Suspension Spindle: Ultimate Guide 2026

WHY INDUSTRIAL MANUFACTURING SPINDLES ARE THE HEART OF PRECISION MACHINING

In industrial manufacturing, a suspension spindle is the precision rotating assembly holding and driving cutting tools or workpieces. The term “suspension” refers to its mounting system, which manages vibration, distributes loads, and maintains accuracy during high-speed operation.

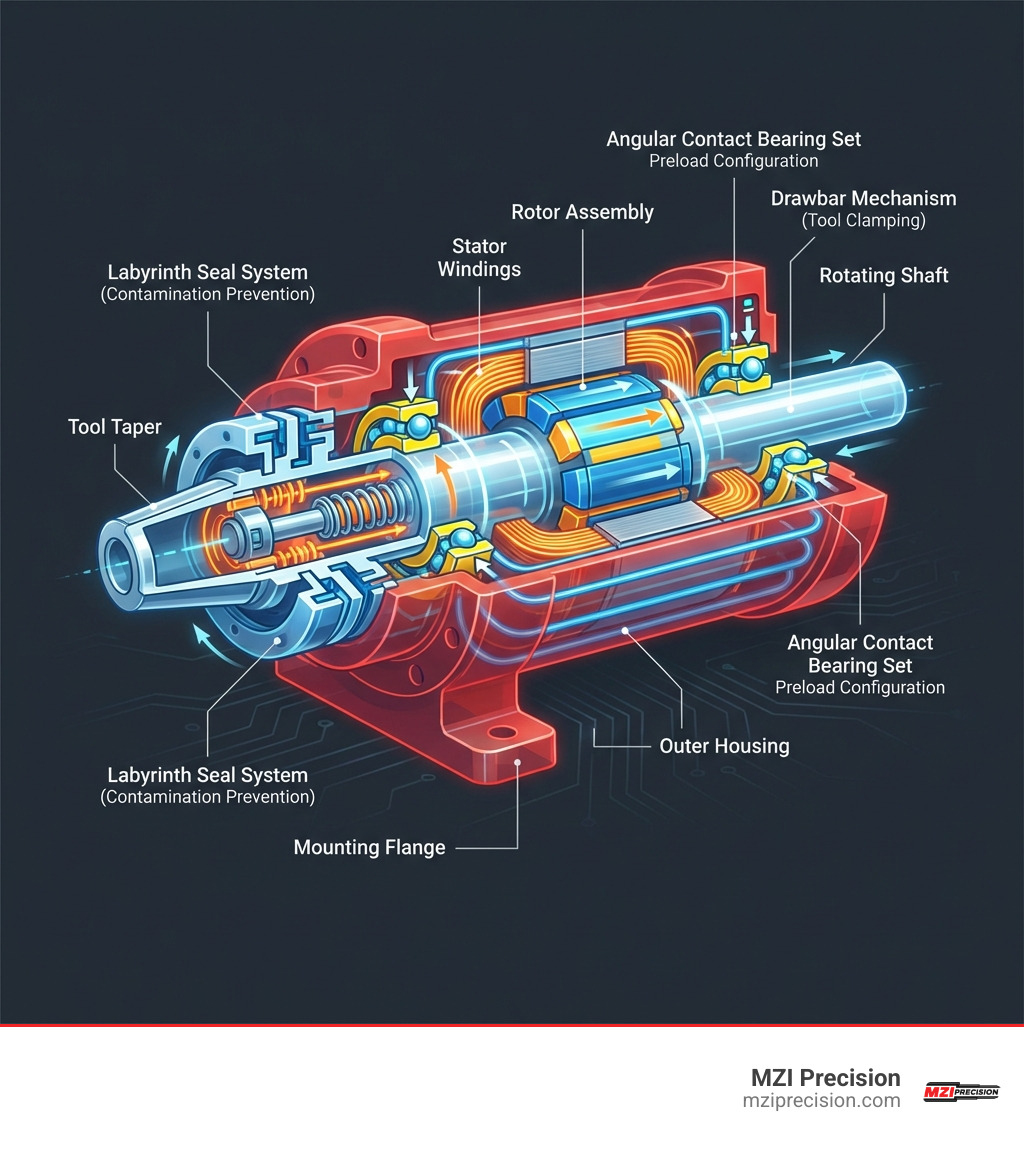

Key Components of an Industrial Manufacturing Spindle:

- Shaft – Transmits torque and houses the tool retention system

- Bearing System – Supports radial and axial loads while enabling rotation

- Housing – Integrates with the machine frame and provides vibration dampening

- Stator & Rotor – Create the electromagnetic field for motorized spindles

- Drawbar Mechanism – Secures tooling in place during operation

- Seals – Protect internal components from contamination

At the heart of every CNC MILLING MACHINE, grinding system, or precision lathe sits a spindle. This rotating assembly transforms electrical power into controlled cutting force. The spindle’s mounting system, or “suspension,” is key to managing the extreme forces, speeds, and thermal changes of machining.

