On-Site Spindle Repair: #1 Ultimate

Why On-Site Spindle Repair is Critical for Manufacturing Operations

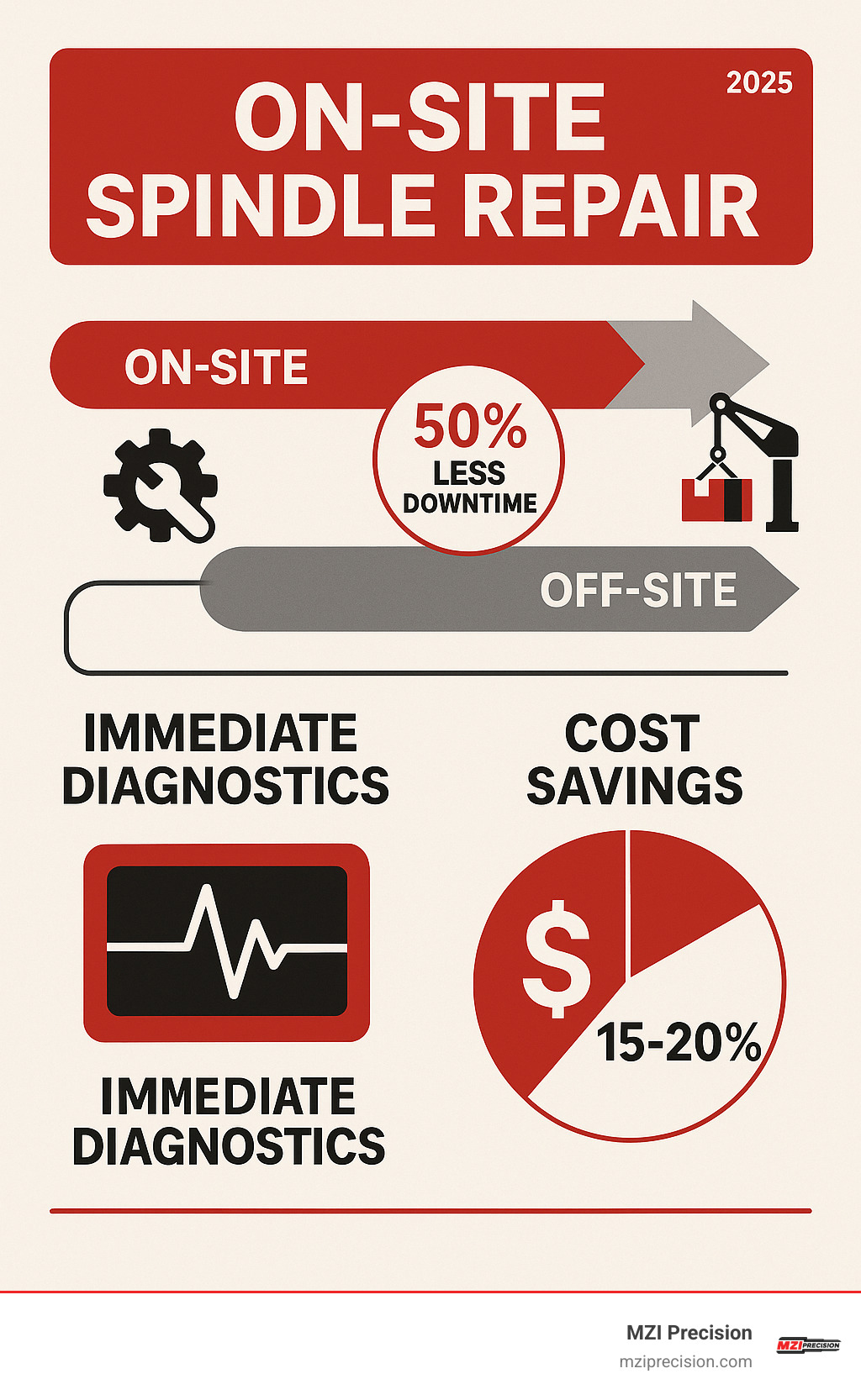

On-Site Spindle Repair is a specialized service that brings expert technicians and equipment directly to your manufacturing facility to diagnose, repair, and restore industrial spindles without removing them from your machines. This approach can reduce downtime by up to 50% compared to traditional off-site repairs.

