Spindle Router: The Ultimate 2025 Guide

Understanding the Critical Difference Between Spindles and Routers

The term Spindle Router highlights the fundamental choice manufacturers face when selecting cutting tools for their CNC machines. Here’s what you need to know:

Key Differences:

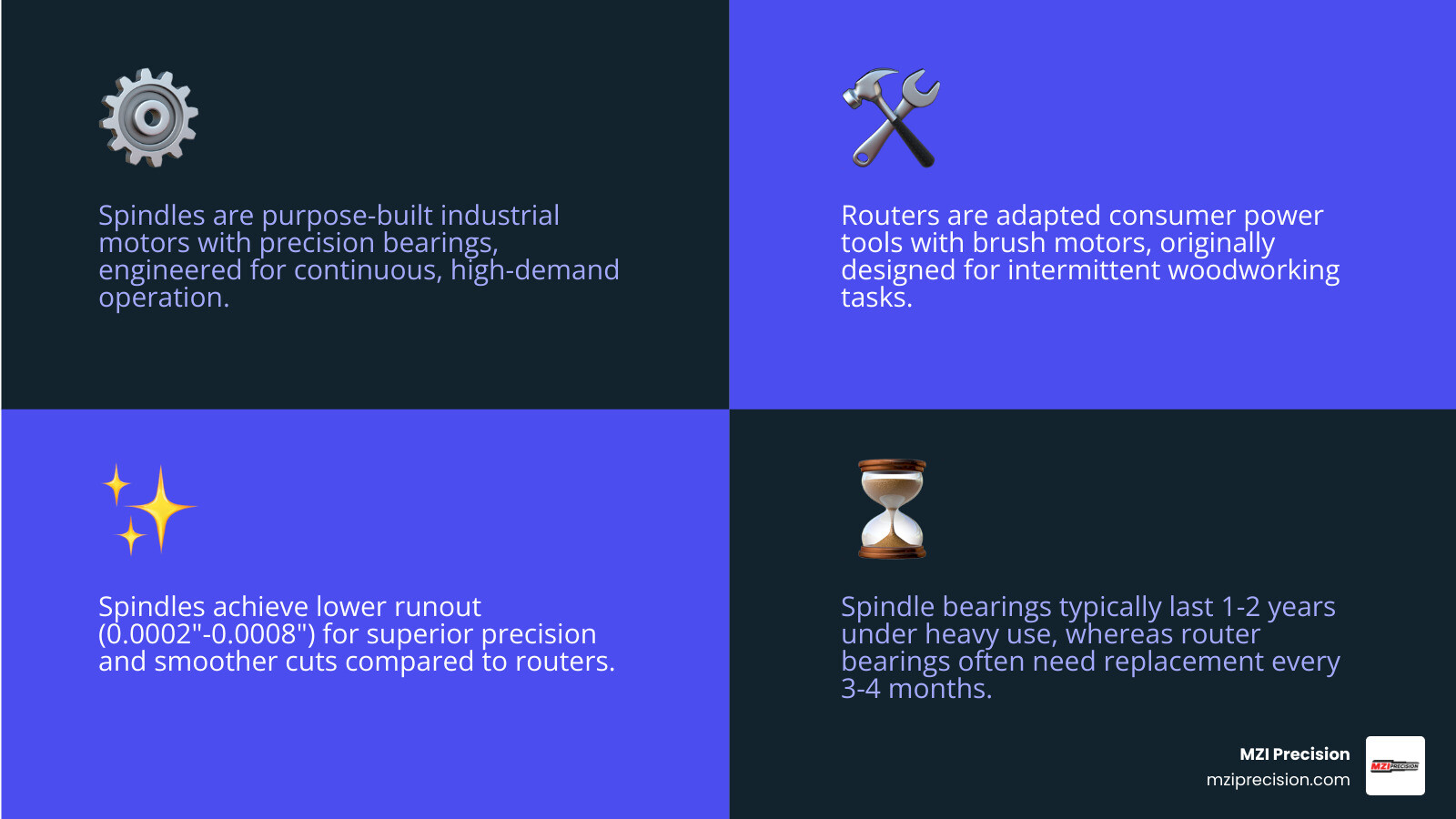

- Spindle: Purpose-built industrial motor with precision bearings, designed for continuous operation

- Router: Adapted consumer power tool with brush motors, intended for intermittent use

- Power: Spindles deliver sustained cutting power; routers provide peak power that drops under load

- Precision: Spindles have lower runout (0.0002″-0.0008″) vs routers with higher runout

- Lifespan: Spindle bearings last 1-2 years under heavy use; router bearings need replacement every 3-4 months

If the “almost unbearable noise” of trim routers on CNC machines is a familiar problem, you’re likely considering an upgrade to an industrial spindle system.

