Spindle Repair Services Los Angeles: Definitive 2025

Why Industrial Spindle Precision Matters for Los Angeles Manufacturing

For Los Angeles manufacturers, the precision of an industrial spindle is paramount. In critical sectors like aerospace, defense, and medical device manufacturing, these high-speed components are the heart of production. When a spindle fails, the consequences are severe, with downtime costs quickly escalating into thousands of dollars per hour.

Industrial manufacturing spindles often operate at speeds exceeding 30,000 RPM. At such high velocities, minor imperfections from bearing wear, contamination, or imbalance can lead to significant problems, including vibration, poor surface finishes, and expensive tool breakage.

Fortunately, most spindle issues are correctable. Opting for professional industrial manufacturing spindle repair is a cost-effective solution, typically costing about half as much as a new replacement. This process not only fixes the immediate problem but can also restore the spindle to performance levels that meet or exceed original factory specifications.

Recognizing the Red Flags: When Does Your Industrial Spindle Need Repair?

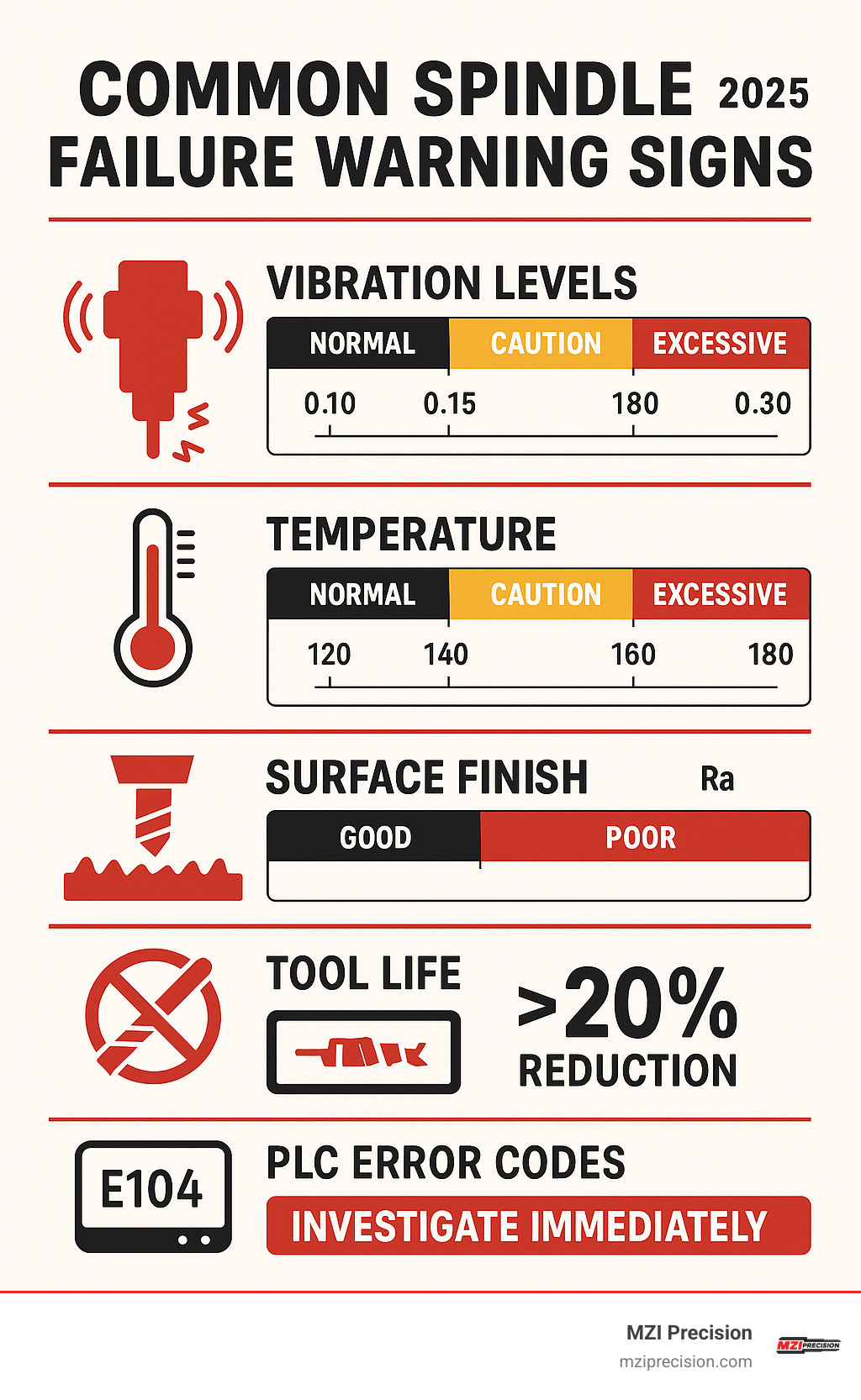

For Los Angeles manufacturers, catching spindle problems early is essential for preventing costly downtime. Industrial manufacturing spindles rarely fail without warning. Learning to recognize these signs can save your operation from catastrophic failure.

- Vibration Analysis: Every spindle has a unique vibration signature. Modern analysis tools can detect changes caused by bearing wear or contamination long before they become noticeable, serving as a critical early warning system.

- Unusual Noises: Grinding, squealing, or rattling sounds are clear indicators of trouble, often pointing to failing bearings or lubrication issues that Spindle Repair Services Los Angeles professionals can address.

- Overheating: Excessive heat is a major red flag, typically signaling failing bearings, lubrication breakdown, or cooling system problems. Ignoring it can lead to rapid component destruction.

- Poor Surface Finish: If finished parts are rough, chattered, or inconsistent, your spindle likely has runout or balance issues that compromise precision.

- PLC Error Codes: These are not suggestions but urgent messages from your machine indicating sensor, drive, or mechanical problems that require immediate attention.

- Reduced Tool Life: When cutting tools wear out or break frequently, excessive vibration or runout is often the root cause, putting stress on the entire system.

