CNC Servo Drive: 7 Powerful Benefits for Precision in 2025

Why CNC Servo Drives Are Essential for Modern Manufacturing

A cnc servo drive is the electronic amplifier that controls servo motors in CNC machines, providing precise position, speed, and torque control through closed-loop feedback systems. Here’s what you need to know when buying one:

Key CNC Servo Drive Types:

– AC Servo Drives – Most common, 100W to 22kW power range, three-phase input

– DC Servo Drives – Simpler control, 7-40 in-lb torque range, single-phase compatible

– Integrated Motor-Drive Units – All-in-one solutions starting around $249-$598

Essential Specifications to Consider:

– Power rating (match to motor requirements)

– Voltage compatibility (single-phase 220V or three-phase)

– Feedback type (incremental encoder, absolute encoder, resolver)

– Interface (step/direction, analog, fieldbus communication)

– Protection features (overcurrent, thermal shutdown, regenerative braking)

As one forum user noted: “Good does not come cheap—paying more for quality servos is worth the investment for long-term reliability.” This rings especially true in precision manufacturing where downtime costs far exceed the initial investment in quality servo drives.

Modern CNC operations demand the precision that only closed-loop servo control can deliver. Unlike stepper motors that run open-loop, servo drives use real-time encoder feedback to ensure the motor reaches exactly the commanded position. This eliminates the step loss and resonance issues that plague stepper systems under heavy loads.

The servo drive market offers solutions from budget-friendly units around $200 to industrial-grade systems exceeding $5,000 per axis. Quality manufacturers provide proven reliability, while newer integrated solutions simplify installation and reduce wiring complexity.

For manufacturing operations requiring consistent precision, servo drives aren’t just an upgrade—they’re essential. The closed-loop control ensures your parts meet tolerance specifications batch after batch, while the higher torque-to-weight ratio enables faster cycle times and improved productivity.

Simple cnc servo drive glossary:

– servo motor control system

– servo motor feedback repair

– cnc motors

How a CNC Servo Drive Works (Buyer’s Quick Refresher)

Think of a cnc servo drive as the smart middleman between your CNC controller’s brain and your servo motor’s muscle. When you’re shopping for one, understanding this relationship helps you pick the right drive for your specific needs.

Here’s how the magic happens: Your CNC controller says “move to position X,” and the servo drive takes that command and amplifies it into the power needed to move your motor. But here’s where it gets interesting—the motor has an encoder that constantly whispers back “here’s where I actually am right now.”

This creates what we call a feedback loop, and it’s happening thousands of times every second. The drive compares where you want to be with where you actually are, then makes tiny corrections to keep everything perfectly on track.

The PID algorithm is the mathematical wizard behind this precision. Don’t worry about the technical details—just know that it’s constantly calculating exactly how much current to send to the motor to eliminate any position errors. It’s like having a really good driver who smoothly adjusts the steering wheel to stay perfectly in their lane.

When you’re choosing between AC and DC servo drives, think about your power needs. AC drives handle the heavy lifting—they can manage up to 22kW and deliver excellent speed-torque characteristics for industrial manufacturing spindles. DC drives work beautifully for smaller applications, typically in the 7-40 in-lb torque range, and they’re simpler to wire with single-phase power.

Understanding torque-speed curves helps you buy smart. Servo motors give you maximum torque at low speeds (perfect for heavy cutting operations) and then maintain constant power as speeds increase (great for rapid positioning moves). This versatility is why scientific research on high-speed precision consistently points to servo systems for demanding applications.

Main Components Inside the Box

When you peek inside a servo drive, you’ll find it’s actually quite organized. The power stage contains the switching electronics that convert your facility’s power into the precise three-phase AC that brushless servo motors love. These high-frequency switches work incredibly fast—thousands of times per second—to create smooth motor rotation.

The logic board houses a specialized computer processor designed specifically for motion control. Modern drives use powerful 32-bit processors that can handle complex calculations while simultaneously managing communications with your CNC controller and processing encoder feedback.