Why This Choice Matters:

This decision affects every aspect of manufacturing. Spindles offer precision bearings for less run-out and smoother, more accurate cutting. They maintain full torque at lower RPMs, making them ideal for heavy production.

Routers, though initially cheaper, are limited by their consumer-grade design. They bog down under heavy loads and create significant noise.

For aerospace and other precision manufacturing, this choice directly impacts part quality, cycle times, and overall equipment effectiveness.

What is a CNC Spindle and How Does it Differ from a Router?

Walk into a manufacturing facility, and you’ll hear the difference. A quiet hum from one CNC machine, a deafening roar from another. The quiet one likely uses an industrial spindle; the noisy one, a router.

This illustrates the core difference. A CNC spindle is purpose-built for industrial manufacturing, with every component engineered for continuous production. A router, however, is an adapted handheld power tool. Using it for industrial CNC work is like asking a bicycle to do a motorcycle’s job.

The core difference is design philosophy. Spindles are integrated systems with brushless motors, precision bearings, and robust cooling for continuous performance. Routers are mounted handheld power tools with brushed motors, standard bearings, and loud cooling systems not designed for continuous operation.

| Characteristic | Industrial CNC Spindle | Trim Router (Adapted for CNC) |

|---|---|---|

| Design | Purpose-built, integrated motor | Adapted handheld power tool |

| Motor Type | Brushless, often 3-phase | Brushed (wearable carbon brushes) |

| Bearings | High-precision, ceramic or precision steel | Standard, less precise |

| Runout | Very low (0.0002″ – 0.0008″) | Higher (less accurate) |

| Lifespan (heavy use) | 1-2 years between bearing replacements | 3-4 months between bearing replacements |

| Intended Use | Continuous, industrial, high-precision machining | Intermittent, lighter-duty tasks |

| Cooling | Air-cooled or liquid-cooled | Air-cooled (internal fan) |

| Noise Level | Significantly quieter, especially liquid-cooled | Very noisy |

The Anatomy of a Spindle

Inside an industrial spindle motor for CNC, precision engineering delivers the accuracy and reliability modern manufacturing demands.

The drive system is the heart of the operation. Motorized, belt-driven, or gear-driven systems deliver power differently, with motorized spindles offering great versatility for various cutting conditions.

The robust spindle housing protects internal components and provides the structural integrity needed for industrial applications.

The bearing system is where spindles truly shine. High-precision ceramic or steel bearings minimize friction and eliminate the wobble (runout) that can ruin a part.

The shaft and drawbar work together to hold the cutting tool firmly, reducing vibration and ensuring cuts stay true.

The result is lower runout for higher accuracy, leading to better parts and easier quality control.

The Limitations of a Router in Production

Routers were not designed for industrial manufacturing. While useful for light-duty work, they are not suited for a production environment.

Brush wear is a router’s Achilles’ heel. The carbon brushes constantly wear down, creating dust, losing efficiency, and causing regular downtime for maintenance.

The bearing failure rate is also high. Router bearings last only 3-4 months under heavy use, compared to 1-2 years for spindle bearings. This leads to unpredictable downtime and replacement costs.

A key difference is peak power vs. sustained power. Routers advertise high peak power but bog down under load. Spindles deliver consistent, sustained power across their RPM range.

Overheating is another problem during long production runs, as router fans aren’t designed for continuous operation. This leads to performance drops and reduced component life.

The limited durability of routers makes them unsuitable for demanding industrial environments, leading to higher long-term costs and frequent production interruptions.

Performance and Capability: Spindle vs. Router

When cutting material, the performance gap between a Spindle Router setup and a traditional router is stark. It’s like comparing a race car to a daily commuter—one is built for serious performance.

The difference isn’t just about power ratings; it’s about what happens when the tool meets the material.

Power, Torque, and Cutting Efficiency

Industrial spindles prove their worth here. While routers boast impressive peak horsepower, that power drops significantly under load.

