The Power Behind Precision: Understanding CNC Servo Motors and Drives

CNC servo motors and drives are the critical components that power modern precision machining operations. If you’re comparing systems, here’s what you need to know:

| Feature | Servo Motors | Stepper Motors |

|---|---|---|

| Feedback | Closed-loop with encoders | Typically open-loop |

| Torque | Maintains nearly full torque at max speed | Loses torque at high speeds |

| Resolution | Hundreds of thousands of steps per revolution | Typically 200 steps per revolution |

| Speed | Several thousand RPM | Up to ~2,000 RPM |

| Cost | Higher initial investment | Lower upfront cost |

In CNC machining, the difference between good and exceptional often comes down to motion control. Servo systems represent the gold standard for applications demanding precision, speed, and reliability.

What makes these systems special is their ability to “know” exactly where they are at all times through encoder feedback. Unlike their simpler cousins (stepper motors), servo motors maintain almost all their torque even at high speeds and can briefly exceed their rated capacity when needed.

As Teknic, a leading servo manufacturer, puts it: “By leaving out certain costly features, we made servo systems affordable for applications that could never afford them before.” This democratization of servo technology has expanded precision capabilities across industries.

Whether you’re retrofitting an older machine or building a new system from scratch, understanding the core components and performance characteristics of servo systems is essential for making informed decisions about your CNC equipment investments.

Cnc servo motors and drives word roundup:

