Spindle bearing lubrication: Optimal Guide 2025

Why Spindle Bearing Lubrication is Critical for Industrial Manufacturing

Spindle bearing lubrication is essential for maintaining precision and extending the life of industrial manufacturing equipment. Proper lubrication reduces friction, prevents heat buildup, and ensures your spindles operate at peak performance.

Quick Answer for Spindle Bearing Lubrication:

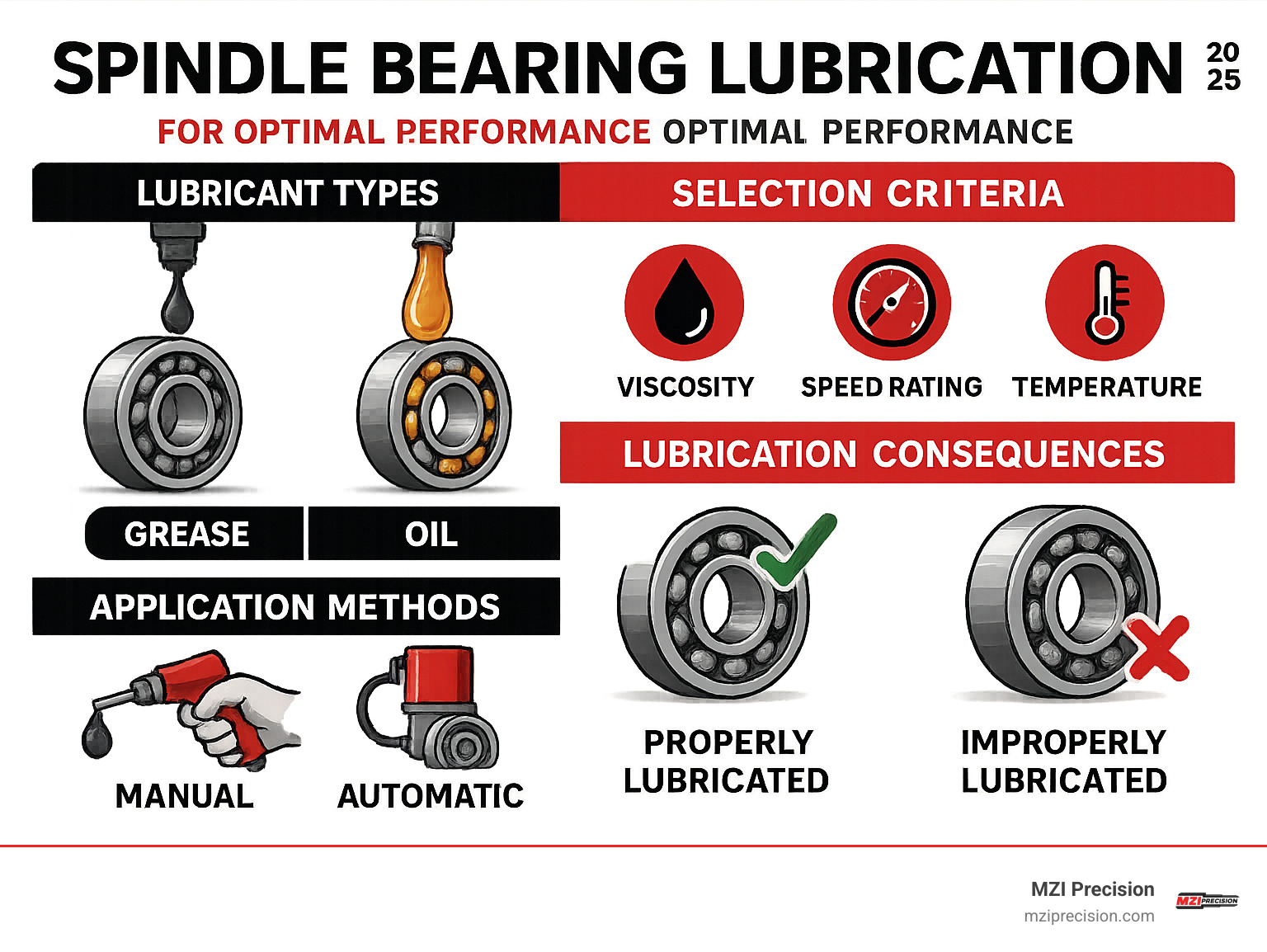

- Primary function: Maintains a protective film between rolling elements and bearing raceways