Current sensors act like the drive’s sense of touch, constantly monitoring how much current flows to the motor. This real-time feedback enables precise torque control and protects your investment by preventing overcurrent damage.

The regenerative brake circuit is particularly clever—it captures energy that flows back from the motor during deceleration. Instead of wasting this energy as heat, quality drives either feed it back to your power supply or safely dissipate it through braking resistors. This feature becomes essential when your spindle frequently changes direction or speed.

Safety I/O provides the critical emergency stop interface that keeps your operators safe. Modern drives include Safe Torque Off (STO) functionality that meets industrial safety standards—a must-have feature for any professional manufacturing environment.

Controller–Drive–Motor Interface Flow

The conversation between your CNC controller and servo drive follows a predictable pattern that’s worth understanding before you buy. Your controller generates motion commands based on your part program, and these commands can take several different forms depending on your drive’s capabilities.

Step and direction signals are the most common interface, especially if you’re retrofitting existing equipment. The controller sends tiny step pulses (each representing a small position increment) along with a direction signal. Your servo drive’s internal position controller converts these digital breadcrumbs into smooth, precise motor motion.

Analog voltage signals offer another approach, where the controller outputs a voltage (typically ±10V) that’s proportional to the desired speed. The drive’s velocity loop maintains that exact speed regardless of load variations—particularly useful for spindle applications where consistent surface speeds matter.

Modern fieldbus communications like EtherCAT or Profinet represent the cutting edge of servo control. These digital networks let your controller send position, velocity, and torque commands simultaneously while receiving detailed status information from each drive. It’s like upgrading from walkie-talkies to smartphones.

Position feedback flows continuously from your motor’s encoder back to the drive. High-resolution encoders delivering 12,800 to 64,000 counts per revolution provide the precision needed for accurate positioning. The drive processes this feedback internally and can also send position data back to your controller for verification.

Real-time diagnostics give you visibility into what’s actually happening inside your system. Quality drives monitor dozens of parameters including motor temperature, bus voltage, following error, and load percentage. This information helps you optimize performance and catch potential issues before they become expensive problems.

Choosing the Right CNC Servo Drive for Your Machine

Picking the perfect cnc servo drive isn’t just about finding the cheapest option—it’s about matching your machine’s real-world demands with the right drive capabilities. We’ve worked with countless manufacturers who learned this lesson the hard way, finding their “bargain” drive couldn’t handle what their industrial manufacturing spindle operations actually required.

Your first step should be understanding your application load completely. Think beyond just the cutting forces. You need to account for the weight and inertia of everything that moves—your spindle, tooling, workpieces, and machine components. A 750W servo might look perfect on the spec sheet, but if you’re moving heavy components or need rapid direction changes, that 2kW model might be your real minimum.

The number of axes you’re controlling directly impacts both your budget and system complexity. A straightforward 3-axis retrofit for a basic mill might run $1,500-3,000 for quality servo drives. But when you’re looking at 5-axis machining centers with high-performance requirements, you could easily hit $15,000 or more. Here’s a tip from our experience: if you think you might add an axis later, buy the extra drive now. The package deals almost always save money.

Duty cycle is where many buyers get tripped up. If you’re running continuous heavy operations—like the kind of precision work that keeps industrial manufacturing spindles busy all day—you need drives built for that punishment. The thermal design and heat management become critical. Lighter, intermittent work can often get by with smaller drives that use their thermal mass to handle occasional peaks.

