High Speed Spindle Balancing: Mastering Precision 2025

Why High Speed Spindle Balancing Matters for Your Manufacturing Operations

High Speed Spindle Balancing is the process of correcting mass distribution in rotating spindle components to eliminate vibration and ensure smooth operation at speeds that can exceed 250,000 RPM. At these extreme speeds, even microscopic imbalances create destructive centrifugal forces that damage bearings, compromise part quality, and lead to costly machine failures.

Quick Overview: What You Need to Know

- What it is: Redistributing weight to align a spindle’s center of mass with its center of rotation.

- Why it matters: Centrifugal force increases with the square of speed, making tiny imbalances catastrophic at high RPM.

- When you need it: During spindle rebuilds, after machine crashes, when vibration increases, or for preventative maintenance.

- Key standards: ISO 1940-1 defines balance quality grades (G-values), with G1.0 or better representing ultra-precision.

- What’s at stake: Bearing life, tool longevity, surface finish, energy costs, and equipment safety.

In industrial manufacturing, precision is everything. When a machine tool spindle’s center of mass doesn’t align with its center of rotation, the resulting vibration acts like “smashing a tiny hammer on your spindle every time it rotates.” The consequences are real and expensive. An unbalanced spindle wastes energy and causes inaccurate machining even at moderate speeds. At higher speeds, the forces multiply rapidly, potentially leading to catastrophic failures that cost thousands in downtime and damaged parts.

Achieving balance down to 24-25 milligrams—20,000 times finer than the weight of a dollar bill—requires specialized equipment and deep expertise. Whether your spindle system uses steep taper or HSK tooling, proper balancing is not optional. It’s the foundation of reliable, high-quality production.

The Critical Role of Balance in High-Speed Machining

Imagine a perfectly balanced top spinning smoothly, then picture the same top with a small weight stuck to one side. The first spins beautifully; the second wobbles uncontrollably. This is essentially what happens with spindle imbalance in industrial manufacturing, but with far more serious consequences.

Spindle imbalance occurs when the center of mass doesn’t align with the center of rotation. This misalignment creates an outward centrifugal force that grows with the square of the speed. Doubling your RPM doesn’t just double the destructive force—it quadruples it.

A tiny imbalance that’s barely noticeable at 5,000 RPM becomes a serious problem at 20,000 RPM and potentially catastrophic at 100,000 RPM. Modern machining spindles routinely operate at speeds where even microscopic imperfections generate enormous forces. These vibrations travel through the spindle, into the bearings, through the tool, and ultimately into the workpiece, compromising your entire operation.

That’s why a thorough Spindle Vibration Analysis is often the first step in diagnosing performance issues. It reveals what’s happening inside your system before small problems become expensive failures.

Consequences of an Unbalanced Spindle

The damage from an unbalanced high-speed spindle is a cascade of issues affecting quality, cost, and safety.

- Premature Bearing Failure: Your bearings take the first hit. Constant vibration and uneven forces create stress, causing them to wear out faster, generate excess heat, and eventually fail unexpectedly.

- Reduced Tool Life: Vibrating cutting tools dull faster, chip more easily, and break prematurely. This leads to more frequent tool changes, higher replacement costs, and lost production time.

- Poor Surface Finish: The surface finish quality of your parts suffers visibly. Chatter marks, inconsistent dimensions, and rough surfaces become common, leading to scrapped parts, especially in industries with tight tolerances.

- Increased Energy Consumption: Your machine works harder to overcome vibrations, drawing more power and generating more heat. It’s an inefficient and expensive way to operate.

- Catastrophic Failure: The most serious risk is complete spindle destruction. Severe vibrations can cause a failure that damages other machine components, resulting in tens of thousands of dollars in downtime, repairs, and potential safety hazards. A comprehensive Spindle Failure Analysis after an incident is crucial to prevent recurrence.

Primary Causes of Spindle Imbalance

Imbalance comes from specific sources, both internal and external to the spindle.