- Main lubricant types: Grease (most common) and oil systems

- Key selection factors: Viscosity, speed rating, temperature range, and load capacity

- Application methods: Manual systems, automatic injection, oil mist, or air-oil systems

- Critical mistake to avoid: Using wrong lubricant type or incorrect amounts

For equipment rotating at thousands of RPMs, proper lubrication is the difference between reliable operation and costly failures. Without it, rolling elements make direct contact with raceways, creating heat, wear, and ultimately complete bearing failure.

Poor lubrication practices lead to severe consequences, including rolling element deterioration, raceway damage, and cage fragmentation. This often results in complete spindle failure and unexpected downtime, not just bearing replacement.

Conversely, proper lubrication delivers measurable benefits. Well-maintained spindle bearings provide thousands of trouble-free operating hours while maintaining the tight tolerances essential for precision manufacturing.

Understanding Lubricant Types and Properties

Choosing the right lubricant for an industrial manufacturing spindle is a critical decision. Spindle bearing lubrication primarily involves two types: grease and oil. Understanding their properties and applications is key to preventing costly downtime.

Grease vs. Oil for Spindle Bearings

Grease is an engineered mixture designed to stay in place. Its composition includes:

- Base oil: The primary lubricating component that creates a protective film.

- Thickeners: Materials like metallic soaps or polyurea that give grease its consistency.

- Additives: Improve properties like corrosion protection or extreme pressure (EP) resistance.

Oils for spindles are either mineral oils (cost-effective, for high-speed use) or synthetic oils (premium, for superior temperature stability).

When to use grease: Grease is ideal for most applications with moderate to high speeds (up to ~200,000 Dn), especially where sealing is difficult. Many spindles are “greased for life,” meaning the grease should last the bearing’s expected lifespan under normal conditions, though contamination can still be an issue.

When to use oil: Oil is necessary for very high-speed operations (beyond 200,000 Dn) or when constant heat dissipation and contamination flushing are required. Oil systems offer precise control and can be filtered for cleanliness.

Key Selection Criteria for Spindle Bearing Lubrication

Selecting the right lubricant requires evaluating several factors that impact spindle performance.

- Viscosity: The lubricant’s thickness is the most critical factor. It must be matched to the spindle’s speed—too thin and it won’t protect, too thick and it creates drag and heat.

- Speed factor (nDm value): This value (bearing diameter x RPM) determines if a lubricant can handle the speed. Exceeding a lubricant’s nDm rating leads to overheating and failure.

- Operating temperature range: The lubricant must maintain its properties from a cold startup to full operating heat.

- Load capacity: For heavy cutting loads, lubricants with extreme pressure (EP) additives are needed to prevent metal-to-metal contact.

- Corrosion resistance: Quality lubricants contain anti-rust additives to protect bearing surfaces from moisture and contaminants.

- Material compatibility: The lubricant must be compatible with seals, gaskets, and cage materials to prevent damage like swelling or shrinking.

Manual vs. Automatic Lubrication Systems

For spindle bearing lubrication, the delivery method is as important as the lubricant itself. The choice between manual and automatic systems involves balancing initial cost against long-term reliability and precision.

Manual Lubrication Systems: Pros and Cons

Manual lubrication involves a technician physically applying lubricant. It is a traditional approach common in simpler operations.

Pros:

- Cost-Effectiveness: Minimal initial equipment investment (grease guns, oil cans).

- Simplicity: No complex systems or specialized training required for the maintenance team.

- On-Demand Application: Technicians can immediately address a bearing that shows signs of needing lubrication.

Cons:

- Risk of Human Error: Applying too much or too little lubricant is a common and damaging mistake.

- Contamination Potential: Opening a bearing housing for manual application increases the risk of introducing dust and debris.

- Inconsistent Application: Different technicians may apply lubricant differently, leading to uneven wear and unpredictable bearing life.