– ac servo motors

– cnc motors

– servo motor in cnc

CNC Servo Motors and Drives 101

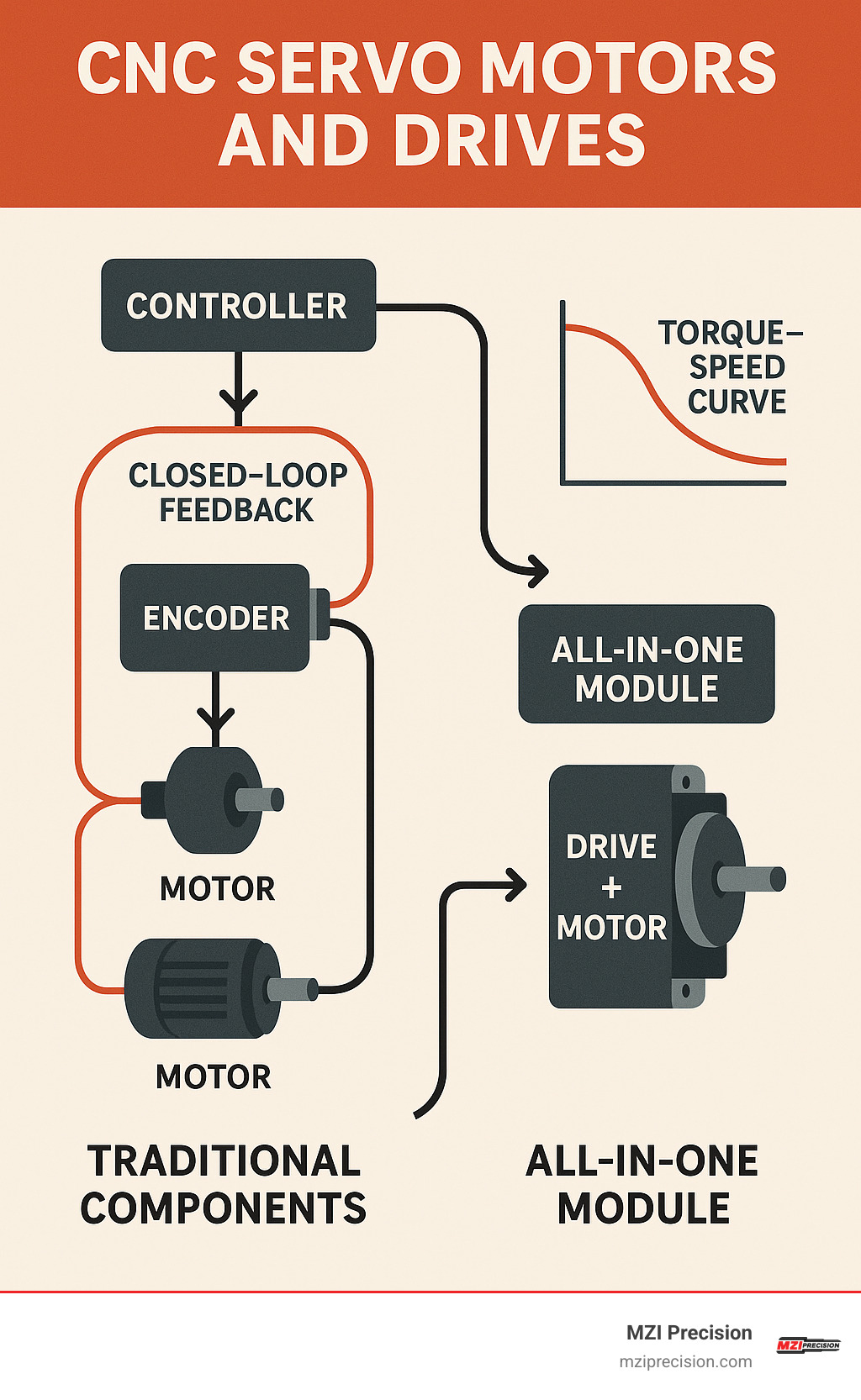

At their core, CNC servo motors and drives operate on a fundamental principle: closed-loop control. This means the system constantly monitors its actual position via feedback devices and compares it to the commanded position, making adjustments as needed for precise positioning.

What Is a Servo Motor?

Think of a servo motor as the muscle behind precision machining. It’s a sophisticated motion control device with several key components working together in perfect harmony.

The stator forms the stationary outer portion, housing electromagnet windings that create the magnetic fields. Inside, the rotor (the rotating shaft assembly) contains permanent magnets that respond to those fields. High-precision bearings support the rotor, ensuring smooth, friction-minimized rotation. The unsung hero of the system is the pulse coder/encoder – a feedback device that constantly tracks position with incredible accuracy.

Most industrial CNC applications today rely on AC brushless servo motors, though DC types still have their place. FANUC, for example, designs most of their servo motors with 8-pole configuration (four pairs of north-south magnets) to deliver exceptional precision and silky-smooth operation.

What makes these motors truly special is their impressive torque-speed relationship. Unlike other motor technologies that lose strength at higher speeds, servo motors maintain nearly all their muscle even when running flat out – a huge advantage when machining parts that require consistent cutting forces regardless of how fast the axes are moving.

Servo Drive Fundamentals

The servo drive is essentially the brain to the motor’s brawn. Often called an amplifier or servopack, this sophisticated electronic controller powers and directs the motor with remarkable precision. Modern drives use pulse-width modulation (PWM) technology to efficiently convert input power into exactly what the motor needs.

Inside a typical servo drive, you’ll find a nested set of control loops working together:

The current loop (the innermost one) controls motor torque directly and runs extremely fast – often at 20kHz or higher. The velocity loop manages speed as a middle layer. The position loop (the outermost) ensures accurate positioning and typically runs at 1-2kHz. This hierarchical control structure is what enables the exceptional precision that CNC servo motors and drives are famous for.

Today’s servo drives pack some impressive additional features too. They include adaptive tuning algorithms that optimize performance on the fly, resonance detection systems that prevent harmful vibration, regenerative braking circuits that capture energy during deceleration, and comprehensive protection systems that guard against electrical and thermal issues.

Key Advantages of CNC Servo Motors and Drives

When it comes to CNC motion control, servo systems offer some compelling benefits that directly impact your machining quality and productivity.

High resolution makes micron-level accuracy possible, thanks to encoders that provide hundreds of thousands of counts per revolution. Your parts come out with exceptional dimensional precision, time after time.

Full-speed torque means consistent cutting performance regardless of axis speed. Unlike steppers that weaken dramatically at higher RPMs, servo motors maintain their muscle throughout their speed range.

Superior load control allows instant response to changing cutting conditions. When your tool hits a harder section of material, the servo system detects and compensates immediately, maintaining position and feed rate.

Managed acceleration through sophisticated motion profiles minimizes jerk (the rate of change of acceleration), resulting in smoother operation and reduced wear on mechanical components. Your machine stays accurate longer with less maintenance.

