Understanding the Cost of CNC Spindle Rebuild

When it comes to cnc spindle rebuild cost, it’s crucial to grasp both the financial implications and the significance of the spindle in CNC machining operations. A spindle is the heart of a CNC machine, and its condition directly affects the machine’s performance and the quality of the work produced. Rebuilding a spindle, rather than opting for a full replacement, can often be a cost-effective and efficient solution, especially for manufacturing companies in the aerospace industry where precision and reliability are paramount.

- Quick Cost Insight: CNC spindle rebuild costs can vary widely but typically range from $1,000 to $15,000, depending on the extent of the damage and the specific repairs required. Factors like bearing replacement, spindle surface restoration, and part replacements significantly influence the final cost.

For those diving into the spindle rebuild process, understanding these costs upfront is essential. It allows for better budgeting and decision-making in maintaining your CNC machine’s optimal performance without unnecessary downtime.

In a simple and clear manner, this guide will walk you through the intricacies of spindle rebuild costs, explaining why certain factors affect the price tag and how to weigh the pros and cons of repair vs. replacement for your specific needs.

Understanding CNC Spindle Rebuild Costs

When it comes to CNC spindle rebuild cost, several elements come into play. Let’s break these down into digestible parts so you can understand what goes into the pricing.

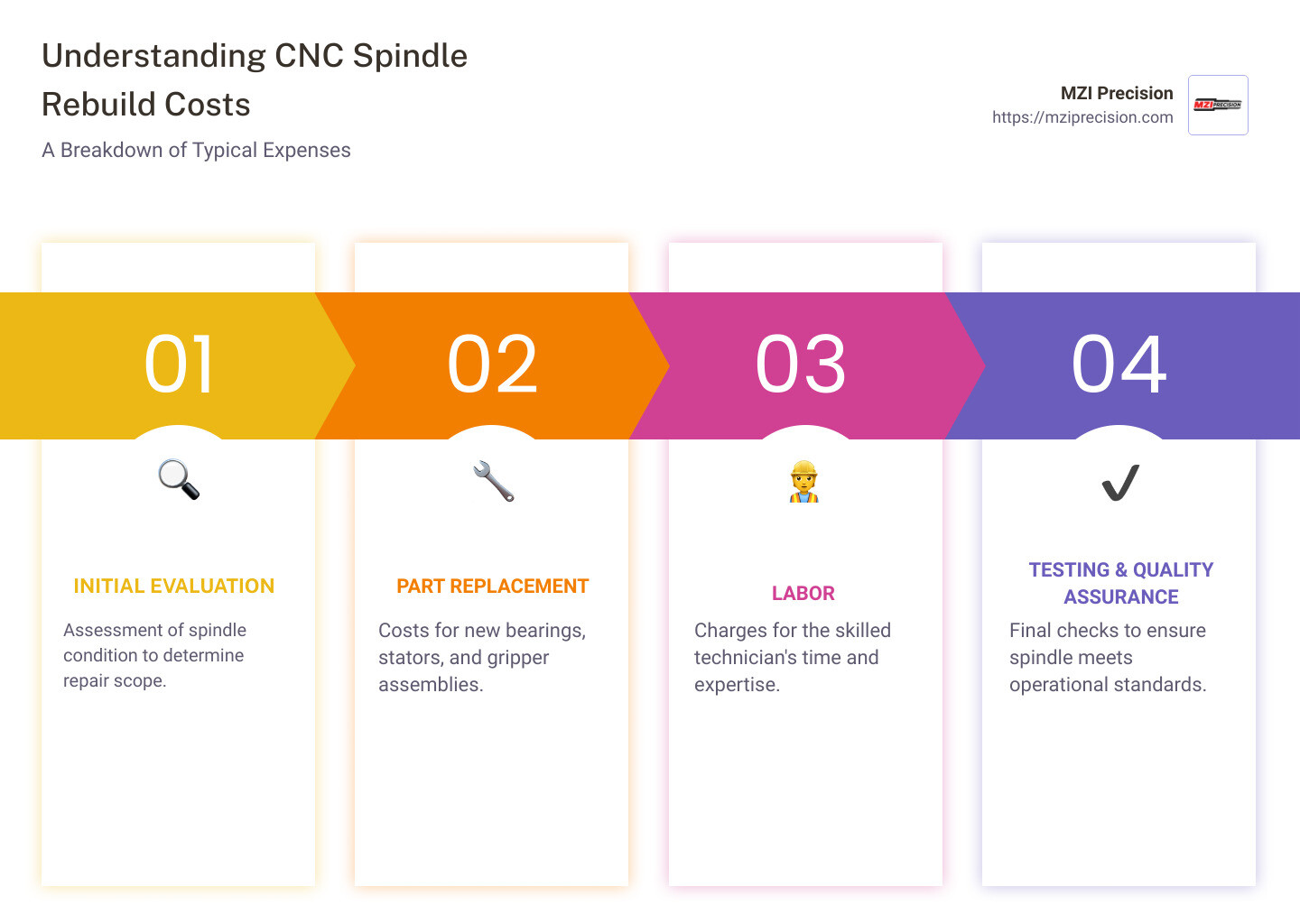

Initial Evaluation

The journey begins with an initial evaluation. This is where experts take a look at your spindle to understand what’s wrong. Think of it as a doctor’s visit for your spindle. There’s usually a small fee for this, but it’s crucial because it tells us what needs fixing.

Repair Quote

After the evaluation, you’ll receive a repair quote. This quote is like a map; it shows you where we’re going, how we’ll get there, and how much it’ll cost. It includes the cost of parts, labor, and anything else needed to get your spindle back in shape.

Part Replacement

Sometimes, parts of your spindle might be too worn out or damaged and need replacing. This can include bearings, burned stators, or gripper assemblies. The cost of these parts can vary widely.

- Bearings are the heart of the spindle, allowing it to rotate smoothly. Depending on the type and quality, their prices can fluctuate.

- A burned stator is a bit like a bad flu for your spindle. Fixing it can cost anywhere from $400 to $4,000.

- Gripper assemblies are crucial for holding tools in place. These can set you back $1,200 to $3,200.

Bearing Price Fluctuation

