Servo Motor Preventive Maintenance: 7 Powerful Tips 2025

Why Servo Motor Preventive Maintenance Is Critical for CNC Operations

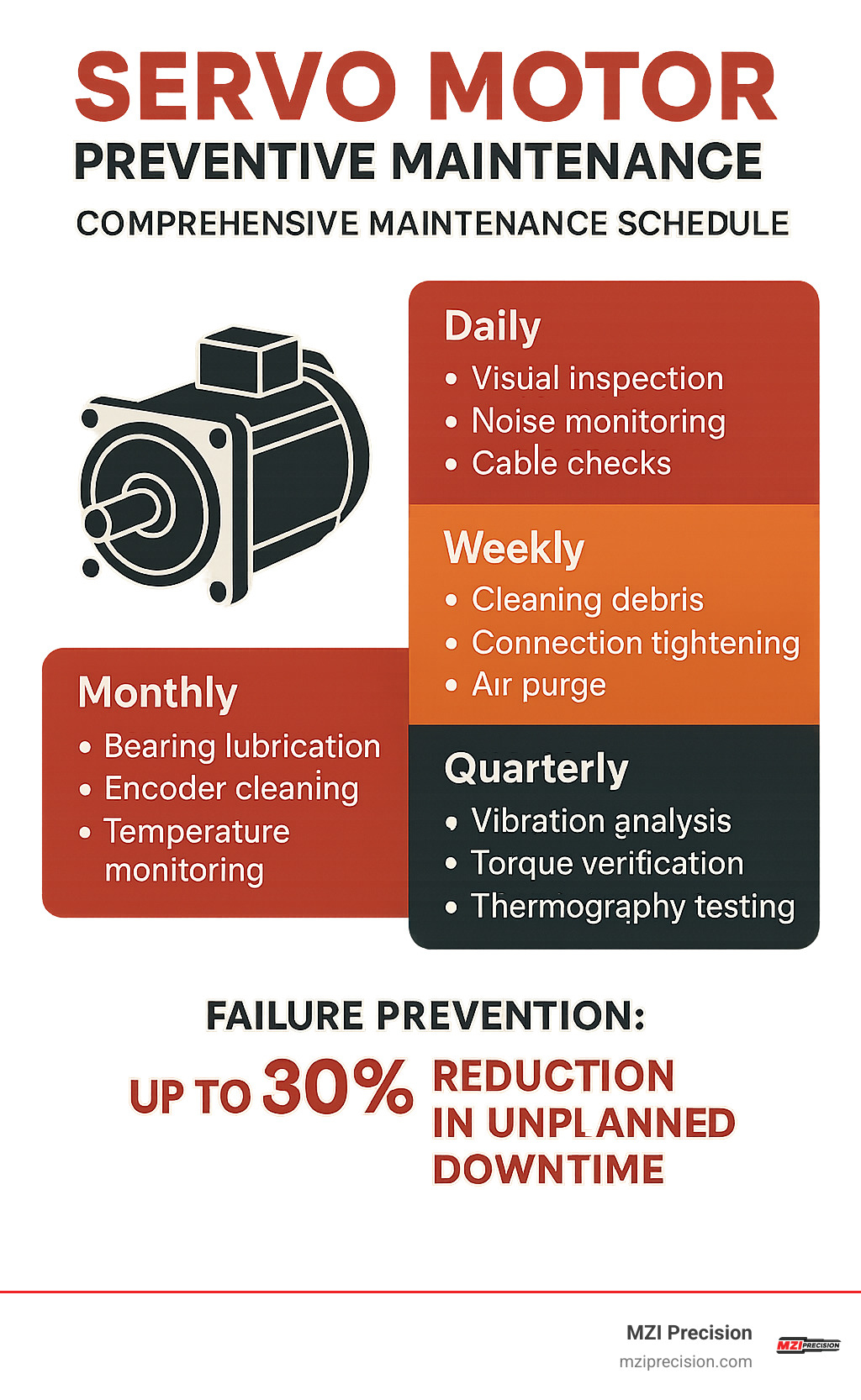

Servo motor preventive maintenance is essential for keeping your CNC machines running at peak performance and avoiding costly downtime. Here’s what you need to know:

Essential Servo Motor Preventive Maintenance Tasks:

– Daily: Visual inspection, noise monitoring, cable checks

– Weekly: Cleaning debris, connection tightening, air purge

– Monthly: Bearing lubrication, encoder cleaning, temperature monitoring

– Quarterly: Vibration analysis, torque verification, thermography testing

– Annually: Complete electrical testing, firmware updates, calibration

Servo motors are the heart of precision CNC operations, providing the closed-loop control that delivers positioning accuracy within microns. Unlike standard motors, servo systems combine high-speed operation with heavy loads and continuous duty cycles—making them more susceptible to wear and failure than other machine components.

The stakes are high. Research shows that for every 10 °C increase in motor operational temperature above insulation class limits, the life of the internal winding insulation is cut in half. Meanwhile, bearing failure remains the most common cause of servo motor breakdowns, often resulting from lack of lubrication, misalignment, or excessive vibration.

But here’s the good news: preventive maintenance can reduce unplanned downtime and repair costs by up to 30 % in industrial servo motor applications. Most electrical failures stem from moisture or loose connections—issues that regular inspections can catch before they cause catastrophic damage.

Servo motor preventive maintenance terms simplified:

– servo motor feedback repair

– controlling a servo

– cnc servo motors and drives

Why Servo Motors Matter to High-Precision CNC Operations

Think of servo motors as the precision athletes of your CNC machine shop. While regular motors just spin at whatever speed you set them to, servo systems are constantly listening, adjusting, and fine-tuning their performance based on real-time feedback. It’s this closed-loop control that makes the difference between “close enough” and “dead-on accurate.”

Here’s how it works: Your CNC controller sends position commands to the servo drive, which then compares those commands to the actual position reported by the encoder. If there’s even the tiniest difference, the system makes instant corrections. This continuous conversation between components is what enables your machines to hold tolerances that would make your grandfather’s machinist tools weep with envy.

The positioning accuracy you get from well-maintained servo systems directly impacts your production quality. When you’re machining aerospace components or defense parts where a few microns can mean the difference between success and scrap, this level of control isn’t just nice to have – it’s absolutely critical.

But here’s the thing about servo motors: when they start to go bad, they don’t usually fail all at once. Instead, you’ll notice subtle changes in your parts first. Surface finishes that aren’t quite as smooth. Dimensions that start drifting just slightly out of spec. Scrap rates that creep up week by week. By the time you realize there’s a problem, you’ve already lost time and money.

The downtime impact hits even harder. Manufacturing facilities typically experience about 20 downtime incidents per month, with each event lasting over an hour. When a servo motor fails in a precision operation, it’s not just a quick fix – it often means shutting down the entire production line while you diagnose and resolve the issue.

Key Components That Suffer Wear

Bearings are enemy number one when it comes to servo motor failures. These precision components support your rotor shaft while allowing smooth rotation at speeds that can exceed 6,000 RPM. The rotor itself depends entirely on these bearings for proper alignment and smooth operation. When bearings start to fail, you’ll hear it first – that grinding or rumbling sound that gets progressively worse.

The encoder is your servo system’s eyes and ears. Whether it’s optical or magnetic, this precision device tells the system exactly where the rotor is positioned at any given moment. Contamination, vibration, or temperature extremes can throw off this critical feedback, leading to positioning errors that show up as quality problems in your finished parts.

Your stator windings create the electromagnetic fields that make everything happen. Over time, the insulation around these windings can break down from heat, moisture, or electrical stress. When windings fail, it’s usually game over – you’re looking at professional repair or replacement.

Don’t overlook the cabling either. Power cables carry high currents while feedback cables transmit sensitive encoder signals. A damaged cable can cause intermittent faults that drive you crazy trying to diagnose, while loose connections create heat and voltage drops that stress other components.