Controlled torque ripple in quality servo systems minimizes tiny force fluctuations that can mar surface finishes in precision machining.

As we often tell our customers at MZI Precision, “You can have the perfect CNC program and the sharpest tooling, but without a responsive motor system that can consistently feed the part and spindle, you’ll never achieve truly exceptional results.” That’s why we emphasize properly specified and maintained servo systems as a critical foundation for precision machining excellence.

Specifying the Right Servo Package

Choosing the perfect CNC servo motors and drives for your application is a bit like finding the right partner – it requires understanding your needs and making sure the match is compatible. Let’s walk through what really matters when making this critical decision.

Load Inertia and Torque Requirements

When we talk with customers at MZI Precision, the first question we often ask is about the mechanical load requirements. Think of this as the “heavy lifting” assessment:

The load inertia ratio is crucial – ideally, you want your motor’s rotor inertia matched well with your mechanical load. Most of our successful installations maintain ratios between 1:1 and 1:5 for smooth, responsive control.

Your motor’s continuous torque needs to comfortably exceed your maximum cutting forces with room to spare. It’s like buying shoes a half-size larger – that extra space prevents pinching when you need it most.

Don’t overlook peak torque capacity. Quality servo motors can deliver 2-3 times their continuous rating for those brief moments of acceleration or heavy cutting. This short-term muscle can make all the difference in challenging applications.

The duty cycle – or how hard you’re pushing the motor and for how long – directly impacts which size motor you’ll need. A motor that’s constantly working at 90% capacity will run hotter and likely wear out faster than one operating comfortably at 60-70% of its rating.

Environmental Considerations

Manufacturing floors can be tough environments, and your servo system needs to stand up to the challenge:

Your shop’s conditions matter tremendously. If you’re running coolant-heavy operations, look for motors with robust IP ratings like the FANUC Alpha i-D Series with IP67 protection, which can handle serious washdown environments without complaint.

Consider your typical temperature range carefully. Extreme heat or cold can significantly impact performance and longevity of even the best servo systems.

In heavy machining applications where cutting forces create substantial vibration, you’ll want motors specifically designed to withstand these conditions. This is particularly important for the kinds of precision manufacturing our customers at MZI typically handle.

Comparing Integrated vs. Traditional Servo Systems

| Feature | Integrated Systems | Traditional Separate Components |

|---|---|---|

| Wiring Complexity | Low (fewer cables) | Higher (separate motor, drive, encoder cables) |

| Installation Space | Compact | Requires separate mounting for drives |

| Heat Dissipation | Limited (all heat in one package) | Better (drive can be mounted away from motor) |

| Serviceability | Often requires complete unit replacement | Individual components can be replaced |

| Cost | Often lower for small systems | Can be more economical for larger systems |

| Power Range | Typically limited to lower power ranges | Available in very high power ratings |

Encoder Types & Feedback Resolution

The encoder is essentially your servo system’s eyes and ears. Without good feedback, even the strongest motor becomes clumsy and imprecise.

Incremental encoders are the workhorses of the industry – more affordable but requiring that “homing” sequence at startup to establish position. They’re like resetting your odometer each time you start your car.

Absolute encoders maintain position information even when powered down – eliminating those homing routines and getting you back to production faster after power interruptions. For many of our customers running high-volume production, this time savings alone justifies the additional cost.

Sine-cosine encoders provide those smooth analog signals that can be interpolated for incredibly fine resolution. When you’re measuring success in microns rather than thousandths, these encoders become essential tools.

Modern servo systems achieve resolutions from 12,800 counts/rev in standard applications up to a remarkable 64,000 counts/rev in high-precision systems. This level of precision is what enables the exacting tolerances many of our aerospace and defense customers require.

Comparing CNC Servo Motors and Drives to Stepper Solutions

While steppers certainly have their place, CNC servo motors and drives offer compelling advantages for serious industrial applications:

The closed-loop accuracy of servo systems means they constantly monitor and correct position errors. Unlike steppers that can lose steps under load (often without warning), servos know exactly where they are at all times.

Speed retention is a major servo advantage – they maintain their torque at high speeds while steppers experience that dreaded torque drop-off above about 2,000 RPM. This means your servo-driven axes maintain accuracy even during rapid moves.

