The Critical Role of Spindle Performance in Manufacturing

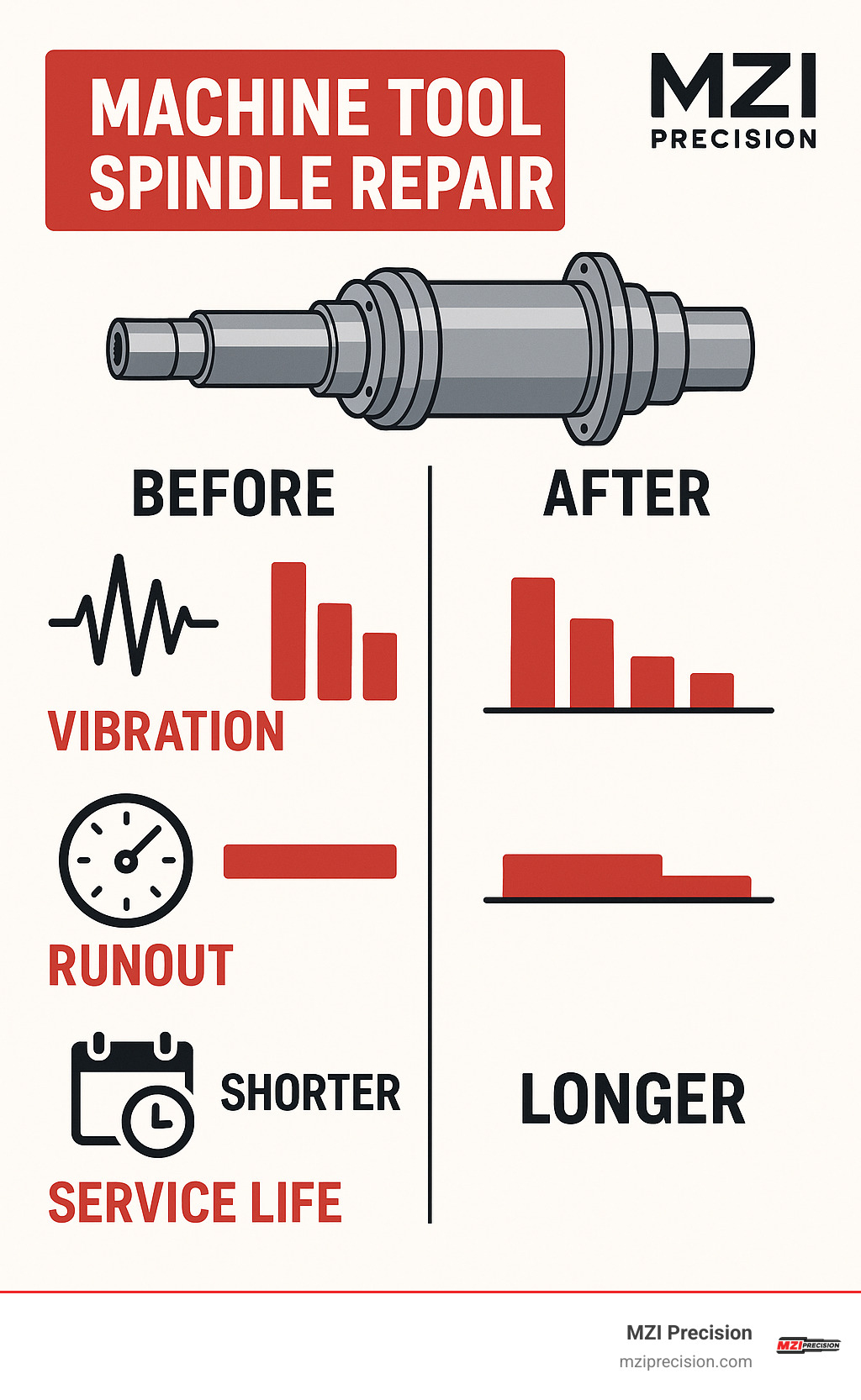

Machine Tool Spindle Repair is the process of restoring damaged or worn spindles in CNC machines to their original specifications or better. For manufacturing operations, this specialized service is essential to maintain production quality and prevent costly downtime.

