Precision CNC spindles: The Ultimate 101 Guide

WHY PRECISION CNC SPINDLES ARE THE BACKBONE OF MODERN MANUFACTURING

Precision CNC spindles are the critical rotating components at the heart of CNC machine tools that hold and spin cutting tools at high speeds to remove material with extreme accuracy. Here’s what you need to know:

Core Function:

- Holds cutting tools securely using specialized clamping systems (HSK, BT, CAT)

- Delivers rotational power at speeds ranging from 10,000 to 250,000 RPM

- Maintains precision through advanced bearing systems and thermal stability

- Supports multiple axes with accurate positioning for complex parts

Primary Components:

- Drive system (motorized or belt-driven)

- Spindle housing and shaft

- High-precision bearing system (ceramic, aerostatic, or hybrid)

- Tool clamping mechanism (drawbar)

- Cooling and lubrication systems

If you’re searching for a spindle that can transform your CNC machine from a standard mill into a high-speed machining center capable of holding tolerances below 1 micron, you’re looking at the difference between good parts and exceptional parts.

The development of modern CNC spindles focuses on speed and precision – two factors that directly impact your bottom line. As one industry expert noted, “The sleek design of modern spindles makes them conversation pieces,” but more importantly, they enable manufacturers to meet ever-changing industry demands with higher quality and more reliable outcomes.

Think about it this way: your spindle is spinning thousands of times per minute while simultaneously maintaining accuracy measured in microns. That’s roughly the width of a human hair. In aerospace manufacturing, where components must meet exacting specifications, or in defense applications where failure isn’t an option, this level of precision isn’t just nice to have – it’s mission-critical.

The difference between a standard spindle and a precision spindle often comes down to the bearing technology, cooling systems, and motor integration. Ceramic bearings minimize deflection and vibration. Advanced cooling prevents thermal expansion that could throw off measurements. Direct-drive motors eliminate the slop and inconsistency of gear systems.

But here’s what many engineers overlook: a spindle is only as good as its maintenance. Even the most advanced high-frequency spindle running at 50,000 RPM will fail prematurely without proper care, proactive inspection, and expert repair when needed.

Precision CNC spindles terms made easy:

THE HEART OF THE MACHINE: UNDERSTANDING SPINDLE ANATOMY AND OPERATION

At the core of every CNC machine, the spindle is the powerhouse responsible for transmitting motion and power to the cutting tool. It’s not just about spinning; it’s about doing so with incredible accuracy, rigidity, and consistency. A precision CNC spindle is a sophisticated piece of engineering, designed to withstand immense forces and temperatures while maintaining tolerances often measured in microns.

The functionality of a CNC spindle hinges on the harmonious interaction of its primary components. These include the drive system, which provides the rotational power; the spindle housing, which encases and protects the internal mechanisms; the shaft, to which the cutting tool is attached; the bearing system, crucial for smooth, precise rotation; the lubrication system, which reduces friction and heat; and the cooling system, which manages thermal expansion. Together, these elements enable the spindle to perform high-speed, high-precision machining operations that are simply unattainable with traditional methods.

KEY COMPONENTS OF PRECISION CNC SPINDLES

Let’s dig into the essential parts that make a precision CNC spindle tick:

- Bearings: These are arguably the most critical components for spindle precision. They support the rotating shaft, ensuring minimal runout and vibration.

- Ceramic Bearings: Often found in high-performance spindles, ceramic bearings offer superior rigidity, higher speed capabilities, and reduced friction compared to traditional steel bearings. They contribute to a longer lifespan and better surface finishes.

- Aerostatic Bearings: Used in ultra-precision spindles, these bearings use a cushion of pressurized air to support the shaft, virtually eliminating friction and wear. They are ideal for applications demanding optical surface finishes and extreme accuracy.

- Spindle Shaft: This is the central rotating component that holds the cutting tool. Its material, design, and balance are crucial for minimizing vibration and maintaining accuracy, especially at high RPMs.

- Motor Integration: In many modern spindles, the motor is integrated directly into the spindle assembly, forming a compact and highly efficient unit. This direct-drive design reduces vibration and improves overall rigidity.

- Housing: The external casing that protects the internal components and provides structural integrity.

- Flanged Cartridge: Motorized CNC spindles with a flanged cartridge design offer high rigidity and stiffness, allowing for more efficient and productive machining. Their design also facilitates easier installation and removal.

- Block Housing: Motorized spindles with block housings provide high torque and speed capabilities. The block housing offers robust support and stability, crucial for improved accuracy and surface finish quality in heavy-duty machining.