For aerospace manufacturers and other precision industries, spindle reliability is crucial. It means maintaining micron-level tolerances while managing forces exceeding 5g. Since external contamination is the leading cause of premature spindle failure, proper design, mounting, and maintenance are essential to protect your investment and ensure part quality.

For more information, see our guide to SPINDLE REPAIR NEAR ME.

THE ANATOMY OF A HIGH-PRECISION INDUSTRIAL SPINDLE

A suspension spindle in industrial manufacturing is an engineering marvel designed for power and precision. This rotating assembly is the workhorse of machines like CNC machining centers and high-speed grinders. It holds and rotates a cutting tool or workpiece with extreme accuracy at high speeds, withstanding immense forces. It is the core engine of precision.

At MZI Precision, we understand these intricate components better than anyone. A typical suspension spindle is composed of several critical parts, each playing a vital role in its overall performance and longevity.

- Shaft: This is the central rotating element of the spindle. It transmits torque from the motor to the tool or workpiece and is designed to house the tool retention system, often with a taper for tool holders. Its integrity is paramount for maintaining concentricity and runout.

- Bearing System: Perhaps the most crucial part, the bearing system supports the shaft, allowing it to rotate smoothly while handling both radial (side-to-side) and axial (thrust) loads. The choice and configuration of bearings—angular contact, roller, or hydrostatic—are dictated by the spindle’s intended application, speed, and load requirements. These bearings must be preloaded precisely to eliminate internal clearance and ensure rigidity.

- Housing: The spindle housing is the outer shell that encases the internal components and provides the interface for mounting the spindle to the machine frame. It’s not just a protective cover; it’s engineered to be rigid, dissipate heat, and often incorporates features for cooling and vibration dampening.

- Drawbar Mechanism: For tool-holding spindles, the drawbar is a critical system that applies force to pull and hold the tool holder securely into the spindle taper. This mechanism ensures consistent tool retention and rigidity during machining.

- Stator & Rotor: In integral motor spindles, these components form the electric motor. The stator is the stationary part with wire windings, and when energized, it creates a magnetic field. The rotor, part of the spindle shaft, interacts with this field to generate the rotational torque. This direct drive eliminates belts and gears, allowing for higher speeds and greater efficiency.

- Seals: These vital components prevent contaminants (like coolant, chips, and dust) from entering the bearing system and retain lubricant within. Non-contact labyrinth seals are common for high-speed spindles, while contact seals might be used in lower-speed, higher-contamination environments.

For more information about how we can help keep your industrial machinery running at peak performance, please explore MORE INFO ABOUT OUR SERVICES.

WHAT ARE THE COMMON MATERIALS USED IN MANUFACTURING SPINDLES?

The performance and durability of a suspension spindle are heavily dependent on the materials from which its components are manufactured. We carefully select materials that can withstand extreme stresses, high temperatures, and continuous operation in demanding industrial environments.

- Hardened Steel Alloys: The spindle shaft and housing are typically crafted from high-grade steel alloys, such as chromium-molybdenum steel or case-hardened steel. These materials offer exceptional tensile strength, fatigue resistance, and hardness after heat treatment. This allows the shaft to resist bending and twisting under load, while the housing maintains its structural integrity.

- Ceramic Bearings: For high-speed applications, ceramic balls (often silicon nitride) are frequently used in angular contact bearings. Ceramic offers several advantages over steel, including lower density (reducing centrifugal forces at high RPMs), higher stiffness, superior hardness, and better heat resistance. These properties contribute to increased spindle life, higher speed capabilities, and improved thermal stability.

- High-Strength Composites: While less common for core structural components, advanced composites might be used in specific spindle designs for components like bearing cages or specialized housings where weight reduction and dampening characteristics are critical.

- Coating Technologies: Surface coatings play a crucial role in enhancing wear resistance, reducing friction, and providing corrosion protection. Common coatings include hard chrome, nickel plating, or advanced ceramic-metallic (cermet) layers applied to shaft journals or tool tapers.