Quick Answer: Machine Tool Spindle Repair Process

1. Initial Evaluation – Inspection and diagnostics to identify issues

2. Disassembly & Cleaning – Complete teardown and ultrasonic cleaning

3. Component Inspection – Detailed analysis of all parts

4. Repair Quote – Detailed breakdown of needed repairs and costs

5. Component Replacement – Installing new bearings, seals, and other parts

6. Precision Assembly – Rebuilding to OEM specifications or better

7. Balancing & Testing – Dynamic balancing and performance verification

8. Final Quality Check – Ensuring tolerances within 2 microns

9. Documentation – Complete repair reports and certification

The spindle is the heart and soul of any machine tool. When a spindle fails, production stops completely – creating a domino effect of missed deadlines, quality issues, and revenue loss. According to industry data, professional spindle repairs can extend equipment life while delivering performance that often exceeds original specifications.

“Precision isn’t just our goal — it’s our legacy,” notes a leading spindle repair provider with over 157 years of combined experience. This sentiment echoes throughout the industry, where micron-level accuracy can make the difference between perfect parts and expensive scrap.

Most industrial spindle failures stem from predictable causes: bearing wear, contamination, improper lubrication, or collision damage. The good news? With proper diagnosis and expert repair, nearly 90% of damaged spindles can be restored to peak performance – often at 30-50% the cost of replacement.

Whether you’re managing aerospace components with tight tolerances or high-volume automotive production, understanding the spindle repair process is crucial for maintaining manufacturing excellence and maximizing uptime.

Understanding Machine Tool Spindles: The Heart of CNC Accuracy

If you’ve ever watched a CNC machine in action, you’ve witnessed the marvel of precision that comes from one critical component – the spindle. This isn’t just another machine part; it’s the beating heart that brings your CNC machine to life.

A typical industrial spindle consists of several essential components working in perfect harmony. The rotor assembly serves as the central shaft that holds and rotates your cutting tools. This shaft is supported by a precision bearing system that enables the smooth, accurate rotation needed for quality parts. The drawbar mechanism creates the force that keeps tools securely in place during operation, while the taper interface provides that precision-ground surface where cutting tools connect. All of this is powered by the motor or drive system that delivers the necessary power and torque.

At MZI Precision, we’ve seen how spindle performance directly impacts part quality. When your spindle operates at peak condition, it maintains consistent RPM, delivers appropriate torque, and holds tools with proper drawbar force – all essential ingredients for achieving those tight tolerances and beautiful surface finishes your customers demand.

Types of Industrial Spindles Explained

Not all spindles are created equal, and choosing the right type for your application makes all the difference:

Motorized Spindles integrate the motor directly into the spindle housing, eliminating external belts or gears. These sleek performers offer higher speeds, better accuracy, and reduced vibration – making them perfect for precision work in aerospace and medical manufacturing where micron-level accuracy matters.

Belt-Driven Spindles connect to motors via belt systems and shine with their simplicity and cost-effectiveness. They’re the reliable workhorses of conventional milling and drilling operations where you need good performance without breaking the bank.

Gear-Driven Spindles use robust gear systems to transfer power from motor to spindle, delivering excellent torque for heavy-duty cutting. When you’re machining tough materials like steel and titanium, these powerful performers won’t let you down.

High-Speed Spindles are the speedsters of the spindle world, designed to operate at incredibly high RPMs (often 15,000 to 150,000). They excel in micro-machining, finishing operations, and applications requiring high surface speeds for optimal results.

Grinding Spindles are built for extreme precision and stability, operating with minimal runout to achieve those mirror-like surface finishes and tight dimensional tolerances that quality control loves to see.