- Tool Clamping System: This mechanism securely holds the cutting tool in place. Different standards exist, each offering unique advantages:

- HSK (Hollow Shank Taper): Known for its high rigidity and excellent repeatability, HSK is common in high-speed machining. We see variations like HSK-E 20, HSK-E 25, HSK-E 32, and HSK-C 63 for ultra-precision applications.

- BT (Bottle Taper): A common taper used in many CNC machines, offering good rigidity.

- CAT (Caterpillar): Similar to BT, CAT tapers are prevalent in North America.

- Drawbar: This internal component pulls the tool holder into the spindle taper, ensuring a tight and secure fit.

CORE TECHNOLOGIES: COOLING AND LUBRICATION

Managing heat and friction is paramount for spindle longevity and precision. Without effective cooling and lubrication, thermal expansion can lead to inaccuracies, and excessive friction can cause premature wear.

- Air Cooling: A common and cost-effective method where ambient air is circulated around the spindle housing to dissipate heat. While simpler, it’s less effective for very high-speed or heavy-load applications.

- Water Cooling: More efficient than air cooling, water (or coolant) is circulated through channels within the spindle housing, providing superior thermal management. This is often preferred for high-performance and high-speed spindles, especially those with integrated motors, to maintain dimensional stability.

- Oil-Air Lubrication: This system delivers a fine mist of oil and air to the bearings, providing continuous lubrication and cooling. It’s highly effective for high-speed spindles, minimizing friction and carrying away heat.

- Grease Lubrication: Bearings can be permanently greased or use a grease replenishment system. While simpler, grease lubrication can generate more heat at very high speeds compared to oil-air. However, modern grease systems, like those with automatic replenishment, can significantly extend maintenance-free operation, sometimes up to 10,000 hours, while reducing environmental impact by cutting oil consumption to zero.

- Thermal Stability: Consistent temperature control is vital. Spindles are often designed with optimized cooling solutions and internal sensors to monitor temperature, ensuring that the spindle maintains its dimensional accuracy even during prolonged, intense operations.

- Vibration Reduction: Proper lubrication and cooling, combined with high-precision bearings and balanced components, significantly reduce vibration. Limiting vibration improves surface finish and accuracy and supports the longevity of machining components.

For more detailed information on how we maintain and restore these critical components, please explore our services. MORE INFO ABOUT OUR SERVICES

A SPECTRUM OF SPINDLES: COMPARING DESIGNS FOR OPTIMAL PERFORMANCE

The world of precision CNC spindles is diverse, with various designs engineered to meet specific machining challenges. The choice of spindle type profoundly impacts a machine’s speed, torque, rigidity, and suitability for different applications.