Automatic Lubrication Systems: Pros and Cons

Automatic systems use pumps and distribution networks to deliver measured amounts of lubricant at set intervals.

Pros:

- Precision and Consistency: Delivers the exact amount of lubricant at the right time, every time, leading to predictable performance and longer life.

- Reduced Labor: Frees up maintenance staff for other critical tasks.

- Improved Safety and Cleanliness: Reduces worker access to dangerous areas and minimizes contaminant exposure in a closed system.

Cons:

- Higher Initial Cost: Significant investment in pumps, controllers, lines, and sensors.

- System Complexity: The system itself requires maintenance. Blocked lines, failed injectors, or controller issues can cause lubrication failure.

- Shifted Maintenance: Requires technical skills to monitor system pressure, check lines, and calibrate controllers.

Comparison of Manual vs. Automatic Lubrication Systems

| System Type | Initial Cost | Consistency | Maintenance | Best For |

|---|---|---|---|---|

| Manual | Low | Inconsistent | High manual effort, risk of human error | Simple, low-speed, or infrequently used spindles where budget is a primary concern |

| Automatic | High | High | Lower manual effort, but requires system monitoring | High-precision, high-speed, continuously operating spindles where consistent performance and extended lifespan are critical |

The investment in an automatic system often pays for itself through reduced downtime for high-speed, high-precision spindles. For simpler applications, manual lubrication can be effective if performed correctly and consistently.

Advanced and Specialized Lubrication Methods

For the most demanding industrial manufacturing applications, standard spindle bearing lubrication methods may not suffice. High-speed operations and specialized designs often require more sophisticated systems to achieve peak performance and accuracy.

High-Speed Oil Lubrication Systems

Oil-based lubrication is essential for high-speed spindles, as it effectively dissipates heat and provides a continuous supply of fresh lubricant.

- Oil Mist Lubrication: Creates a continuous stream of fine oil droplets suspended in air. It’s a cost-effective method for continuous lubrication but can cause air contamination and is prone to venturi clogging.

- Oil Injection (Air-Oil) Lubrication: A more refined system that meters precise oil drops into an air stream. This method enables very high speeds with less oil consumption. However, oil can settle in lines during inactivity, and injector failures may go undetected.

- Under-Raceway Lubrication: A highly specialized method delivering oil directly to bearing raceways via internal channels. It allows for extreme speeds and precision but involves proprietary bearings and complex, costly systems that require exact calibration.

Specialized Bearing and Lubrication Designs

Some applications use bearings that operate on different principles than standard rolling element bearings.

- Hydrostatic Bearings: Use externally pressurized fluid (usually oil) to create a stiff film that completely separates moving surfaces. This eliminates wear and provides exceptional stiffness and load capacity, but the required hydraulic equipment makes them complex and expensive.

- Hydrodynamic Bearings: Generate a lubricating film through the shaft’s own rotation. They offer good radial accuracy for applications like precision grinding but require diligent maintenance and have lower rigidity than roller bearings.

- ‘Greased-for-life’ Bearings: These sealed bearings are pre-packed with grease and require no maintenance. They are reliable but have speed limitations compared to oil systems. External contamination can still shorten their lifespan, and replacement grease cartridges can be expensive.

For more detailed technical information about high-speed greases and their properties, technical data on high-speed greases provides valuable insights into the specialized lubricants used in these demanding applications.

A Practical Guide to Spindle Bearing Lubrication and Maintenance

Proper application and maintenance are critical for effective spindle bearing lubrication. Even the best lubricant is useless if applied incorrectly.

How to Apply Spindle Lubricants Correctly

Careful application is the key to a long-lasting spindle.

- Cleanliness is paramount: Work in a spotless area to prevent contamination. Even a tiny speck of dust can damage precision surfaces. New bearings should be washed with solvent, dipped in spindle oil, and dried on clean towels.