Turning Spindles found in lathes and turning centers hold and rotate the workpiece rather than the cutting tool, requiring excellent rigidity and torque characteristics to handle the unique demands of turning operations.

Why Spindle Health Is Mission-Critical

Your spindle’s health directly impacts everything that matters in manufacturing:

Precision Tolerances: A properly functioning spindle maintains consistent runout of 2 microns or less – essential for producing parts that meet tight specs. One of our aerospace clients finded this the hard way when even a slight increase in spindle runout led to rejected parts and costly rework.

Surface Finish quality depends directly on spindle performance. Even microscopic vibration translates to the surface of your machined parts. A well-maintained spindle produces consistently smooth surfaces, often eliminating the need for secondary finishing operations.

Cycle Time improvements come naturally with healthy spindles that can operate at optimal speeds and feeds. This maximizes your material removal rates without sacrificing quality – directly boosting your throughput and production capacity.

Scrap Reduction is perhaps the most immediate benefit of proper spindle health. When spindles perform consistently, part quality remains stable, dramatically reducing waste. One of our agricultural equipment clients reported a 35% reduction in scrap after we rebuilt their critical milling spindles.

“The system’s ability to collect temperature, vibration, and collision data in real-time is amazing!” shared one manufacturer who implemented spindle monitoring. “Armed with real-time knowledge, we now can predict when to schedule maintenance and having that control is awesome!”

Think of your spindle as the foundation of your machining operation – when it’s solid, everything else falls into place. When it’s compromised, even the best operators and programming can’t compensate for the loss in precision and performance that follows.

Machine Tool Spindle Repair: Signs, Causes, and When to Act

Have you ever heard that distinctive whine from your CNC machine that makes your heart sink? That’s your spindle trying to tell you something important. At MZI Precision, we’ve seen how catching these warning signs early can be the difference between a simple repair and a production disaster.

Bearing Noise is often the first hint of trouble. That high-pitched whining or grinding sound that gets louder as speeds increase isn’t just annoying – it’s a cry for help from your spindle bearings that are starting to fail.

Vibration might be the most telling indicator of all. Even slight increases in vibration can signal bearing issues, imbalance, or misalignment. What starts as a barely noticeable tremor can quickly escalate into a major problem if ignored.

When your spindle starts running hotter than normal, pay attention. Thermal Drift affects dimensional accuracy as components expand with heat, causing your once-precise parts to drift out of spec. This temperature inconsistency is rarely random – it’s usually a symptom of internal friction problems.

Your parts will also tell you when something’s wrong. Poor Surface Finish with visible chatter marks or inconsistent textures is like your spindle sending you a written warning. Similarly, when Tool Pullout occurs despite proper setup, your drawbar mechanism is likely failing.

Two silent killers of spindle health are Contamination and Lubrication Failure. When metal chips or coolant find their way into your spindle housing, they create a grinding paste that accelerates wear. Meanwhile, inadequate lubrication creates friction and heat that can quickly escalate to complete bearing failure.

Early Warning Symptoms Requiring Machine Tool Spindle Repair

Before catastrophic failure strikes, your spindle will typically send several distress signals. Load Spikes during consistent operations often indicate developing bearing or drive system problems. Your monitoring system might show these as sudden current draws that weren’t happening before.

Runout Issues are another red flag. When precision indicators show increased tool runout, even by a few microns, it suggests bearing wear or shaft damage that needs addressing before it affects part quality.

Modern CNC machines are pretty vocal about problems through Encoder Alarms. These aren’t just annoying notifications – they’re your machine telling you something’s wrong with spindle position or performance.

Then there’s Chatter – that distinctive vibration during cutting that wasn’t happening with the same tooling and parameters before. As one of our clients put it: “The parts started singing to us, and it wasn’t a happy tune.”

Heat Rise during operation, especially when cooling systems are working properly, is your spindle crying out about friction problems that need immediate attention.