Don’t overlook environmental factors either. Standard drives work fine tucked inside clean electrical cabinets, but manufacturing floors can be harsh places. If you’re dealing with coolant mist, metal chips, or temperature swings, you’ll need drives with proper protection ratings. The upgrade cost is always less than dealing with premature failures.

| AC Servo Drives | DC Servo Drives |

|---|---|

| Power Range: 100W – 22kW | Power Range: 50W – 500W |

| Input: Three-phase preferred | Input: Single-phase compatible |

| Speed: Up to 6,000 RPM typical | Speed: Up to 3,000 RPM typical |

| Control: More complex algorithms | Control: Simpler PID tuning |

| Cost: Higher initial investment | Cost: Lower entry price |

| Applications: Industrial CNC | Applications: Light machining, hobby |

Power, Voltage & Current: Sizing a cnc servo drive

Getting the power sizing right saves you from both poor performance and unnecessary expenses. Most industrial manufacturing applications fall somewhere between 100W for light operations and 5kW for heavy-duty work. Our recommendation? Size up by about 20-30%. The extra headroom gives you better dynamic response and typically extends drive life.

The single-phase versus three-phase decision often comes down to what’s available in your facility. Single-phase 220V works well up to about 2kW, making it popular for smaller machines and retrofit projects. Beyond that power level, you’ll need three-phase input for efficiency and to meet electrical codes. The installation costs can add up, so factor that into your budget early.

Understanding the difference between peak and continuous ratings can save you significant money. A drive rated for 5A continuous might handle 15A peaks for short bursts. This peak capability is what enables those rapid positioning moves and quick direction changes. But if your application involves frequent reversals—common in precision manufacturing—you’ll want to size closer to those peak requirements rather than just the continuous ratings.

Thermal design separates the quality drives from the budget options. Look for drives that maintain full performance up to 40°C ambient temperature. Cheaper units start derating at 25°C, which can leave you with insufficient power when your shop gets warm. Intelligent fan control and proper heat sinking aren’t glamorous features, but they’re the ones that keep your spindle operations running when it matters.

Feedback & Control Interfaces When Specifying a cnc servo drive

The feedback system is really where servo drives earn their keep over simpler alternatives. Incremental encoders are the workhorses of the industry, typically providing anywhere from 2,500 to 64,000 counts per revolution. Before you assume more is always better, know that 12,800 counts per revolution handles most precision manufacturing applications beautifully.

Absolute encoders cost about 20-30% more, but they eliminate those annoying homing routines every time you power up. The system remembers exactly where everything is, even after a power outage. For production environments where startup time matters, this feature pays for itself quickly.

For truly harsh environments, resolver feedback offers best reliability. These analog devices have no delicate digital electronics to fail and can handle extreme temperatures that would kill standard encoders. They’re probably overkill for most applications, but in critical manufacturing environments, that reliability is worth the premium.

Step and direction interfaces make retrofitting existing systems much simpler. You can often reuse your current controller wiring with minimal changes. Modern servo drives accept step rates up to 500kHz, so even demanding applications won’t push them to their limits.

Ethernet-based motion control represents where the industry is heading. Systems like EtherCAT can synchronize multiple axes within microseconds while providing rich diagnostic information. The setup is more complex initially, but the performance and troubleshooting capabilities are in a different league.

Feature Checklist Before You Buy

Auto-tuning capability might be the most underrated feature in modern servo drives. Quality drives can automatically measure your system’s characteristics and optimize all the control parameters. This saves hours of commissioning time and means you don’t need a motion control expert on staff. The time savings alone often justifies choosing a drive with this feature.

Adaptive gain algorithms continuously fine-tune performance as conditions change. As your cutting tools wear or you switch between different materials, these smart systems maintain consistent performance. It’s like having an experienced technician constantly optimizing your system.

Integrated damping helps control those mechanical resonances that can cause chatter or poor surface finish. Some drives include sophisticated filtering that can be tuned to suppress specific problem frequencies. Others use advanced algorithms that automatically adapt as conditions change.

Safe Torque Off (STO) functionality is becoming essential for meeting modern safety standards. When activated, it removes power from the motor while keeping the drive’s logic circuits active for diagnostics. This eliminates the need for external safety relays and simplifies your electrical design.

Field-upgradeable firmware extends your investment’s life by adding new features and fixing issues through software updates. Drives with USB or Ethernet connectivity make updates straightforward. Avoid drives that require proprietary programming tools—they create headaches down the road.