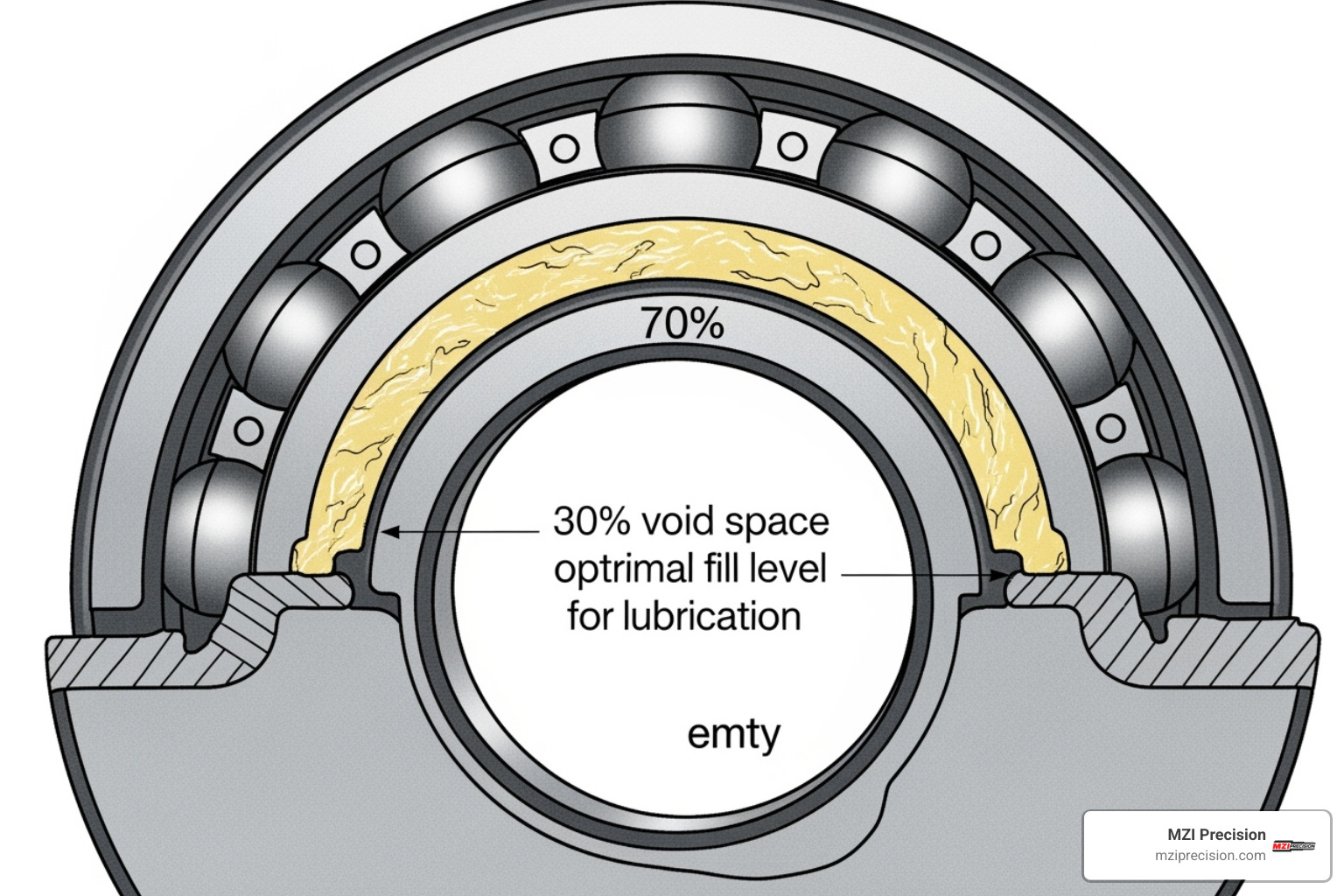

- Use the proper amount: Both under-greasing and over-greasing are destructive. Under-greasing causes metal-to-metal contact, while over-greasing creates excess heat and pressure that can blow out seals. The ideal amount for grease is filling about 30% of the bearing’s internal volume.

- Proper packing technique: For open bearings, work the grease thoroughly into all elements and hand-turn the bearing to distribute it evenly.

- Purge old grease: When re-lubricating, always purge the old grease. If switching grease types, completely clean out all traces of the old product first.

- Follow run-in procedures: After lubrication, gradually increase spindle speed per the manufacturer’s recommendations to allow the lubricant to distribute properly.