One manufacturing manager shared this costly lesson with us: “We ignored the slight increase in vibration readings for weeks. When the spindle finally failed, it crashed mid-job and damaged not only the spindle but also our expensive fixture and scrapped a $15,000 part. The lesson was expensive but clear – address spindle issues early.”

Root Causes Behind Spindle Failure

Understanding why spindles fail helps prevent history from repeating itself after repairs:

Bearing Fatigue happens even with perfect maintenance. These precision components have a finite life, with microscopic surface damage accumulating until failure eventually occurs. It’s not a matter of if, but when.

Contamination Ingress occurs when seals deteriorate or damage happens, allowing contaminants to enter the spindle housing. Coolant contamination is particularly harmful to precision bearings – it’s like putting sand in your watch mechanism.

Improper Tool Change events, whether manual or automatic, can damage taper interfaces and bearing systems. We frequently see this with ATC (Automatic Tool Changer) misalignment issues that create subtle but cumulative damage.

When Crashes happen – those heart-stopping collisions between tools and workpieces or fixtures – they create shock loads that damage bearings, bend shafts, or crack housings. These traumatic events typically require complete Machine Tool Spindle Repair or rebuilding.

Imbalance from tooling creates cyclic stresses that prematurely wear bearings and can create resonance issues throughout your machine structure, like a washing machine with an uneven load.

At MZI Precision, we’ve learned that proper diagnosis of the root cause is essential for effective repair. Simply replacing bearings without addressing underlying issues like contamination pathways or alignment problems leads to repeated failures – and nobody wants to fix the same problem twice.

Step-by-Step Guide to the Spindle Repair & Rebuild Process

Ever wonder what actually happens when your spindle goes in for repair? Let me walk you through the journey your spindle takes when it arrives at our shop for Machine Tool Spindle Repair.

The process begins with a meticulous tear-down. Our technicians carefully disassemble your spindle, documenting everything with photographs and detailed notes. Think of it as creating a precise roadmap that will guide us during reassembly. We measure critical dimensions and record the condition of every component – nothing escapes our attention.

Next comes the deep clean. We submerge components in our ultrasonic cleaning system, where specialized solvents and high-frequency sound waves work together to remove even the most stubborn contaminants. It’s amazing (and sometimes a bit alarming!) to see what comes out of seemingly clean components. This step is crucial because even microscopic particles can cause premature failure if left behind.

“The first time I saw the ultrasonic cleaning in action, I was shocked at how much contamination came out of what looked like a clean spindle,” one of our customers told us recently. “No wonder it wasn’t running right!”

After cleaning, our inspection phase begins. Each component goes under the microscope – literally. We examine bearing races for microscopic flaws, measure shaft journals with precision instruments, and check housing bores for any dimensional changes. This detective work often reveals the root cause of the original failure, which helps prevent it from happening again.

Dynamic balancing follows for all rotating components. We balance to G1 tolerances or better, which is critical for minimizing vibration when your spindle returns to service. Think of it like balancing the tires on your car, but with precision measured in microns rather than ounces.

The precision assembly stage is where the magic happens. Working in clean-room conditions, our technicians rebuild your spindle using either OEM-quality or superior replacement parts. Every detail matters – from the exact bearing preload to the precise alignment of components and the specific lubrication requirements.

Finally, no spindle leaves our facility without passing a rigorous test stand runoff. We run your spindle for a full 12 hours at maximum RPM, continuously monitoring vibration levels and performance metrics. Only spindles that meet or exceed original specifications earn our seal of approval.

One manufacturing manager shared: “The comprehensive 19-point checklist MZI Precision uses for spindle rebuilds gave us complete confidence in the process. The detailed documentation and before/after performance metrics proved we made the right choice.”