The thermal efficiency difference is striking. Servos draw only the current needed for the actual load, while steppers typically run hot, drawing full current regardless of what they’re actually doing. In a multi-axis machine, this efficiency adds up to significant energy savings and cooler operation.

The dynamic response of servo systems allows for faster acceleration and more responsive direction changes – critical for complex contouring operations in aerospace and medical part manufacturing.

Integrated vs. Separate Components

Today’s market offers two main architectural approaches to consider:

All-in-one modules combine motor, drive, and encoder in a single package. These integrated units offer simplicity – fewer cables, automatic tuning, less hardware to mount, and typically easier setup. They’re particularly appealing for smaller machines or retrofits where space is at a premium.

The modular stack approach uses separate motors, drives, and sometimes encoders. While requiring more integration work upfront, this traditional approach offers greater flexibility for customization and often makes troubleshooting and repairs more straightforward.

Wiring simplicity shouldn’t be underestimated – integrated systems significantly reduce cabling complexity, which becomes increasingly valuable as your axis count grows. One of our customers recently converted a 5-axis machine to integrated servos and eliminated nearly 60% of their motion control wiring!

At MZI Precision, we’ve worked with both approaches across numerous machine rebuilds and can help you evaluate which architecture best suits your specific application requirements, maintenance capabilities, and long-term performance goals. The right choice depends on your unique situation – there’s no one-size-fits-all answer when it comes to precision motion control.

For more insights on high-precision machining technologies, check out the latest research on high-precision machining that’s informing our approach to spindle and motion system integration.

Performance, Cost & Maintenance Insights

When evaluating CNC servo motors and drives, it’s worth looking beyond the sticker price to understand what you’re really investing in over time.

![]()

Cost of Ownership Across Life Cycle

The true cost story of a servo system is more like a novel than a price tag. Here’s what that story includes:

That initial price can range dramatically – from about $249 for an entry-level Teknic ClearPath integrated system to several thousand dollars per axis for industrial powerhouses. But that’s just chapter one.

The energy efficiency of CNC servo motors and drives often shines brightest in the middle chapters. Unlike some other motor types that run at full current regardless of what they’re doing, servos draw only what they need for the task at hand – a bit like a disciplined dinner guest who only takes what they’ll eat.

Perhaps the most compelling chapter, though, is about downtime – or rather, the lack of it. Quality servo systems with built-in diagnostics and protection features are like having a doctor constantly monitoring your equipment’s health. They can spot problems before they become catastrophes, saving you from the most expensive words in manufacturing: “The line is down.”

Reliability & Preventive Care

Modern CNC servo motors and drives are engineering marvels when it comes to longevity. Take ClearPath servo motors – they’re rated for more than 25 billion revolutions of bearing life. To put that in perspective, that’s like driving a car around the equator about 600,000 times. Or in more practical terms, nearly 50 years of non-stop operation at 1,000 RPM.

What makes these systems so durable? It starts with premium bearings that can handle billions of revolutions without breaking a sweat. Then there’s thoughtful thermal management – some designs use compression-fit housings that pull heat away from critical components like a good radiator.

For shops working in challenging environments, IP67-rated motors stand up to coolant spray and dust like a duck in water. And individually custom-balanced rotors reduce vibration, which is a bit like having perfectly balanced tires on your car – everything just runs smoother and lasts longer.

At MZI Precision, we’ve learned through years of spindle work that a little prevention is worth a pound of emergency repair. That’s why we recommend:

- Regularly checking those servo drive diagnostic parameters (they’re telling you something important!)

- Taking a close look at cables and connectors before they become problems

- Verifying that encoder signals are clean and reliable

- Keeping an eye on temperature trends – they’re often the first warning of trouble brewing

Troubleshooting Common Servo Issues

Even the most reliable servo systems occasionally have bad days. When they do, here’s what you might encounter:

Position error alarms are the servo’s way of saying “I can’t get where you want me to go.” This might happen because you’re asking for more acceleration than physics allows, something is binding mechanically, your tuning parameters need adjustment, or your encoder is having communication issues.

