Why Upgrading to AC Servo Motors Transforms CNC Router Performance

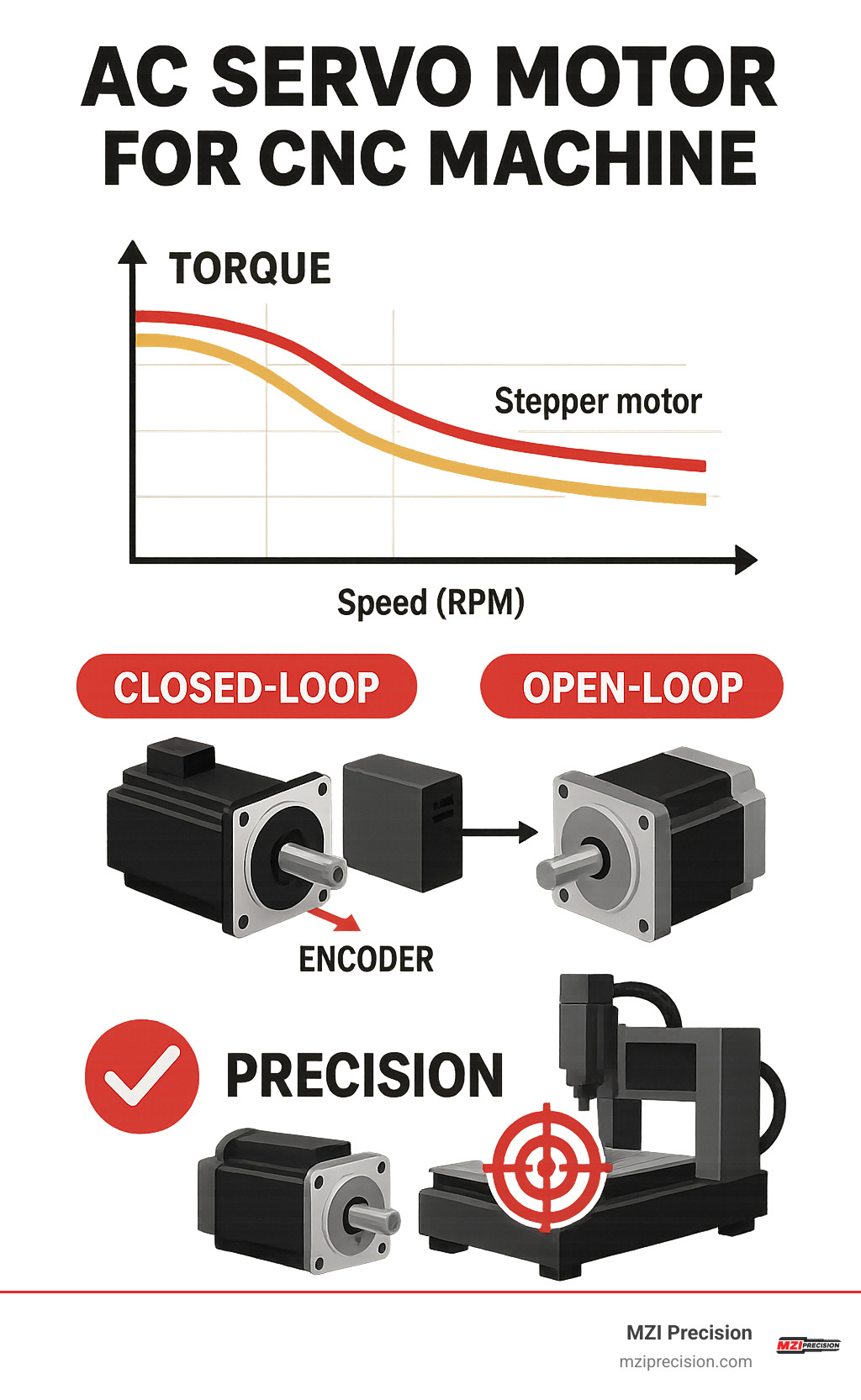

AC servo motor for CNC machine applications deliver superior precision and power compared to traditional stepper motors. Here’s what you need to know:

Key Benefits:

– Closed-loop control prevents lost steps with encoder feedback

– Constant torque at speeds up to 3,000+ RPM

– Peak torque capability up to 2× rated torque for rapid acceleration

– High-resolution positioning with encoders delivering hundreds of thousands of steps per revolution

Power Range: 400W to 2.6kW+ depending on machine size

Typical Applications: X/Y/Z axis drives, spindle control, rotary tables

Price Range: $600-$650 for entry-level 2.6kW kits with brake and driver

If you’re running a CNC router for aerospace manufacturing or precision machining, the upgrade from steppers to AC servo motors can dramatically improve your surface finish quality and machining speed.

