Why servo motor used in cnc machine: 7 Powerful Reasons 2025

Why Servo Motors Are the Heart of Modern CNC Precision

Why servo motor used in CNC machine comes down to one simple truth: they deliver the precision, speed, and reliability that modern manufacturing demands. When you’re machining aerospace components or critical industrial parts, there’s no room for error.

Here’s why CNC machines rely on servo motors:

- Closed-loop feedback control – Real-time position correction prevents lost steps

- High torque at speed – Maintains cutting force even at several thousand RPM

- Energy efficiency – Up to 90% efficiency under light loads vs 70% for steppers

- Dynamic response – Rapid acceleration and deceleration without precision loss

- Multi-axis synchronization – Perfect coordination for complex geometries

As one industry expert put it: “Even with perfect code and tooling, part quality suffers if the motor can’t accurately feed the spindle.” This captures exactly why servo motors have become the standard in professional CNC operations.

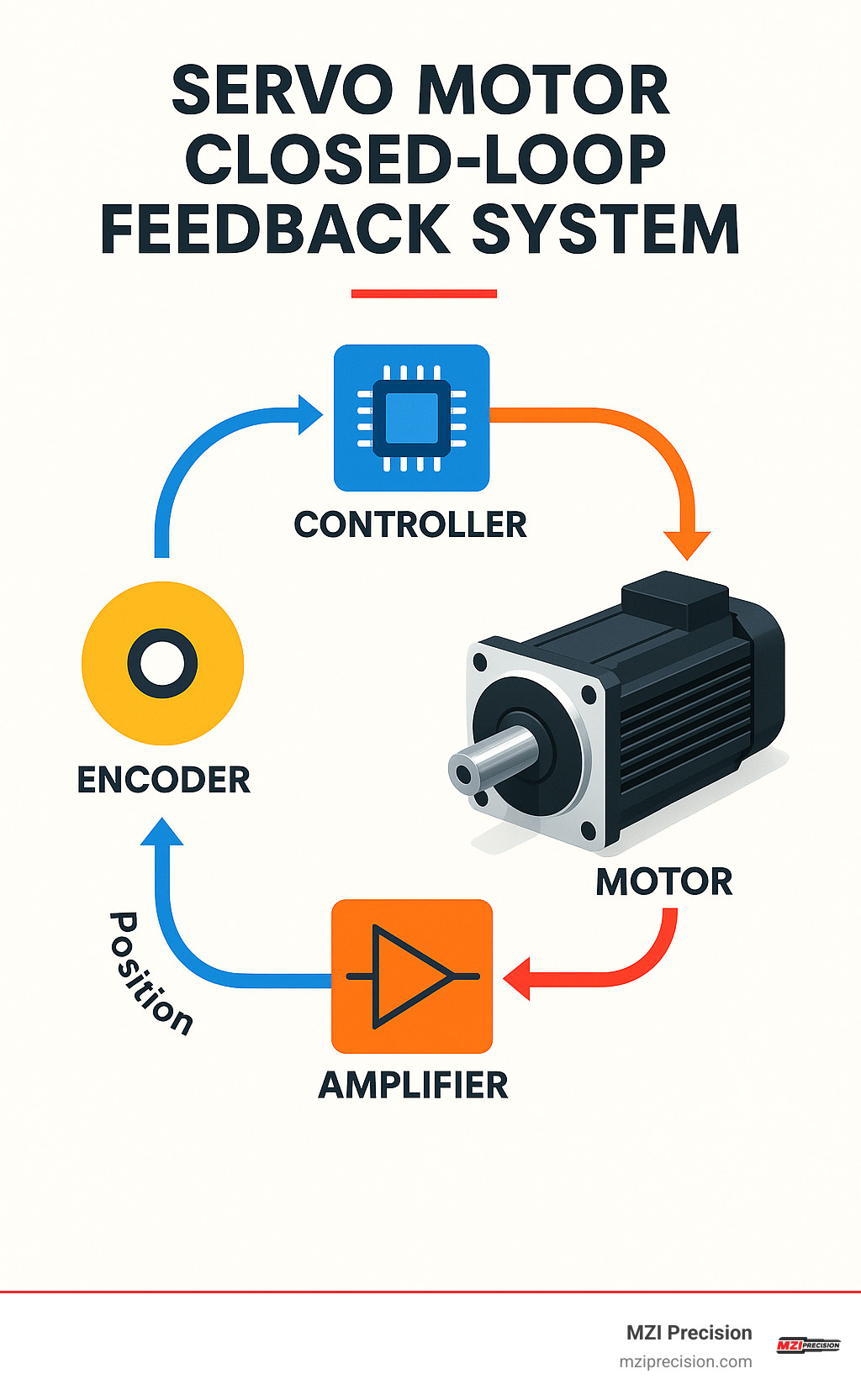

The feedback loop makes all the difference. Unlike stepper motors that run “blind” in open-loop systems, servo motors constantly monitor their actual position through encoders. Think of it like GPS navigation – when you miss a turn, the system immediately recalculates and corrects course.

This closed-loop control means servo motors can handle varying loads, unexpected resistance, and rapid direction changes while maintaining micron-level accuracy. They also generate less heat, run quieter, and can deliver 5-10 times their rated torque for short bursts when needed.

Quick why servo motor used in cnc machine definitions:

What You’ll Learn

In this comprehensive guide, we’ll explore every aspect of servo motor advantages in CNC applications. You’ll find the technical benefits that make servo motors indispensable for precision machining, learn how to select the right servo system for your needs, and understand the maintenance practices that keep these systems running at peak performance.

We’ll also compare servo motors to stepper alternatives, showing you exactly when and why industrial CNC shops choose servos for their most demanding applications. By the end, you’ll have a complete understanding of why servo motors are the preferred choice for professional CNC operations.

What Is a Servo Motor & How Does It Work?

A servo motor is an electric motor designed for precise control of acceleration, velocity, and angular position. At its core, it’s a synchronous motor that combines three essential elements: an electromagnet stator, a permanent-magnet rotor, and a feedback device that creates a closed-loop control system.