Common Causes of Industrial Spindle Failure

Understanding the root cause of failure is key to prevention. Most issues stem from a few common culprits.

- Contamination: Microscopic particles like metal chips or coolant residue can infiltrate seals and bearings, causing abrasive wear.

- Improper Lubrication: Using too much, too little, or the wrong type of lubricant can cause overheating and metal-on-metal contact.

- Bearing Failure: Often the result of contamination or lubrication issues, bearing failure is a common end-stage problem. Bearings in these spindles support rotation at extremely high speeds.

- Physical Damage: Collisions or mishandling can cause immediate and severe damage.

- Overloading: Pushing a spindle beyond its designed cutting forces, speeds, or feeds accelerates wear.

- Drawbar Issues: A worn drawbar can fail to secure tool holders properly, leading to poor accuracy and potential damage.

For more detailed information about these failure modes, Machine Design offers a comprehensive Spindle Failure 101 – Quick Guide to Causes and Solutions that’s worth bookmarking. Acting on these warning signs quickly can mean the difference between a minor repair and a complete spindle replacement.

The Comprehensive Industrial Spindle Repair Process Explained

A professional industrial manufacturing spindle repair follows a meticulous, multi-stage process to ensure a return to OEM-level performance.

- Diagnosis: Technicians use advanced diagnostic tools to identify the root cause of the failure, analyzing vibration, runout, clamp force, and sensor data.

- Disassembly and Cleaning: Each component is carefully removed and thoroughly cleaned to strip away contamination and reveal its true condition.

- Component Inspection: Every part, including bearings, shafts, and drawbars, is measured against micron-level tolerances.

- Precision Balancing: Spindles operate at extremely high speeds, where the smallest imbalance causes major issues. Components are dynamically balanced to tight tolerances (typically 0.3 G’s or better) to ensure smooth operation.

- Bearing Replacement: Worn bearings are replaced with high-quality units, such as ABEC 7 precision bearings, that meet or exceed factory specifications.

- Reassembly: The spindle is reassembled in a cleanroom environment to prevent contamination, with each component aligned and torqued to precise specifications.

- Run-in Testing and Quality Control: The repaired spindle undergoes rigorous testing at various speeds and loads while monitoring temperature and vibration. A final inspection verifies that it meets or exceeds OEM standards.