- Thermal Stability: Materials are also chosen for their thermal stability. Minimizing thermal expansion is critical to maintaining precision, especially in high-speed spindles where heat generation is significant. Alloys with low coefficients of thermal expansion are often preferred for critical dimensions.

WHAT IS THE DISTINCTION BETWEEN A SPINDLE, A HOUSING, AND AN UPRIGHT IN INDUSTRIAL TERMS?

In industrial manufacturing, precise terminology is key. While some terms are used interchangeably, we understand the distinct roles of a spindle, its housing, and the machine frame. The machine frame’s structural support for the spindle assembly is sometimes referred to as an upright.

- A spindle is the complete rotating assembly itself. It comprises the shaft, bearings, and often the motor’s rotor and stator, designed to impart motion and power to a tool or workpiece. It is the active, rotating component.

- The housing is the stationary external structure that encapsulates the spindle’s internal components (shaft, bearings, motor elements). Its primary functions are to provide a rigid mount for the bearings, facilitate cooling, and serve as the interface for attaching the entire spindle unit to the machine. It’s the protective and structural shell of the spindle assembly.

- The machine frame (or main casting, column, or gantry) is the machine tool’s main structural component. This massive, rigid structure provides the foundation for all other components, including the spindle housing. The spindle housing is mounted to the machine frame, which integrates the suspension spindle into the larger system, ensuring its stability and positional accuracy.

Understanding these distinctions helps us accurately diagnose issues and provide precise industrial manufacturing spindle repair and rebuilding services.

HOW MOUNTING AND DESIGN CREATE THE “SUSPENSION SPINDLE”

The term “suspension spindle” refers to how a spindle is integrated into a machine tool to manage dynamic forces, vibrations, and thermal effects. This “suspension” is the sophisticated engineering that ensures smooth, rigid, and accurate operation under the immense stresses of machining. It focuses on vibration damping and load distribution.

The way a suspension spindle is mounted profoundly impacts its performance. Different mounting styles are chosen based on machine design, application, and required precision:

- Cartridge Style: This is a self-contained spindle unit that is pressed or bolted into a bore within the machine’s main casting or housing. The cartridge itself contains the shaft, bearings, and often the motor. This design allows for relatively easy replacement and maintenance. The “suspension” here comes from the precise fit and often elastic elements (like O-rings or specialized epoxies) used to dampen vibrations between the cartridge and the machine’s bore.

- Block Style: Here, the spindle’s housing is a robust, often rectangular block that is bolted directly onto a flat surface of the machine frame. This offers extreme rigidity and is common in heavy-duty milling applications.

- Flange Mount: Similar to block style, a flange-mounted spindle has a mounting flange integrated into its housing, which is then bolted to the machine structure. This provides a strong, stable connection.

These mounting configurations, along with advanced bearing technology and cooling systems, collectively form the “suspension” that allows the suspension spindle to maintain its precision under dynamic loads. Different machine types, from compact benchtop mills to massive gantry machines, incorporate spindles with designs optimized for their specific tasks.

HOW DOES A SPINDLE ATTACH TO OTHER MACHINE COMPONENTS?

Attaching a suspension spindle to a machine tool is a complex integration of mechanical, electrical, and fluid connections. It’s more than just bolting a part; it requires creating a rigid, stable, and functional interface to support high-performance operation.

- Mounting Flange or Bore Alignment: As discussed, the primary mechanical connection is typically via a mounting flange that bolts to a precision-machined surface on the machine frame, or a cartridge design that fits precisely into a bore. The alignment of this interface is absolutely critical. Any misalignment can introduce stresses, increase runout, and lead to premature bearing failure.

- Utility Connections: Modern industrial spindles require a lifeline of utilities to function.

- Coolant Lines: For spindles with through-spindle coolant capabilities, lines are connected to a rotary union at the rear of the shaft. This allows coolant to flow directly through the spindle and tool, providing efficient cooling and chip evacuation at the cutting interface.

- Pneumatic/Hydraulic Lines: These are essential for actuating the drawbar mechanism (for tool clamping and unclamping), operating automatic tool changers, or providing air purge to seals to prevent contamination.

- Electrical Connections: Integral motor spindles require robust electrical connections to power the stator windings. These include power lines, encoder feedback cables (for precise speed and position control), and thermistor wires (for temperature monitoring).