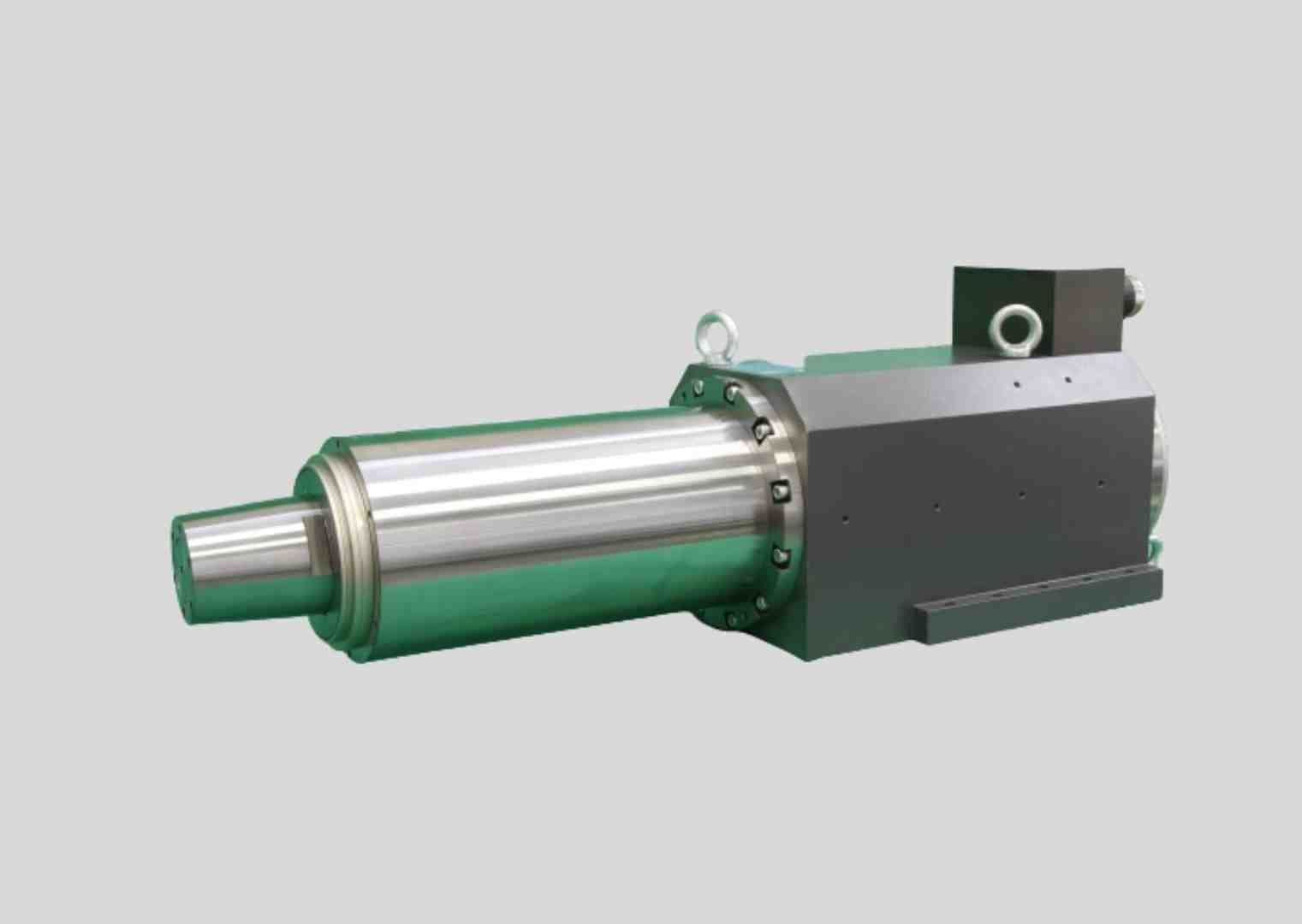

MOTORIZED (INTEGRAL) SPINDLES

These are the workhorses of modern CNC machining, also known as electrospindles or built-in motor spindles. They feature an integrated motor and spindle shaft, creating a compact and highly efficient unit.

- Integrated Motor: The motor is directly coupled to the spindle shaft, eliminating the need for belts, gears, or other power transmission components. This direct-drive system significantly reduces vibration and mechanical losses.

- High Rigidity and Stiffness: The compact, integrated design inherently offers superior rigidity and stiffness, allowing for more efficient and productive machining, even with heavier cuts. Motorized spindles with flanged cartridges or block housings exemplify this, providing robust support.

- High Speed Capabilities: Motorized spindles can achieve very high RPMs, with some high-frequency models reaching up to 50,000 rpm or even 150,000 RPM for ultra-precision tool motor spindles. This makes them ideal for High-Speed Machining (HSM) and High-Performance Cutting (HPC) applications.

- Compact Design: Their all-in-one nature allows for smaller machine footprints and more flexible machine designs, particularly in multi-axis machines.

- Reduced Vibration: The direct drive and integrated motor design inherently produce less vibration compared to belt-driven systems, which translates to improved surface finish, accuracy, and longer tool life.

- Applications: Motorized spindles are highly versatile, excelling in milling, boring, grinding, and turning operations across a wide range of materials and industries, from aerospace to general production.

BELT-DRIVEN AND OTHER SPINDLE TYPES

While motorized spindles dominate high-speed applications, other designs offer distinct advantages for different scenarios.

- Belt-Driven Spindles: In these systems, an external motor transmits power to the spindle shaft via a belt.

- External Motor: The motor is separate from the spindle housing.

- Power Transmission via Belt: A belt connects the motor to the spindle, transferring rotational energy.

- High Torque at Lower Speeds: Belt-driven spindles often provide excellent torque at low to medium speeds (up to 15,000 RPM), making them suitable for heavy material removal and applications where brute force is more critical than ultra-high speed.

- Maintenance: While the belt itself is a wear item, the separation of the motor can sometimes simplify motor replacement.

- Application Suitability: Ideal for VMCs, lathes, gantry machines, and custom CNC systems where robust, consistent power at moderate speeds is required.

- Gear-Driven Spindles: These spindles use gears to transmit power and often offer high torque at lower speeds, similar to belt-driven, but with different mechanical characteristics.