Following errors typically show up when your motor is undersized for what you’re asking it to do – like trying to tow a boat with a compact car. They can also appear when there’s mechanical trouble in the drivetrain or when servo loops aren’t properly tuned.

Regeneration faults occur during aggressive deceleration, when the motor becomes a generator and pumps energy back into the drive. If there’s nowhere for that energy to go (like a properly sized regeneration resistor), the drive protects itself by faulting.

Oscillation or instability feels like a nervous twitch in your machine. It’s usually the result of improper gain settings, mechanical resonances that amplify rather than dampen movement, or excessive backlash in the drivetrain.

The good news is that modern drives are chatty – they provide detailed diagnostic information that can help you pinpoint exactly what’s happening. It’s a bit like having your car tell you exactly which spark plug is misfiring, rather than just flashing a generic “check engine” light.

At MZI Precision, we’ve found that addressing these issues methodically saves time and frustration. It’s tempting to start swapping parts, but understanding the root cause is almost always faster and more effective in the long run.

Industrial Servo System Roundup

Let’s examine some representative categories of CNC servo motors and drives available in today’s market:

High-Torque AC Servo Package

These systems are designed for demanding applications like heavy milling and turning operations where substantial cutting forces must be overcome while maintaining precision.

Key characteristics include:

- Power ratings from 2 kW to 22 kW

- Torque values from 7.7 Nm to 140 Nm

- Speeds typically ranging from 1500 to 2500 RPM

- Robust construction with high-quality bearings

- Sophisticated thermal management

- Advanced tuning capabilities for optimizing performance

These systems excel in applications like:

– Heavy metal cutting operations

– Large format machining centers

– Applications requiring sustained high torque

Compact All-in-One Servo Module

These integrated systems combine the motor, drive, and encoder in a single package, simplifying installation and reducing wiring complexity.

Notable features include:

- Power ratings typically from 200W to 1.5kW

- USB connectivity for easy setup and tuning

- Auto-tuning capabilities that eliminate complex manual adjustment

- Built-in protection features

- Compact form factors ideal for space-constrained applications

As Teknic notes about their ClearPath systems: “Get up and running faster than ever with an all-in-one servo system—fewer cables, automatic tuning, less hardware to mount, and easy-to-use software.”

These systems are ideal for:

– Retrofit applications where simplicity is valued

– Multi-axis machines where wiring complexity is a concern

– Applications where space is limited

Budget-Friendly Entry-Level Servo Kit

For smaller machines and less demanding applications, entry-level servo packages offer a cost-effective path to closed-loop performance.

These typically feature:

- Power ratings from 200W to 750W

- Basic encoder feedback (often 2500-5000 PPR)

- Simplified tuning interfaces

- Standard NEMA frame sizes for easy mechanical integration

- Reasonable performance at a lower price point

These systems are well-suited for:

– Small CNC routers and mills

– Educational and prototyping equipment

– Light-duty automation applications

Heavy-Duty Washdown Servo Option

For harsh industrial environments, especially those involving coolant or other fluids, specialized washdown-rated servo systems are available.

These feature:

- IP67 or higher environmental protection

- Stainless hardware and sealed connectors

- Special shaft seals to prevent ingress

- Corrosion-resistant materials and coatings

- Robust cable management systems

FANUC notes that their Alpha i-D Series servo motors come standard with IP67 protection, making them suitable for heavy washdown environments commonly found in manufacturing facilities.

These systems excel in:

– Machine tools using heavy coolant

– Food processing equipment

– Outdoor applications

– Chemical processing environments

At MZI Precision, our experience with industrial manufacturing spindles has given us insight into how critical environmental protection is for long-term reliability. The same principles apply to CNC servo motors and drives in demanding industrial settings.

Frequently Asked Questions about CNC Servo Motors and Drives

How do encoders improve accuracy?

Encoders are the unsung heroes of precision in the servo world. Think of them as the keen eyes of the system, constantly watching and reporting the motor’s exact position.

Unlike the simpler stepper motors with their modest 200 steps per revolution, modern cnc servo motors and drives use encoders that can detect a whopping 12,800 to 64,000 counts for every single revolution. That’s like comparing a yardstick to a micrometer!