- Sensor Integration: Beyond basic utilities, many advanced spindles incorporate a variety of sensors. These can include vibration sensors, proximity sensors for tool detection, and additional temperature sensors, all integrated with the machine’s control system for real-time monitoring and adaptive control.

This intricate network of attachments ensures that the suspension spindle is not only firmly anchored but also fully functional and continuously monitored within its operational environment.

WHAT ARE THE KEY DESIGN CONSIDERATIONS FOR A SUSPENSION SPINDLE?

Designing a suspension spindle for industrial applications is a balancing act, prioritizing strength, speed, accuracy, and longevity. We consider numerous factors to ensure the spindle can perform its demanding role day in and day out.

- Force Management: Spindles must withstand tremendous forces generated during machining.

- Radial Loads: These are forces perpendicular to the spindle axis, primarily from cutting forces pushing against the tool. High radial stiffness is crucial to prevent deflection and maintain accuracy.

- Axial Loads: These forces act along the spindle axis, such as those from drilling, tapping, or face milling. The bearing system must be designed to handle significant thrust loads. The research indicates that design considerations for spindles include tolerance to vertical and horizontal forces, sometimes exceeding 5 times the acceleration of gravity, approximately 50 meters per second squared. This highlights the extreme demands placed on these components.

- Rotational Speed: Spindles operate across a vast range of speeds, from a few hundred RPM for heavy-duty milling to over 100,000 RPM for ultra-precision grinding. Bearing selection, lubrication method, and balancing become increasingly critical at higher speeds.

- Thermal Expansion: Heat generated by bearings, motors, and cutting processes can cause components to expand. Managing this thermal expansion is vital to prevent loss of precision and premature wear. Active cooling systems (liquid or air) and carefully chosen materials with low thermal expansion coefficients are employed.

- Stiffness: A rigid spindle is essential for precision machining. Stiffness minimizes deflection under load, leading to better surface finish, tighter tolerances, and extended tool life. This is achieved through robust shaft design, optimized bearing configurations, and high preload.

- Vibration Damping: Minimizing vibration is a core aspect of the “suspension” of a suspension spindle. Vibration can degrade surface finish, accelerate wear, and even damage the workpiece. Housing design, mounting methods, and specialized dampening materials all contribute to controlling vibration.

The design of a suspension spindle is a holistic process, aiming to create a robust, precise, and reliable component that can tackle the most challenging manufacturing tasks.

SPINDLE PERFORMANCE: FORCES, APPLICATIONS, AND EVOLUTION

A suspension spindle’s performance is defined by its ability to deliver consistent power and precision. We categorize applications by how they are driven (e.g., an internal motor) and the nature of the machining operation, such as high-speed material removal versus high-torque, heavy-duty cutting.

- Driven Applications (Motorized Spindles): These are typically integral motor spindles where the motor’s rotor is directly integrated onto the spindle shaft. They are designed to provide the rotational power for cutting tools or to rotate workpieces in applications like turning. The forces here include the torque required for cutting, as well as radial and axial loads from the cutting process itself.

- Non-Driven Applications (Tool-Holding Spindles): While still rotating, some spindles might be driven externally (e.g., by a belt from a separate motor) or are primarily designed to hold a tool or workpiece rigidly while another component provides the cutting action. The design focuses on rigidity, runout, and the ability to withstand cutting forces without deflection.

Whether it’s high-speed grinding or high-torque milling, the suspension spindle must exhibit exceptional force tolerance. The research highlights the need for tolerance to vertical and horizontal forces greater than those due to 5 times the acceleration of gravity. This translates directly to the demands on industrial spindles, especially during abrupt changes in cutting direction or heavy material removal.

Here’s a simplified comparison of design priorities:

| Feature | High-Speed Grinding Spindle | High-Torque Milling Spindle |

|---|---|---|

| Primary Goal | Precision surface finish, minimal heat, high RPM | Heavy material removal, rigidity, high cutting forces |

| Bearings | Ceramic, high-precision angular contact, grease/air-oil | Steel, larger angular contact/roller, oil-mist/grease |

| Cooling | Active liquid cooling, air purge | Often liquid-cooled, robust heat dissipation |

| Shaft Design | Lightweight, high stiffness-to-weight ratio, dynamic balance | Massive, maximum rigidity, large diameter |

| Motor Type | Integral motor (direct drive) | Integral motor or geared drive for torque multiplication |

| Housing | Vibration-dampening, thermally stable | Extremely rigid, heavy-duty construction |

| Force Tolerance | Focus on dynamic loads, thermal stability | Focus on static and dynamic cutting loads, shock resistance |

ARE THERE DIFFERENCES IN SPINDLE DESIGN FOR VARIOUS MANUFACTURING APPLICATIONS?