The magic happens in the electromagnetic interaction. The stator contains multiple coil windings that create rotating magnetic fields when energized. The rotor, equipped with rare-earth permanent magnets, follows this rotating field synchronously. Unlike basic motors that simply spin, servo motors use encoders or resolvers to constantly report their actual position back to the drive system.

This feedback creates what engineers call a closed-loop PID (Proportional-Integral-Derivative) control system. The servo drive continuously compares the commanded position with the actual position, making real-time corrections to minimize error. It’s like having a GPS system that not only knows where you are, but actively steers you back on course if you drift.

Modern CNC machines typically use AC servo motors or brushless DC (BLDC) servo motors. AC servos dominate industrial applications because they’re smaller, lighter, more efficient, and offer faster dynamic response compared to older DC servo designs. They can maintain nearly full torque even at maximum speed – a crucial advantage for high-speed machining operations.

The torque curve of a servo motor is remarkably flat across its speed range, meaning it delivers consistent cutting force whether you’re running at 100 RPM or 3,000 RPM. This consistency allows CNC machines to maintain surface finish quality and dimensional accuracy across varying cutting speeds.

Energy regeneration is another servo advantage often overlooked. When the motor decelerates or acts as a brake, regenerative drive systems can recover 30-40% of that kinetic energy and feed it back to the power supply rather than dissipating it as heat.

For more detailed information about servo motor reliability and performance, check out this scientific research on servo reliability.

Main Components Inside a CNC Servo System

Understanding the components helps explain why servo systems deliver such superior performance. Every CNC servo system includes several critical elements working in harmony:

Power Supply and Servo Drive: The servo drive acts as the brain and muscle of the system. It receives low-voltage command signals from the CNC controller and amplifies them into high-power, precisely timed electrical pulses that drive the motor.

Motor Windings and Magnetic Assembly: The motor itself contains precisely wound electromagnetic coils in the stator and high-strength permanent magnets in the rotor. The quality of these components directly affects torque output, speed capability, and thermal performance.