For more detailed information about our comprehensive approach, check out our CNC Spindle Repair services.

Types of Industrial Spindle Repair Services Available

Industrial manufacturing spindle repair includes a range of specialized services:

- Taper Grinding: Restores the critical tool holder seating area after damage from crashes, correcting runout and improving accuracy.

- Drawbar Repair: Fixes worn or faulty drawbars to ensure proper tool clamping and prevent poor accuracy or tool pull-out.

- Motor Rebuilds: For motorized spindles, this service addresses electrical issues by rewinding stators, replacing rotors, and repairing other electrical components.

- Spindle Rebuilding: A complete restoration that can upgrade older spindles with modern components to improve performance and extend their service life.

- Precision Balancing: A vital service that minimizes vibration, extends bearing life, and improves surface finish quality.

To learn more about our comprehensive industrial capabilities, visit our Industrial Spindle Repair page.

Why Los Angeles Industries Rely on Specialized Industrial Spindle Repair Services

In Los Angeles’s demanding manufacturing landscape, which includes the aerospace, defense, and medical device sectors, precision and uptime are non-negotiable. A failed spindle can halt production, jeopardize deadlines, and compromise quality where tolerances are measured in microns.

This is why specialized industrial manufacturing spindle repair is critical. Key benefits include:

- Minimizing Downtime: Expert repair services can often restore a spindle in 3-5 days, a fraction of the time it might take to procure a new one.

- Extending Machine Lifespan: Professional repair addresses the root cause of failure, extending the life of the entire machine and protecting significant capital investments.

- Cost-Effectiveness: Repairing a spindle typically costs about 50% of a replacement, freeing up capital for other business needs.

- Access to Expertise: Specialized technicians possess the knowledge and equipment to restore complex components to original specifications, a capability most manufacturers lack in-house.

- Improved Performance: Through precision balancing and high-quality components, a repaired spindle can often perform better and more reliably than it did before the failure.

The True Cost: Industrial Spindle Repair vs. Replacement for Los Angeles Businesses

When a spindle fails, the choice between repair and replacement has significant financial implications. While buying new seems straightforward, a closer look at the numbers reveals that industrial manufacturing spindle repair is often the smarter decision.

![TABLE] COMPARING THE TYPICAL COSTS, TURNAROUND TIMES, AND WARRANTIES FOR INDUSTRIAL SPINDLE REPAIR VERSUS FULL REPLACEMENT – SPINDLE REPAIR SERVICES LOS ANGELES INFOGRAPHIC ](https://images.bannerbear.com/direct/4mGpW3zwpg0ZK0AxQw/requests/000/102/752/284/5R7NlW8nEzjb8pEGzmvbxgLyP/c84ff6d29eb641eadc20c1e765bcf4c7795cb5a2.jpg)

| Feature | Industrial Spindle Repair | New Spindle Replacement |

|---|---|---|

| Typical Cost | ~50% of a new spindle | 100% of the new spindle cost |

| Turnaround | 3-10 business days (often faster for emergency repairs) | Varies (immediate if in stock, weeks to months if not) |

| Warranty | 12-24 months (industry-leading options available) | Typically 12 months (standard OEM warranty) |

| Longevity | Restores to OEM specs or better, extends machine life | New lifespan, but original machine issues may persist |

| Benefits | Cost-effective, fast, environmentally friendly | Guaranteed new, but higher upfront cost |

For Los Angeles manufacturers, the combination of lower costs, faster turnaround, and comparable or superior warranties makes repair the clear winner. It’s a proven process that gets you back to production quickly and affordably.

Choosing the Right Partner: What to Look for in an Industrial Spindle Repair Provider

Selecting the right provider for Spindle Repair Services Los Angeles is crucial for your business. The stakes are high, so look for a partner with a proven track record.

Key evaluation criteria include:

- Experience and Specialization: Seek providers with decades of experience and specific expertise in demanding industries like aerospace and medical devices.

- Technical Capabilities: A top-tier facility should have in-house capabilities for diagnostics, precision balancing, grinding, and machining, all within a cleanroom environment.