The essential protection features you absolutely need include overcurrent protection with both hardware and software limits, thermal shutdown monitoring for both motor and drive temperatures, and overvoltage/undervoltage protection. Ground fault detection, motor cable break detection, and following error limits with configurable responses round out the must-have list. Regenerative brake monitoring and phase loss detection for three-phase systems complete the package that keeps your equipment—and your operators—safe.

Installation, Tuning & Maintenance Best Practices

Proper installation determines whether your cnc servo drive investment delivers the promised performance or becomes a source of ongoing frustration. We’ve troubleshot countless systems where poor installation practices negated the benefits of quality drives.

Shielded wiring is non-negotiable for reliable servo operation. Motor cables should use continuous shield from drive to motor with 360-degree shield termination at both ends. Signal cables need separate shielding, and power and signal cables should never share the same conduit. This isn’t just good practice—it’s essential for passing EMC requirements.

Grounding creates the foundation for noise immunity. Establish a single-point ground at your main electrical panel and run dedicated ground conductors to each drive. Never use conduit or cable tray as a ground path, and ensure ground impedance stays below 1 ohm from drive to main ground point.

Inertia matching affects both performance and mechanical life. The general rule suggests keeping reflected load inertia within 10:1 of motor inertia for optimal performance. Higher ratios require more sophisticated tuning and may need gearing changes for acceptable response.

Vibration analysis during commissioning identifies potential mechanical issues before they cause failures. Modern drives often include built-in vibration monitoring that can detect bearing wear, coupling problems, or mechanical resonances. This data helps schedule preventive maintenance and avoid catastrophic failures.

For comprehensive industrial manufacturing spindle maintenance and repair services, we offer specialized expertise in precision manufacturing applications. Our team understands the critical relationship between servo drives and spindle performance in industrial manufacturing environments. More info about spindle services

Step-By-Step Commissioning Workflow

Mounting considerations affect both performance and service life. Servo drives generate significant heat and require adequate ventilation. Mount drives vertically when possible to promote natural convection cooling. Maintain manufacturer-specified clearances around drives and ensure ambient temperature stays within rated limits.

Power-up testing should follow a systematic sequence to avoid damage. Start with motor disconnected and verify bus voltage, logic power, and I/O signals. Connect the motor and perform static tests before enabling motion. This methodical approach identifies wiring errors before they can damage expensive components.

Auto-tune procedures vary by manufacturer but generally follow similar patterns. The drive applies test signals to measure system response and calculates optimal PID parameters. Some drives require the system to be unloaded during auto-tune, while others can tune under actual operating conditions.

Manual fine-tuning becomes necessary when auto-tune results don’t meet performance requirements. Start with position loop gains, then adjust velocity loop parameters. Modern drives often provide tuning wizards that guide you through the process step-by-step.

Load validation confirms that your tuned system meets performance specifications under actual operating conditions. Run typical machining cycles while monitoring following error, motor current, and system response. Document these baseline measurements for future troubleshooting reference.

Common Issues & Quick Fixes

Overshoot problems typically indicate excessive position loop gain or insufficient damping. Reduce the position loop gain by 20% and retest. If overshoot persists, increase velocity loop integral gain to improve damping. Some drives offer automatic overshoot suppression that can eliminate this issue entirely.

Hunting or oscillation suggests unstable tuning parameters. This often occurs when velocity loop gains are too high relative to position loop settings. Reduce velocity loop proportional gain first, then readjust position loop gain to maintain desired stiffness.

Overheating can result from inadequate ventilation, excessive ambient temperature, or drive overloading. Check that cooling fans operate properly and clean any dust buildup from heat sinks. Verify that actual motor current doesn’t exceed drive ratings during normal operation.

Regenerative trips occur when deceleration energy exceeds the drive’s ability to dissipate it. This is common in applications with high inertia loads and frequent direction changes. Solutions include adding external braking resistors, reducing deceleration rates, or upgrading to drives with higher regenerative capacity.