Encoder or Resolver Feedback: This is where the “closed-loop” magic happens. Encoders provide digital position feedback with hundreds of thousands of counts per revolution – vastly superior to the 200 steps typical of stepper motors. Some systems use absolute encoders that retain position information even when power is lost.

Cabling and Controller Interface: Servo systems require both power cables for high-current motor drive and signal cables for encoder feedback. The controller interface handles communication protocols between the CNC control system and the servo drives.

Environmental Protection: Industrial servo motors often feature IP67 protection ratings, meaning they’re completely dust-tight and can withstand temporary water immersion. This protection is crucial in machining environments where coolant and debris are constant threats.

Types of Servo Motors Used in CNC Machines

AC Synchronous Servo Motors are the workhorses of modern CNC systems. They offer the best balance of performance, reliability, and cost-effectiveness. These motors excel in applications requiring high speed, precise positioning, and consistent torque output.

Brushless DC (BLDC) Servo Motors provide the highest efficiency and are ideal for applications where energy consumption is critical. While they require more complex control electronics, BLDC motors offer superior speed control and can achieve very high RPM with minimal vibration.

High-Torque Spindle Servos are specialized motors designed specifically for CNC spindle drives. These motors often integrate directly with the spindle assembly, eliminating belts and gears that can introduce backlash and vibration.

Why Servo Motor Used in CNC Machine: Core Advantages

The question of why servo motor used in CNC machine has a multi-faceted answer rooted in measurable performance advantages. Servo motors deliver precision that’s simply impossible with other motor technologies, making them indispensable for modern manufacturing.

High Precision and Repeatability: Servo motors can achieve positioning accuracy measured in microns. With encoder feedback providing hundreds of thousands of position counts per revolution, they offer resolution that’s orders of magnitude better than stepper motors. This precision translates directly to better part quality and tighter tolerances.

Dynamic Response: Servo motors excel at rapid acceleration and deceleration without losing position accuracy. They can handle sudden load changes, direction reversals, and complex motion profiles while maintaining smooth operation. This dynamic capability is essential for machining complex geometries and maintaining consistent surface finishes.