Key benefits of on-site spindle repair:

- Faster turnaround: 24-48 hour completion vs. weeks for off-site repairs

- Cost savings: 15-20% average reduction in total repair costs

- Zero shipping risks: No damage during transit or logistics delays

- Immediate diagnostics: Problems identified and addressed on-spot

- Minimal production disruption: Machines return to service quickly

Industrial manufacturing spindles are the heart of precision machining operations. These critical components rotate cutting tools at thousands of RPM while maintaining tolerances measured in microns. When spindle bearings fail, tapers wear, or vibration increases, the entire production line can grind to a halt.

Traditional spindle repair requires removing the spindle, shipping it to a repair facility, waiting weeks for completion, then reinstalling and realigning everything. This process often takes 2-4 weeks and costs thousands in lost production time.

On-site repair changes this equation completely. Expert technicians arrive with portable diagnostic equipment, precision tools, and replacement parts. They can perform taper grinding, bearing replacement, vibration analysis, and dynamic balancing right on your shop floor.

WHY CHOOSE ON-SITE REPAIR OVER TRADITIONAL METHODS?

Picture this: your most critical CNC machine suddenly starts producing parts that are out of tolerance. The spindle bearings are making that dreaded grinding noise, and you know what’s coming next – complete failure. In the old days, this meant weeks of downtime while your spindle took a slow journey to a repair facility and back.

On-Site Spindle Repair changes everything about this scenario. Instead of boxing up your spindle and sending it away like a patient going to a distant hospital, we bring the operating room directly to your shop floor.

The change is remarkable. What used to be a logistical nightmare becomes surprisingly straightforward. No more coordinating shipping schedules, no more crossing your fingers that delicate components survive the journey, and definitely no more watching your production schedule fall apart while you wait.

| Metric | On-Site Spindle Repair | Off-Site Repair (Traditional) |

|---|---|---|

| Downtime | Up to 50% reduction (24-48 hours aim) | Weeks (2-4 weeks typical) |

| Total Cost | 15-20% average savings | Higher due to lost production, shipping, and logistics |

| Logistics | Minimal; technicians come to you | Complex; crating, shipping, tracking |

| Risk of Transit Damage | Zero; repair at machine location | Significant concern for delicate components |

| Diagnostics | Immediate, real-time assessment | Delayed until spindle arrives at facility |

| Production Impact | Minimized disruption; faster return-to-service | Significant disruption; extended production halts |

The numbers tell the story, but the real impact goes beyond statistics. When your production line stops, it’s not just about one machine – it’s about meeting customer deadlines, maintaining cash flow, and keeping your team productive.

MINIMIZING DOWNTIME AND PRODUCTION IMPACT

Time is everything in manufacturing. When a spindle fails, every hour counts toward meeting delivery commitments and maintaining profitability. Traditional repair methods force you into a waiting game that nobody wins.

With On-Site Spindle Repair, we flip the script entirely. Our technicians arrive with everything needed to diagnose problems immediately – no guesswork, no delays waiting for your spindle to reach a distant facility. Most repairs are completed within our 24-48 hour target, achieving up to 50% reduction in downtime compared to off-site alternatives.

This isn’t just about speed for speed’s sake. It’s about protecting your production schedule integrity. When repairs happen on-site, you maintain control over timing and can coordinate maintenance with your existing workflow. Emergency shutdowns transform into manageable maintenance windows.

The strategic value extends beyond individual repairs. On-Site Spindle Repair enables true predictive maintenance strategies. Instead of running equipment until failure, you can schedule proactive service during planned downtime periods.

More info about our spindle repair services

COST IMPLICATIONS AND SAVINGS

The financial benefits of on-site repair extend far beyond the obvious elimination of shipping and crating costs. While avoiding these expenses helps, the real savings come from preventing the cascade of costs that follow extended downtime.