Unlike stepper motors that lose torque as speed increases, servo motors maintain nearly all their torque at maximum speed. This makes them ideal for high-speed machining operations where consistent performance matters.

The closed-loop feedback system acts like GPS navigation for your machine – if something goes wrong or a step is missed, the system instantly corrects itself. This prevents the catastrophic “lost step” failures that can ruin expensive aerospace parts.

Simple guide to ac servo motor for cnc machine:

– 3 axis servo motor controller

– cnc motors

– servo motor in cnc

Why an AC Servo Motor for CNC Machine Matters

After years of working on industrial manufacturing spindle repair and rebuilding at MZI Precision, we’ve learned that motor choice can make or break your machining operation. The difference between stepper and servo motors isn’t just about fancy specifications – it’s about whether your parts meet aerospace tolerances or end up in the scrap bin.

AC servo motors for CNC machines deliver something steppers simply can’t: torque-at-speed performance. While stepper motors start strong with high torque at zero speed, they quickly lose steam as RPMs climb. Servo motors flip this script entirely, maintaining nearly full torque even at 2,000-3,000+ RPM.

Think of it like comparing a marathon runner to a sprinter. Steppers are great for short bursts but fade fast. Servo motors keep their strength throughout the entire speed range – exactly what you need for precision manufacturing.

The real game-changer is encoder feedback. This closed-loop system acts like having a quality inspector watching every single movement. If something goes wrong – maybe a chip gets stuck or the material shifts slightly – the encoder catches it instantly and makes corrections. We’ve seen this prevent countless expensive crashes on industrial manufacturing spindles.

| Feature | Stepper Motors | AC Servo Motors |

|---|---|---|

| Speed Range | Up to 1,200 RPM effectively | 2,000-3,000+ RPM |

| Torque at Speed | Decreases significantly | Maintains full torque |

| Feedback System | Open-loop (no feedback) | Closed-loop with encoders |

| Peak Torque | Fixed rating | Up to 2× rated torque |

| Positioning Accuracy | 200 steps/revolution | Hundreds of thousands of steps |

| Lost Step Protection | None | Instant correction |

Inertia matching is another crucial factor we consider during spindle rebuilding projects. Servo motors can handle peak torque demands up to twice their rated capacity, making them perfect for rapid acceleration and deceleration cycles that industrial manufacturing demands.

Closed-Loop Accuracy with Encoders

Here’s where servo motors really shine: micro-positioning accuracy that would make a Swiss watchmaker jealous. The encoder feedback system provides resolution in the hundreds of thousands of steps per revolution – that’s literally ten times more precise than typical stepper setups.

We’ve worked on aerospace components where being off by even a few thousandths of an inch means starting over with expensive materials. With zero lost steps capability, servo systems eliminate that heart-stopping moment when you realize your stepper motor skipped a beat somewhere during a four-hour machining cycle.

The rapid correction feature works like cruise control for your CNC. If resistance increases – maybe you’re cutting through a harder section of material – the servo instantly adjusts to maintain exact positioning. No drama, no lost steps, just smooth, consistent performance.

High-Speed Machining Benefits

When you’re pushing speeds above 3000 RPM for high-speed machining applications, servo motors become absolutely essential. The constant torque delivery means your surface finish stays consistent whether you’re creeping along at 100 RPM or flying at maximum speed.

This translates to smoother finish quality that often eliminates secondary operations. We’ve seen shops reduce their finishing time by 30-40% simply by upgrading to servo-driven systems that can maintain cutting quality at higher speeds.

For industrial manufacturing spindle applications, this performance consistency is critical. When you’re machining components that need to meet strict aerospace or defense specifications, you can’t afford the torque dropoff that comes with traditional stepper motors.