- Air-Turbine Spindles: These unique spindles use compressed air to drive a turbine, achieving extremely high speeds. Air Turbine Spindles®, for example, can transform CNC machines into high-speed machining centers at governed 25,000 RPM – 90,000 RPM. Ultra-Precision Tool Motor Spindles can reach up to 150,000 RPM, and High Speed MTC Grinding and Milling Spindles can even hit 250,000 rpm. They are excellent for detail work, finishing, and micro-machining with small tools, offering benefits like no heat generation and no duty cycle due to their direct-drive pneumatic motor design.

| FEATURE | MOTORIZED (INTEGRAL) SPINDLES | BELT-DRIVEN SPINDLES |

|---|---|---|

| Speed | Very High (up to 250,000 RPM) | Moderate (typically up to 15,000 RPM) |

| Torque | High at high speeds; can be powerful across wide ranges | Excellent at low to medium speeds |

| Rigidity | Very High (direct drive, compact) | High (can be very robust) |

| Maintenance | Potentially complex due to integrated components; long life | Belt replacement, simpler motor replacement |

| Vibration | Very Low | Slightly higher due to belt/gear engagement |

| Applications | HSM, HPC, precision milling, grinding, turning | Heavy stock removal, general milling, drilling, turning |

SPECIALIZED FEATURES AND THEIR ROLE

Modern precision CNC spindles often incorporate advanced features that further improve their functionality and performance:

- Automatic Tool Changers (ATC): Essential for automated production, ATC systems allow the CNC machine to quickly swap cutting tools without human intervention. This dramatically increases productivity and reduces cycle times.

- High-Speed Capabilities: As discussed, the ability to reach tens or hundreds of thousands of RPM is crucial for efficient machining of hard materials, micro-machining, and achieving superior surface finishes.

- Advanced Cooling Systems: Beyond basic air or water, these can include thin-film liquid cooling for ultra-precision spindles, ensuring precise thermal management and dimensional stability.

- Internal Sensors: Integrated sensors monitor critical parameters like temperature, vibration, and rotation, providing real-time feedback for optimal performance, predictive maintenance, and tool breakage detection.

- Rotary Encoder Systems: These provide highly accurate feedback on spindle speed and position, vital for precise motion control in complex machining operations.

- Through-Spindle Coolant: Delivering coolant directly through the center of the cutting tool improves chip evacuation, cools the cutting edge, and extends tool life, especially in deep-hole drilling and demanding milling applications.

THE PRECISION ADVANTAGE: APPLICATIONS AND BENEFITS ACROSS INDUSTRIES

The advent of precision CNC spindles has revolutionized industrial manufacturing, enabling capabilities that were once unimaginable. These advanced components are not just about speed; they’re about delivering accuracy, repeatability, and efficiency that directly impact product quality and profitability.

KEY INDUSTRIAL APPLICATIONS

Our expertise in precision CNC spindles and their repair serves a broad spectrum of demanding industrial applications right here in California, including Los Angeles and Huntington Beach.

- Aerospace Manufacturing: The aerospace industry, with its stringent safety standards and complex geometries, relies heavily on high-precision spindles for machining critical components like turbine blades, structural parts, and engine components. The ability to hold tight tolerances and achieve superior surface finishes is paramount.

- Defense Components: Similar to aerospace, the defense sector requires manufacturing components with extreme reliability and precision. Spindles are integral to producing parts for military equipment, weaponry, and advanced defense systems.

- Solar Energy Parts: As the solar energy industry expands, the need for precisely machined components for solar panels, mounting systems, and energy storage devices grows. Precision spindles ensure the accuracy and consistency required for efficient energy capture.

- General Metal Cutting: Across various manufacturing sectors, from heavy machinery to specialized tooling, precision spindles enable efficient and accurate cutting of diverse metals, facilitating the production of high-quality parts.

- Grinding Operations: High-speed grinding spindles are essential for achieving extremely fine surface finishes and tight dimensional tolerances on hardened materials, from internal and external grinding to surface grinding.

- High-Speed Machining (HSM) and High-Performance Cutting (HPC): These techniques leverage the high RPM and rigidity of precision spindles to rapidly remove material while maintaining excellent surface quality, significantly reducing cycle times in industries like mold making and general production.

WHY PRECISION CNC SPINDLES OUTPERFORM TRADITIONAL METHODS

The advantages of precision CNC spindles over older, more traditional machining methods are clear and quantifiable:

- Increased Productivity: With higher RPMs (sometimes 6-10x faster), precision spindles drastically cut cycle times, allowing manufacturers to produce more parts in less time. This directly translates to increased output and profitability.