Manufacturing operations report average savings of 15-20% when choosing on-site repair services. This includes reduced overhead from simplified logistics, faster resolution times that prevent prolonged production halts, and elimination of transit damage risks that could require additional repairs or complete replacement.

Consider the hidden costs of traditional methods: lost production revenue while machines sit idle, overtime costs to catch up on delayed orders, potential penalty fees for missed deliveries, and the administrative burden of managing complex shipping logistics. On-Site Spindle Repair eliminates most of these concerns by keeping your equipment operational and your production flowing smoothly.

The faster return-to-service times mean you’re not just saving money – you’re protecting revenue streams and maintaining the reliability your customers expect.

THE ON-SITE SPINDLE REPAIR PROCESS: FROM DIAGNOSIS TO OPERATION

When your industrial manufacturing spindle starts acting up, the last thing you want is a drawn-out repair process that keeps your machines idle for weeks. That’s exactly why we’ve perfected our On-Site Spindle Repair approach to be as smooth and efficient as possible.

Think of us as your spindle’s personal medical team. We start with an initial consultation where we listen carefully to what you’ve noticed – unusual noises, vibration, poor part quality, or any other concerns. This conversation helps us understand the symptoms and prepare the right tools and parts for your specific situation.

Next comes our on-site evaluation, where our technicians arrive with advanced diagnostic equipment. We’re not just guessing at what’s wrong; we’re using precision tools to pinpoint exactly what’s happening inside your spindle. This thorough assessment covers everything from bearing condition to taper wear.

After our diagnosis, we provide detailed reporting that breaks down our findings in plain English. You’ll know exactly what’s wrong, why it happened, and what we recommend to fix it. No surprises, no technical jargon that leaves you scratching your head.

Once you approve our repair plan, we get to work with repair execution. Our skilled technicians handle everything from bearing replacement to taper grinding right there on your shop floor. Finally, we conduct rigorous final testing and quality assurance to make sure your spindle meets OEM specifications before we consider the job complete.

COMMON ISSUES ADDRESSED BY ON-SITE SPINDLE REPAIR

You’d be surprised how many spindle problems that once meant weeks of downtime can now be fixed right at your facility. Our On-Site Spindle Repair services tackle the most common culprits that plague industrial manufacturing operations.

Bearing noise or failure is probably the issue we see most often. When bearings start making that telltale grinding or squealing sound, it’s usually because of wear, contamination, or lubrication problems. Left unchecked, this leads to excessive heat and vibration that can damage other components.

Poor part tolerances are often the first sign that your spindle isn’t holding its precision anymore. If your finished parts aren’t meeting specs, the spindle is likely the culprit. We can restore that crucial accuracy that keeps your quality control manager happy.

Excessive vibration is another red flag we address regularly. This can stem from imbalanced components, bearing issues, or misalignment. Not only does vibration produce poor surface finishes, but it also accelerates wear on expensive machine components.

Taper wear or damage is critical because your spindle’s taper is what holds your cutting tools. When the taper gets worn or damaged – often from a spun tool in taper situation – you end up with poor tool clamping, runout issues, and reduced tool life. This creates a cascade of problems throughout your machining process.

Drawbar retention force issues might sound technical, but they’re actually pretty straightforward. When your drawbar isn’t providing enough clamping force, tools can pull out during operation or chatter during cutting. Neither scenario is good for productivity or safety.

TECHNOLOGIES AND TECHNIQUES USED

Our mobile repair units are essentially precision workshops on wheels, equipped with the same advanced technology you’d find in a dedicated spindle repair facility. We bring factory-level capabilities directly to your machine.

Vibration analysis is our detective work tool. Using sophisticated analyzers, we can detect subtle problems that indicate bearing wear, imbalance, or misalignment long before they cause catastrophic failure. This technology helps us practice predictive maintenance rather than reactive repairs.

For taper grinding, we use specialized portable systems that can restore your spindle’s precision tool-holding taper without removing the entire spindle. We perform detailed inspections before and after grinding, including visual checks, bluing tests, runout measurements, and test bar analysis to ensure everything meets specifications.