![]()

Servo Motor Preventive Maintenance Checklist

Think of servo motor preventive maintenance as insurance for your precision manufacturing operations. Just like you wouldn’t skip oil changes in your car, you can’t afford to neglect the motors that keep your CNC machines running smoothly.

The numbers tell the story clearly: servo motor drives typically last 20,000 to 30,000 hours under normal conditions. But here’s the thing – “normal” conditions rarely exist in real manufacturing environments. Without proper preventive maintenance, you might see that lifespan cut in half. On the flip side, a solid maintenance routine can add several years to your servo motors’ working life.

The secret sauce is combining two approaches that work better together than apart. Schedule-based maintenance ensures you never forget critical tasks like lubrication, while condition-based monitoring acts like an early warning system for developing problems.

Schedule-based maintenance gives you predictable costs and consistent execution – you know exactly when tasks will happen and how much they’ll cost. The downside? You might end up doing maintenance that isn’t really needed yet, and it won’t catch those surprise issues that pop up between scheduled intervals.

Condition-based maintenance flips this around. You only perform maintenance when monitoring equipment tells you it’s actually needed, and you catch developing problems before they become expensive failures. But it requires investment in monitoring equipment and training for your team.

Most successful precision manufacturers use a hybrid approach. They schedule the critical stuff that absolutely can’t be missed – like bearing lubrication – while using condition monitoring to spot trouble brewing between scheduled maintenance windows.

Predictive maintenance takes this even further, using advanced analytics to optimize maintenance timing for maximum uptime. It requires a bigger upfront investment, but for high-value CNC equipment running continuous operations, the payoff can be substantial.

Daily & Weekly Servo Motor Preventive Maintenance Tasks

Your daily and weekly servo motor preventive maintenance routine is like taking your pulse – quick checks that tell you if everything’s running normally or if something needs attention. The best part? Most of these tasks can be done by your machine operators during their regular startup procedures.

Every day, spend just 5-10 minutes per machine doing a visual inspection. You’re looking for the obvious troublemakers: oil leaks around seals, damaged or frayed cables, connections that have worked loose, or unusual wear patterns. Don’t forget to check that cooling fans are spinning and air vents aren’t clogged with chips or debris.

Your ears are one of your best diagnostic tools. Listen to each servo motor during normal operation – healthy motors run quietly with minimal vibration. When you start hearing grinding, squealing, or rumbling sounds, that’s usually your bearings telling you they need attention before they fail completely.

Cable connections deserve special attention because they’re often the weak link. Vibration loves to work connections loose, creating resistance that generates heat and voltage drops. A quick check to ensure power and feedback cables are properly secured can prevent a lot of headaches down the road.

Weekly tasks require a bit more time – about 15-30 minutes per machine – but they’re worth every minute. Use clean, dry compressed air (keep it under 50 PSI) to blow out dust and debris from motor housings, cooling fins, and air vents. Pay extra attention to encoder housings since they’re particularly sensitive to contamination.

Take a closer look at all electrical connections for tightness, corrosion, or damage. Look for telltale signs of arcing or burning around terminals, and make sure cable strain reliefs are doing their job properly.

Monthly & Quarterly Servo Motor Preventive Maintenance Tasks

Monthly and quarterly servo motor preventive maintenance tasks require more time and technical know-how, but they’re your insurance policy against major failures that can shut down production for days.

Monthly maintenance typically takes 30-60 minutes per motor, and bearing lubrication tops the priority list. This isn’t a “more is better” situation – over-lubrication can be just as harmful as under-lubrication. Follow manufacturer specifications exactly for lubricant type, quantity, and application method.

Encoder cleaning requires a delicate touch since these precision devices provide the feedback that makes closed-loop control possible. Use appropriate solvents and lint-free cloths to carefully clean encoder housings and optical discs. Never touch glass discs directly, and always ensure encoders are properly sealed against contamination when you’re finished.

Temperature monitoring with infrared thermometers or thermal imaging helps you establish baseline readings for each motor. Document these readings religiously – they’re your early warning system for developing problems.