Machine Tool Spindle Repair Diagnosis

Accurate diagnosis forms the foundation of effective spindle repair. At MZI Precision, we approach diagnosis with both art and science:

We begin with a pre-run vibration test whenever possible. By running the spindle and capturing its vibration signature, we can identify specific bearing failures and other issues before disassembly. It’s like listening to your spindle tell us what’s wrong.

The drawbar pull check measures the actual force generated by the drawbar mechanism. This critical measurement ensures your tools will be held securely when the spindle returns to service.

We also use thermal imaging to reveal hot spots that may indicate bearing issues, lubrication problems, or electrical concerns in motorized spindles. Heat patterns don’t lie – they point directly to problem areas.

| Diagnostic Approach | In-House Capability | Outsourced to MZI Precision |

|---|---|---|

| Visual Inspection | Basic assessment possible | Microscopic examination with specialized equipment |

| Vibration Analysis | Limited without specialized equipment | Full spectrum analysis with pattern recognition |

| Runout Measurement | Basic indicators may be used | Precision measurement to 0.5 micron accuracy |

| Bearing Evaluation | Difficult without disassembly | Complete assessment with specialized tools |

| Root Cause Analysis | Often limited to symptoms | Comprehensive analysis of failure mechanisms |

| Performance Testing | Limited by available equipment | Full-load testing under controlled conditions |

Rebuild, Retrofit, or Replace?

When facing spindle issues, you have several options to consider:

Rebuild your spindle to restore it to original specifications by replacing worn components. This is typically your most cost-effective approach when the housing and shaft remain in good condition. Our precision rebuilds breathe new life into tired spindles.

Consider a retrofit when you want to improve performance beyond original specifications. We can upgrade your spindle with ceramic bearings, improved sealing systems, or improved cooling designs. One aerospace customer told us, “The ceramic bearing upgrade not only solved our temperature issues but allowed us to increase cutting speeds by 15%!”

Replacement becomes necessary when damage is extensive or when you need significant performance improvements. While this carries the highest upfront cost, sometimes it’s the most economical long-term solution.

Your decision should weigh several factors. From a cost perspective, a quality rebuild typically runs 30-50% of a new spindle’s price while delivering 90-100% of the performance. If time is critical, rebuilds can often be completed in 3-5 days, while new spindles might require weeks or months for delivery.

Consider your performance goals carefully. If your original spindle design was limiting production, a retrofit or replacement might deliver substantial ROI through improved capabilities. And don’t forget sustainability – rebuilding extends equipment life, reducing waste and resource consumption.

A defense industry client of ours saved over $45,000 by choosing precision rebuilds with ceramic bearing upgrades rather than replacing three critical spindles. The best part? The rebuilt spindles not only matched but exceeded the original performance specifications.

Watch video on spindle teardown

Advanced Technologies Elevating Spindle Repair Quality

The world of Machine Tool Spindle Repair has come a long way from simply swapping out worn bearings. Today, we’re using cutting-edge technology that brings aerospace-level precision to every repair we perform at MZI Precision.

Imagine being able to hear a bearing whisper that it’s starting to fail – weeks before any visible problems appear. That’s essentially what vibration analysis technology gives us. These sophisticated systems detect microscopic bearing defects long before they cause trouble, allowing us to use this technology both for initial diagnosis and as our final quality verification check.

Dynamic balancing to G1 precision is another game-changer. This ultra-precise balancing reduces rotating mass imbalance to virtually imperceptible levels. The result? Extended bearing life and dramatically improved surface finishes on your machined parts.

When we clean components at MZI Precision, we don’t just wipe them down. Our ultrasonic cleaning systems use sound waves to create microscopic bubbles that remove contaminants from even the tiniest crevices. This ensures every component is pristine before reassembly – a critical factor in long-term spindle performance.

For spindles with worn surfaces, laser cladding technology offers remarkable restoration possibilities. This process allows us to precisely apply material to rebuild damaged areas to exact specifications, often saving components that would otherwise need replacement.