Top 5 AC Servo Motors for CNC Router Performance

We’ve evaluated servo motors based on real-world CNC router requirements: reliability, torque-to-weight ratio, encoder quality, and compatibility with common drive systems. Our selection covers frame sizes from NEMA 23 up to 180mm, supporting diverse machine sizes and load requirements.

The sweet spot for most CNC router upgrades falls in the 400W to 2.6kW range, with integrated brake options for Z-axis safety and rapid positioning capabilities.

Entry-Level 400 W Kits for Light Tables

Power Rating: 400W

Torque: 1.27 Nm continuous, 3.82 Nm peak

Speed: 3,000 RPM rated, 5,000 RPM maximum

Frame Size: 60mm

Encoder: 20-bit resolution (1,280,000 pulses per revolution)

These compact units bridge the gap between hobby and professional applications. The 400W servo motor with matched drive delivers precise control for small-footprint CNC routers handling aluminum and composite materials.

The 20-bit encoder provides glass-scale accuracy that minimizes thermal expansion issues compared to plastic encoders. At around $175-$200 for motor and drive combinations, they offer professional closed-loop performance without breaking the budget.

1 kW–1.5 kW Workhorses for Mid-Size Gantries

Power Rating: 1-1.5 kW

Torque: 4-5 Nm continuous, 12-15 Nm peak

Speed: 3,000 RPM

Frame Size: NEMA 34 (86mm)

Features: Shielded construction, IP65 rating

This category represents the workhorses of CNC router servo systems. The 1 kW models deliver 4 Nm continuous torque with 12 Nm peak capability – perfect for rapid acceleration and deceleration in production environments.

NEMA 34 frame servos fit most mid-size router gantries without modification. The shielded construction reduces EMI interference that can cause positioning errors in sensitive manufacturing environments like those we service in aerospace applications.

2 kW+ Heavy-Duty Options for Production Routers

Power Rating: 2-2.6 kW

Torque: 10+ Nm continuous, 20+ Nm peak

Speed: 2,500 RPM

Frame Size: NEMA 52 (130mm)

Special Features: Integrated holding brake, IP67 rating

For production CNC routers handling heavy cutting loads, these high-torque servos provide the muscle needed. The 2.6 kW units we’ve tested deliver 10 Nm of continuous torque – enough for aggressive material removal in aluminum and steel components.

The integrated brake is crucial for Z-axis applications, providing holding power when the spindle stops. Entry-level 2.6kW AC servo motor kits with brake and driver are available around $600-$650, making them cost-effective for production upgrades.

How to Choose the Right AC Servo Motor for CNC Machine Axes

Choosing the perfect AC servo motor for CNC machine setup feels a bit like matchmaking – you need the right compatibility between motor and machine to make everything work smoothly. After years of helping customers upgrade their industrial manufacturing spindle systems at MZI Precision, we’ve learned that getting this match right makes all the difference.

The golden rule we follow is simple: match the largest possible motor with the lightest possible table. This optimizes your inertia ratio and keeps everything running accurately. When this balance is off, you’ll see vibration, reduced accuracy, and parts wearing out faster than they should.

Your load calculation starts with understanding what you’re actually moving. Add up the total moving mass including your table, workpiece, and any fixtures. Then estimate the friction forces from your linear guides and ballscrews. Factor in your required acceleration profile, and here’s the important part – add a 20-30% safety margin. Trust us on this one; it’s better to have power you don’t need than to need power you don’t have.

The inertia ratio is where many people get tripped up. Keep your motor inertia to load inertia ratio at 10:1 or less for optimal performance. Go higher than this, and you’ll deal with oscillation and poor settling time that’ll drive you crazy during precision work.

Duty cycle considerations matter more than most people realize. Servo motors can briefly deliver up to twice their rated torque, which is incredibly useful for those rapid starts and stops that CNC applications demand. But remember – that’s peak performance, not something you can sustain all day long.

Environmental factors can make or break your installation. Most servos work best between 0-40°C in non-condensing humidity conditions. Look for IP65 minimum protection rating, or IP67 if you’re in harsh environments. Vibration tolerance becomes critical in high-speed machining scenarios. Scientific research on high-speed machining confirms that proper motor sizing directly impacts both surface finish quality and tool life.