Noise immunity issues manifest as erratic operation or random faults. Verify shield connections and ground integrity first. Separate power and signal cables, and consider using fiber optic communication for severe noise environments. Some drives offer adjustable noise filtering that can help in marginal situations.

Frequently Asked Questions about CNC Servo Drives

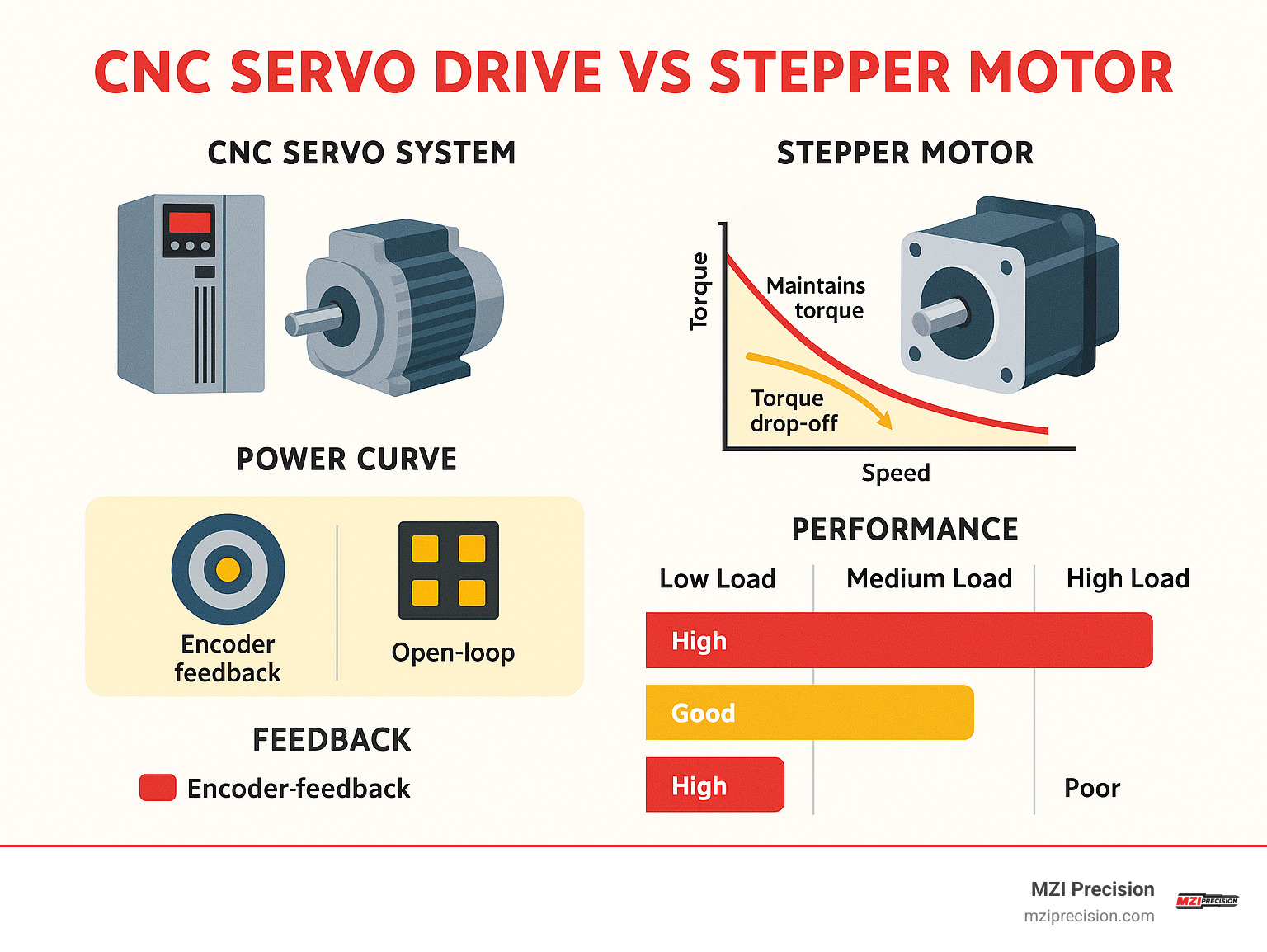

What advantages do servo drives offer over stepper drives?