Absolutely! Just as a carpenter chooses the right tool for the job, we understand that a suspension spindle must be perfectly matched to its manufacturing application. The specific requirements of different machining processes lead to highly specialized spindle designs.

- Grinding Spindles: These are often the epitome of high-speed precision. Designed for minimal runout and exceptional surface finish, they typically feature ceramic bearings, integral motors capable of extremely high RPMs (often well over 50,000 RPM), and sophisticated liquid cooling systems to manage heat. Their rigidity is paramount to prevent deflection during abrasive processes.

- Milling Spindles: Milling involves significant cutting forces, requiring high torque and substantial rigidity. These spindles balance speed with power, often featuring robust steel bearings, powerful integral motors, and a strong drawbar mechanism to securely hold large cutting tools. They are designed to resist both radial and axial loads that can vary rapidly during contouring and pocketing operations.

- Lathe Spindles (Workpiece Holding): For turning operations, the spindle holds and rotates the workpiece. While they might not reach the extreme speeds of grinding spindles, they require immense rigidity and axial load capacity to withstand cutting forces, especially during heavy roughing. Precision in concentricity is vital to ensure perfectly round parts.

- Drilling Spindles: While often integrated into milling machines, dedicated drilling spindles (especially for small holes or specific materials) might prioritize higher speeds for efficient chip evacuation and tool life, or precise depth control.

Each application demands a unique blend of speed, torque, rigidity, and thermal management, which we expertly address in our industrial manufacturing spindle repair and rebuilding processes.

HOW HAS THE DESIGN AND ROLE OF THE INDUSTRIAL SUSPENSION SPINDLE EVOLVED?

The industrial suspension spindle has evolved from simple rotating shafts to today’s high-tech, intelligent components. This evolution is driven by the increasing demands for speed, precision, and automation in manufacturing.

- Early Belt-Driven Spindles: Historically, spindles were often driven by belts from a separate motor. This design was simple and allowed for speed changes via pulleys. However, belts introduced vibration, limited maximum speed, and required frequent maintenance.

- Gear-Driven Spindles: To achieve higher torque and more direct power transmission, gearboxes were integrated. These offered more power but came with increased complexity, heat generation, noise, and potential backlash issues that impacted precision.

- Integral Motor Spindles: A significant leap forward came with the development of integral motor spindles, where the motor’s rotor is built directly onto the spindle shaft. This eliminated belts and gears, dramatically increasing speeds, reducing vibration, improving power transmission efficiency, and enhancing dynamic response. This design is now standard for most high-performance CNC machines.

- Active Cooling Systems: As speeds and power increased, so did heat generation. Active liquid cooling systems became essential to maintain thermal stability, prevent expansion-induced inaccuracies, and prolong bearing life.

- Sensor Integration: Modern spindles are often equipped with an array of sensors—thermistors to monitor motor winding heat (as the research notes, monitoring thermistor outputs can prevent overheating), vibration sensors, and encoders for precise speed and position feedback. This integration allows for real-time monitoring, predictive maintenance, and adaptive control.

- Industry 4.0 and Smart Spindles: The latest evolution sees spindles becoming “smart” components. Through integrated sensors and connectivity, they can communicate their health, performance data, and even anticipate maintenance needs. This aligns with Industry 4.0 principles, enabling greater automation, efficiency, and preventative industrial manufacturing spindle repair.

This continuous evolution underscores why expertise in industrial manufacturing spindle repair and rebuilding is so critical today – keeping these advanced components running at their peak is essential for modern production.

SPINDLE MAINTENANCE, FAILURE, AND SAFETY

Even the most robust suspension spindle requires diligent maintenance and monitoring for long-term performance and safety. A spindle failure can halt production, incur significant costs, and pose safety risks. MZI Precision emphasizes proactive maintenance and expert industrial manufacturing spindle repair.

WHAT ARE THE SIGNS OF A FAILING OR DAMAGED SPINDLE?

Recognizing the early warning signs of a failing suspension spindle is crucial for preventing catastrophic damage and minimizing downtime. The most common indicators of trouble include:

- Increased Vibration: This is often the first and most noticeable symptom. A healthy spindle runs smoothly; excessive vibration, felt in the machine frame or heard, indicates bearing wear, imbalance, or alignment issues.