Just like the stock market, the price of bearings can go up and down. This bearing price fluctuation affects the overall cost of the repair. It’s something to keep in mind as you consider the quote.

Understanding these factors helps you see why the cost of a CNC spindle rebuild can vary so much. It’s not just about fixing what’s broken; it’s about ensuring your spindle can continue to do its job effectively for as long as possible. In the next section, we’ll dive into the factors influencing CNC spindle rebuild costs further, giving you a clearer picture of what to expect.

Factors Influencing CNC Spindle Rebuild Cost

When it comes to understanding cnc spindle rebuild cost, several key factors come into play. Each of these aspects can significantly impact the overall price of the repair. Let’s break them down:

Damaged Tool Interface

The tool interface is where your spindle connects with the tool it’s driving. Damage here can vary from minor wear and tear to significant issues that require complete replacement. Repair costs can range from $700 to $1,600, depending on the extent of the damage and the spindle’s make and model.

Bearing Journals

Bearings play a crucial role in the smooth operation of your spindle. When bearing journals are damaged, they can add between $400 and $1,400 to your repair bill. The price varies based on the size of the spindle and the complexity of the bearing system.

Shaft Damage

A damaged shaft is one of the most severe problems a spindle can face. In some cases, shaft damage can double the base repair cost, with replacements often costing around $4,000. This kind of damage typically requires the most work and can significantly influence the decision between repair and replacement.

Surface Restoration

Surface restoration, or GPG, is essential for ensuring your spindle operates smoothly. This process can vary in cost, depending on the extent of the damage and the specific requirements of your spindle.

Spindle Repair vs. Replacement

One of the most significant factors influencing the cost is whether to repair or replace the spindle. Repairs can save money in the short term but might not always be the best long-term solution. Replacement is more costly upfront but can offer better value over time, especially if the spindle is severely damaged or outdated.

In Summary:

- Damaged Tool Interface: $700 – $1,600

- Bearing Journals: $400 – $1,400

- Shaft Damage: Can double repair cost, up to $4,000

- Surface Restoration: Cost varies

- Spindle Repair vs. Replacement: Decision impacts cost significantly

When considering a cnc spindle rebuild, it’s crucial to weigh these factors carefully. The right choice between repair and replacement will depend on the specific damage, the cost implications, and how each option fits into your long-term operational plans.