A stepper moves in open looponce it misses a step, accuracy is gone. A cnc servo drive closes that loop with encoder feedback, so the axis always knows its exact position and corrects errors instantly. Servo motors also keep high torque across a wider speed range, accelerate faster, and run more quietly. In production terms that means shorter cycle times, smoother finishes, and fewer scrapped parts.

How much should I budget for a mid-range 1 kW kit?

Expect about $80000 for a quality 1 kW motor/drive combo that includes basic cables. Professional installation and tuning typically add another $500000 per axis if you outsource the work. DIY installers save labor costs but should plan on extra time for wiring, shielding, and PID tuning. For a typical 3-axis retrofit youre looking at $3 000 000 all-in, assuming the machine cabinet and power supply are in good shape.

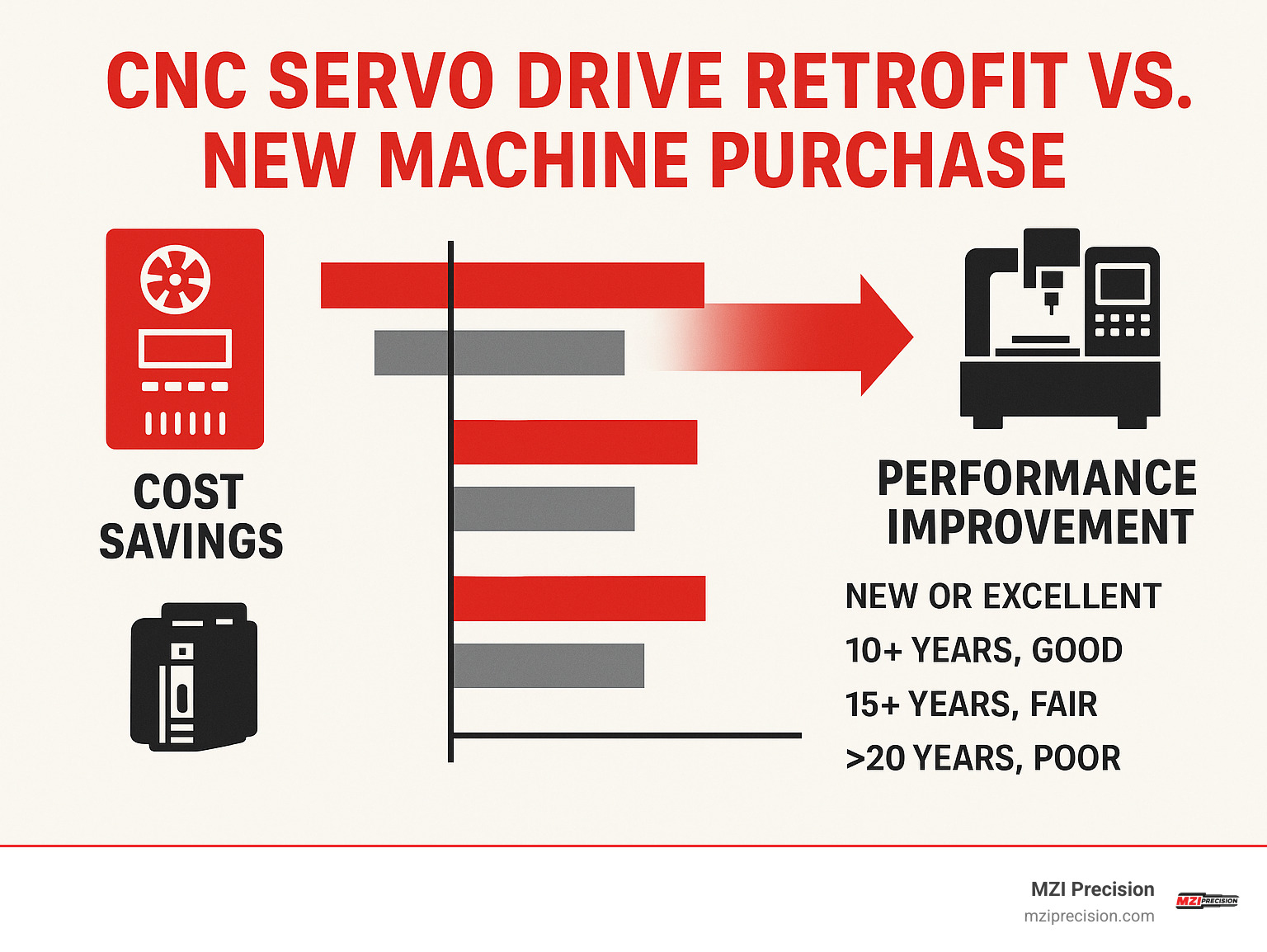

Can I retrofit older CNC machines without changing the motors?

Often, yes. Many legacy industrial motors are still mechanically sound; its the electronics that age out. Modern drives can accept a variety of feedback devicesencoders, resolvers, or even analog tachometersso electrical compatibility is usually the deciding factor. Check the motors voltage and current ratings, verify the feedback type, and be ready to build adapter cables. Mechanical mountings or shaft couplings may need minor rework, but when the iron is solid, a drive upgrade can add years of productive life for a fraction of a new-machine cost.

Conclusion

Investing in a quality cnc servo drive isn’t just about upgrading your equipment—it’s about changing how your manufacturing operation performs. The precision and reliability these systems deliver have become essential for staying competitive in today’s demanding market. Whether you’re breathing new life into an older machine or building a state-of-the-art system from scratch, the servo drive you choose will impact your operation for years to come.

The journey from budget-friendly integrated units around $249 to industrial-grade powerhouses exceeding $5,000 per axis might seem daunting. But here’s the thing: the right drive for your application isn’t necessarily the most expensive one. It’s the one that matches your specific needs while providing room for growth. We’ve seen too many shops struggle with drives that seemed like bargains until they couldn’t handle the real-world demands of production.