Runout measurements using precision air gauges and test bars help us verify that your spindle rotates with minimal deviation. We often guarantee less than two microns of runout – that’s incredibly precise.

Dynamic balancing is crucial for high-speed spindles. We perform this on-site to reduce vibration and extend bearing life, ensuring your spindle runs smoothly at operating speeds. Laser alignment provides unparalleled accuracy for certain components and machine alignments, reducing stress on the spindle assembly.

Drawbar force gauges help us measure and verify proper clamping force, preventing tool pull-out during machining. We also use thermal monitoring during testing to ensure bearings run at optimal temperatures without overheating.

Our eight-channel data loggers record critical parameters like RPM, vibration, temperature, and axial displacement throughout the repair process. This gives you documented proof that your On-Site Spindle Repair meets OEM specifications and provides a baseline for future maintenance planning.

KEY INDUSTRIES AND MACHINERY THAT BENEFIT

When your production line depends on precision machining, every minute of downtime hits hard. That’s why On-Site Spindle Repair has become such a game-changer across so many industries. We’ve worked with manufacturers who thought they’d be down for weeks, only to have their machines humming again in 24 hours.

The aerospace industry probably feels spindle downtime more than anyone. When you’re machining titanium components that need to meet NASA-level specs, there’s no room for “good enough.” We’ve seen how a failed spindle on a horizontal machining center can derail an entire aircraft production schedule. That’s why aerospace manufacturers love our on-site approach – we can restore their CNC machining centers and vertical machining centers (VMCs) to perfect precision without the weeks-long wait.

Defense contractors face similar pressures, but with the added complexity of security clearances and restricted facilities. Shipping sensitive equipment off-site isn’t always an option. Our technicians can work within these secure environments, keeping critical horizontal machining centers (HMCs) and specialized grinding machines operational for mission-critical components.

The medical device industry operates under incredibly tight tolerances – we’re talking about parts that literally save lives. When a high-speed milling machine goes down in a medical manufacturing facility, patients waiting for implants or surgical instruments feel the impact. Our on-site service ensures these precision lathes and machining centers get back to producing life-saving devices quickly.

Energy sector manufacturers, including those in solar and wind power, often work with massive components that require specialized grinding machines and heavy-duty machining centers. Moving these spindles off-site isn’t just expensive – it’s often logistically impossible. We bring our expertise directly to their facility floor.

Even general manufacturing operations – the backbone of American industry – rely heavily on our services. Whether it’s a small job shop with a single VMC or a massive production facility running dozens of machining centers around the clock, spindle failures don’t discriminate. We’ve helped everyone from family-owned machine shops to Fortune 500 manufacturers get their CNC machining centers, lathes, and vertical machining centers back online fast.

The beauty of On-Site Spindle Repair is its universal application. If your business depends on precision machining – whether you’re running horizontal machining centers, grinding machines, high-speed milling machines, or any combination of CNC equipment – we can help keep your operation running smoothly. Because at the end of the day, a broken spindle is a broken spindle, no matter what industry you’re in.

CHOOSING THE RIGHT SERVICE PROVIDER

When your critical industrial manufacturing spindle breaks down, choosing the right repair partner can make the difference between a quick recovery and weeks of lost production. Not every provider offering On-Site Spindle Repair services delivers the same level of expertise, and frankly, some shortcuts in this business can cost you dearly down the road.

At MZI Precision, we’ve seen what happens when repairs aren’t done right the first time. That’s why we believe in helping you understand what separates truly qualified providers from those who might leave you with bigger problems than when you started.

OEM expertise should be your first consideration. You want a provider who doesn’t just fix spindles—they need to understand the original manufacturer’s specifications inside and out. This means knowing exactly how your spindle was designed to perform and having the capability to restore it to those exact standards. When we work on OEM rebuilt spindles, we’re not guessing at specifications; we’re following the blueprint that made your spindle work perfectly in the first place.