- Improved Quality: Our spindles typically produce less vibration due to the precision of their design. Limiting vibration improves surface finish and accuracy, leading to higher quality end products that meet the most demanding specifications.

- Improved Reliability: Designed for robust performance, precision CNC spindles are built to withstand continuous, demanding operations, leading to less downtime and more consistent production.

- Greater Torque: Modern CNC spindles have increased torque output, which allows for heavier cuts without sacrificing accuracy and facilitates machining different, tougher materials.

- Tighter Tolerances: The combination of high rigidity, advanced bearings (like ceramic or aerostatic), and precise thermal management allows these spindles to hold extremely tight tolerances, often below 1 micron, which is crucial for mission-critical components.

- Superior Surface Finish: Reduced vibration and high speeds enable finer cuts, resulting in mirror-like surface finishes that often eliminate the need for secondary finishing operations.

- Multi-Axis Machining Support: Precision CNC spindles can support multiple axes with the power to deliver high speeds and accurate cuts, which lifts the quality of the end product and increases profitability for the manufacturer.

- Reduced Downtime: While maintenance is still crucial, the inherent durability and advanced diagnostic capabilities of precision spindles lead to more predictable performance and less unscheduled downtime.

MAXIMIZING UPTIME: A GUIDE TO SPINDLE SELECTION AND MAINTENANCE

CHOOSING THE RIGHT PRECISION CNC SPINDLES FOR YOUR NEEDS

Selecting the ideal spindle requires a thorough understanding of your specific application and operational requirements. Here are the key factors we consider:

- Torque Requirements: How much rotational force do you need? Heavy material removal or large-diameter tools will demand higher torque. Motorized spindles with block housings, for instance, are known for their high torque capabilities.

- Speed Range (RPM): What is the optimal cutting speed for your materials and tools? For micro-machining or finishing, ultra-high speeds (e.g., 90,000 RPM for micro tools) are critical. For general milling, 15,000-45,000 RPM might suffice. Air Turbine Spindles® can retrofit machines with 25,000 – 90,000 RPM, delivering power up to 1.4 HP.

- Material Compatibility: Different materials (e.g., hardened steel, aluminum, composites) have varying machining characteristics that influence the required spindle speed, power, and rigidity.

- Tooling Interface: Ensure compatibility with your existing or planned tool holders (HSK, BT, CAT, etc.). The tool interface impacts clamping force and precision.

- Power (kW/HP): The spindle’s power output should match the demands of your cutting operations. High-performance spindles can range from 1.4 HP (1.03 kW) to 150 kW for very heavy-duty applications.

- Application Demands: Are you performing heavy stock removal, fine surface finishing, high-speed engraving, or grinding? Each demands a specific spindle profile. For example, high-frequency spindles are designed for ultra-fast machining applications demanding high RPM, minimal vibration, and superior surface finish.

- Budget Considerations: While precision comes at a cost, the long-term benefits in productivity and part quality often outweigh the initial investment. We help you find the best balance for your budget.

BEST PRACTICES FOR SPINDLE MAINTENANCE AND REPAIR

Even the most robust precision CNC spindles require diligent care to ensure longevity and optimal performance. Proactive maintenance is not just about extending the life of the spindle; it’s about safeguarding the precision and quality of your manufactured parts.

- Regular Cleaning: Dirt, dust, and coolant residue can contaminate bearings and compromise sealing systems. Regular, thorough cleaning of the spindle exterior and tool clamping area is essential.

- Inspection Schedule: Implement a proactive inspection schedule. Before each use, inspect the spindle for any visible damage, unusual noises, or excessive vibration. Daily, weekly, and monthly checks can catch minor issues before they become major problems.

- Recognizing Signs of Wear: Pay attention to warning signs such as increased noise levels, excessive heat generation, decreased machining accuracy, poor surface finish, or unusual vibrations. Addressing these early can prevent catastrophic failures and costly downtime.

- Vibration Analysis: Regular vibration analysis can provide crucial insights into the health of your spindle bearings and balance. Trends in vibration levels can indicate impending issues long before they become apparent.

- Lubrication Checks: Ensure your lubrication system is functioning correctly. For oil-air systems, verify proper oil and air pressure. For grease-lubricated spindles, adhere to the manufacturer’s recommended replenishment schedule.