Think of your servo drive upgrade as building a foundation for future success. Starting with a solid 3-axis retrofit gives you immediate benefits while setting the stage for expansion. Modern servo systems play well together, so adding that fourth axis or integrating advanced features becomes straightforward when you’ve chosen wisely from the start.

At MZI Precision, we see how cnc servo drives work hand-in-hand with other precision components. Our industrial manufacturing spindle rebuilding expertise has taught us that servo drive performance and spindle condition are intimately connected. A perfectly tuned servo drive can’t compensate for a worn spindle, just like a rebuilt spindle can’t reach its potential with a poorly functioning drive. Everything needs to work together.

The real cost of servo drives extends beyond that initial purchase price. Factor in installation time, the learning curve for your operators, and ongoing support needs. Quality drives from established manufacturers might cost more upfront, but they typically come with better documentation, responsive technical support, and clear upgrade paths. That peace of mind is worth the investment when production schedules are on the line.

Here’s what makes servo drives indispensable: they eliminate the guesswork. The closed-loop feedback means you know exactly where your axes are at all times. No more wondering if that stepper motor skipped steps during a heavy cut. No more scrapped parts because positioning accuracy drifted over time. The superior speed-torque characteristics let you push cycle times while maintaining surface finish quality.

For comprehensive support with your precision manufacturing equipment needs, including the industrial manufacturing spindle services that complement your servo drive installations perfectly, our team brings decades of real-world experience to every project. We understand that cnc servo drives are just one piece of the precision manufacturing puzzle, and we’re here to help make all the pieces work together seamlessly. More info about spindle services