Years of experience matter more in spindle repair than almost any other field. A provider with decades in the business—like our 40+ years in the industry—has encountered virtually every type of failure mode imaginable. They’ve learned from mistakes, refined their techniques, and developed solutions for problems that newer companies haven’t even seen yet. This accumulated knowledge becomes invaluable when your unique situation demands creative problem-solving.

The qualifications of the actual technicians who will touch your spindle are crucial. These aren’t general mechanics—spindle repair requires specialized training in precision measurement, bearing installation, and complex diagnostics. The technician arriving at your facility should be someone you’d trust with a $50,000 piece of equipment, because that’s exactly what they’re handling.

Advanced diagnostic tools separate professional operations from amateur ones. Look for providers using vibration analyzers, precision air gauges, test bars, motor analyzers, and multi-channel data loggers. These aren’t just impressive gadgets—they’re essential for accurately diagnosing problems and validating repairs. Without proper diagnostic equipment, even the most experienced technician is working partially blind.

In-house engineering support becomes critical when standard solutions don’t fit. Sometimes a spindle needs custom parts, reverse engineering, or modifications to improve performance. Providers with their own engineering teams can solve complex problems that would stump others, rather than simply telling you “it can’t be fixed on-site.”

Comprehensive testing capabilities should be non-negotiable. After repair, your spindle needs thorough break-in procedures, dynamic balancing, and performance validation at full operating speed. The provider should test using your spindle’s own motor, not some generic substitute. This testing phase often reveals issues that weren’t apparent during the repair itself.

Warranty policies tell you everything about a provider’s confidence in their work. Reputable companies offer clear warranties on both parts and labor, typically six months to a year. If someone won’t stand behind their repair work, why should you trust them with your production schedule?

ENSURING QUALITY WITH ON-SITE SPINDLE REPAIR

Quality in On-Site Spindle Repair isn’t just about getting your machine running again—it’s about ensuring it performs reliably for years to come. We’ve learned that taking shortcuts during on-site repairs often creates bigger problems later, which is why our approach prioritizes doing things right over doing things fast.

Adherence to OEM specifications forms the foundation of every quality repair. This isn’t just about using similar parts; it means restoring your spindle to its exact original configuration unless the OEM specifically recommends improvements. Every clearance, every torque specification, every assembly sequence matters when you’re dealing with components that rotate at thousands of RPM while maintaining micron-level precision.

Super-precision bearings aren’t optional—they’re essential. We use only the highest quality bearings that meet or exceed OEM standards because compromising here means compromising the entire repair. These bearings cost more, but they’re what separate a repair that lasts months from one that lasts years.

Our post-repair testing protocols happen right there at your facility, not in some distant lab. We continuously monitor vibration and temperature during test runs because problems often only appear under actual operating conditions. Runout verification using precision test bars confirms we’ve achieved the accuracy your machining operations demand—often less than two microns of deviation.

Dynamic balancing of the entire rotating assembly reduces vibration and extends bearing life significantly. This isn’t something you can skip and hope for the best; it’s fundamental to spindle longevity. We also verify drawbar retention force to ensure your tools won’t pull out during operation, because a loose tool can destroy both your workpiece and your spindle.

Documented quality control reports provide you with complete transparency about what we found, what we fixed, and how we validated the repair. This documentation becomes valuable for tracking spindle performance over time and planning future maintenance.

Perhaps most importantly, we focus on root cause analysis rather than just treating symptoms. If bearing failure was caused by contamination, we’ll recommend improvements like air purge systems. If excessive heat was the culprit, we might suggest ceramic bearings for better thermal performance. This approach helps prevent the same problem from recurring and often improves your spindle’s performance beyond its original capabilities.

The combination of on-site convenience with uncompromising quality standards ensures your On-Site Spindle Repair becomes a smart investment in your machine’s future, not just a quick fix to get through today’s production schedule.

FREQUENTLY ASKED QUESTIONS ABOUT ON-SITE SPINDLE REPAIR

When you’re considering On-Site Spindle Repair for your manufacturing facility, it’s natural to have questions. We’ve been helping companies across the aerospace, defense, energy, and general manufacturing sectors for years, and these are the questions we hear most often. Let’s explore the practical details that matter most to your operation.