- The Importance of Expert Repair: When issues arise, especially with complex, high-precision spindles, repairs and replacements are best left to experts. We specialize in the repair and rebuilding of industrial manufacturing spindles, including OEM rebuilt spindles, ensuring they are restored to original specifications. Our certified technicians understand the intricate design and precise tolerances required for optimal performance, utilizing specialized assembly rooms and maintaining an inventory of most OEM parts.

- Scientific Research on Modern Tool Development: The continuous advancement in spindle technology, driven by scientific research, underscores the need for expert knowledge in their maintenance and repair. As noted in a relevant study, the development of modern tools focuses on speed and precision, and understanding these advancements is key to effective spindle care. SCIENTIFIC RESEARCH ON MODERN TOOL DEVELOPMENT

FREQUENTLY ASKED QUESTIONS ABOUT PRECISION CNC SPINDLES

WHAT IS THE DIFFERENCE BETWEEN A SPINDLE AND A MOTOR?

A motor is the component that generates rotational power. A spindle, in the context of CNC machines, is a complete assembly that includes a shaft, bearings, and a tool clamping system, and it is driven by a motor. In many modern precision CNC spindles, especially motorized or electrospindles, the motor is integrated directly into the spindle assembly itself, making it a single, compact unit. However, in belt-driven systems, the motor is external to the spindle.

HOW DO I KNOW IF MY CNC SPINDLE NEEDS REPAIR?

Several signs indicate your precision CNC spindle might need repair. These include:

- Unusual Noise: Grinding, whining, or rattling sounds that weren’t present before.

- Excessive Heat: The spindle running hotter than normal, even under light loads.

- Increased Vibration: Noticeable shaking or trembling during operation, which can be detected through vibration analysis.

- Poor Surface Finish: A decline in the quality of the machined surface, indicating increased runout or tool chatter.

- Decreased Accuracy: Difficulty holding tolerances or inconsistent part dimensions.

- Tool Breakage: An increase in tool breakage, which can sometimes be linked to spindle issues.

- Coolant or Lubricant Leaks: Visible leaks around the spindle housing.

If you observe any of these symptoms, it’s crucial to consult with spindle repair specialists promptly to prevent further damage and costly downtime.

WHAT IS SPINDLE RUNOUT AND WHY IS IT IMPORTANT?

Spindle runout refers to any deviation of the spindle’s rotation from a perfect axis. It’s essentially how much the spindle “wobbles” as it spins. Runout can be axial (movement along the axis of rotation) or radial (movement perpendicular to the axis). It is measured in microns or thousandths of an inch.

Spindle runout is critically important because it directly impacts machining accuracy, tool life, and surface finish. Even a tiny amount of runout can cause:

- Inaccurate Cuts: The cutting tool will not follow the intended path precisely.

- Premature Tool Wear: Uneven loading on the cutting tool leads to faster wear and increased tool breakage.

- Poor Surface Finish: Vibrations and uneven cutting result in rougher surfaces.

- Bearing Damage: Excessive runout can put undue stress on the spindle bearings, shortening their lifespan.

Minimizing runout is a hallmark of precision CNC spindles, achieved through high-quality bearings, precise manufacturing, and careful balancing.

CONCLUSION

Precision CNC spindles are more than just spinning components; they are the technological heartbeats of modern industrial manufacturing. Their ability to deliver unparalleled speed, accuracy, and surface finish has transformed industries from aerospace to solar energy, enabling the creation of complex components with micron-level precision. We’ve explored their intricate anatomy, from advanced ceramic and aerostatic bearings to sophisticated cooling and lubrication systems, and compared the performance nuances of motorized versus belt-driven designs.

The advantages are clear: increased productivity, superior quality, improved reliability, greater torque, and significantly reduced vibration. These benefits translate directly into a competitive edge for manufacturers, allowing them to meet changing demands and achieve higher profitability.

As technology continues to advance, the future of spindle technology promises even greater speeds, tighter tolerances, and more intelligent integration with predictive maintenance capabilities. But regardless of future innovations, one truth remains constant: the longevity and optimal performance of these critical components depend on expert care.

At MZI Precision, we are committed to ensuring your precision CNC spindles operate at their peak. With our expertise in OEM rebuilt spindles and our dedication to exceptional service, we understand the intricate demands of industrial manufacturing. Whether you’re in California, Los Angeles, or Huntington Beach, our team is ready to provide the specialized repair and rebuilding services that keep your operations running smoothly and precisely. Don’t let spindle issues compromise your production; partner with us to maintain the precision that defines your success. CONTACT US FOR YOUR SPINDLE SERVICE NEEDS