“One prevented spindle crash will pay for a single vibration analysis many times over!” notes one of our precision manufacturing specialists. This preventive mindset has completely transformed how forward-thinking companies approach spindle maintenance.

Ceramic bearings represent another significant advancement we’re implementing. Compared to traditional steel bearings, ceramic alternatives offer longer service life, higher speed capabilities, and better thermal stability – particularly valuable in high-precision, high-speed applications.

Perhaps most exciting is the development of in-line health monitoring systems. These integrated sensors continuously track performance metrics, essentially giving your spindle the ability to tell you when it needs attention, often predicting failures weeks or months before they would occur.

Digital Tools for Predictive Maintenance

The future of spindle care is decidedly digital, and at MZI Precision, we’re helping manufacturers accept these transformative technologies.

IoT sensors embedded directly in spindle assemblies measure critical parameters like vibration, temperature, and power consumption in real-time. These tiny sentinels transmit data continuously, creating a detailed picture of spindle health that simply wasn’t possible a decade ago.

The data from these sensors feeds into intuitive cloud dashboards that maintenance teams can access from anywhere. Imagine being able to check the health of every spindle in your facility from your smartphone – that’s the reality for our clients who’ve acceptd this technology.

Behind these dashboards, AI analytics work tirelessly to detect patterns. These machine learning algorithms can identify subtle changes in performance data that might indicate developing problems, often catching issues weeks or months before human operators would notice anything wrong.

Perhaps most impressive are advanced collision detection systems that can recognize and respond to crashes in milliseconds. When a collision occurs, these systems can stop machine movement almost instantly, potentially preventing catastrophic damage to both the spindle and expensive workpieces.

One manufacturing manager who implemented these technologies with our help shared: “The system’s ability to collect temperature, vibration, and collision data in real-time is amazing! Armed with real-time knowledge, we now can predict when to schedule maintenance and having that control is awesome!”

At MZI Precision, we’re not just repairing spindles – we’re partnering with clients to implement these technologies as ongoing monitoring solutions. The result is dramatically reduced unplanned downtime and a new level of confidence in manufacturing operations.

Choosing the Right Spindle Repair Partner

Finding the perfect partner for your Machine Tool Spindle Repair needs isn’t just about getting your equipment fixed—it’s about building a relationship with experts who understand how critical your spindles are to your operation. When production stops, you need someone you can trust completely.

At MZI Precision, we’ve seen how the right repair partner can transform a crisis into an opportunity for improvement. Quality spindle repair isn’t just about replacing bearings—it’s about restoring confidence in your manufacturing process.

ISO 9001 Certification should be non-negotiable when selecting a repair partner. This international standard ensures the repair shop follows consistent, documented processes rather than taking shortcuts. Our ISO 9001:2015 certification means every spindle receives the same meticulous attention to detail, regardless of size or complexity.

The best shops guarantee micron-level tolerances after repair. When a technician tells you they can achieve radial runout of 2 microns or less, they’re promising precision that’s thinner than a human hair. This level of accuracy is what separates true precision rebuilders from basic repair shops.

“We once had a customer who’d been through three different repair shops before finding us,” shares one of our senior technicians. “They couldn’t understand why their spindles kept failing after just a few months. Turns out, those shops were assembling in standard shop environments. The microscopic contamination was dooming those spindles from day one.”

That’s why clean-room assembly matters so much. Our climate-controlled assembly areas maintain strict environmental standards, keeping dust and contaminants away from your precision components. When you peek through our clean room windows and see technicians in protective gear handling your spindle with the care of surgeons, you’ll understand the difference quality makes.

Strong warranty terms tell you everything about a repair shop’s confidence in their work. When we offer comprehensive coverage on our repairs, we’re putting our money where our mouth is. We can offer these warranties because we know our rebuilt spindles often outlast the originals.