Internal sources include fabrication defects, inconsistencies in raw materials, or improper assembly during a rebuild. Over time, worn components like bearings and seals naturally develop imbalances as they degrade.

External sources come from everything attached to the spindle. Tool holders, collets, and chucks all contribute to the total system balance. Even if each component is individually balanced, combining them can introduce new imbalances. Cutting tools, especially long or irregular ones, also significantly affect balance. A perfectly balanced spindle becomes unbalanced the moment you mount an out-of-spec tool holder. The entire rotating assembly requires attention, not just the spindle itself.

A Guide to High Speed Spindle Balancing Methods

High Speed Spindle Balancing is the science of redistributing mass so a spindle’s center of mass aligns perfectly with its axis of rotation. This ensures the spindle spins smoothly, delivering the precision industrial manufacturing demands.

The process begins by measuring the location and severity of the imbalance. Once identified, we apply precise corrections using one of two approaches.

Material removal is a permanent correction made by carefully drilling or grinding away small amounts of material from the heavy side of a component. Conversely, mass addition involves adding small weights to the light side, often with epoxy or by adjusting set screws in bearing locking nuts for trim balancing.

Types of Balancing Explained

Different balancing methods are used for specific applications and levels of precision.

Static balancing is the simplest form, suited for narrow, disc-like components. It corrects imbalance in a single plane by letting the heavy spot settle to the bottom due to gravity and then adding a counterweight. However, it cannot correct for couple imbalance, which involves forces in different planes along the spindle’s length.

Dynamic balancing is the standard for high-speed applications. This advanced method corrects for both static and couple imbalance simultaneously. The spindle is spun on a specialized machine while sensors measure vibration, allowing for precise corrections in two separate planes. For long, complex industrial spindles, two-plane balancing is essential to counteract the wobble effect created by imbalances at different points along the shaft.

Trim balancing is a final refinement process, often performed while the spindle is on a runoff stand, to account for the interaction of all assembled components. This allows for extremely high precision, sometimes reaching the G0.4 balance quality grade.

| Feature | Static Balancing | Dynamic Balancing |

|---|---|---|

| Principle | Corrects imbalance in one plane (heavy spot) | Corrects imbalance in two planes (static and couple) |

| Method | Gravity-based (knife edges, roller stands) | Machine-based (rotates rotor, uses sensors) |

| Application | Narrow rotors, discs, low-speed components | High-speed spindles, long rotors, complex assemblies |

| Precision | Lower, only addresses static imbalance | Higher, addresses static and dynamic (couple) imbalance |

| Equipment | Simple stands | Sophisticated balancing machines with sensors and software |

| Limitations | Does not detect or correct couple imbalance | More complex setup, requires specialized equipment |