Quarterly tasks are your deep-dive maintenance sessions, taking 1-2 hours per motor but potentially saving you from catastrophic failures. Torque verification ensures motors are producing expected torque levels across their operating range. Declining torque can indicate winding problems, bearing issues, or drive malfunctions.

Thermography testing with thermal imaging cameras reveals hot spots in windings, connections, and bearings that aren’t apparent during visual inspection. Electrical testing measures insulation resistance, winding resistance, and continuity to identify developing electrical problems before they cause failures.

Maintenance Scheduling, Documentation & Software Updates

The difference between a good servo motor preventive maintenance program and a great one often comes down to three things: smart scheduling, meticulous documentation, and staying current with software updates.

Modern Computerized Maintenance Management Systems (CMMS) automate scheduling, send reminders to technicians, and maintain detailed historical records that reveal patterns you might otherwise miss.

When setting up schedules, start with OEM guidelines, then adjust for your actual shop environment. A servo motor running in a pristine facility may exceed manufacturer recommendations, while one in a dusty plant will need more frequent attention.

Here’s something many maintenance teams overlook: firmware patches and software updates can actually improve servo motor reliability. Modern servo drives are essentially computers; updates often include better diagnostic tools, improved motor-control algorithms, and improved protection features.

Smart maintenance programs track key performance indicators such as Mean Time Between Failures (MTBF), maintenance cost per motor, and unplanned downtime incidents. These metrics turn maintenance from a cost center into a strategic advantage.

More info about spindle services

Best-Practice Record-Keeping

Good documentation preserves insights that would otherwise be lost. Record not only what maintenance was performed and when, but also what you observed—temperature changes, vibration levels, or unusual noises. Over time, these notes build a baseline that helps identify developing problems.

Inspection forms bring consistency, while trend charts turn raw data into actionable intelligence. Digital systems make searching, sharing, and analyzing this information quick and accurate.

Troubleshooting & When to Call in the Pros

Even the best servo motor preventive maintenance program can’t prevent every problem. When issues do arise, quick and accurate diagnosis makes the difference between a minor hiccup and major downtime. The trick is knowing what you can handle in-house and when it’s time to bring in the experts.

Let’s be honest – servo motor problems never happen at convenient times. They show up right before a big delivery deadline or during your most critical production run. That’s why having a systematic troubleshooting approach saves both time and stress.

Overheating is often the first sign something’s wrong. Your servo motor should run warm, but not hot enough to burn your hand. When motors overheat, it’s usually telling you about bearing problems, electrical issues, or blocked cooling pathways. Start by checking that cooling fans are running and air vents aren’t clogged with debris.

Excessive vibration is another red flag that’s hard to ignore. Healthy servo motors run smoothly – when they start shaking, it typically means bearing wear, rotor imbalance, or misalignment issues. You’ll often feel this through the machine structure before you hear it.

Positioning errors can be particularly frustrating because they directly impact part quality. These problems usually trace back to encoder issues – contamination on optical discs, loose connections, or misalignment from vibration. Before assuming your encoder is dead, check the simple stuff like cable connections and mounting hardware.

Unusual noise changes are your servo motor’s way of calling for help. A healthy motor has its own quiet hum. When you hear grinding, squealing, or rumbling sounds, pay attention. Grinding usually means bearing problems, while electrical issues often create higher-pitched noises.

Most manufacturing facilities can handle basic maintenance like cleaning, lubrication, and connection checks. But certain problems require specialized equipment and expertise that most shops don’t have on hand. Encoder alignment and calibration needs precision tools and experience. Winding repairs require specialized knowledge of motor construction. Bearing replacement in sealed motors often means complete disassembly that’s best left to professionals.

Latest research on minimizing downtime shows that facilities with clear escalation procedures and established relationships with repair specialists experience significantly less downtime when problems occur.

Rapid Root-Cause Diagnosis Steps

When servo motor problems strike, panic is your enemy. A systematic approach gets you back to production faster and prevents the costly mistake of replacing parts that aren’t actually broken.

Start with error codes – modern servo drives are pretty smart and will tell you exactly what’s wrong if you listen. Before you start taking things apart, check the drive display for fault codes. Your drive manual will translate these codes into plain English and point you toward the real problem.