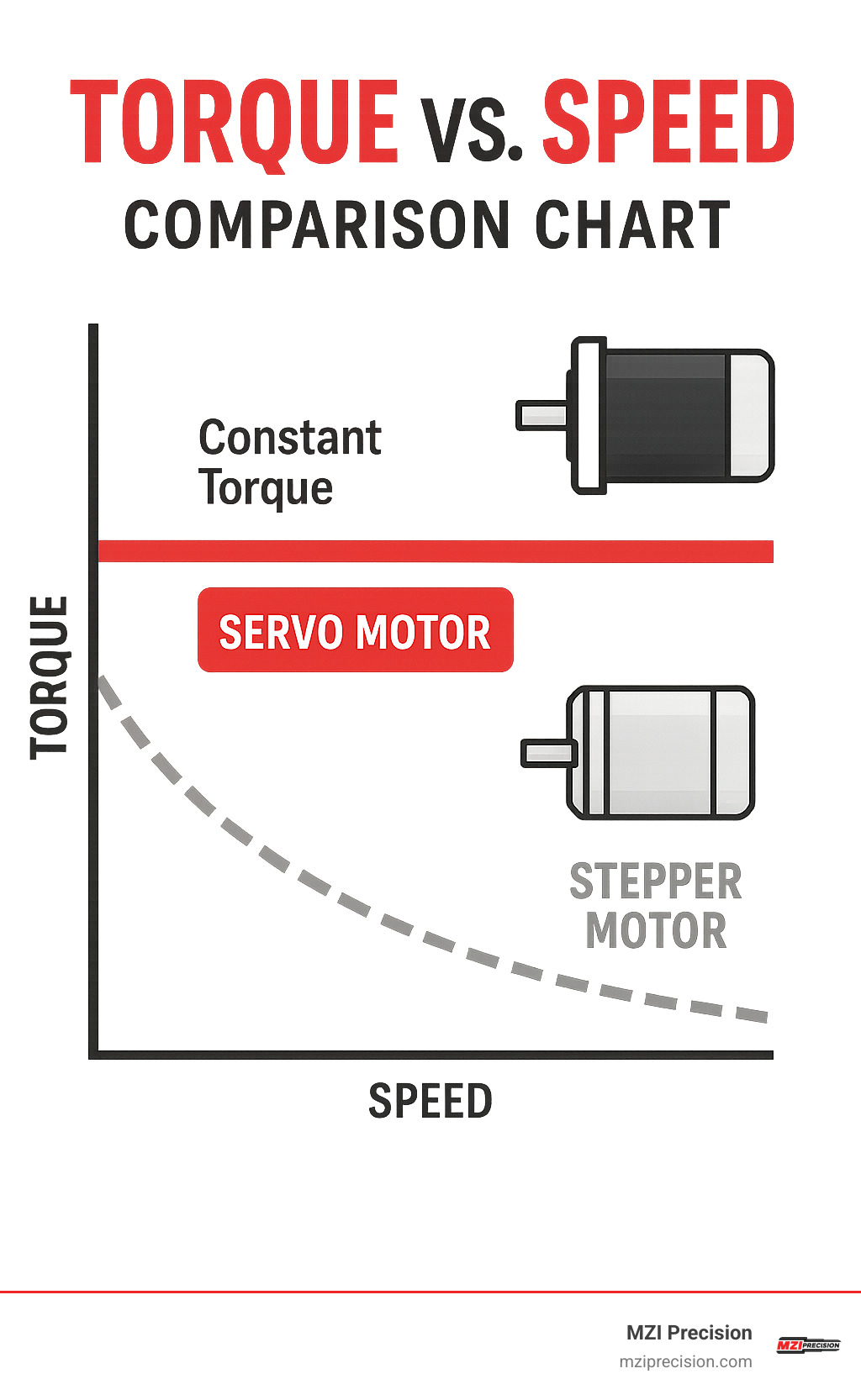

Constant Torque Across Speed Range: Unlike stepper motors that lose torque as speed increases, servo motors maintain nearly constant torque throughout their speed range. This means they can deliver full cutting force whether you’re running at low speeds for heavy roughing cuts or high speeds for finishing operations.

Multi-Axis Synchronization: CNC machines often require precise coordination between multiple axes. Servo motors excel at synchronized motion, allowing complex interpolated moves where multiple axes must move in perfect harmony to create curved surfaces or angled cuts.

Energy Efficiency: Servo motors can achieve up to 90% efficiency under light load conditions, significantly better than the ~70% efficiency typical of stepper motors. This efficiency reduces operating costs and heat generation, improving overall machine performance.

Quiet Operation: Servo motors run much quieter than stepper motors, which tend to produce audible humming and vibration. This quiet operation improves the work environment and can indicate smoother mechanical operation that benefits surface finish quality.

Environmental Resilience: Industrial servo motors are built to withstand harsh machining environments. With IP67 protection ratings, they resist coolant infiltration, dust, and temperature extremes that would damage lesser motors.

Closed-Loop Feedback: The Accuracy Game-Changer

The closed-loop feedback system is what truly sets servo motors apart from stepper alternatives. This system creates a continuous monitoring and correction loop that ensures actual motor position matches commanded position with exceptional accuracy.

Real-Time Position Correction: The encoder constantly sends position data back to the servo drive, typically thousands of times per second. If the motor position deviates from the commanded position due to load changes, mechanical resistance, or external forces, the servo drive immediately applies corrective torque to bring the motor back on target.

Zero Lost Steps: Stepper motors can “lose steps” when overloaded, leading to cumulative positioning errors that compound over time. Servo motors eliminate this problem entirely – if the motor can’t reach the commanded position, the system detects this immediately and can either apply more torque or trigger a fault condition to prevent damage.

Adaptive Load Control: The closed-loop system automatically adjusts to varying loads. When cutting through hard material that creates more resistance, the servo system increases torque to maintain the commanded feed rate. When the load decreases, it reduces power consumption accordingly.

This adaptive behavior is like having an intelligent assistant that constantly monitors and adjusts performance to maintain optimal results regardless of changing conditions.