In the next section, we’ll explore the process of CNC spindle repair in detail, providing insights into what goes into bringing your spindle back to top condition.

The Process of CNC Spindle Repair

When your CNC spindle starts showing signs of trouble, knowing the repair process can make the decision-making path clearer. Let’s dive into each step of the spindle repair journey.

Evaluation

The first step is like a doctor’s check-up for your spindle. Technicians take a close look at the spindle, using specialized tools and their expertise to figure out what’s wrong. This might involve visual inspection, testing how the spindle spins, and other diagnostic methods. It’s a crucial step because it lays out the repair roadmap.

Part Breakdown

After understanding the problem, the spindle is carefully taken apart. This is where technicians get to see each piece of the puzzle. They look at bearings, seals, and other components, checking for wear and tear or damage. This step is detailed and methodical, ensuring nothing is missed.

Repair Quote

With a clear picture of what needs fixing, you’ll receive a repair quote. This quote covers the cost of parts, labor, and any additional services needed. It’s your guide to understanding the financial aspect of the repair. This is the point where you decide whether to proceed with the repair based on the estimated cost and the value it adds to your operations.

Part Replacement and Repair

Once you give the green light, the actual repair work begins. This could involve replacing worn-out bearings, fixing the spindle shaft, or dealing with electrical issues. Each part is treated with care, ensuring it meets strict standards. The goal is to not just fix the spindle but to make it as good as, or better than, new.

Part Tests

After the spindle is put back together, it’s not just sent back to you. It goes through a series of tests to make sure it’s ready for action. These tests check for things like how well it spins, if it’s balanced, and if there are any vibrations. It’s the quality assurance step that ensures the repair meets high standards.

Part Returns

Finally, the spindle is ready to come back to you. It’s packed up and shipped with care, ready to be reinstalled in your CNC machine. This is where you see the results of the repair process firsthand, with a spindle that’s ready to get back to work.

Throughout this process, the focus is on precision, care, and transparency. Repairing a CNC spindle is about more than just fixing what’s broken; it’s about understanding the cause of the problem and ensuring it’s set up for long-term success. This detailed repair journey ensures your spindle returns to you in top condition, ready to contribute to your manufacturing operations once again.

In the next section, we’ll discuss when CNC spindle replacement becomes necessary and what to consider if you’re facing that decision.

CNC Spindle Replacement: When Is It Necessary?

Sometimes, no matter how thorough the repair process is, a CNC spindle reaches a point where repair is no longer viable. This could be due to extreme wear, irreversible damage, or simply the age of the spindle. Let’s explore the key considerations when facing the decision to replace your CNC spindle.

Unavoidable Replacement

There are scenarios where replacement is the only option. This could be due to:

– Severe damage that cannot be repaired

– Cost of repair exceeding the cost of replacement

– Older spindles where parts are no longer available

Lead Times

One critical factor to consider is the lead time for a new spindle. Unlike repairs that might take a few days to a few weeks, obtaining a new OEM spindle can take much longer. Given the intricate manufacturing and testing process, waiting times can stretch up to 32 weeks. This extended downtime can significantly impact production schedules and, ultimately, your bottom line.

New OEM Spindle Costs

Cost is a major factor in the decision-making process. A new OEM spindle can be considerably more expensive than repairing an existing one. Prices can range significantly based on the spindle’s specifications and capabilities. When considering replacement, it’s important to weigh the immediate cost against the long-term benefits of a new spindle.

Monitoring Spindle Health

Preventative maintenance plays a crucial role in extending the life of a spindle. Regular monitoring and maintenance can identify potential issues before they escalate to the point of requiring replacement. Key health indicators include unusual noises, vibrations, or changes in performance. Keeping a close eye on these signs can help you make informed decisions about whether to repair or replace.

Operational Downtime

Finally, the impact of operational downtime cannot be overstated. Both repair and replacement processes require your CNC machine to be out of commission. However, the extended lead times associated with spindle replacement can result in significant production delays. It’s crucial to consider the potential impact on your operations and plan accordingly.

In conclusion, deciding whether to repair or replace a CNC spindle involves careful consideration of several factors, including the severity of damage, cost implications, lead times, and the potential for operational downtime. Regularly monitoring spindle health can help in making timely decisions, potentially saving costs and minimizing disruption to your operations.