Turnaround time can make or break your production schedule. While some shops might quote weeks, our standard repairs are completed in just 3-5 days. For truly urgent situations, we offer expedited options that can have your spindle back even faster—because we understand that every hour of downtime hits your bottom line.

When disaster strikes at midnight, you need a partner who answers the phone. Our emergency service is available 24/7, including door-to-door pickup and delivery for those middle-of-the-night crises. One automotive parts manufacturer called us at 11 PM on a Friday with a down spindle threatening Monday’s production. By Sunday afternoon, their rebuilt spindle was back in service—crisis averted.

“We bet you’ll be hooked by our quality and turnaround time,” is more than just a catchy phrase—it’s our promise to every client. Many of our best customer relationships started with an emergency repair that showed them what true spindle expertise looks like.

Questions to Ask Before Sending Your Spindle

Before entrusting your critical components to any repair service, have a conversation about these key points:

What quality certifications does your facility maintain? The answer should include ISO 9001:2015 at minimum, but additional certifications specific to your industry are even better.

Do you stock components for my spindle model? Shops with extensive parts inventories can deliver faster turnarounds without waiting for special orders. At MZI, we maintain a comprehensive stock of bearings, seals, and components for most common industrial spindles.

What documentation will I receive after repair? Comprehensive reporting isn’t just paperwork—it’s your assurance that the job was done right. Our detailed reports include before/after measurements, replaced components, and performance test results that verify your spindle is ready for production.

Can you recommend improvements to the original design? The best providers don’t just restore—they improve. We often suggest targeted upgrades that improve performance or reliability, like improved sealing systems or ceramic bearings that can take your spindle beyond its original capabilities.

“How many spindles of this type have you repaired?” is perhaps the most revealing question you can ask. Specific experience with your exact spindle model is invaluable—it means they’ve already solved the common problems and know the quirks of your equipment.

Finally, ask about testing protocols. Quality shops test extensively under load at maximum rated RPM, not just a quick spin to make sure it turns. Our testing protocols simulate production conditions to ensure your spindle performs when it matters most.

At MZI Precision, we welcome these tough questions because they give us the chance to demonstrate our capabilities and our unwavering commitment to quality. When your production depends on precision, you deserve a partner who’s as invested in your success as you are.

Frequently Asked Questions about Industrial Spindle Repair

What turnaround time can I expect?

When your production line is down, every hour counts. At MZI Precision, we understand this pressure, which is why our standard Machine Tool Spindle Repair turnaround is typically just 3-5 business days after receiving your spindle. This timeframe includes our complete process: disassembly, ultrasonic cleaning, thorough inspection, precision repair, rigorous testing, and final certification.

“We had a critical spindle failure that threatened to shut down our entire production line,” one manufacturing manager told us. “MZI had us back up and running in just four days, saving us thousands in lost production time.”

For those truly urgent situations where even a few days feels too long, we offer expedited emergency service with 1-3 day turnaround, including weekend and overtime work. We’ve been known to work through the night when a client’s production schedule demands it!

Your specific timeline will vary based on several factors: the extent of damage finded during inspection, the availability of specialized replacement components, the complexity of testing required for your application, and any performance upgrades you might request. We pride ourselves on providing realistic timeline estimates upfront and keeping you informed at every stage of the repair process.

How does repair cost compare to a new spindle?

The financial math on spindle repair is compelling. A professional spindle rebuild from MZI Precision typically costs between 30-50% of what you’d pay for a brand new spindle, while delivering performance that matches or even exceeds original specifications.

We believe in transparent pricing, so we provide detailed cost breakdowns that help you make informed decisions about your equipment investment. The economic advantages extend beyond just the initial price difference:

Reduced downtime is perhaps the biggest hidden value – our repair turnaround is almost always significantly faster than the lead time for a new spindle delivery, which can stretch into months for specialized models.

Component upgrades during rebuild often provide performance improvements that weren’t available when your original spindle was manufactured.

Extended service life frequently matches or exceeds what you’d get from a new unit, especially when paired with our preventive maintenance recommendations.