Creating a Maintenance and Re-lubrication Schedule

A proactive maintenance schedule prevents costly failures. The frequency of re-lubrication depends on speed, load, temperature, and environment.

Be aware of signs that lubrication is needed:

- Increased noise: Grinding, squealing, or humming sounds.

- Liftd temperature: Detectable by touch or with thermal imaging.

- Vibration analysis: Can reveal subtle changes in bearing health.

- Visual inspection: Look for lubricant leakage, discoloration, or hardening.

Start with the manufacturer’s recommendations and adjust based on real-world conditions. Annual professional spindle services can help identify issues before they become critical.

Common Mistakes in Spindle Bearing Lubrication to Avoid

Most spindle failures are preventable. Avoid these common errors:

- Using the wrong lubricant: Incorrect viscosity or incompatible base oils can quickly destroy a bearing.

- Mixing incompatible greases: This can cause chemical reactions that ruin the lubricant’s properties.

- Contamination: Allowing dust or debris into the lubricant during storage or application.

- Ignoring manufacturer specifications: Always follow guidelines for lubricant type, quantity, and intervals.

- Over- or under-lubrication: Both cause premature failure.

- Reusing old oil: Used oil contains microscopic metal particles that act as an abrasive.

- Failing to clean bearings: Always clean bearings before applying new grease, especially when switching types.

- Neglecting automatic system lines: Check for kinks, clogs, or component failures that can starve bearings of lubricant.

Frequently Asked Questions about Spindle Lubrication

Here are answers to three common questions about spindle bearing lubrication that we encounter at our repair facility.

What are the consequences of using the wrong amount of grease?

Using the incorrect amount of grease is a leading cause of bearing failure. Both too little and too much are destructive.

- Too little grease fails to create a sufficient protective film, leading to direct metal-to-metal contact. This causes a rapid increase in friction and temperature, resulting in catastrophic bearing failure.

- Too much grease is equally damaging. Over-packing a bearing causes it to churn through the excess lubricant, which generates heat and pressure. This can damage seals, cause leaks, and lead to premature bearing fatigue. The recommended amount is to fill approximately 30% of the bearing’s internal volume.

How do I know which lubricant viscosity to use for my spindle?

Always start with the manufacturer’s specifications. The spindle designer has determined the optimal viscosity for your specific application.

If specs are unavailable, follow this general rule: faster speeds require thinner (lower viscosity) lubricants, while heavier loads require thicker ones. High-speed spindles need lower viscosity lubricants to minimize drag and heat. You must also consider the operating temperature, as the lubricant’s viscosity changes with temperature. The chosen lubricant must provide a stable protective film across the entire operating range.

When in doubt, consult a lubrication specialist or a spindle repair expert.

Can different types of spindle bearing grease be mixed?

No, never mix different types of grease. Greases use different thickener systems and additives that are often incompatible. Mixing them can trigger chemical reactions that destroy the lubricant’s properties, causing it to become too thin or to harden into an abrasive paste.

If you must switch grease types, you must thoroughly clean and purge every trace of the old grease from the bearing and housing. This extra step is critical to prevent a lubrication-related failure and costly downtime.

Conclusion

Spindle bearing lubrication is more than a maintenance task; it’s a foundational element of operational reliability and precision. Every successful cut and every day of uptime depends on a thin film of lubricant protecting critical components.

As we’ve covered, the right choice between grease and oil, the precision of automatic systems, and the application of proper techniques are all crucial. Correct lubrication practices extend bearing life by thousands of hours and maintain tight manufacturing tolerances. Conversely, simple mistakes like using the wrong lubricant or incorrect amount can lead to rapid, costly failures.

At MZI Precision, we frequently see catastrophic failures that stem from simple oversights. By understanding and implementing the principles in this guide, you can turn proper lubrication into a competitive advantage, resulting in quieter machines, tighter tolerances, and reduced downtime.

For complex lubrication challenges or when a spindle shows signs of trouble, a professional assessment is invaluable. Our experienced team has diagnosed every type of lubrication failure and can restore your equipment to peak performance, saving you from expensive long-term problems.

Learn more about our expert spindle repair and rebuilding services