HOW LONG DOES AN ON-SITE REPAIR TYPICALLY TAKE?

Here’s where On-Site Spindle Repair really shines – speed without sacrificing quality. Most standard spindle repairs can be completed within our target window of 24-48 hours. We’re talking about common issues like bearing replacement, taper grinding, or fixing drawbar retention problems.

Now, we’ll be honest with you – not every repair fits into a neat timeframe. If your spindle has unusual damage or we’re working with specialized equipment we haven’t seen before, it might take a few days. But even in these cases, you’re still looking at a fraction of the time you’d spend waiting for traditional off-site repairs.

The beauty of having our technicians right there on your shop floor is that we can work continuously without the delays of shipping, scheduling, and logistics that plague traditional repair methods. Your machine stays put, and we bring everything needed to get it running again.

CAN ALL SPINDLE PROBLEMS BE FIXED ON-SITE?

We wish we could say yes to everything, but let’s be realistic about what On-Site Spindle Repair can and can’t handle. The good news? We can tackle the vast majority of common industrial manufacturing spindle problems right at your facility.

Issues like bearing noise or failure, excessive vibration, taper wear, poor part tolerances, and drawbar retention force problems are all well within our wheelhouse for on-site resolution. We can perform vibration analysis, taper grinding, dynamic balancing, and precision measurements without ever removing your spindle from the machine.

However, there are some situations where we’ll need to take the spindle back to our facility. If there’s extensive shaft damage requiring complex machining, major housing repairs, or highly specialized procedures that need our full shop capabilities, we’ll let you know upfront during our initial evaluation.

The silver lining? Our on-site assessment quickly determines what’s possible, so you’re not left guessing or wasting time with multiple service calls.

WHAT KIND OF WARRANTY IS PROVIDED FOR ON-SITE REPAIRS?

We stand behind our work, period. When MZI Precision performs On-Site Spindle Repair, you’re not just getting a quick fix – you’re getting a repair we’re confident will last.

Our warranty coverage typically includes both parts and labor, though the specific terms can vary based on the type of repair and components involved. For example, you might see a six-month warranty for motorized spindles and up to a one-year warranty for non-motorized spindles, starting from when your spindle returns to service.

This isn’t just paperwork we hand you and forget about. Our warranty reflects our commitment to doing the job right the first time. We use super-precision bearings that meet or exceed OEM specifications, perform rigorous post-repair testing, and document everything with detailed quality control reports.

If something isn’t performing as expected after our repair, we’ll make it right. That’s not just good business – it’s how we’ve built our reputation over decades of serving industries where precision and reliability aren’t optional.

CONCLUSION

When your industrial manufacturing spindle starts acting up, every minute counts. Throughout this guide, we’ve shown you how On-Site Spindle Repair isn’t just another service option—it’s a game-changer that can save your production schedule and your bottom line.

Think about it: instead of watching your machines sit idle for weeks while your spindle takes a round trip to a repair shop, you can have expert technicians working on your equipment within hours. That up to 50% reduction in downtime we talked about? That’s real money staying in your pocket instead of disappearing into lost production time.

The numbers speak for themselves. Companies choosing on-site repair typically see cost savings of 15-20% when you factor in eliminated shipping costs, reduced overhead, and most importantly, keeping your production line running. No more worrying about your precision spindle getting damaged in transit or dealing with complex logistics that eat up valuable time.

At MZI Precision, we’ve built our reputation on understanding that quality can’t be rushed, but time can’t be wasted. Our approach brings decades of OEM expertise directly to your shop floor, complete with advanced diagnostic equipment and the skills to perform everything from taper grinding to dynamic balancing right where your machine stands.

We believe in doing things right the first time. That means adhering to OEM specifications, using super-precision bearings, and putting every repaired spindle through rigorous testing before we consider the job complete. When we walk away, you can trust that your spindle will perform like new—because that’s exactly what we’ve restored it to be.

The future of spindle maintenance is here, and it’s happening right on your production floor. Why settle for weeks of downtime when you can have your critical machinery back up and running in days?