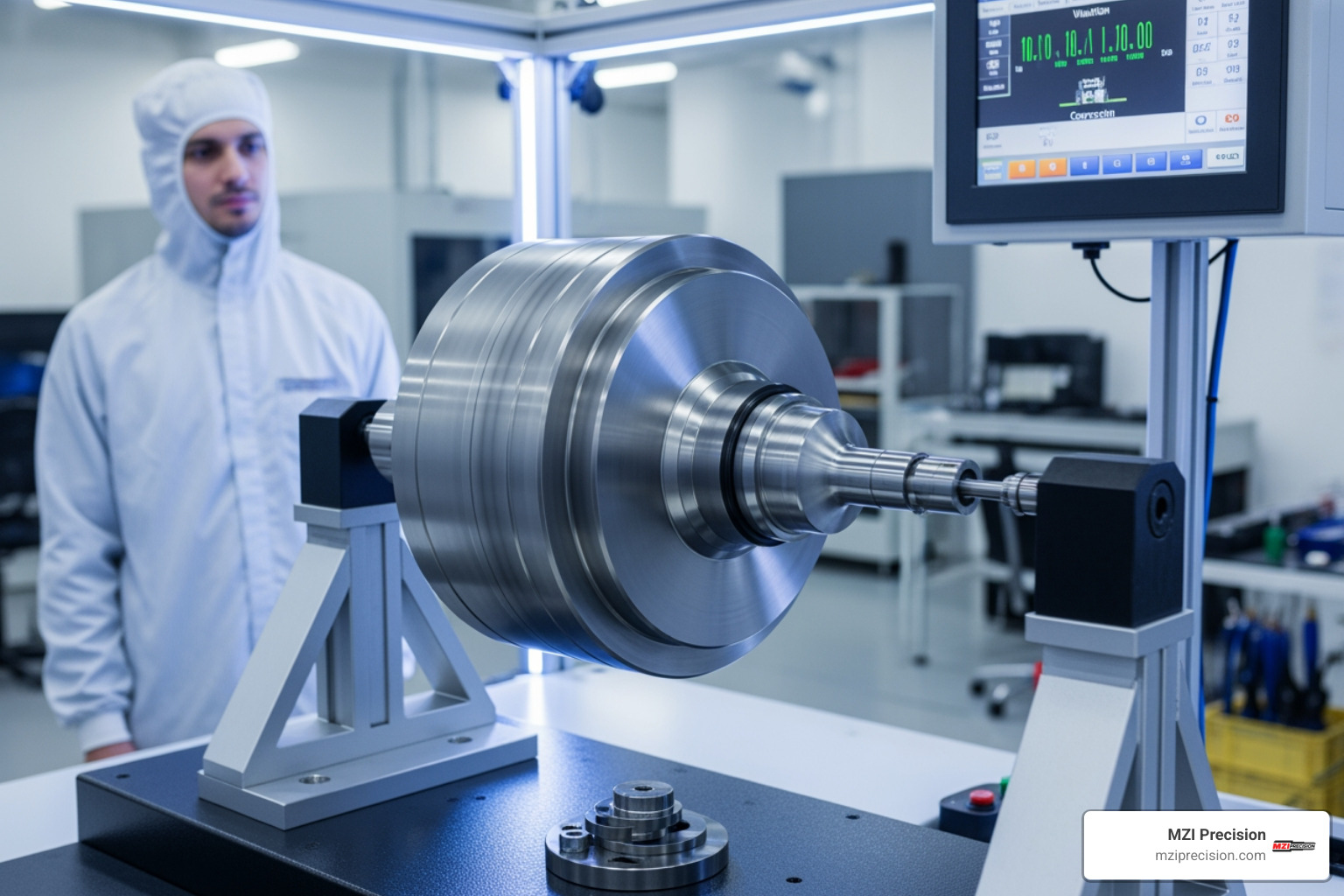

The Step-by-Step Process of High Speed Spindle Balancing

Achieving exceptional balance is a methodical process combining precision measurement with expert intervention.

- Initial Inspection and Cleaning: Every component is thoroughly cleaned and inspected for wear, damage, or debris that could affect readings.

- Measurement of Initial Imbalance: The spindle is mounted on a dynamic balancing machine. As it rotates, sensitive accelerometers and a tachometer detect vibrations, speed, and phase angle, feeding data into balancing software.

- Calculation of Correction: The software analyzes the sensor data to determine the precise mass and angular position of the needed correction.

- Applying Corrections: Technicians apply the correction by either removing material (drilling/grinding) or adding mass with surgical precision.

- Verification Run: The spindle is spun again to confirm the imbalance has been reduced to within the specified tolerance. If needed, minor trim balancing adjustments are made until the desired quality is achieved.

This rigorous approach is fundamental to our High Speed Spindle Repair – Keep Your Machines Running Smoothly services.

Spindle vs. Toolholder Balancing

A perfectly balanced spindle does not guarantee smooth operation if the toolholder is unbalanced. These are distinct but related processes that create the “total system balance.”