Sustained cutting power is what separates the two. A quality spindle delivers consistent power throughout its RPM range, from 6,000 RPM for heavy cuts to 24,000 RPM for fine finishing.

The low RPM torque advantage is significant. Spindles maintain full torque at low speeds, which is critical for cutting tough materials like steel, a task routers cannot handle effectively.

Higher material removal rates are a direct result of this sustained power. In testing with maple hardwood, a 4 HP spindle achieved 95 cubic inches per minute. This translates directly to reduced cycle times and higher throughput. Modern manufacturing focuses on speed and precision, and spindles deliver both.

Precision, Accuracy, and Material Finish

In industrial manufacturing, precision is everything. This is where spindles dominate.

Precision bearings create a cutting environment where the tool follows the programmed path with incredible accuracy. The low runout of 0.0002″ to 0.0008″ means your cutting tool stays true to center, even under heavy loads.

Vibration reduction is another game-changer. A smooth, balanced spindle eliminates the chatter and vibration that plague router-based systems, extending tool life and improving part quality.

The result is a superior surface finish that often eliminates secondary operations, saving time and money on every part.

For machining hard metals like steel or titanium, only industrial spindles have the required power, rigidity, and precision. At this level, maintaining performance is crucial, making professional High Speed Spindle Repair services invaluable.

The material versatility of a quality spindle opens up possibilities with composites, ceramics, and exotic alloys that routers can’t touch. Plus, the significantly quieter operation creates a more productive work environment.

Choosing and Integrating an Industrial Spindle Router System

Selecting the right industrial Spindle Router system goes beyond raw horsepower. It’s about matching performance, precision, and practicality to your shop’s specific needs.

Key Factors for Selecting a Spindle Router

Start by defining your application requirements. The material—whether aluminum, steel, or composites—dictates the spindle’s capabilities. Tough metals like steel and titanium need spindles with high torque at low speeds. Softer materials may require higher RPMs with less force.

Power ratings in kilowatts (kW) guide your choice. A 0.8kW spindle might handle light engraving, while a robust 4kW unit can power through heavy milling. The RPM range works with power, offering from 6,000 RPM for heavy work up to 60,000 RPM for specialized tasks.

The cooling system choice is critical. Air-cooled spindles are simpler and cost less upfront. They handle most jobs well but are noisier and less suited for continuous use.

Liquid-cooled spindles run almost silently, manage heat exceptionally well during long sessions, and maintain precision under heavy loads. For continuous work with heat-sensitive materials like aluminum, liquid cooling is essential for quality and equipment life.

Tool holding relies on systems like ER-style collets, which grip cutting tools with unwavering determination. An ER20 collet system can hold tool shanks up to 1/2 inch, offering flexibility for various jobs.

Installation and VFD Integration

The Variable Frequency Drive (VFD) is the brain that makes your spindle smart. Most industrial spindles run on three-phase power, and the VFD bridges this gap by converting standard single-phase power into the three-phase power the spindle needs.

More importantly, the VFD provides precise speed control, responding instantly to CNC program commands. It smoothly adjusts RPM for delicate finishing passes or ramps up for aggressive material removal.

The electrical requirements are significant. A 4 HP spindle system needs a dedicated 30-amp, 220VAC circuit. A licensed electrician should handle the installation to protect your equipment and ensure safety.

Machine compatibility is also key; your CNC frame must handle the increased weight and cutting forces. Many modern spindle packages are “plug-and-play” systems with pre-programmed VFDs that work with common CNC controllers.

At MZI Precision, our Spindle for CNC Router solutions are designed with these real-world integration challenges in mind. We know the best spindle is only as good as how well it integrates with your existing setup.

Maintenance, Longevity, and Cost of a Spindle Router

While the upfront investment in an industrial Spindle Router system is higher, the long-term economics tell a different story. It’s an investment in reliability over frequent repairs.

The total cost of ownership for a spindle is dramatically lower than a router when factoring in downtime, replacements, and lost productivity. A router’s initial low cost is offset by frequent maintenance and noise.

Maintenance Differences for a Spindle Router

The maintenance requirements for spindles and routers are night and day.

Industrial spindles have a manageable, proactive maintenance schedule. Regular cleaning, periodic inspections of collets and nuts, and checking the cooling system are straightforward preventive care steps that pay dividends.