Speed & Torque Where It Counts

Servo motors deliver superior performance in the speed and torque characteristics that matter most for CNC machining. While stepper motors typically operate effectively at 1,200 RPM or lower, servo motors can run at several thousand RPM while maintaining full torque output.

Rapid Acceleration Capability: Servo motors can accelerate and decelerate much faster than stepper motors without losing position accuracy. This rapid response enables shorter cycle times and better surface finishes, especially when machining complex contours that require frequent direction changes.

Short-Burst Peak Torque: Servo motors can deliver 5-10 times their rated continuous torque for short periods. This peak torque capability is invaluable for breaking through tough materials, making rapid direction changes, or handling sudden load increases without stalling.

Surface Finish Quality: The smooth, consistent motion of servo motors directly translates to better surface finishes. Unlike stepper motors that move in discrete steps and can create visible step marks, servo motors provide truly smooth motion that results in superior part quality.

The combination of high speed capability and consistent torque output makes servo motors ideal for both roughing operations that require high material removal rates and finishing operations that demand superior surface quality.

Reliability & Cost of Ownership

While servo motors have higher upfront costs than stepper alternatives, their total cost of ownership is often lower due to superior reliability and energy efficiency.

Regenerative Drive Technology: Modern servo drives can recover and reuse energy during deceleration cycles. Instead of dissipating braking energy as heat, regenerative drives feed this energy back to the power supply. This technology can reduce overall power consumption by 30-40% compared to traditional discharge systems.

Reduced Heat Generation: Servo motors generate heat proportional to their actual load, unlike stepper motors that dissipate excess current as heat even under light loads. This reduced heat generation means less cooling requirements and longer component life.

Lower Maintenance Requirements: The brushless design of modern servo motors means virtually no wear parts beyond bearings. With proper maintenance, servo motors can operate for years without requiring significant service, reducing downtime and maintenance costs.

Predictable Performance: The closed-loop feedback system provides early warning of potential problems. Servo drives can monitor motor performance and alert operators to issues like bearing wear, encoder problems, or excessive loading before they cause failures.

Servo vs. Stepper Motors in CNC Applications

Understanding the fundamental differences between servo and stepper motors helps explain why industrial CNC operations consistently choose servos for demanding applications.

Open-Loop vs. Closed-Loop Control: Stepper motors operate in open-loop systems, meaning they execute commands without feedback about their actual position. They assume each step command results in precise movement, but have no way to verify this assumption. Servo motors operate in closed-loop systems with constant position feedback, ensuring commanded and actual positions always match.

Torque Characteristics: Stepper motors provide maximum torque at zero speed but lose torque rapidly as speed increases. This torque drop-off limits their effectiveness in high-speed applications. Servo motors maintain consistent torque across their entire speed range, making them suitable for both low-speed precision work and high-speed production runs.

Speed Limitations: Stepper motors typically operate most effectively at 1,200 RPM or lower, while servo motors can achieve several thousand RPM. This speed advantage is crucial for modern high-speed machining operations.

Efficiency and Heat Generation: Stepper motors continuously draw current to maintain position, generating heat even when stationary. Servo motors only draw current proportional to their load, resulting in higher efficiency and lower heat generation.

Resolution and Accuracy: While stepper motors typically provide 200 steps per revolution (1.8° per step), servo motors with encoders can provide hundreds of thousands of position counts per revolution, offering vastly superior resolution and accuracy.

| Characteristic | Stepper Motor | Servo Motor |

|---|---|---|

| Control Type | Open-loop | Closed-loop |

| Torque at Speed | Decreases rapidly | Constant |

| Maximum Speed | ~1,200 RPM | Several thousand RPM |

| Efficiency | ~70% | Up to 90% |

| Resolution | 200 steps/rev | Hundreds of thousands |

| Heat Generation | Continuous | Load-proportional |

| Maintenance | Moderate | Low |

When a Stepper Still Makes Sense

Despite the advantages of servo motors, stepper motors still have their place in certain CNC applications. For hobby CNC routers and small-scale prototyping machines where cost is the primary concern, stepper motors can provide adequate performance at a fraction of the cost.