Spindle balancing focuses on the internal rotating components—the shaft, drawbar, and locking nuts—and is typically done during a rebuild. However, an unbalanced toolholder can negate this work, reintroducing vibration and wear.

The toolholder, collet, and cutting tool introduce their own imbalance. For high-speed applications, both the spindle and the tooling assembly must be balanced. Toolholders are often balanced to a G2.5 rating, but the total system balance changes with every tool combination. For speeds above 25,000 RPM, HSK tooling systems are often preferred for their superior balance characteristics. To achieve optimal performance, you must balance the entire rotating assembly as one integrated system. Learn more in our guide on The Balancing Game: Achieving Precision with High-Speed Spindles.

Achieving Peak Performance: Standards, Tools, and Technology

In ultra-precision machining, peak performance hinges on having the right tools, following strict standards, and leveraging the latest technology. For High Speed Spindle Balancing, this commitment to excellence is what separates adequate results from exceptional ones. When spindles rotate at speeds exceeding 250,000 RPM, there is no room for approximation. Every measurement and correction counts.

Understanding Industry Standards for High Speed Spindle Balancing

The industry uses the ISO 1940-1 standard to define balancing quality for rigid rotors, including high-speed industrial spindles. This standard uses Balance Quality Grades, or G-values, to represent the permissible residual imbalance. A lower G-value signifies a higher degree of balance and less vibration.

For high-speed spindles, several G-values are key:

- G6.3 is a common benchmark for general high-speed cutting applications.

- G2.5 is required for applications demanding higher tolerances and superior surface finish.

- G1.0 represents very high precision, essential for ultra-precision machining where every micron matters. Achieving this level of precision directly impacts the quality of finished parts and defines a true High Precision Spindle.

Selecting the right G-value depends on the spindle’s operating speed, mass, and the specific requirements of the machining operation. For most high-speed industrial applications, a G2.5 to G1.0 grade is the target for optimal performance and longevity.

Essential Tools and Equipment

Achieving these exacting standards requires specialized, calibrated equipment that most machine shops do not possess.

The centerpiece is a hard-bearing dynamic balancing machine. These systems, like the Schenck machines used at MZI Precision, rotate a spindle at high speeds while measuring vibration in two planes.

- Accelerometers, mounted on the machine’s bearing supports, act as sensitive sensors that detect the amplitude and frequency of vibrations.

- A tachometer measures rotational speed and provides a phase reference signal, which is critical for pinpointing the imbalance location.

- Vibration analyzers use Fast Fourier Transform (FFT) to break down complex vibration signals, allowing technicians to isolate imbalance-related frequencies from other noise.

- Precision scales are used to measure correction masses, which are often calculated in milligrams.

This combination of specialized equipment and experienced technicians is what makes professional balancing fundamentally different from amateur attempts and is integral to our Precision Spindle Design philosophy.

The Future of Balancing: Latest Advancements

The field of High Speed Spindle Balancing is constantly evolving to meet the demand for higher speeds and tighter tolerances.

Active balancing systems represent a significant leap forward. Unlike traditional static corrections, these systems continuously monitor and adjust for imbalance while the spindle is running. Research on active balancing devices shows they can maintain balance across all speeds, compensating for factors like thermal expansion in real-time.

Another innovation is real-time data analysis using disturbance observers. This high-accuracy method leverages a machine’s own CNC system data to estimate imbalance without external sensors, achieving balance grades as fine as G0.0073.

Looking ahead, researchers are exploring electromagnetic and microfluidic balancing concepts. These emerging technologies promise non-contact, highly responsive adjustments that could push the boundaries of spindle speed and reliability even further.

Frequently Asked Questions about High-Speed Spindle Balancing

When should spindle balancing be performed?

Proper timing for High Speed Spindle Balancing is crucial for preventing costly downtime and equipment damage. Balancing is essential in several key situations:

- During a Spindle Rebuild: This is the most critical time. Assembling new or refurbished components, even those made to tight tolerances, can introduce imbalance.

