality.

Throughout this guide, we’ve explored important considerations to help you select the right industrial spindle repair service. You now understand the specialized role these technicians play and the importance of choosing a provider with the right certifications, experience, and equipment. You’ve also finded how certified facilities offer clear advantages like consistent quality, advanced tools, thorough documentation, and meaningful warranties.

As one manufacturing manager wisely said, “A good mechanic you can rely on for quality workmanship at a fair rate is worth their weight in gold.” We couldn’t agree more—especially when it comes to precision industrial spindle repair. Investing in expert repairs today can save you significant headaches, downtime, and expenses down the road.

At MZI Precision, we’re proud to stand out through our dedication to exceptional spindle repair and rebuilding services. Our team of specialized technicians brings decades of combined experience, continuing education, and genuine care to each project. We’re committed to helping manufacturers in industries like aerospace, agriculture, automotive manufacturing, defense/military, and solar energy achieve reliability and efficiency in their operations.

Protecting your valuable equipment means partnering with someone who understands the unique challenges of industrial spindle applications. By following the guidance outlined here, you can find a spindle repair partner who not only meets your immediate needs but also supports your long-term manufacturing goals.

If you’d like to learn more about MZI Precision’s industrial spindle repair and rebuilding services, we’d love to hear from you. Visit MZI Precision’s services page for more details or contact us directly to discuss your specific requirements.

When it comes to industrial spindle repair, choosing the right motor mechanic near me isn’t just smart—it’s essential. We wish you smooth operations, minimal downtime, and maximum productivity!