Sizing Checklist

Getting your sizing right the first time saves headaches later. Mass and friction calculations form your foundation – know exactly what forces you’re working against. Your acceleration profile needs to match your production requirements, not just what sounds impressive on paper. That safety margin we mentioned isn’t optional; it’s insurance against real-world variables that spec sheets don’t capture.

Drive & Controller Compatibility

Modern servo drives offer several control interfaces, and picking the right one depends on your existing setup. Analog ±10V signals provide universal compatibility with almost any motion controller. PWM signals work great for direct connection from motion controllers, while EtherCAT gives you high-speed industrial networking capabilities. Modbus/TCP integration works well when you need to connect with existing PLCs.

Your drive must match your motor’s voltage and current ratings – no exceptions here. Most CNC servo systems run on 220V nominal input with current ratings ranging from 2.6A to 15A+ depending on power requirements.

Tuning software isn’t just nice to have; it’s essential for getting optimal performance. Parameters like torque limit, feed-forward compensation, and low-pass filtering need adjustment for each specific application. Every machine has its own personality, and the tuning process helps you find what yours needs.

At MZI Precision, we regularly work with customers who are upgrading entire motion systems alongside their industrial manufacturing spindle repairs. Our experience with spindle services has taught us that recommending compatible servo solutions requires understanding how everything integrates with existing CNC controllers. Getting this integration right from the start prevents costly do-overs later.

Installation & Maintenance Essentials

Getting your AC servo motor for CNC machine installation right makes all the difference between smooth operation and endless headaches. After years of working with industrial manufacturing spindle systems, we’ve learned that most servo problems trace back to installation shortcuts.

The biggest mistake we see? Mixing power and signal cables in the same conduit. This creates electrical noise that confuses the encoder, causing erratic positioning that’ll drive you crazy. Always run shielded cables for both encoder and motor power connections, and keep them separated by at least 6 inches.

Ground loops are another common culprit behind mysterious positioning errors. They can even damage expensive encoder circuits. The solution is simple but critical: use star grounding with a single-point earth connection. Think of it like having one main electrical panel for your house instead of multiple competing ground points.

Cable specifications matter more than you might think. Motor power cables come in standard lengths of 3m, 5m, 10m, and 15m. Encoder cables need twisted pair construction with shielding, typically 3-10m long. Brake cables require their own separate circuit – budget around 22.90€ for quality 10m lengths.

Don’t forget ventilation around your drive units. These components generate significant heat, and overheating kills performance and component life. We recommend maintaining ambient temperatures below 40°C with adequate airflow.

Tuning Tips for Surface Finish

Here’s where servo systems really shine – but only if you tune them properly. Poor tuning shows up immediately in your finished parts as chatter marks, dimensional variations, and that dreaded following error that makes precision impossible.

Position loop gain is your first adjustment point. Higher values improve tracking accuracy, but push too hard and you’ll create instability that ruins surface finish. Start conservative and work your way up while monitoring system response.

S-curve acceleration profiles are game-changers for surface quality. They smooth out mechanical stress and reduce vibration that transfers to your workpiece. The difference in finished aluminum parts is dramatic – we see this constantly in our aerospace spindle work.

Feed-forward compensation helps the system anticipate known loads instead of just reacting to them. This improves tracking performance, especially during rapid direction changes that can leave witness marks on precision parts.

Always use an oscilloscope or your drive’s built-in diagnostics to spot instability before it affects your parts. Trust your ears too – unusual sounds often indicate tuning problems before they show up in measurements.

Reliability Best Practices

Smart maintenance keeps your servo system running when you need it most. We recommend monthly visual inspections of connections and cables, looking for wear, corrosion, or loose connections that cause intermittent problems.

Quarterly encoder cleaning prevents the buildup of machining debris that can affect positioning accuracy. Industrial manufacturing environments are tough on encoders, and a little preventive care goes a long way.

Annual parameter backups save you hours of re-tuning if a drive fails. Store these files safely – losing optimized parameters means starting tuning from scratch, which costs production time and money.

Temperature monitoring protects your investment. Servo motors and drives hate heat, and overheating shows up as reduced accuracy long before components fail completely. Most modern drives include thermal monitoring, so use it.