- After a machine crash: Any impact, no matter how minor it seems, can cause subtle deformations that create significant imbalance at high speeds.

- As part of preventative maintenance: Regular balancing checks are a smart investment to catch developing issues before they lead to catastrophic failure.

- When performance degrades: If you notice increased vibration, degrading surface finish quality (e.g., chatter marks), or unexpectedly short tool life, an unbalanced spindle is a likely cause.

What are common issues encountered during balancing?

Professional balancing requires troubleshooting complex issues that go beyond simple measurement.

- Misalignment: Vibration can be caused by misalignment of the spindle within its housing or with drive components. This must be corrected before balancing.

- Faulty Bearings: Worn or damaged bearings generate vibration that can be mistaken for imbalance. Our CNC Spindle Repair process often identifies bearing issues during balancing.

- Sensor and Calibration Errors: Incorrect placement of sensors or drifted calibration can lead to inaccurate data and faulty corrections.

- Tooling vs. Spindle Imbalance: It can be challenging to differentiate between imbalance originating from the spindle and that from an attached toolholder. Isolating components is often necessary.

- Thermal Fluctuation: Spindles heat up during operation, causing thermal expansion that can shift mass distribution. Balancing at operating temperature (trim balancing) can correct for this.

Why Professional Balancing is Essential

While it may be tempting to attempt balancing with in-house resources, High Speed Spindle Balancing for industrial applications demands professional expertise and equipment for several reasons.

First, non-professional methods are severely limited. Simple static balancing techniques are inadequate for high-speed spindles, as they cannot detect or correct the complex couple imbalances that occur in two planes along the spindle’s length.

Second, specialized, calibrated equipment is non-negotiable. Achieving precision balance grades like G2.5 or G1.0 requires industrial-grade dynamic balancing machines, sensitive accelerometers, and sophisticated analysis software. Without these calibrated tools, any adjustments are based on guesswork, not data.

Most importantly, the risks of improper balancing are significant. An incorrect correction can amplify vibrations, accelerate bearing wear, and lead to catastrophic failure. The cost of repairing damage from a failed balancing attempt often far exceeds the cost of professional service.

Professional expertise ensures the job is done correctly. Experienced technicians understand how to diagnose complex issues, use advanced equipment properly, and apply corrections with the necessary precision. For critical high-speed spindles, trusting a professional Spindle Repair Service is the safest and most effective way to ensure optimal performance, reliability, and longevity.

Conclusion: Partnering for Precision and Performance

Throughout this guide, we’ve seen the critical importance of High Speed Spindle Balancing in industrial manufacturing. From the exponential increase of centrifugal force to the costly consequences of microscopic imbalances, one truth stands out: proper spindle balance is the foundation of reliable, profitable production.

An unbalanced spindle systematically destroys bearings, reduces tool life, ruins surface finishes, and increases energy costs, with the ultimate risk of catastrophic failure. Conversely, a precisely balanced spindle ensures consistent part quality, extends component life, and maintains smooth production. The link between precision balance and manufacturing profitability is undeniable.

Achieving the ultra-precise balance grades modern machining demands, such as G1.0 or finer, requires specialized equipment and deep expertise. It is a science that cannot be accomplished with basic tools or guesswork.

At MZI Precision, we bring that expertise to your operations. Our commitment to excellence in spindle services runs deep. With our specialized knowledge in OEM rebuilt spindles and state-of-the-art balancing equipment, we serve critical industries across the United States—from aerospace and defense to solar energy manufacturing. We understand that when your spindles are down, your entire operation suffers. That’s why we are dedicated to providing not just technical precision, but exceptional service that keeps your machines running at peak performance.

Don’t let spindle imbalance undermine your productivity and quality. Partner with professionals who have the tools and expertise to deliver results that meet the most demanding standards.

Contact MZI Precision for expert High Speed Spindle Balancing services and experience the difference that true precision makes.