We’ll address some of the most common questions related to CNC spindle rebuild and replacement, providing you with further insights to navigate these critical decisions.

Frequently Asked Questions about CNC Spindle Rebuild and Replacement

Navigating CNC spindle maintenance can be tricky. Whether you’re facing a spindle that’s seen better days or just planning for the future, you likely have questions. Let’s dive into some of the most frequently asked questions to shed some light on cnc spindle rebuild cost, replacement, and maintenance.

How much does a spindle replacement cost?

The cost of replacing a spindle can vary widely, depending on several factors like the spindle’s size, power, and the specific machine it’s designed for. Generally speaking, a new spindle can set you back anywhere from $14,000 to $24,000. However, this is a ballpark figure, and the actual cost can be higher based on the complexity and specifications required.

For those looking at cost-effective alternatives, a spindle rebuild or repair by a reputable service like MZI Precision can be significantly less expensive. A typical rebuild might cost between $2500 and $3500, but this can fluctuate based on the extent of damage and the parts needed. A thorough evaluation by experts can give you a more precise quote tailored to your spindle’s condition.

How do I know if my CNC spindle is bad?

Identifying a failing spindle early can save you from more significant problems down the line. Here are a few telltale signs:

- Unusual noises, such as grinding or screeching, which could indicate bearing wear or failure.

- Excessive vibration, affecting precision and potentially causing further damage.

- Decreased cutting performance or quality, signaling that the spindle may be struggling to maintain speed or torque.

If you notice any of these symptoms, it’s wise to consult with a spindle repair specialist like MZI Precision promptly. They can diagnose the issue accurately and recommend the best course of action.

How long does a spindle last?

The lifespan of a CNC spindle is influenced by various factors, including the intensity of use, the type of materials being machined, and how well the spindle is maintained. On average, a well-maintained spindle in a machine that sees moderate use can last between 5 to 10 years. However, in high-production environments, where the spindle operates at high speeds for extended periods, its performance might begin to degrade around the 3 to 5-year mark.

Proper maintenance and timely repairs are crucial to extending the life of your spindle. Regular check-ups and addressing issues as they arise can keep your spindle running smoothly for years, ensuring your operations stay efficient and productive.

Understanding the costs and signs of spindle wear can help you make informed decisions about maintenance and replacement. Choosing a reliable service partner like MZI Precision can significantly impact the longevity and performance of your CNC spindle, ensuring your operations run smoothly with minimal downtime.

Conclusion

When it comes down to the nitty-gritty of maintaining your CNC machinery, the spindle is the heart that keeps your operations alive and kicking. The decision between a CNC spindle rebuild and replacement hinges on a multitude of factors, but one thing remains constant: the need for a trusted partner with deep expertise and an unwavering commitment to service. That’s where MZI Precision steps into the spotlight.

Expertise in OEMs Rebuilt Spindles

At MZI Precision, we pride ourselves on our profound understanding of OEM spindle requirements and specifications. Our years of experience have equipped us with the knowledge to not only repair but significantly improve the performance of your CNC spindle. We don’t just fix; we enhance, ensuring that your spindle returns to you operating at its peak, sometimes even surpassing its original capabilities.

Commitment to Service and Support

Our dedication to service is unmatched. We comprehend the critical nature of spindle repair and replacement in minimizing downtime and maintaining productivity. That’s why we offer swift, efficient processes and emergency services to get your operations back up and running as soon as possible. With MZI Precision, you’re not just getting a service provider; you’re gaining a partner who’s committed to ensuring your success and satisfaction. Our comprehensive approach includes a detailed diagnosis, use of the latest technology for repairs, and rigorous testing to ensure your spindle is in optimal condition before it returns to you. Plus, our full one-year in-service warranty on all repaired units provides that extra peace of mind.

Choosing MZI Precision means opting for a partner deeply invested in the health and efficiency of your CNC machinery. Our expertise in OEMs rebuilt spindles and commitment to exceptional service and support stand as our pledge to you. We understand the critical role your spindle plays in your operations, and we’re here to ensure it performs at its best, now and in the future.

For those navigating the complexities of CNC spindle rebuild costs and decisions, remember: the right partner can make all the difference. Let MZI Precision be your guide and support in keeping your operations efficient and productive.