Most servo motors use sealed bearings that need no maintenance, but don’t forget about mechanical components like couplings and drive elements. They need regular lubrication per manufacturer specifications to prevent premature wear.

At our facilities in Huntington Beach and Los Angeles, we see the results of proper maintenance daily. Well-maintained servo systems run reliably for years in demanding aerospace and defense applications, delivering the precision these industries require.

Frequently Asked Questions about AC Servo Motors

When we talk with customers about upgrading their CNC systems at MZI Precision, these same questions come up repeatedly. Let’s tackle the most common concerns about AC servo motor for CNC machine applications.

What voltage do most CNC servos require?

The short answer is 220V for most industrial applications. Nearly all AC servo motors for CNC machines in the 400W to 2.6kW range operate on 220V nominal input voltage, with acceptable ranges from 180-240V. This matches standard industrial power supplies perfectly and gives you optimal performance.

Think of it like plugging in a heavy-duty appliance – you need the right voltage or things won’t work properly. Some smaller servos under 400W might accept 110V input, which is handy for smaller shops. On the flip side, larger industrial units often require 380V three-phase power for those really demanding applications.

Here’s the thing though – always verify voltage requirements before installation. We’ve seen expensive servo drives get fried because someone assumed the voltage was compatible. It’s like checking the plug before you stick it in the wall, except much more expensive if you get it wrong.

Can I retrofit a stepper-based router with servos?

Absolutely, but don’t expect it to be as simple as swapping out motors. We get this question a lot, and while it’s definitely doable, there’s more to it than meets the eye.

You’ll need several components beyond just the motors: compatible servo drives (one per axis), a motion controller with servo capability, proper feedback cables and connections, and a revised electrical panel layout. Then comes parameter tuning and calibration – which is where experience really matters.

The good news is that mechanical mounting often works out fine since many servo motors use standard NEMA frame sizes. Your existing motor mounts probably won’t need major modifications.

Our recommendation? Start with your most critical axis first. Usually that’s the Z-axis because you get the benefit of holding brake capability right away. Then upgrade your X and Y axes as your budget allows. This approach spreads out the cost and lets you learn the system gradually.