- Unusual Noise: Any new or escalating noises—whining, grinding, rattling, or clicking—are red flags. These sounds typically point to compromised bearings, lubricant starvation, or debris ingress.

- Overheating: A spindle that feels excessively hot to the touch (beyond its normal operating temperature) or triggers temperature alarms is a clear sign of trouble. This usually indicates bearing issues, inadequate lubrication, or a cooling system malfunction. The research mentions that thermistors placed on or near the stator monitor motor winding heat and can shut down the spindle if overheating occurs, highlighting the importance of this monitoring.

- Poor Part Surface Finish: If your machined parts suddenly exhibit chatter marks, poor surface texture, or dimensional inaccuracies, the spindle’s precision (often due to bearing wear or excessive runout) is likely compromised.

- Loss of Accuracy: Inability to hold tight tolerances, consistent dimensional errors, or difficulty achieving desired geometric features are strong indicators that the spindle’s internal components are worn or damaged. This could manifest as increased runout (deviation of the spindle axis from its ideal rotation).

- Runout Issues: Excessive radial or axial runout, measurable with precision instruments, indicates that the spindle shaft is no longer rotating concentrically or without wobble. This is a direct consequence of worn bearings or a bent shaft.

Ignoring these signs can lead to cascading failures, more extensive damage, and significantly higher industrial manufacturing spindle repair costs.

WHAT ARE THE TYPICAL MAINTENANCE REQUIREMENTS AND SAFETY IMPLICATIONS?

Proper maintenance is the lifeblood of any suspension spindle. By adhering to best practices, we can significantly extend spindle life, maintain precision, and ensure a safe working environment.

- Lubrication Schedules: Bearings require precise lubrication—either grease, oil-air mist, or oil circulation. Following the manufacturer’s recommended lubrication schedule and using the correct type and amount of lubricant is paramount. Too little leads to wear, too much leads to overheating.

- Contamination Prevention: As the research indicates, external contamination is the leading cause of premature spindle failure. Maintaining clean air purge systems, ensuring seals are intact, and keeping the machining environment free of excessive dust, chips, and coolant ingress are critical. A clean spindle is a happy spindle!

- Bearing Inspection: During planned maintenance, bearings should be inspected for signs of wear, pitting, or discoloration. While often sealed, the overall health of the bearing system can be inferred from noise, heat, and vibration analysis.

- Drawbar Force Testing: For tool-holding spindles, the drawbar’s clamping force can degrade over time. Regular testing ensures the tool is held securely, preventing tool pull-out during aggressive cutting, which can be both costly and dangerous.

- Catastrophic Failure Risk: A failing spindle, if left unaddressed, can lead to catastrophic failure. This might involve bearings seizing, the shaft breaking, or the tool being ejected at high speed. Such events pose significant safety risks to operators and can cause extensive damage to the machine tool itself.

- Unplanned Downtime: Beyond safety, a sudden spindle failure results in unplanned downtime, disrupting production schedules and leading to costly delays. Proactive industrial manufacturing spindle repair and rebuilding through MZI Precision helps mitigate these risks, ensuring your operations in California, Huntington Beach, and Los Angeles run smoothly.

CONCLUSION

The suspension spindle is the heart of industrial manufacturing, an epitome of precision engineering. From its internal anatomy of hardened alloys and ceramics to its mounting system that manages extreme forces, every aspect is engineered for performance. We’ve explored how spindles attach to machine tools, their key design considerations, and their evolution from simple belt-driven units to intelligent, sensor-laden powerhouses.

Understanding different spindle designs and recognizing early signs of wear are crucial for manufacturing excellence. Ignoring these warnings can lead to costly downtime, poor part quality, and safety hazards.

At MZI Precision, we pride ourselves on our expertise in industrial manufacturing spindle repair and rebuilding. Our commitment to precision and reliability ensures that your vital equipment operates at its peak. When your suspension spindle needs attention, choosing professional rebuilding offers significant benefits, restoring your spindle to OEM specifications, often at a fraction of the cost of a new unit.

Don’t let a failing spindle compromise your operations.

CONTACT US FOR A SPINDLE REPAIR QUOTE today, and let our expertise bring your equipment back to life. Our professional rebuilding services ensure your spindles deliver the precision and performance your business demands.