- Turnaround Time: Look for a commitment to fast turnarounds, such as 3-5 business days for standard repairs, with emergency services available.

- Warranty: A solid warranty of at least one year (with 24-month options being a sign of a top provider) shows confidence in the quality of the repair.

- Quality of Parts: The provider must use high-quality replacement components, such as ABEC 7 precision bearings, to ensure longevity and performance.

- Customer Testimonials: Positive reviews that highlight communication, transparency, and reliability are strong indicators of excellent service.

At MZI Precision, we believe choosing a repair partner is about building a relationship to keep your operation running smoothly. More info about our company demonstrates our commitment to excellence.

Key Factors for Choosing Spindle Repair Services Los Angeles

Beyond the basics, look for these indicators of a superior repair service:

- OEM Specification Adherence: The service must restore your spindle to meet or exceed original manufacturer specifications.

- In-House Capabilities: A single facility handling all aspects of the repair ensures better quality control and faster service.

- Root Cause Failure Analysis: A great partner doesn’t just fix the symptom; they identify and address the underlying cause to prevent future failures.

- Precision Balancing Standards: Insist on dynamic balancing to extremely tight tolerances (0.3 G’s or better) to minimize vibration and extend bearing life.

Understanding how to prevent spindle failures in the first place can save you significant time and expense. For detailed insights into proactive maintenance strategies, you can explore Information on Spindle Failure Prevention.

Proactive Protection: Maintenance Tips to Prevent Industrial Spindle Failures

Most spindle failures are preventable. A proactive maintenance strategy can significantly reduce your industrial manufacturing spindle repair costs and boost productivity for your Los Angeles operations.

- Regular Inspections: Implement daily visual checks and more detailed weekly or monthly inspections. Look for leaks, measure tool clamp force and runout, and listen for unusual noises. Use vibration analysis tools to detect subtle changes before they become major problems.

- Proper Lubrication Schedules: Adhere strictly to the manufacturer’s recommendations for the type, amount, and frequency of lubrication. Using clean, high-quality lubricant is critical for bearing health.

- Operator Training: Train operators to recognize early warning signs like temperature changes or unusual vibrations. Proper tool handling techniques are also essential to prevent damage to the spindle taper.

- Adhering to Operational Limits: Always operate the spindle within its specified maximum speed, torque, and load ratings. Pushing a spindle too hard with aggressive cutting parameters will generate excessive heat and stress, leading to premature failure.

- Monitoring and Logging: Use built-in machine monitoring systems to track temperature, vibration, and power consumption. Keep detailed maintenance logs to identify patterns and predict potential issues.

- Maintaining a Clean Environment: Keep the area around your spindles free of contaminants like coolant, metal chips, and dust. Ensure machine enclosures are sealed and coolant systems are clean.

Investing in a formal preventative maintenance program is far more cost-effective than dealing with emergency repairs. A small investment in proactive care can save you days of downtime and thousands of dollars.

Conclusion: Ensuring Peak Performance for Your LA-Based Operations

In the Los Angeles manufacturing sector, maintaining peak equipment performance is essential. This guide has covered the critical aspects of industrial manufacturing spindle repair, from identifying warning signs like vibration and overheating to understanding the detailed repair process.

For LA’s aerospace, defense, and medical industries, the benefits of professional Spindle Repair Services Los Angeles are undeniable. It is a cost-effective strategy that minimizes downtime, extends machine lifespan, and often results in a spindle that performs better than its original specifications.

Choosing the right partner is key. Look for a provider with deep experience, comprehensive in-house capabilities, and a commitment to quality demonstrated by a strong warranty. While preventive maintenance is your best defense, having an expert repair service ready is crucial for when issues inevitably arise.

At MZI Precision, we understand that your spindles are the heart of your operation. Our industry-leading expertise and commitment to quality ensure we treat every repair with the urgency and precision it deserves. We know that in Los Angeles manufacturing, there is no room for error.

Don’t wait for a minor issue to become a major crisis. Take control of your production schedule with proactive maintenance and expert repair services.

Contact us for expert spindle repair services today, and let’s keep your Los Angeles operation spinning smoothly toward success.