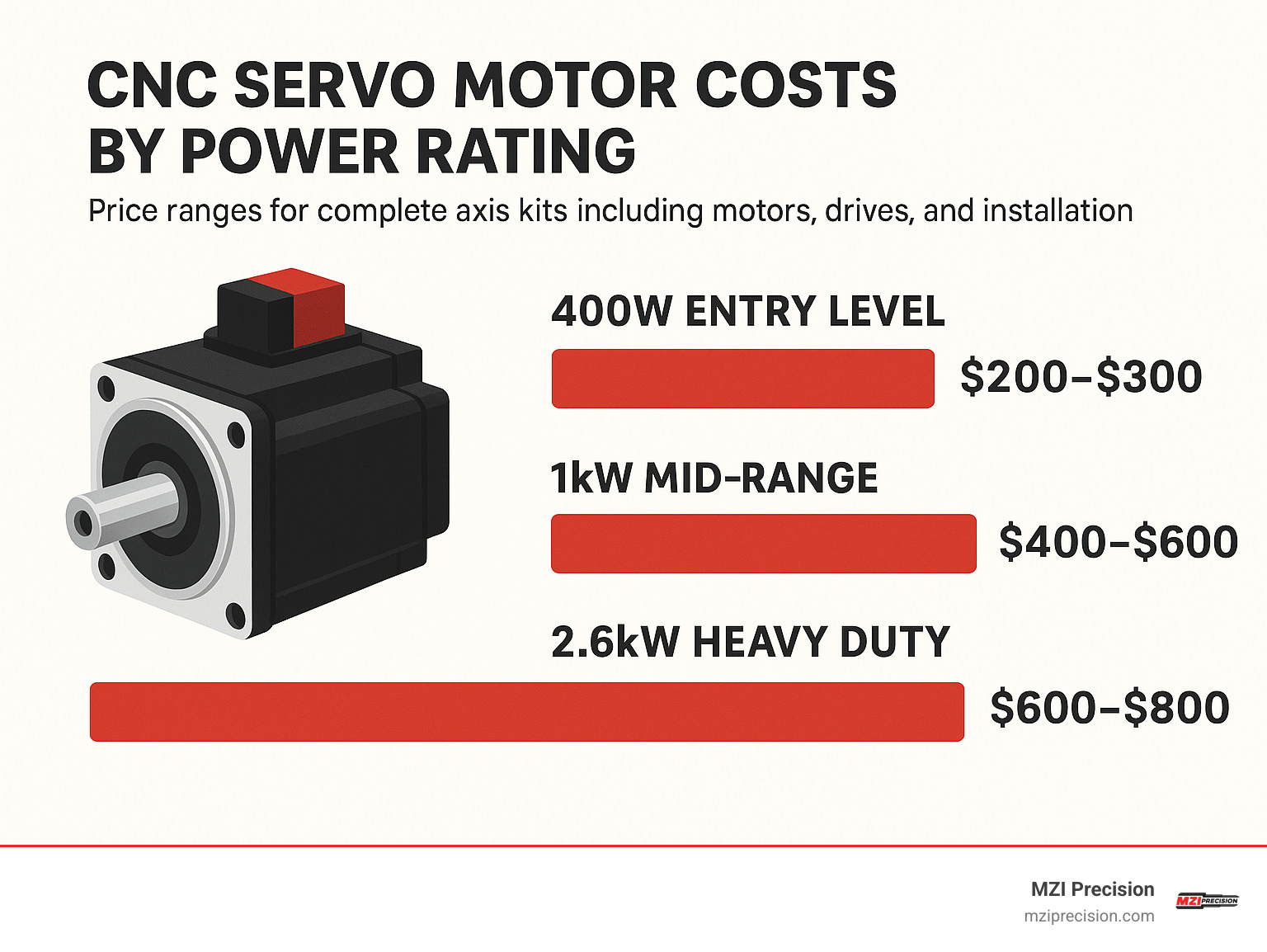

How much should I budget for a full axis kit?

This is probably the most important question, and the answer depends on what level of performance you need. Budget ranges for motor plus drive plus cables break down like this: 400W entry level runs $200-$300 per axis, 1kW mid-range costs $400-$600 per axis, and 2.6kW heavy duty hits $600-$800 per axis.

But here’s where it gets real – those are just the basic components. Additional costs add up quickly: motion controller upgrades run $500-$2,000, installation and tuning typically costs $1,000-$3,000, and emergency stop plus safety circuits add another $200-$500.

When you add it all up, a complete 3-axis router upgrade typically runs $3,000-$8,000 depending on your power requirements and how compatible your existing equipment is. That might sound like a lot, but consider the improved precision and reliability you’re getting.

The investment pays off when you’re machining precision parts for aerospace or defense applications where accuracy matters. We’ve seen customers recoup their servo upgrade costs within months through improved part quality and reduced scrap rates.

Conclusion

Looking at this beautifully finished aluminum part, you can see the difference that precision motor control makes. This is exactly what happens when you upgrade to AC servo motors for CNC machines – the change isn’t just technical, it’s visible in every cut.

After working with countless industrial manufacturing spindle repair and rebuilding projects, we’ve seen how the right motor choice separates good machining from exceptional results. The closed-loop precision means your CNC router knows exactly where it is at all times, like having a GPS system that never loses signal.

The numbers tell the story clearly. While stepper motors lose torque as speed increases, servo motors deliver constant torque at maximum speed – maintaining nearly full power even at 3,000+ RPM. This consistency translates directly into better surface finishes and faster cycle times.

Your investment in servo motor technology pays back through reduced scrap rates and increased productivity. When you’re machining aerospace components or precision industrial parts, there’s no room for the “lost step” failures that can ruin expensive materials. The encoder feedback system catches and corrects these issues instantly.

The repeatability you achieve with servo motors becomes especially important in production environments. Whether you’re running one part or one thousand, each piece comes out with the same precision and surface quality.

At MZI Precision, our experience with industrial manufacturing spindle systems has taught us that motor selection affects everything downstream. The spindle, cutting tools, and surface finish all benefit when your axes move with servo motor precision and reliability.

Ready to make the upgrade? The journey from stepper to servo motors might seem complex, but the results speak for themselves in every precisely machined component. More info about spindle services