Verify power and connections next because many “motor” problems are actually electrical supply issues. Check that input voltage is stable, all connections are tight, and grounding is proper. Loose connections create heat and voltage drops that make motors act sick when they’re actually fine.

Test the motor under no load by disconnecting it from its mechanical load. If the problem disappears, you’re looking at a mechanical issue – misalignment, binding, or excessive load. If the problem persists, focus on the motor and drive system.

Check encoder signals using an oscilloscope or encoder tester if you have one. Encoder problems often masquerade as motor issues, causing positioning errors and erratic behavior that seems motor-related but isn’t.

The key is working methodically rather than jumping to conclusions. That grinding noise might sound like a bearing problem, but it could also be a loose coupling or misalignment issue that’s much easier and cheaper to fix.

Frequently Asked Questions about Servo Motor Preventive Maintenance

Let’s address the most common questions we hear from manufacturers about keeping their servo motors running smoothly. These questions come up repeatedly because servo motor preventive maintenance can seem complex at first—but the answers are more straightforward than you might think.

How often should I perform servo motor preventive maintenance on a CNC machine?

The honest answer? It depends on how hard you’re working your machines and where they’re operating. Think of it like car maintenance—a vehicle driven in dusty conditions needs more frequent service than one that stays on clean highways.

For most precision manufacturing environments, we recommend daily visual checks that take just 5 minutes. You’re looking for obvious problems like loose cables, unusual noises, or excessive heat. These quick inspections catch problems before they become expensive failures.

Weekly cleaning and basic inspections should take 15–30 minutes per motor. This includes removing dust and debris, checking connections, and verifying that everything looks normal.

Monthly maintenance gets more involved—typically 30–60 minutes per motor for lubrication, temperature monitoring, and more detailed inspections.

Quarterly comprehensive testing takes 1–2 hours but provides deep insights into motor health, including vibration analysis, thermography, and electrical testing.

Harsh environments need more frequent attention. If your facility has high dust levels, temperature swings, or heavy contamination, double the frequency of cleaning tasks.

What early warning signs indicate imminent servo failure?

Servo motors are actually pretty good at telling you when they’re in trouble—you just need to know what to listen for.

Changes in sound are often your first clue. Healthy servo motors run quietly with a consistent hum. Grinding usually indicates bearing problems, while electrical humming can signal winding issues.

Temperature increases happen gradually but consistently when problems develop. Establish baseline temperatures for each motor.

Vibration changes often precede other symptoms. Even small increases can signal bearing wear, rotor imbalance, or alignment issues.

Performance degradation shows up in your parts first. Reduced positioning accuracy or slower response times suggest developing problems.

Intermittent error codes deserve immediate attention. Drive diagnostics often warn of issues long before failure occurs.

Can software updates really improve servo motor reliability?

Yes. Modern servo drives are specialized computers, and like any computer system they benefit from updates.

Improved control algorithms can reduce physical stress on motors, lowering operating temperature and extending component life.

Improved diagnostics help identify problems earlier, providing more detailed fault information for faster troubleshooting.

Bug fixes resolve known issues that may cause intermittent faults.

Plan updates carefully: test on non-critical systems first, ensure rollback procedures, and coordinate with scheduled downtime.

Conclusion

Servo motor preventive maintenance isn’t just another checklist item—it’s the foundation that keeps your precision CNC operations running smoothly and profitably. With well-maintained motors, you can reduce unplanned downtime and repair costs by up to 30 %.

Daily visual checks, weekly cleaning, monthly lubrication, and quarterly analysis catch problems early. Your operators are on the front lines, so investing in their training pays dividends.

At MZI Precision, we understand how servo motor health directly impacts spindle performance and overall machine accuracy. Our systems approach ensures that both components receive the care they need for consistent results.

More info about predictive maintenance

Preventive maintenance is always less expensive than emergency repairs. Start simple, document everything, and expand your program as you gain experience. Your servo motors—and your bottom line—will thank you.