What makes this truly powerful is the continuous feedback loop created. The drive tells the motor where to go, the encoder reports where it actually is, and the drive makes tiny adjustments to eliminate any gap between the two. This constant conversation happens thousands of times per second, resulting in positioning accuracy that can be measured in microns.

As one of our customers recently told us, “Once you’ve experienced the precision of a good servo system with high-resolution feedback, it’s hard to imagine going back to anything less.”

What’s the main difference from stepper setups?

The difference between steppers and servos is a bit like comparing a reliable sedan to a performance sports car – both will get you there, but the experience is entirely different.

Cnc servo motors and drives operate in a closed loop, constantly checking their position and adjusting as needed. Steppers typically run “open-loop,” essentially following commands blindly with no way to know if they’ve actually reached their target.

When it comes to torque, steppers start losing their muscle above 1,000 RPM and might drop to less than half their rated strength by 2,000 RPM. Servo motors, on the other hand, maintain nearly all their torque even at top speed – a crucial advantage when you’re making heavy cuts at high feed rates.

Efficiency is another night-and-day difference. Steppers constantly draw full current regardless of what they’re doing (even when standing still!), while servos intelligently use only the power needed for the task at hand. This not only saves energy but also runs cooler, extending component life.

I often tell our customers that steppers are perfect for lighter-duty applications where budget matters more than performance, but when precision and productivity are on the line, cnc servo motors and drives are the clear choice for industrial manufacturing environments.

Are integrated servos worth the premium?

Integrated servo systems package the motor, drive, and encoder into one tidy unit – and yes, they usually come with a premium price tag. But as with most things in life, whether that premium is “worth it” depends entirely on your specific situation.

The advantages are compelling. Wiring simplicity alone can save hours of installation time and eliminate numerous potential failure points. I’ve seen technicians spend entire days troubleshooting complex wiring issues that simply don’t exist with integrated systems. The clean, compact design also frees up valuable real estate in your machine.

Cnc servo motors and drives in integrated packages come pre-optimized to work together perfectly, eliminating the component matching guesswork. As one manufacturer aptly puts it, they’re “tuned at the factory, not on your shop floor.”

That said, these all-in-one wonders aren’t perfect for every application. Heat management can be challenging since everything generates heat in one spot. When something does go wrong, you’re often replacing the entire unit rather than just the failed component. And if you need serious power, integrated options typically top out at lower ratings than their separate counterparts.

At MZI Precision, we’ve helped many customers steer this decision based on their specific application requirements, maintenance capabilities, and long-term production goals. Whether integrated or traditional is right for you depends on factors beyond just the price tag – it’s about finding the perfect match for your unique manufacturing environment.

Conclusion

CNC servo motors and drives truly represent the beating heart of modern precision machining. After exploring their capabilities throughout this guide, it’s clear why these systems have become the gold standard for manufacturers who refuse to compromise on accuracy, speed, or reliability.

When you’re weighing your options for motion control systems, remember to look beyond the sticker price. The true value of a quality servo system reveals itself over time through energy savings, reduced maintenance headaches, and—perhaps most importantly—minimized downtime. A premium servo package often pays for itself many times over through improved part quality and production consistency.

At MZI Precision, we’ve seen how the right motion control solution transforms manufacturing capabilities. Our years working with industrial manufacturing spindles have given us a deep appreciation for precision components that simply work, day in and day out. Your servo system isn’t just another part—it’s the foundation that determines what your entire machine can achieve.

Whether you’re breathing new life into an older machine with a retrofit or specifying components for an exciting new build, choosing the right CNC servo motors and drives sets the trajectory for years of production. The principles we’ve covered—from closed-loop feedback to torque characteristics and maintenance considerations—provide a roadmap for making choices aligned with your specific needs and budget realities.

The world of precision manufacturing demands excellence in every component, and your motion system sits at the very center of that requirement. A well-chosen servo package delivers the consistent, reliable performance that modern machining demands, turning programming precision into physical reality with every move.

For those looking to maintain peak performance across all aspects of their precision manufacturing equipment, MZI Precision offers expert spindle repair and rebuilding services that complement your motion control systems. To learn more about how we can support your industrial manufacturing needs, visit our website or reach out to our team. We’re here to help you keep the precision in precision manufacturing.