Low-Speed Applications: When machining operations don’t require high speeds, stepper motors can deliver acceptable performance. Their high torque at low speeds makes them suitable for applications like engraving, light cutting, and positioning tasks.

Simple Control Requirements: Stepper motors are easier to control and don’t require the complex tuning that servo systems need. For basic applications where ultimate precision isn’t critical, this simplicity can be an advantage.

Budget Constraints: The lower initial cost of stepper motor systems makes them attractive for budget-conscious applications where the performance advantages of servo motors don’t justify the additional expense.

Why Industrial CNC Shops Choose Servos Every Time

Professional CNC operations consistently choose servo motors because the performance advantages directly translate to better profitability and part quality.

High-Speed Spindle Operations: When running spindles at several thousand RPM, servo motors maintain the torque and precision needed for quality cuts. Stepper motors simply can’t deliver the performance needed for high-speed machining operations.

Heavy-Cut Stability: Servo motors excel in heavy cutting applications where varying loads and high forces are common. The closed-loop feedback system automatically adjusts to maintain consistent performance regardless of cutting conditions.

Automatic Fault Detection: Servo systems can detect problems like excessive loading, position errors, or mechanical binding and automatically shut down to prevent damage. This protection capability can save thousands of dollars in damaged tooling and workpieces.

Production Efficiency: The combination of higher speeds, better accuracy, and more reliable operation means servo-equipped machines can produce more parts with better quality in less time. This productivity advantage quickly justifies the higher initial investment.

For comprehensive information about industrial spindle services and how they integrate with servo motor systems, visit our spindle services page.

Selecting & Maintaining Servo Motors for Peak CNC Performance

Proper selection and maintenance of servo motors is crucial for achieving optimal CNC performance. The wrong motor choice or inadequate maintenance can negate all the potential advantages that servo systems offer.

Load Inertia Matching: One of the most critical selection criteria is matching the motor’s inertia to the load inertia. The ideal ratio is typically between 1:1 and 10:1 (load to motor inertia). Proper inertia matching ensures optimal acceleration performance and minimizes vibration.

Torque and Speed Sizing: Calculate both continuous and peak torque requirements for your application. Consider not just the cutting forces, but also the torque needed for rapid acceleration and deceleration.

Encoder Resolution Selection: Higher resolution encoders provide better position accuracy but increase system cost. Match encoder resolution to your actual accuracy requirements.

Environmental Considerations: Consider the operating environment when selecting motors. Machines using coolant require IP67 or better protection. High-temperature environments may require special motor designs.

Controller Compatibility: Ensure the servo motor and drive are compatible with your CNC controller’s communication protocols. Common protocols include analog voltage, step/direction, and various fieldbus standards.

Software Tuning Requirements: Servo systems require proper tuning to achieve optimal performance. This includes setting acceleration and deceleration rates, gain parameters, and feedback loop characteristics.

Key Selection Checklist

When selecting servo motors for CNC applications, consider these essential factors:

Application Torque Requirements: Calculate the continuous torque needed for your cutting operations, including factors like cutting forces, friction, and mechanical advantage of your drive system.

Duty Cycle Considerations: Determine whether your application requires continuous operation or intermittent duty. Continuous duty applications may require larger motors or additional cooling.

Feedback Type Selection: Choose between absolute and incremental encoders based on your application needs. Absolute encoders retain position information when power is lost.

Voltage and Power Compatibility: Ensure the motor’s voltage and power requirements match your facility’s electrical supply and the capabilities of your servo drives.

Controller Protocol Requirements: Verify that the servo system uses communication protocols compatible with your CNC controller.

Maintenance Best Practices

Proper maintenance is essential for maximizing servo motor life and maintaining peak performance.

Regular Visual Inspection: Inspect motors monthly for signs of damage, contamination, or wear. Look for damaged cables, loose connections, or accumulation of debris.

Cleaning and Lubrication: Keep motors clean and properly lubricated according to manufacturer specifications. Replace bearing grease at recommended intervals.