Router brush replacement, on the other hand, is a constant issue. The carbon brushes wear out, stopping production and causing frustrating delays.

The bearing lifespan difference is where spindles truly shine. Under heavy use, router bearings fail every three to four months. Precision spindle bearings can last one to two years, dramatically reducing labor costs and production interruptions.

For liquid-cooled spindles, cooling system checks are simple but essential. Monitoring coolant levels and using distilled water to prevent mineral buildup ensures quiet operation and superior thermal management.

The Value of Professional Spindle Repair

Even the most robust industrial spindle will eventually need service. When that time comes, professional repair is invaluable.

Maintaining precision during repair is everything. A poorly repaired spindle that can’t hold its original tolerances is useless. Professional expertise ensures every repaired unit performs to its original specifications.

Rebuilding spindles to OEM specifications means your repaired equipment integrates seamlessly back into your process. It performs like new, a critical factor for industries like aerospace and defense where precision is non-negotiable.

Extending lifespan through professional repair is often more cost-effective than replacement. Our CNC Router Spindle Repair services are designed to get your equipment back to peak performance quickly, minimizing downtime and maximizing your return on investment.

Frequently Asked Questions about Spindle Routers

What are the main benefits of upgrading from a router to a spindle on a CNC machine?

Upgrading from a router to an industrial Spindle Router system is one of the most impactful upgrades for a CNC machine. Key advantages include significantly greater power and torque, higher precision due to lower runout, much quieter operation, and superior durability for continuous industrial use. This leads to increased productivity and better quality parts.

What is a VFD and why is it necessary for a CNC spindle?

A Variable Frequency Drive (VFD) is the brain that allows your industrial spindle to work with your shop’s electrical setup and CNC controller. Its primary job is power conversion. Most industrial spindles require three-phase power, but many workshops have single-phase. The VFD converts single-phase to the necessary three-phase power. Its second function is precise speed control. A VFD allows you to dynamically adjust the spindle’s RPM to optimize cutting for different materials and tools.

How does a spindle’s cooling system affect its performance?

A spindle’s cooling system is vital for preventing overheating, which can ruin precision and shorten its life.

Liquid-cooled systems are the standard for serious manufacturing. They circulate coolant (typically distilled water) to maintain consistent temperatures during long jobs. This thermal stability is crucial for maintaining precision, as heat causes metal to expand, which can throw off tolerances.

Beyond performance, liquid-cooled spindles are remarkably quiet, making them ideal for facilities where noise is a concern.

Air-cooled systems use fans to dissipate heat. They are simpler and less expensive but can struggle with long, heavy cutting cycles. They are also noisier and can circulate dust in the work environment.

The cooling system you choose should match your application demands. For continuous, heavy-duty operations, liquid cooling provides the thermal management needed to maintain precision and extend equipment life.

Conclusion: Making the Right Choice for Your Manufacturing Needs

Choosing between an industrial Spindle Router system and an adapted trim router is a decision about your manufacturing operation’s future. This choice goes far beyond the initial price tag.

While routers seem budget-friendly, they are often more expensive long-term. Constant brush and bearing replacements, plus performance issues, lead to high costs in lost productivity and operator frustration.

Industrial spindles represent a different philosophy. Built for continuous operation, their precision bearings, sustained power, and high torque transform your shop’s capabilities. The quieter operation of liquid-cooled systems also improves the work environment.

The real impact is on your bottom line. Faster cycle times, better surface finishes, longer tool life, and tighter tolerances are all significant competitive advantages.

The investment in a spindle system pays dividends. Less downtime means more predictable delivery schedules. Quieter operation leads to happier employees. Better precision means fewer rejected parts and stronger customer relationships.

For manufacturers seeking to maximize uptime and precision, partnering with an expert in Spindle Repair Services like MZI Precision ensures that your equipment performs to OEM specifications throughout its lifecycle. We’ve seen how critical these components are across industries, from aerospace to solar energy.

When your spindle eventually needs attention, having a partner who understands the intricacies of spindle rebuilding makes all the difference. We don’t just fix a broken part; we restore the heart of your manufacturing process to its original specifications, ensuring years more of reliable service.

Ready to take the next step toward more efficient, precise manufacturing? Whether you’re considering your first spindle upgrade or need expert repair services for your existing equipment, we’re here to help you make the right choice for your operation.