Avoided reconfiguration costs can be substantial, as new spindle models sometimes require machine modifications that add to the total replacement expense.

One of our agricultural manufacturing clients recently saved over $85,000 by choosing to rebuild six production-critical spindles rather than replacing them. Even more valuable was the nearly three weeks of production time they saved compared to waiting for new spindle delivery.

Are repaired spindles guaranteed for accuracy?

Absolutely! A properly repaired spindle should perform as well as—or better than—a new one, and we stand firmly behind this promise. At MZI Precision, we guarantee our rebuilt spindles will achieve radial runout of 2 microns or less and axial runout of 1 micron or less. These aren’t just marketing claims; they’re performance specifications we verify through testing.

Every spindle leaving our facility undergoes a battery of rigorous testing procedures to ensure it meets our exacting standards:

Dynamic two-plane balancing to G1 tolerances eliminates vibration issues that could affect part quality.

Extended run testing at maximum rated RPM confirms thermal stability and performance under load.

Comprehensive vibration analysis verifies bearing performance and identifies any potential issues before they cause problems.

Precision measurement of all critical dimensions ensures perfect geometric accuracy.

Detailed documentation provides you with before-and-after performance metrics for your records.

“The spindle MZI rebuilt for us is actually running better than when it was new,” reports a precision aerospace component manufacturer. “Our surface finishes have improved, and we’re seeing less tool wear than before.”

We back our repairs with a comprehensive warranty covering both parts and workmanship. When properly installed and maintained, our rebuilt spindles typically deliver service life equal to or better than new spindles—often at substantial savings.

Conclusion

When your production line grinds to a halt because of a spindle issue, it’s more than an inconvenience—it’s a direct hit to your bottom line. That’s why Machine Tool Spindle Repair deserves your full attention as a manufacturing professional. At MZI Precision, we’ve built our reputation by not just fixing spindles, but often sending them back to you performing better than when they first left the factory.

After working with thousands of spindles across every industry imaginable, we’ve learned a few important lessons worth sharing:

First, those small warning signs—that slight vibration or unusual noise—are actually golden opportunities. Addressing spindle issues early can save you thousands in emergency repairs and lost production time. Think of it as preventive medicine for your manufacturing operation.

Our meticulous 19-point repair checklist might seem excessive to some, but our clients appreciate the difference this attention to detail makes. When we rebuild your spindle in our clean-room environment, we’re not just replacing bearings—we’re restoring the heart of your machine to peak performance.

The technology we use today would have seemed like science fiction just a decade ago. Vibration analysis systems can detect microscopic bearing flaws long before failure, while ceramic bearings and improved sealing systems often allow your repaired spindle to outperform its original specifications. As one customer told us with a smile, “This thing runs smoother than the day we bought it!”

Looking ahead, the most successful manufacturers are shifting from the old “run it till it breaks” approach to smart, predictive maintenance. The data doesn’t lie—companies using monitoring systems to schedule maintenance during planned downtime are seeing productivity increases of 15-20% compared to those still operating reactively.

Choosing the right spindle repair partner matters tremendously. Experience, technical capabilities, quality standards, and simply being easy to work with all contribute to whether your repair experience is a headache or a relief. We’ve built our business on being the kind of partner we’d want to have if our own production was on the line.

At MZI Precision, we understand the pressure you’re under when equipment fails. That’s why we’ve streamlined our processes to deliver fast, reliable repairs without cutting corners. Our team brings decades of combined experience to every job, ensuring your spindle returns performing at its absolute best.

Whether you’re machining critical aerospace components where tolerances are measured in microns or pushing high-volume production for agricultural equipment, we have the expertise to keep your spindles—and your business—running smoothly.

For more information about our precision spindle services or to discuss your specific needs, contact us today. We’re ready to help you maintain peak performance and maximize uptime for all your critical manufacturing assets.