Encoder Calibration: Periodically verify encoder accuracy and recalibrate if necessary. Encoder drift can gradually reduce positioning accuracy, affecting part quality.

Thermal Monitoring: Monitor motor temperatures during operation. Excessive heat can indicate problems like bearing wear, electrical faults, or inadequate cooling.

Vibration Analysis: Use vibration monitoring tools to detect early signs of bearing wear, misalignment, or mechanical problems.

Performance Trending: Keep records of motor performance parameters like position accuracy, temperature, and vibration levels. Trending this data over time can reveal gradual degradation.

Frequently Asked Questions about Why Servo Motor Used in CNC Machine

What makes a servo motor “closed-loop”?

A servo motor is considered “closed-loop” because it incorporates a feedback system that continuously monitors and corrects its position. The encoder or resolver attached to the motor shaft constantly reports the actual position back to the servo drive. The drive compares this actual position with the commanded position and makes real-time corrections to minimize any error.

This is fundamentally different from stepper motors, which operate “open-loop” – they execute position commands without any feedback about whether they actually reached the commanded position. The closed-loop system ensures that servo motors maintain accuracy even when subjected to varying loads, mechanical resistance, or external disturbances.

Can a servo motor improve my spindle surface finish?

Absolutely. Servo motors can significantly improve spindle surface finish through several mechanisms. First, their smooth, continuous motion eliminates the discrete steps that can create visible marks on machined surfaces. Second, their ability to maintain constant torque at varying speeds ensures consistent cutting forces that produce uniform surface textures.

The closed-loop feedback system also helps maintain precise spindle speeds even under varying cutting loads, preventing the speed variations that can cause surface finish irregularities. Additionally, servo motors’ low vibration characteristics reduce chatter marks and other surface defects that can occur with less stable motor systems.

Are AC or BLDC servos better for high-speed machining?

Both AC and BLDC servo motors can excel in high-speed machining applications, but each has specific advantages. AC servo motors are generally more cost-effective and easier to integrate, making them the preferred choice for most industrial CNC applications. They offer excellent speed control and can handle the varying loads typical of machining operations.

BLDC servo motors offer higher efficiency and can achieve very high speeds with minimal vibration, making them ideal for specialized high-speed spindle applications. However, they require more complex control electronics and are typically more expensive. The choice depends on your specific speed requirements, efficiency needs, and budget constraints.

For most CNC machining applications, AC servo motors provide the best balance of performance, reliability, and cost-effectiveness.

Conclusion

The advantages of servo motors in CNC applications are clear and compelling. Their precision, reliability, and efficiency make them the preferred choice for professional manufacturing operations where quality and productivity matter most.

Precision and Accuracy: The closed-loop feedback system ensures positioning accuracy that’s simply impossible with open-loop alternatives. This precision translates directly to better part quality and tighter tolerances.

Energy Efficiency: With up to 90% efficiency and regenerative braking capabilities, servo motors can reduce energy consumption by 30-40% compared to traditional motor systems. This efficiency reduces operating costs and environmental impact.

Reliability and Performance: The combination of brushless design, intelligent monitoring, and adaptive load control makes servo motors exceptionally reliable. They can handle the demanding conditions of industrial machining while providing consistent performance over years of operation.

Total Cost of Ownership: While servo motors have higher upfront costs, their superior efficiency, reliability, and performance often result in lower total cost of ownership through reduced energy consumption, less maintenance, and higher productivity.

Understanding why servo motor used in CNC machine comes down to recognizing that modern manufacturing demands precision, speed, and reliability that only closed-loop servo systems can deliver. Whether you’re machining critical aerospace components or high-volume production parts, servo motors provide the performance foundation that enables success.

At MZI Precision, we understand the critical role that servo motors play in CNC operations. Our expertise in industrial spindle repair and rebuilding includes comprehensive knowledge of servo motor integration and optimization. When your servo-driven spindles need service, our team has the experience to restore them to peak performance.

For more information about our industrial spindle rebuilding services and how we can help optimize your servo motor systems, visit our spindle rebuilding page.